Professional Documents

Culture Documents

Soap Workshop

Soap Workshop

Uploaded by

Marisa Solano0 ratings0% found this document useful (0 votes)

6 views21 pagesTaller sobre fabricación de jabón en frío con ejemplos prácticos de cálculos y pasos. En inglés.

Original Title

Soap workshop

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTaller sobre fabricación de jabón en frío con ejemplos prácticos de cálculos y pasos. En inglés.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views21 pagesSoap Workshop

Soap Workshop

Uploaded by

Marisa SolanoTaller sobre fabricación de jabón en frío con ejemplos prácticos de cálculos y pasos. En inglés.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 21

SOAP MAKING

WORKSHOP IES Sierra Almijara

WELCOME TO

OUR SOAP

MAKING

WORKSHOP!

Get ready to dive into the world of soap making!

Today, we'll guide you through each step to create

your very own soap, focusing on using recycled

materials.

From repurposing used cooking oil to transforming

Tetra Paks into soap molds, we're all about being

eco-friendly.

Let's start this sustainable crafting journey together

and make some amazing soap!

SOAP MAKING VOCABULARY

Let's learn some basic soap making terms in Spanish, English, and Romanian!

Spanish English Romanian

Jabón Soap Săpun

Aceite Oil Ulei

Agua Water Apă

Sosa caústica Lye Sodă Caustică

Molde Mold Formă

Saponificación Saponification Saponificare

Cura Cure Cura

Seguridad Safety Siguranța

Vinagre Vinegar Oțet

Guantes Gloves Mănuși

Gafas de Seguridad Safety Goggles Ochelari de protecție

Mascarilla Mask Mască

UNDERSTANDING THE

PROCESS

Saponification is a chemical reaction where you mix oil

(or any type of fat) with an alkaline substance, commonly

lye, to create soap and glycerin.

After mixing and allowing them to react for a while, the

mixture thickens and transforms into a paste which, upon

hardening, becomes soap.

This soap needs to cure (or dry) for several weeks so that

all the extra water evaporates, and the soap becomes soft

and safe to use.

THE IMPACT OF USED

COOKING OIL ON THE

ENVIRONMENT

Used cooking oil is highly polluting, if not disposed of properly, can have a

significant negative impact on the environment:

1. Clogs Waterways: When poured down the drain, it solidifies and can clog

pipes and sewage systems, leading to expensive clean-ups and

environmental damage

2. Harms Aquatic Life: If it reaches natural water bodies, it forms a thick layer

on the water's surface, blocking sunlight and oxygen from reaching marine

plants and animals, disrupting their habitats.

3. Difficult to Break Down: It contains substances that are hard to break down

by natural processes, leading to long-term pollution in soil and water.

By recycling used cooking oil into soap or other products, we can prevent these

pollutants from harming our planet and contribute to a more sustainable world.

nt to be

INGREDIENTS AND p o rt a

lly im ith lye

It's rea k i n g w

a fe w h en wor y strong

s r

t's a ve

MATERIALS a u s e i

bec

a l. and

chemic e you underst

Make s

ur

b e fo re y ou

e l l e v ery step every

w follow re not

Stuff You Need for Making the Soap: r t a n d

sta

c ti o n . If you’

• Used Oil: Make sure it's filtered and clean. instru for help

.

, a s k

• Lye (Sodium Hydroxide): This is super important for sure

turning the oil into soap. Safety Gear You Must Wear:

• Water: To mix with the lye. • Safety Goggles: To protect your eyes from splashes.

• Soap Molds: We will use cleaned and cut-up Tetra Paks as • Protective Gloves: They should be chemical-resistant to

recycled molds. keep your hands safe.

• Precision Scale: To measure your ingredients accurately. • Mask: To avoid breathing in any strong smells from the lye.

• Heat-Resistant Containers: For mixing everything • Protective Clothing: To keep your clothes clean and

together. splash-free.

• Mixing Stick or Hand Blender: To make sure everything Other Stuff:

blends well and reaches the right thickness.

• Vinegar: Keep some nearby as a safety measure, in case

• Thermometer: To check the temperature of your mix. you need to neutralize any accidental spills or splashes of

• Spatula: For stirring. lye.

SAFETY FIRST!

Soap making is a chemical process that requires caution, especially

when handling lye.

Wear protective goggles and gloves – Lye is very caustic and can

cause chemical burns on skin and eyes.

