Professional Documents

Culture Documents

Additional Salient Features - Jab'09

Additional Salient Features - Jab'09

Uploaded by

Kumar Subramanian0 ratings0% found this document useful (0 votes)

2 views20 pagesOriginal Title

_Additional Salient features_Jab'09

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views20 pagesAdditional Salient Features - Jab'09

Additional Salient Features - Jab'09

Uploaded by

Kumar SubramanianCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 20

Addition - Salient points

Industry Quality Control

Manual

For

Non-Aviation Petroleum Products

Revised , effective from Jan-2009

Quality Quest no. 15 21.03.200 1

9

Quality Quest – Issue 15

HO QC brings out Quality Quest Issue 15

listing the changes of Revised Non Aviation

Industry Quality Control Manual (IQCM)

RJP Quality Quest no. 15 21.03.200 2

9

Need for Revision

BIS published BS II & BS III specification for MS &

HSD. Auto Fuel Policy published by MOP&NG.

The tolerance limit for specification published are more

stringent.

Introduction of Ethanol Blended Petrol and publication of

Bio-Diesel Purchase policy by MOP&NG.

This document gives new revised Salient points of IQCM.

For any doubt, pl refer the complete manual.

RJP Quality Quest no. 15 21.03.200 3

9

Addition - Salient points

Manufacturing Specification.

– SKO – FP 42oC min. (Naphtha/MS interface)

– FP 38oC min for other products interface

– HSD – KV at 40oC > by 0.2 cSt

- Cetane No. > by 0.5 Unit

- Sulphur 40ppm < than Spec.

– MS - RON > by 1 Unit than spec.

– FBP < by 15oC than requirement

– Sulphur 40ppm < than Spec.

RJP Quality Quest no. 15 21.03.200 4

9

Addition - Salient points

Interface management

For multi product receipts, in addition to the

Batch Formation Test, the bottom sample shall be

tested for Density and Distillation Test separately.

For first five (05) minutes the tanker discharge

shall be closely monitored (i.e. Test ‘A’).

RJP Quality Quest no. 15 21.03.200 5

9

Addition - Salient points

In case of layering during receipts, Batch

formation test shall be carried out individually for

layers having lowest and highest density.

In case of multi product discharge of tanker

through a single pipeline, for Motor Gasoline,

Distillation & Sulphur additional test also shall be

carried out on Bottom sample and for HSD,

Viscosity & Sulphur test also shall be carried out

on top sample.

RJP Quality Quest no. 15 21.03.200 6

9

Addition - Salient points

In case of layering after T/W receipts, density

shall be closely monitored during despatches

at filling point and record maintained.

Location receiving Kerosene by Rail / Road

shall carry out flash point & Density tests on

a top sample of the tank after each receipt

Receipt of additives / dye / marker. –(New

clause added)

Batch Number. –(Procedure elaborated in

detail)

RJP Quality Quest no. 15 21.03.200 7

9

Addition - Salient points

Inlet & Outlet of all the white / black oil tanks

should be provided with a filter of 100/ 60 mesh

size with appropriate coalescer.

Use of common pipeline for different generations

of the same grade of fuel should be avoided

Storage tanks shall be cleaned once in every five

years. However, with the specific approval of

Quality Control Department, cleaning of the tank

may be extended for a maximum period of three

years and subsequently by two years under

monitoring of sample at the suction and datum

plate level as per monitoring tests.

RJP Quality Quest no. 15 21.03.200 8

9

Addition - Salient points

If SKO inter tank transfer is necessary, then

SKO shall be released based on the flash

point and density test. The observations

shall be recorded.

Colour coding system suitably modified to

include new generation fuels.

The locations while sending the Monthly

Monitoring samples shall provide the

results of density at 15°C for all products

and flash point for SKO tank-wise

RJP Quality Quest no. 15 21.03.200 9

9

Addition - Salient points

Retention sample to be kept for Monthly

Monitoring sample sent to Lab for testing

and the same to be retained till test results

are obtained.

