Professional Documents

Culture Documents

Turbinas - CC Dos Bocas

Uploaded by

Diego garcia baizabal0 ratings0% found this document useful (0 votes)

3 views9 pagesTurbinas Ciclo combinado Dos Bocas

Original Title

TURBINAS- CC DOS BOCAS

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTurbinas Ciclo combinado Dos Bocas

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views9 pagesTurbinas - CC Dos Bocas

Uploaded by

Diego garcia baizabalTurbinas Ciclo combinado Dos Bocas

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 9

UNIVERSIDAD VERACRUZANA-

FACULTAD INGENIERIA

SUBJECT: TURBOMACHIENERY

STUDENT NAMES: GARCIA BAIZABAL

DIEGO AND

SANCHEZ CONDADO EDUARDO

PROFESSOR: DR. OSVALDO

VIGUERAS ZÚÑIGA

DATE: 21/11/2023

EQUIPMENTS: GAS TURBINE MODEL

CC DOS BOCAS

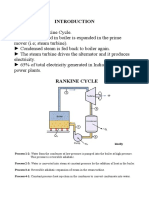

INTRODUCTION

• We will talk about how

the combined cycle of the

CFE plant, called two

mouths, works in this 3

gas turbines These are

important in the power

generation process of the

plant.

THEORETICAL INTRODUCTION

The process of transforming

natural gas into electricity

begins when air from the

outside is compressed at high

pressure in the compressor.

From there, it leads to the

combustion chamber where it

mixes with the fuel. The flue

gases then pass through the

gas turbine where they expand.

This causes the heat energy to

transform into mechanical

energy, transmitting it to the

axis.

• Subsequently, the gases leaving the

gas turbine are taken to a heat

recovery boiler to produce steam.

From this moment the conventional

steam water cycle occurs in which

the steam spins the steam turbine.

At the exit of the turbine the steam

condenses (transforming again into

water) and returns to the boiler to

start a new cycle of steam

production. Usually, the gas turbine

and steam turbine are coupled to

the same axis, so that they jointly

operate the same electric generator.

TECHNICAL DESCRIPTION

The gas turbines consist of a 17-speed

axial compressor, a combustion chamber

equipped with 16 gas atomization

nozzles and a 4-speed action type gas

turbine, the additional burners and the

gas turbine use natural gas to its

operation, the average maximum gas

consumption at maximum load for each

power plant is approximately 50 million

cubic feet per day.

The steam turbine consists of a rotor with 13

speeds of movable blades, of which 10 are

action and 3 are reaction, this turbine has a

steam extractor in the speed 11, this is with

the purpose of making the thermodynamic

cycle more efficient.

APPLICATION • The electric power plant "Dos

Bocas" consists of two

combined cycle plants, which

are independent of each other,

both belong to the

"Westinghouse" trademark

and currently only one of them

continues to operate. Each of

the powerplants consists of:-2

gas turbines of 63 MW

effective capacity each- 2

steam generators for heat

recovery- 1 Nano cylindrical

steam turbine of 100 MW

effective capacity with axial

condensation exhaust

CONCLUSION

• We can conclude that combined cycle power plants are more flexible than

conventional power plants. By being more efficient, having greater

efficiency by a wider range of powers, their emissions are lower, their

cooling water consumption is lower and saves energy in the form of fuel,

are faster to build and have a lower area ratio per MW installed, this

reduces the visual impact.

• One of its most notable advantages is that CO2 emissions in relation to the

kilowatts/hour produced are less than half the emissions of a conventional

coal plant.

• Working as a team always in good, more when there is a good coordination

and availability to do things, it is always good to have approach to these

plants, since they leave us pleasant experiences.