Follow the specified order by pouring the lye into the water and

not the other way around, otherwise, it may splash.

Mask and window: When the lye is dissolving, it releases irritating

vapors. It's important to wear a mask and goggles and ensure the

space is well-ventilated.

Aluminum cannot be used because it reacts with the lye.

Mathematics plays a significant role in the soap-making process, so MATHS AND

before we start, let's see how to calculate the different ingredients. SOAP!

SAPONIFICATION RATE

The saponification index indicates the Oil / Fat Saponification rate

amount of lye needed to saponify one

Olive oil 0,136

gram of and specific oil.

Sunflower oil 0,135

This is essential for calculating the right Coconut oil 0,184

lye amounts for different oils.

Almond oil 0,138

Here you have a table with some Shea butter 0,128

saponification rates.

CALCULATING LYE FOR

OLIVE OIL SOAP

The saponification index for olive oil is

0,136. That means that we need 0,136 g of

lye to saponificate 1g of olive oil.

To calculate the amount of lye, we just

need to multiply the amount if oil by its

rate.

For example, for 250g of olive oil, we

need:

250 · 0.136 = 34g of lye to saponify the

oil completely, considering the

saponification index.

SUPERFATTING

The lye we have calculated transforms all the oil into soap. This soap would be too

dry for the skin. So, we add a little bit more of oil to have a smooth and moisturizing

soap. This is called superfatting.

Soaps that are intended to use on skin, usually have between 5-1’% of superfatting.

To achieve a 10% superfat level, we reduce the lye amount by 10%.

In our example, for 250g of olive oil, we calcuted 34g of lye. With a 10% superfat

level, we would need: 34 · 0,9 = 30.15g of lye.

CALCULATING WATER

AMOUNT FOR OUR SOAP

Our third ingredient is water. We need it to dissolve lye.

There are different ways of calculating water, we are going to follow this proportion:

For every 420g of oil, we use 135g of water.

Based on our example, where we have 250g of olive oil, we calculate the water in

proportion:

HOW TO DO IT? Step by step

STEP 1: PREPARING THE SOAP

MOLD

Begin by preparing your soap mold:

Take a clean Tetra Pak and cut off one of the long sides to create

an open box.

This will be our mold.

Ensure it's thoroughly cleaned and dried before use.

Preparing the mold first allows it to be ready for pouring the

soap mixture immediately after it's prepared, ensuring a smooth

workflow.

STEP 2: PREPARING THE USED

OIL

Strain the used oil to remove any

particles or impurities, then weigh it to

ensure the correct amount for your

recipe.

Clean oil is essential for smooth, quality

soap.

STEP 3: PREPARING THE LYE

SOLUTION

Carefully measure the lye and cold water.

Always add the lye to the water, never the

reverse, to avoid a violent reaction.

Stir until dissolved and let it cool to 35-40°C

(95-104°F) before combining with oils.

STEP 3: COMBINING LYE AND

OILS

Once at the same temperature, slowly

pour the lye solution into the oils,

using a stick blender to mix until it

reaches 'trace'.

STEP 4: ADDING EXTRAS AND

MOLDING

Now add any extras like fragrances or

colors (this is optional).

Mix well, then pour into molds,

tapping gently to remove air bubbles.

STEP 5: CURING THE SOAP

Cover lightly and insulate for 24 hours.

Check if it's solid enough to cut, then

cure in a cool, dry place for 6-8 weeks.

LET'S PRACTICE TOGETHER!

It's your turn to apply what we've learned!

Weigh your oil, calculate the lye and water needed, and let's start making

soap…

SOAP MAKING PROCESS: AT A

GLANCE This chart summarizes the key steps in making your own soap. Follow

these steps to ensure a successful batch:

1. Mold Preparation: Cut and prepare a Tetra Pak as your mold.

2. Oil Preparation: Strain and weigh the used oil.

3. Calculations: calculate the amount of lye and water.

4. Lye Solution: Carefully mix lye into water and cool to 35-40°C.

5. Combine Lye and Oils: Mix at the right temperature until 'trace'.

6. Add Extras: Incorporate colors, fragrances, or additives.

7. Pour into Mold: Transfer the mixture into your prepared mold.

8. Curing: Allow to set for 24 hours, then cut and cure the soap for 6-8

weeks.