In a location carrying out batch formation

test, if there is no fresh receipt in a

particular product tank for 30 days, sample

from such tank shall be sent for monthly

monitoring tests

RJP Quality Quest no. 15 21.03.200 10

9

Addition - Salient points

UML composite samples from individual tanks,

nominated for receiving the product, shall be

taken, labelled, sealed and retained.

In case of T/W despatches, Open the bottom

valves completely and ensure from the manholes

that T/W is completely dry. Record the same in

the log book. The black oil T/W shall not be used

for loading white oil product. While change over

of black oil grade of T/W, ensure that T/W are

empty and no sludge is left over at the bottom.

Product doped with marker for the purpose of

checking the adulteration shall not be transported

through T/W.

RJP Quality Quest no. 15 21.03.200 11

9

Addition - Salient points

Same line for different generation of fuel of the

same grade should not be used. In case of the

operation constraint such type of operation shall

be carried out after prior approval from the head

of the regional QC and the line content shall be

downgraded into the lower generation of the

grade.

Retention sample quantity at location, modified in

line with MDG.

Retention sample period at locations modified to

30 days to increase the availability of location

retention sample for sales function.

RJP Quality Quest no. 15 21.03.200 12

9

Addition - Salient points

At all hospitality locations the assisting company

shall make available TLF / TWF retention samples

or corresponding test reports to assisted company

as and when required .

In case of specific requirement, the sample

container may be resealed / relabelled / codified

and proper record is to be maintained. A separate

guideline is to be made in this regard.

New clause explaining sealing of sample container

has been added providing a broad guideline in this

regard.

RJP Quality Quest no. 15 21.03.200 13

9

Addition - Salient points

List of static laboratories of Industry

has been updated.

The reference to MOP&NG guideline

on Disposal of off-spec MS/ HSD at

Retail Outlets has been included.

BIS specification of BSII & BSIII MS/

HSD has been included.

RJP Quality Quest no. 15 21.03.200 14

9

Addition - Salient points

In Monthly Monitoring tests following changes

have been done.

MS - Existent Gum & Potential Gum tests have

been deleted and Sulphur & RON tests have been

included.

HSD - Sulphur & Copper Strip Corrosion tests

have been incorporated for all grades of HSD.

Naphtha - ROE test have been replaced with

NVM test.

New tests “J” & “K” have been included for

testing tank bottom sample after PLT in case of

multi product pipeline receipt.

RJP Quality Quest no. 15 21.03.200 15

9

Addition - Salient points

In case of Pre-Discharge tests, following changes

have been made.

MS - Sulphur has been included and in case of

imported product, RVP & Potential Gum have

been deleted.

SKO- Distillation has been included for

indigenous product also and smoke point test has

been deleted in case of imported product.

HSD- Sulphur, Distillation & Cetane Index to be

done for all grades.

LDO- KV has been included for indigenous

product also .

RJP Quality Quest no. 15 21.03.200 16

9

Addition - Salient points

Storage Tank Cleaning Data at Appendix-8 has

been modified.

Appendix –9 – PLT has been included. The format

has been suitably modified.

Appendix – 10 – One more table has been added.

Appendix –12 has been modified.

RJP Quality Quest no. 15 21.03.200 17

9

Addition - Salient points

Batch Formation Test – Modifications.

MS- Sulphur test, RON included.

HSD – Sulphur for all grades and Cetane

Index has been included.

Naphtha – CH ratio (calculated), Olefine %

V, GCV, ROE, Lead ppb have been

included.

RJP Quality Quest no. 15 21.03.200 18

9

Addition - Salient points

Procedure for Up-gradation of marker

doped SKO TT for carrying MS / HSD has

been included.

Appendix – 19 containing Product

Acceptance Limits Ex Refineries / Pipe

Lines / Imports has been added.

RJP Quality Quest no. 15 21.03.200 19

9

Cross References

Industry Product Acceptance Manual

Industry Ethanol Manual

Industry Bio-Diesel Manual

Market Discipline Guidelines.

Relevant BIS Specifications.

RJP Quality Quest no. 15 21.03.200 20

9

You might also like

- 2018 QMS Asphalt ManualDocument364 pages2018 QMS Asphalt ManualhabtamualemNo ratings yet

- 2012 Qms Asphalt ManualDocument502 pages2012 Qms Asphalt Manualistiar100% (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNo ratings yet

- Corrosion GuideDocument23 pagesCorrosion Guideachmaddach100% (4)

- 2018 QMS Asphalt ManualDocument364 pages2018 QMS Asphalt ManualhabtamualemNo ratings yet

- Google NCLDocument152 pagesGoogle NCLPieter Benjamin GrebeNo ratings yet

- Manual of Petroleum MeasurementDocument7 pagesManual of Petroleum Measurementsreeyuktha50% (2)

- 05 Strategic Mine Planning 1Document39 pages05 Strategic Mine Planning 1minerito22110% (1)

- PIPESIM V.2014 Suggested CorrelationsDocument2 pagesPIPESIM V.2014 Suggested Correlationsnicolascm94No ratings yet

- Hydrostatic Test Procedure: Salalah Ammonia ProjectDocument6 pagesHydrostatic Test Procedure: Salalah Ammonia ProjectAbdelkhak KhallaNo ratings yet

- Shimadzu System GC CatalogDocument48 pagesShimadzu System GC CatalogTerry Osenbach100% (1)

- Stimulation by Acidizing BPDocument77 pagesStimulation by Acidizing BPStan Andrei100% (5)

- Working Capital Management & Comparative Financial Analysis of Indian Oil With Its Major CompetitorsDocument97 pagesWorking Capital Management & Comparative Financial Analysis of Indian Oil With Its Major Competitorsamitstud200185% (20)

- Fuel Oil TreatmentDocument40 pagesFuel Oil Treatmentswapneel_kulkarni100% (2)

- Off Brochure Flng-Mar-2018 LRDocument8 pagesOff Brochure Flng-Mar-2018 LRLinnie Mcleod100% (2)

- Inspection Guidelines by LincolnDocument30 pagesInspection Guidelines by LincolnOrlando Fl L WebbNo ratings yet

- Design and Rating of Packed Distillation ColumnsDocument50 pagesDesign and Rating of Packed Distillation Columnsjdgh1986100% (1)

- Kavin Engineering - ProjectDocument2 pagesKavin Engineering - Projectagarwal.rmNo ratings yet

- Oil Filled Transformers Standard Testing ProcedureDocument17 pagesOil Filled Transformers Standard Testing ProcedureNajeeb AbbasiNo ratings yet

- Instrumentation Standards ListDocument45 pagesInstrumentation Standards ListRajeevNo ratings yet

- Hydrocarbon Dewpoint DeterminDocument8 pagesHydrocarbon Dewpoint Determineng20072007No ratings yet

- Saudi Arabia Position PaperDocument2 pagesSaudi Arabia Position PaperShashank SrikanthNo ratings yet

- Overview of Gas Conditioning and ProcessingDocument14 pagesOverview of Gas Conditioning and ProcessingJOSE GONZALEZ VALERONo ratings yet

- Bechtle EngineeringDocument21 pagesBechtle EngineeringMohammad Elhedaby100% (1)

- PVT ExpressDocument5 pagesPVT ExpressHadi HendizadehNo ratings yet

- QCP For Hot Tap PDFDocument30 pagesQCP For Hot Tap PDFjahaan100% (1)

- ISO 82172010 by BP Marine Fuels PDFDocument26 pagesISO 82172010 by BP Marine Fuels PDFgreenhen15100% (1)

- CPRS Application in The OilfieldDocument68 pagesCPRS Application in The OilfieldAnonymous i3xDz4TNo ratings yet

- Catalyst Chage OperationDocument59 pagesCatalyst Chage OperationcutefrenzyNo ratings yet

- Ibp1325 12Document7 pagesIbp1325 12Marcelo Varejão CasarinNo ratings yet

- Mini LabDocument6 pagesMini Labsotonye boyleNo ratings yet

- Gdflo 497Document9 pagesGdflo 497raritylimNo ratings yet

- Checklist For Inspection of RCDs On Indian RailwaysDocument11 pagesChecklist For Inspection of RCDs On Indian RailwaysHanuma ReddyNo ratings yet

- Bulletin 137 Supply Chain Periodic Testing of Avgas July 2021 3Document4 pagesBulletin 137 Supply Chain Periodic Testing of Avgas July 2021 3PETENo ratings yet

- Bulletin 137 Supply Chain Periodic Testing of Avgas July 2021 3Document4 pagesBulletin 137 Supply Chain Periodic Testing of Avgas July 2021 3viktor_gligorovNo ratings yet

- Gammon Contamination Test Kits PDFDocument3 pagesGammon Contamination Test Kits PDFpersadanusantaraNo ratings yet

- M02 - Product SpecificationDocument8 pagesM02 - Product Specificationhoghost123No ratings yet

- Relief Valves ProcedureDocument15 pagesRelief Valves ProcedureNuwan RanaweeraNo ratings yet

- Bulletin 96 AFQR Oct 2016Document9 pagesBulletin 96 AFQR Oct 2016Thupten Gedun Kelvin OngNo ratings yet

- MCML Qahsed Part Developed by Reverse Engineering Evaluation SopDocument4 pagesMCML Qahsed Part Developed by Reverse Engineering Evaluation Sopabbas razaNo ratings yet

- Certifying Suppliers of Performance-Graded Asphalt Binders: Standard Practice ForDocument10 pagesCertifying Suppliers of Performance-Graded Asphalt Binders: Standard Practice ForXarmdNo ratings yet

- ETP Operation SopDocument5 pagesETP Operation SopaadeefactoryNo ratings yet

- Calgaz QAP For Dry Gas StandardsDocument2 pagesCalgaz QAP For Dry Gas StandardsDoncrot Oye0% (1)

- Note On The Seal Qualification Test and Cooler Test For Kochi - Coimbatore - Erode - Salem - LPG Pipeline ProjectDocument1 pageNote On The Seal Qualification Test and Cooler Test For Kochi - Coimbatore - Erode - Salem - LPG Pipeline ProjectAbhinav SinghNo ratings yet

- Safety Working Paper AnnexesDocument35 pagesSafety Working Paper Annexesshabbir626No ratings yet

- Carrier Transicold TECHLINE July2012Document4 pagesCarrier Transicold TECHLINE July2012Carlitos Enrique Corpus PonceNo ratings yet

- Pvtsim Technical Overview 2020-2-1Document16 pagesPvtsim Technical Overview 2020-2-1Emad ZalamNo ratings yet

- Technical Presentation On Condensate ClassificationDocument23 pagesTechnical Presentation On Condensate ClassificationRaboni ZitelinaNo ratings yet

- Suez Proposal Comments Sum 12.12.18Document9 pagesSuez Proposal Comments Sum 12.12.18Arie PanjunanNo ratings yet

- 16 Gas Lift OptimizationDocument3 pages16 Gas Lift OptimizationAhmed FahmyNo ratings yet

- PDS - GulfSea Power MDO Series 2019-10Document1 pagePDS - GulfSea Power MDO Series 2019-10Bassam AljiffryNo ratings yet

- CD-16-09 Certification of Diesel Engines Equipped With Vanadium-Based SCR CatalystDocument7 pagesCD-16-09 Certification of Diesel Engines Equipped With Vanadium-Based SCR CatalystandrelennonNo ratings yet

- WM-DUB-HAL-SDL-397 - 9100 CallibrationDocument16 pagesWM-DUB-HAL-SDL-397 - 9100 CallibrationSheryar ShahNo ratings yet

- Service Letter SL2020-695/JSST: Regular Operation of The SCR System To Maintain Correct FunctionalityDocument3 pagesService Letter SL2020-695/JSST: Regular Operation of The SCR System To Maintain Correct FunctionalityOctavian DinuNo ratings yet

- S BraneDocument16 pagesS Branemsr22No ratings yet

- S. No. Item Description Analysis Results and RecommendationsDocument2 pagesS. No. Item Description Analysis Results and Recommendationsramadoss_alwar7307No ratings yet

- 7 CFT MOM 29 10 14 - With Comments - 1Document2 pages7 CFT MOM 29 10 14 - With Comments - 1spdhimanNo ratings yet

- Mohammad Jehad Shanablhe Civil Engineering 2015988186Document13 pagesMohammad Jehad Shanablhe Civil Engineering 2015988186Mohammed MigdadyNo ratings yet

- OPSS - PROV 1101 - Nov 2020Document9 pagesOPSS - PROV 1101 - Nov 2020Samantha McLachlinNo ratings yet

- 86261-Annulus Test Reporting Requirements DirectiveDocument7 pages86261-Annulus Test Reporting Requirements DirectiveNgoVietCuongNo ratings yet

- Type - 4 Cascade TenderDocument24 pagesType - 4 Cascade TenderrajNo ratings yet

- 06 Gas and Condensate Allocaton TesakerDocument8 pages06 Gas and Condensate Allocaton TesakerMinh NguyễnNo ratings yet

- CDI NORSOK Testing Elastomers Tech Report WebDocument2 pagesCDI NORSOK Testing Elastomers Tech Report WebwholenumberNo ratings yet

- ISO-8217 UpDocument9 pagesISO-8217 UpChemical EngNo ratings yet

- Beautiful BookDocument16 pagesBeautiful BookKumar SubramanianNo ratings yet

- Board Exam Qns - Measurement & Metrology (N - Scheme)Document8 pagesBoard Exam Qns - Measurement & Metrology (N - Scheme)Kumar SubramanianNo ratings yet

- POLYTECHNIC 2023-24 First Year Instructions To CandidatesPart TimeDocument3 pagesPOLYTECHNIC 2023-24 First Year Instructions To CandidatesPart TimeKumar SubramanianNo ratings yet

- Product Data Guide 2005Document58 pagesProduct Data Guide 2005Kumar SubramanianNo ratings yet

- Fatima College (Autonomous), Madurai - 625018. Department of Chemistry (P.G. 2009) - CbcsDocument37 pagesFatima College (Autonomous), Madurai - 625018. Department of Chemistry (P.G. 2009) - CbcsKumar SubramanianNo ratings yet

- Comments - UG SyllabusDocument1 pageComments - UG SyllabusKumar SubramanianNo ratings yet

- Yc Ha 6 T NSD ERFsj YHRd XHDocument34 pagesYc Ha 6 T NSD ERFsj YHRd XHKumar SubramanianNo ratings yet

- Mech III-IDocument156 pagesMech III-IKumar SubramanianNo ratings yet

- Unitrac Results - R&DDocument10 pagesUnitrac Results - R&DKumar SubramanianNo ratings yet

- Unit IDocument93 pagesUnit IKumar SubramanianNo ratings yet

- Unit IDocument93 pagesUnit IKumar SubramanianNo ratings yet

- EG 2 CompressedDocument149 pagesEG 2 CompressedKumar SubramanianNo ratings yet

- Chemistry Polytechnic Engineering-Chemistry Semester 1 and 2 Text BooksDocument272 pagesChemistry Polytechnic Engineering-Chemistry Semester 1 and 2 Text BooksKumar SubramanianNo ratings yet

- MT-1 (English) - N SchemeDocument288 pagesMT-1 (English) - N SchemeKumar Subramanian100% (1)

- Measurements & Metrology (English)Document29 pagesMeasurements & Metrology (English)Kumar SubramanianNo ratings yet

- Chem-Practical Handbook (From 2018)Document179 pagesChem-Practical Handbook (From 2018)Kumar SubramanianNo ratings yet

- Chemistry, Importent 7 and 8 Mark QuestionsDocument2 pagesChemistry, Importent 7 and 8 Mark QuestionsKumar SubramanianNo ratings yet

- The Caspian Sea and Southern Gas Corridor: A View From RussiaDocument31 pagesThe Caspian Sea and Southern Gas Corridor: A View From RussiaThe Atlantic CouncilNo ratings yet

- Dheri SaydenDocument1 pageDheri SaydenZubair KhanNo ratings yet

- BPDocument1 pageBPEce KıtaybahadırNo ratings yet

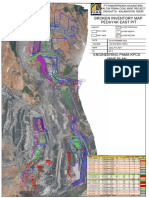

- Broken Map Pde 231123Document1 pageBroken Map Pde 231123alifrosyadi1991No ratings yet

- History of LPG-Propane - Who Invented or Discovered It & When - Origin of LPG - ELGAS - LPG Gas For Home & BusinessDocument3 pagesHistory of LPG-Propane - Who Invented or Discovered It & When - Origin of LPG - ELGAS - LPG Gas For Home & BusinessVenkatesh ChNo ratings yet

- Api RP 500Document128 pagesApi RP 500guptax3aNo ratings yet

- DNO CompanyDocument2 pagesDNO CompanySirajNo ratings yet

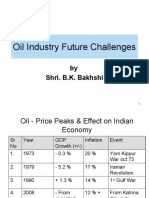

- Oil Industry Future Challenges: by Shri. B.K. BakhshiDocument21 pagesOil Industry Future Challenges: by Shri. B.K. BakhshiGirish1412No ratings yet

- Geophysical ProspectingDocument27 pagesGeophysical ProspectingbvkvijaiNo ratings yet

- UK Defence Standard of Fuel and LubricantsDocument16 pagesUK Defence Standard of Fuel and LubricantsMukarram MNo ratings yet

- IPCA Journal Jan-March 2015Document16 pagesIPCA Journal Jan-March 2015MCCIN L&WNo ratings yet

- JPT 2017 JunioDocument96 pagesJPT 2017 Junioabraham dominguezNo ratings yet

- Optech Density Correction Values Calculated As Per ASTMDocument14 pagesOptech Density Correction Values Calculated As Per ASTMEjaz Ahmed RanaNo ratings yet

- K Values CalculationDocument3 pagesK Values CalculationAlexis HaleyNo ratings yet

- Executive Summary RSM 221204Document30 pagesExecutive Summary RSM 221204bimonurainiNo ratings yet

- List of Crosby Rvs Need To Be Fixed ImmediatelyDocument6 pagesList of Crosby Rvs Need To Be Fixed ImmediatelyEr Bishwonath ShahNo ratings yet

- ZOFD Onshore Utilities and Water Treatment Facilities Package II Saudi Arabia - Profile - 130122Document8 pagesZOFD Onshore Utilities and Water Treatment Facilities Package II Saudi Arabia - Profile - 130122salman KhanNo ratings yet

- Technical Guide On Internal Audit Issued by ICAI - Oil & Gas (Downstream)Document117 pagesTechnical Guide On Internal Audit Issued by ICAI - Oil & Gas (Downstream)Sarang SinghNo ratings yet

- Five Star Petroleum LNG Business PresentationDocument12 pagesFive Star Petroleum LNG Business PresentationDhaval JobanputraNo ratings yet

- Overview Pertamina Ep Asset 1 Field RambaDocument24 pagesOverview Pertamina Ep Asset 1 Field Rambafauzan kartiyasaNo ratings yet

- BashundharaDocument2 pagesBashundharaSajadur Rashid SabbirNo ratings yet

- Experience The Benefits of Tomorrow'S Fuel, Today: What ChoiceDocument2 pagesExperience The Benefits of Tomorrow'S Fuel, Today: What ChoiceUJJWALNo ratings yet

- Petroleum and Natural Gas Geology - Prof.Dr. Nam─▒k ├Зa─ЯatayDocument45 pagesPetroleum and Natural Gas Geology - Prof.Dr. Nam─▒k ├Зa─ЯatayStephen FortisNo ratings yet