You might also like

- Report On Jenco Thermal Power PlantDocument18 pagesReport On Jenco Thermal Power PlantMuhammadAbbasJafriNo ratings yet

- Summer Training Report On NTPC Tanda, Ambedkar NagarDocument9 pagesSummer Training Report On NTPC Tanda, Ambedkar NagarAliraza7660% (5)

- Combined - Cycle Power PlantDocument9 pagesCombined - Cycle Power PlantRavi Kumar GuptaNo ratings yet

- Me Lab 3Document27 pagesMe Lab 3Jerome Vega AndesNo ratings yet

- A Thermal Power Station Comprises All of TheDocument24 pagesA Thermal Power Station Comprises All of TheAnirban BanerjeeNo ratings yet

- Thermal Power StationDocument13 pagesThermal Power StationmuthucharaNo ratings yet

- CHAPTER III IV and VDocument84 pagesCHAPTER III IV and VJohn Louie Pimentel0% (1)

- Indraprastha Power Generation Co. Ltd. (Ipgcl) :: Under IPGCL Two Power Stations Are in OperationDocument9 pagesIndraprastha Power Generation Co. Ltd. (Ipgcl) :: Under IPGCL Two Power Stations Are in OperationKirti GuptaNo ratings yet

- Basic Power Plant OperationDocument22 pagesBasic Power Plant OperationMehmet TuncarNo ratings yet

- Training ReportDocument61 pagesTraining ReportAnkur PanchalNo ratings yet

- Project Report by Manish YadavDocument53 pagesProject Report by Manish Yadavmanish yaduvanshiNo ratings yet

- Thermal Power PlantDocument11 pagesThermal Power PlantAnand Kalani100% (1)

- Steam Power PlantDocument7 pagesSteam Power PlantNav Mehra50% (2)

- 06 Steam TurbineDocument32 pages06 Steam Turbinesakera 88No ratings yet

- Mr. Hassan Alam: Heat Recovery Boiler of SNPC Power PlantDocument11 pagesMr. Hassan Alam: Heat Recovery Boiler of SNPC Power PlantYashal Syed, AhmedNo ratings yet

- Uni AssignmentDocument10 pagesUni AssignmentIt's MaharNo ratings yet

- SWITCHYARD, NTPC SIPAT Training ReportDocument35 pagesSWITCHYARD, NTPC SIPAT Training ReportSuresh Sunny80% (5)

- Thermal Power Plant: Shubham Thakur 13BME8149 5MEL3 Mechanical EngineeringDocument34 pagesThermal Power Plant: Shubham Thakur 13BME8149 5MEL3 Mechanical EngineeringMos MohNo ratings yet

- NTPC Ltd. - Simhadri Super Thermal Power Station, Visakhapatnam, Andhra PradeshDocument27 pagesNTPC Ltd. - Simhadri Super Thermal Power Station, Visakhapatnam, Andhra PradeshNiharika KolliNo ratings yet

- NTPCDocument33 pagesNTPCSubodh DuhanNo ratings yet

- NTPCDocument32 pagesNTPC12 EC ATUL KUMAR SRIVASTAVANo ratings yet

- Thermal Power Plant: Gaini Zail Singh Punjab Technical University Campus (Bathinda)Document30 pagesThermal Power Plant: Gaini Zail Singh Punjab Technical University Campus (Bathinda)Sriram ramsNo ratings yet

- Report On "Generation of Thermal Power" AT NTPC DadriDocument17 pagesReport On "Generation of Thermal Power" AT NTPC DadriVaibhav RaoNo ratings yet

- NTPC DADRI TrainingDocument21 pagesNTPC DADRI Trainingra malNo ratings yet

- To Improve Thermal Efficiency of 27mw CoDocument24 pagesTo Improve Thermal Efficiency of 27mw Codixie0630No ratings yet

- Training ReportDocument20 pagesTraining Reportahmedmidoo1595No ratings yet

- Industrial Training Report NTPCDocument30 pagesIndustrial Training Report NTPCTabish KhanNo ratings yet

- Distributed Digital Control and Monitoring and Information System" by Designing andDocument29 pagesDistributed Digital Control and Monitoring and Information System" by Designing andjhonnyjungleNo ratings yet

- Thermal Power PlantDocument16 pagesThermal Power PlanthebishtNo ratings yet

- Summer Training in Badarpur NTPCDocument54 pagesSummer Training in Badarpur NTPCRohit VermaNo ratings yet

- Thermal Power PlantDocument36 pagesThermal Power PlantAshvani Shukla100% (1)

- Lecture 2 - Steam TurbineDocument32 pagesLecture 2 - Steam TurbineZulyadain Ishak100% (1)

- Ennore Thermal Power StationDocument14 pagesEnnore Thermal Power StationRajesh Kumar100% (2)

- Power Plants in The PhilippinesDocument25 pagesPower Plants in The PhilippinesJo Sofia Delos SantosNo ratings yet

- Genesee Generating Station Environmental AnalysisDocument4 pagesGenesee Generating Station Environmental AnalysisTharindu WeerasingheNo ratings yet

- Thermal Power Plants-FinalDocument61 pagesThermal Power Plants-FinalBhavya ShrivastwaNo ratings yet

- Steam Power PlantDocument20 pagesSteam Power PlantSiddi Sampath Kumar Reddy100% (1)

- Chandrapur CTPS 15 Days Training ReportDocument21 pagesChandrapur CTPS 15 Days Training ReportUday Wankar0% (1)

- Thermal Power StationDocument17 pagesThermal Power StationJayAr EsquilloNo ratings yet

- Electrical Engg.: Panipat Thermal Power Station (A Unit of H.P.G.C.L., Haryana)Document43 pagesElectrical Engg.: Panipat Thermal Power Station (A Unit of H.P.G.C.L., Haryana)dinesh66jattNo ratings yet

- Steam Power Plant PresentationDocument37 pagesSteam Power Plant PresentationsharenslaNo ratings yet

- Ocean Thermal Energy ConversionDocument10 pagesOcean Thermal Energy ConversionRaviteja RokzNo ratings yet

- 17.THERMAL POWER PLANT PPT 1Document25 pages17.THERMAL POWER PLANT PPT 1Amit kumar Gupta100% (6)

- The Initial Process in Coal Based Thermal Power Plant Is Coal Handling - The Function of Coal Handling Plant in Thermal Power Plant Is To ReceiveDocument5 pagesThe Initial Process in Coal Based Thermal Power Plant Is Coal Handling - The Function of Coal Handling Plant in Thermal Power Plant Is To ReceiveSubhadip MondalNo ratings yet

- Thermal Power PlantDocument34 pagesThermal Power PlantRama Krishna KariNo ratings yet

- Amulya Gaikwada ProjectDocument34 pagesAmulya Gaikwada ProjectHarikrishna NethaNo ratings yet

- " " NTPC (Dadri) : BY: Kulvinder Singh B. Tech (IV Year) Electronics & Communication DepartmentDocument17 pages" " NTPC (Dadri) : BY: Kulvinder Singh B. Tech (IV Year) Electronics & Communication DepartmentKulvinder SinghNo ratings yet

- Thermal Power Plant BasicsDocument79 pagesThermal Power Plant BasicsMukundan SwamynathanNo ratings yet

- NTPC DADRI TrainingDocument21 pagesNTPC DADRI Trainingpankaj sahuNo ratings yet

- Report On Thermal Power PlantDocument22 pagesReport On Thermal Power PlantNitinNo ratings yet

- Thermal Power StationDocument16 pagesThermal Power StationDinesh Karthik VithiyananthNo ratings yet

- Power Plant EngineeringDocument25 pagesPower Plant EngineeringlitonNo ratings yet

- Failure Analysis and Design Modification of Oil Cooler in Boiler Feed PumpDocument78 pagesFailure Analysis and Design Modification of Oil Cooler in Boiler Feed Pumpsai kiranNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Electricity for the farm Light, heat and power by inexpensive methods from the water wheel or farm engineFrom EverandElectricity for the farm Light, heat and power by inexpensive methods from the water wheel or farm engineRating: 5 out of 5 stars5/5 (1)

- SlfEvWeek2 1Document2 pagesSlfEvWeek2 1Diego garcia baizabalNo ratings yet

- Evaluation 3Document3 pagesEvaluation 3Mariela OlmedoNo ratings yet

- Universidad VeracruzanaDocument5 pagesUniversidad VeracruzanaDiego garcia baizabalNo ratings yet

- Universidad Veracruzana: Experiencia Educativa Lengua Ii Facilitador Garcia Diaz Maria de Los Angeles Actividad OralDocument3 pagesUniversidad Veracruzana: Experiencia Educativa Lengua Ii Facilitador Garcia Diaz Maria de Los Angeles Actividad OralDiego garcia baizabalNo ratings yet