You might also like

- The Management Body of Knowledge - Book - Protected (002) - UnlockedDocument532 pagesThe Management Body of Knowledge - Book - Protected (002) - Unlockededuardo sanchez100% (1)

- James K Peckol Embedded Systems A Contemporary Design Tool PDFDocument3 pagesJames K Peckol Embedded Systems A Contemporary Design Tool PDFvaishak Ar0% (3)

- Still Waters Packing List: TipsDocument1 pageStill Waters Packing List: TipsMoisés Elías Vivas RamírezNo ratings yet

- Triominos Advanced VocabDocument3 pagesTriominos Advanced VocabAbrilNo ratings yet

- EnglishDocument15 pagesEnglishGulshan PhotoNo ratings yet

- Ibu Izza 2Document1 pageIbu Izza 2RANZ K.ONo ratings yet

- The Ridge: Green Carnival Green CarnivalDocument48 pagesThe Ridge: Green Carnival Green CarnivalLu Feng100% (3)

- Concept PaperDocument10 pagesConcept PaperLyle March Bernabat ZamboNo ratings yet

- Mil Whylearnanotherlanguage 073015Document1 pageMil Whylearnanotherlanguage 073015api-248115700No ratings yet

- Helaena, School EtiquetteDocument12 pagesHelaena, School EtiquetteMary Grace DELA PEÑANo ratings yet

- Milli-Q IQ 7003 - 05 - 10 - 15 - MK - BR2157EN - Merck - Web PDFDocument24 pagesMilli-Q IQ 7003 - 05 - 10 - 15 - MK - BR2157EN - Merck - Web PDFMiranti PuspitasariNo ratings yet

- Bonsai - More Than A Science and An Artform PDFDocument24 pagesBonsai - More Than A Science and An Artform PDFJhinsher TagleNo ratings yet

- Unit 7Document39 pagesUnit 7Manan GandhiNo ratings yet

- HarpersBazaar ConsciousBeautyAwards 2019 PDFDocument7 pagesHarpersBazaar ConsciousBeautyAwards 2019 PDFKROYNo ratings yet

- RoleDocument16 pagesRoleMelatot HiraoNo ratings yet

- Coniferous BrochureDocument16 pagesConiferous BrochureVedansh GuptaNo ratings yet

- Ove: Evolution of A BrandDocument7 pagesOve: Evolution of A BrandAnik GuinNo ratings yet

- AZ-204T00-A - Developing Solutions For Microsoft Azure - Skillpipe - 15Document1 pageAZ-204T00-A - Developing Solutions For Microsoft Azure - Skillpipe - 15Hafiz Abdul RahmanNo ratings yet

- Case 1 San Miguel Corporation 1 Defining The Problem PDF Free PDFDocument7 pagesCase 1 San Miguel Corporation 1 Defining The Problem PDF Free PDFlowi shooNo ratings yet

- Information About Soaps and Detergents - Healthy Cleaning 101Document22 pagesInformation About Soaps and Detergents - Healthy Cleaning 101Ömer ErcanNo ratings yet

- THE Biomimicry Taxonomy:: Biology Organized by FunctionDocument3 pagesTHE Biomimicry Taxonomy:: Biology Organized by FunctionРангел ЧипевNo ratings yet

- San Miguel Corp. Case Study 1Document7 pagesSan Miguel Corp. Case Study 1Casiano SeguiNo ratings yet

- 2022 Avenli Catalog 210728 - Cannot Do Private LabelDocument23 pages2022 Avenli Catalog 210728 - Cannot Do Private Labelmkpcgcqf4bNo ratings yet

- Dacor Obad20 ManualDocument12 pagesDacor Obad20 ManualElla MariaNo ratings yet

- Mantic All Out War Revival-CompressedDocument16 pagesMantic All Out War Revival-CompressedMichael OvsenikNo ratings yet

- Cuadernillo 3 C y 3 D 2022Document142 pagesCuadernillo 3 C y 3 D 2022sarai tosca100% (1)

- Lovely Katalog 2020 EN AP WWWDocument66 pagesLovely Katalog 2020 EN AP WWWPopescu-sustreanu CristinaNo ratings yet

- Second Grade January NewsletterDocument2 pagesSecond Grade January Newsletterapi-339302820No ratings yet

- Unit 15Document6 pagesUnit 1521070442 Trần Khánh LinhNo ratings yet

- Doms Catalogue 22-CompressedDocument111 pagesDoms Catalogue 22-CompressedGarena Free fire100% (1)

