0% found this document useful (0 votes)

23 views25 pages01 - Valves

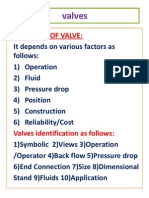

This document provides an overview of various types of valves used in surface testing, including gate, needle, ball, plug, butterfly, globe, check, and relief valves. It details their functions, pressure ratings, sealing methods, and standard sizes, as well as safety practices for their operation. The information is aimed at ensuring proper usage and maintenance of these valves in fluid control systems.

Uploaded by

Mahmoud NassarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

23 views25 pages01 - Valves

This document provides an overview of various types of valves used in surface testing, including gate, needle, ball, plug, butterfly, globe, check, and relief valves. It details their functions, pressure ratings, sealing methods, and standard sizes, as well as safety practices for their operation. The information is aimed at ensuring proper usage and maintenance of these valves in fluid control systems.

Uploaded by

Mahmoud NassarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd