0% found this document useful (0 votes)

985 views38 pagesProCAST Simulation Overview for Casting

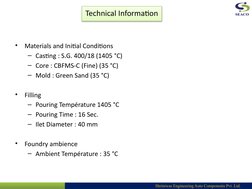

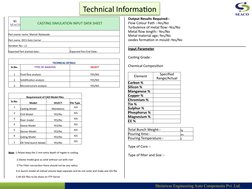

The document discusses simulation of a gravity casting process. It provides details on the casting material, mold material, core material, pouring parameters and other technical information required as input for the simulation. It also outlines the various steps involved in setting up the simulation including CAD preparation, meshing, defining material properties and process parameters.

Uploaded by

science ki DuniyaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

985 views38 pagesProCAST Simulation Overview for Casting

The document discusses simulation of a gravity casting process. It provides details on the casting material, mold material, core material, pouring parameters and other technical information required as input for the simulation. It also outlines the various steps involved in setting up the simulation including CAD preparation, meshing, defining material properties and process parameters.

Uploaded by

science ki DuniyaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

- Introduction to ProCAST Simulation

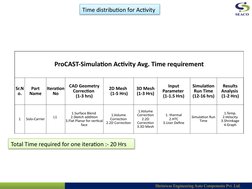

- Time Distribution for Activity

- Technical Information

- Mesh Application

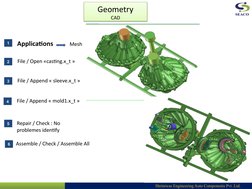

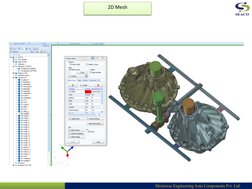

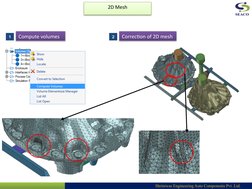

- Geometry and 2D Mesh

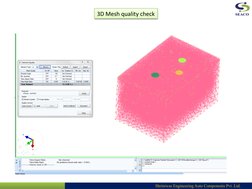

- 3D Mesh Quality Check

- Cast Application

- Process Definition

- Simulation Parameter Definition

- Flow Analysis

- Thermal Analysis

- Gating System Comparison

- Conclusion