- PZO90197 Pathfinder 2E Season of Ghosts AP #2 of 4 Let The LeavesDocument7 pagesPZO90197 Pathfinder 2E Season of Ghosts AP #2 of 4 Let The LeavesTio TonyNo ratings yet

- Customer Relationship Management ShellDocument9 pagesCustomer Relationship Management ShellbilalyasirNo ratings yet

- ApurvaBandyopadhyay CV CompressedDocument1 pageApurvaBandyopadhyay CV CompressedApurva BandyopadhyayNo ratings yet

- NRT 2019 State of Conservancies ReportDocument88 pagesNRT 2019 State of Conservancies ReportamosNo ratings yet

- Toddler Program PyramidDocument1 pageToddler Program Pyramidlutbas3379100% (1)

- Q4Tday MAG2009 enDocument32 pagesQ4Tday MAG2009 enJose ManuelNo ratings yet

- Magalogue 012024Document33 pagesMagalogue 012024Emmanuel John FranciscoNo ratings yet

- Urine To Save The WorldDocument5 pagesUrine To Save The WorldmiguelNo ratings yet

- WT SanitarywareDocument84 pagesWT SanitarywarePOOJA YOGENDRANo ratings yet

- Lesson 1Document18 pagesLesson 1BPISHERENo ratings yet

- Brochure Premium Pet Food 2016Document44 pagesBrochure Premium Pet Food 2016muhamadhilmi06032006No ratings yet

- Tle9 W8 9 - Day2 3Document17 pagesTle9 W8 9 - Day2 3Mary Jane RamosNo ratings yet

- Brand S Product S Sub-ProductsDocument23 pagesBrand S Product S Sub-ProductsShahnawaz ShaikhNo ratings yet

- Brooks - Agate - Waterways - Wetlands - A Practical Handbook - 2012 - C - CompressedDocument170 pagesBrooks - Agate - Waterways - Wetlands - A Practical Handbook - 2012 - C - CompressedEmilia RaduNo ratings yet

- WWW Khuraq Com Pages Biotin Hair Gummies MultivitaminsDocument7 pagesWWW Khuraq Com Pages Biotin Hair Gummies Multivitaminssaloni yadavNo ratings yet

- Guide To Natural DyesDocument21 pagesGuide To Natural DyesRogelioNo ratings yet

- AMSADocument185 pagesAMSABùi Duy ThànhNo ratings yet

- (1240-MC-245) 25713-220-V1A-ECM1-00017 - PDFDocument1 page(1240-MC-245) 25713-220-V1A-ECM1-00017 - PDFAngela CamaggiNo ratings yet

- Chemistry in The LaundryDocument38 pagesChemistry in The LaundryAldayantiNo ratings yet

- Consumer Communications: Defining Terms Used in Environmental SustainabilityDocument32 pagesConsumer Communications: Defining Terms Used in Environmental SustainabilityAlma AcostaNo ratings yet

- Presentation For August 15, 2012Document2 pagesPresentation For August 15, 2012elton jay amilaNo ratings yet

- Livin: G Wall TutorialDocument14 pagesLivin: G Wall TutorialmusicinteresNo ratings yet

- Af Chapter 4 Waxes by DR Asad FarooqDocument51 pagesAf Chapter 4 Waxes by DR Asad FarooqGareth Bale100% (1)

- Soymilk Production Process Dos and Donts Ignace DebruyneDocument31 pagesSoymilk Production Process Dos and Donts Ignace Debruynelejla biberNo ratings yet

- 2016Document23 pages2016mchess77No ratings yet

- Easter Chocolate Shopping Guide 2020Document4 pagesEaster Chocolate Shopping Guide 2020ComunicarSe-ArchivoNo ratings yet

- Microbial Technique Iii HndiiDocument11 pagesMicrobial Technique Iii Hndiisanusi bello bakuraNo ratings yet

- 2010 Laerdal Medical CatalogDocument180 pages2010 Laerdal Medical CatalogEnerspect Medical Solutions100% (1)

- SpacesSummit2020 SociotechnicalArchitecture EduardoDaSilva PDFDocument40 pagesSpacesSummit2020 SociotechnicalArchitecture EduardoDaSilva PDFhewasNo ratings yet

- Carbondale Mountain Fair July 24-26 2009Document24 pagesCarbondale Mountain Fair July 24-26 2009Rory Moulton100% (6)

- Stories of Love and AdventureDocument24 pagesStories of Love and AdventureMargie HernandezNo ratings yet

- Skoda Yeti Brake Systems EngDocument174 pagesSkoda Yeti Brake Systems EngJonattan Javier Ramirez BolañosNo ratings yet

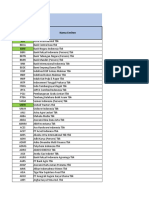

- Barangay Population Consolidation Purok 1Document53 pagesBarangay Population Consolidation Purok 1JePongNo ratings yet

- First Periodic Plan of NepalDocument44 pagesFirst Periodic Plan of NepalRamesh PokharelNo ratings yet

- 4 Principles of Tai Chi ChuanDocument3 pages4 Principles of Tai Chi ChuanAida PioNo ratings yet

- Vaidyam 2003 Jul - SepDocument24 pagesVaidyam 2003 Jul - SepPaulNo ratings yet

- Types of Nouns: Albert Einstein The President My Mother A GirlDocument5 pagesTypes of Nouns: Albert Einstein The President My Mother A GirlaudyNo ratings yet

- Edit Final Thesis of ProjectDocument54 pagesEdit Final Thesis of ProjectAshok KumarNo ratings yet

- LNG - BORTCL - Financial ModelDocument17 pagesLNG - BORTCL - Financial ModelTafweezNo ratings yet

- Monthly Reports 08-02-16Document37 pagesMonthly Reports 08-02-16L. A. PatersonNo ratings yet

- RBS 6601Document15 pagesRBS 6601Pritesh Khilnani100% (3)

- Physics Assignment 2Document6 pagesPhysics Assignment 2anisha.tayade2023No ratings yet

- Van Duyn May 11, 2021 InspectionDocument12 pagesVan Duyn May 11, 2021 InspectionJames MulderNo ratings yet

- Manual Hyperthem Powermaxx 65Document150 pagesManual Hyperthem Powermaxx 65suspekt_no1No ratings yet

- Spiromatic S8 ScbaDocument36 pagesSpiromatic S8 ScbaForum PompieriiNo ratings yet

- Worksheet Partial in DerivativesDocument2 pagesWorksheet Partial in DerivativesVanessa HardjadinataNo ratings yet

- Falcon Corporation Letter of Intent For Natural Gas UtilizationDocument2 pagesFalcon Corporation Letter of Intent For Natural Gas UtilizationWazir Ahmed TaquiddinNo ratings yet

- Study Guide and Student Solutions Manual For Mcmurrys Organic Chemistry John Mcmurry Full Chapter PDF ScribdDocument67 pagesStudy Guide and Student Solutions Manual For Mcmurrys Organic Chemistry John Mcmurry Full Chapter PDF Scribdcharles.bowman556100% (6)

- The Effect of Oxidized and Unoxidized Filtrate On Oxygen DelignificationDocument40 pagesThe Effect of Oxidized and Unoxidized Filtrate On Oxygen DelignificationAria DarmawanNo ratings yet

- Data Fundamental 2011 - 2019Document660 pagesData Fundamental 2011 - 2019Arya PanggalihNo ratings yet

- Campus Map 2016 - 0Document1 pageCampus Map 2016 - 0KylieNo ratings yet

- Ship Particular Sitia Bay PDFDocument1 pageShip Particular Sitia Bay PDFRego FrantoniNo ratings yet

- CDO Supplier Pricelist CurrentDocument4 pagesCDO Supplier Pricelist CurrentRachel AmanteNo ratings yet

- Nut CokeDocument10 pagesNut Cokescribdaccount0No ratings yet

- HandwashingDocument2 pagesHandwashingBonita MendozaNo ratings yet

- 04 PFE Diet and PregnancyDocument4 pages04 PFE Diet and PregnancyHind ChehabeddineNo ratings yet

- Dye Laser PardeepDocument25 pagesDye Laser PardeepPardeep Kumar 29No ratings yet

- Cooking Verbs Vocabulary Esl Unscramble The Words Worksheets For KidsDocument4 pagesCooking Verbs Vocabulary Esl Unscramble The Words Worksheets For KidsYayah UrofiyahNo ratings yet

- Master Thesis in Production EngineeringDocument5 pagesMaster Thesis in Production Engineeringroxyrobertssavannah100% (1)