Professional Documents

Culture Documents

How To Calculate Cut and Fill Accurately

Uploaded by

Wan MahiramOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

How To Calculate Cut and Fill Accurately

Uploaded by

Wan MahiramCopyright:

Available Formats

How to Calculate Cut and Fill Accurately The Grid method

Overview In the grid method, we are going to calculate cut and fill by dividing our site plan into equally sized grid cells and then calculating the cut or fill volume in each cell. Well do this by drawing sets of horizontal and vertical lines at equally spaced intervals across the plan. Then for each corner of every grid cell we will determine both the existing elevation and proposed elevation at that point. The difference between the two will be the cut or fill depth for that point. ositive differences will be fill and negative differences will be cut. !nce weve determined the cut or fill depth for every corner, well add up the cut or fill numbers for each of the four corners, average them, then multiply that number by the number of square feet in the grid cell and then finally dividing that number by "# to calculate cut and fill in cubic yards for that grid cell. Then for every grid cell, well add up all of the cuts and all of the fills separately. These are the total cuts and fills for the site. The difference between those two numbers is the import or export of dirt from the site. Tools youll need $ large flat surface bigger than your plan %& inch T'square, (airgate T%&T $ pencil )preferably mechanical* $ calculator or spreadsheet Step 1 - Gridding o the drawing Ta+e your site plan and lay it on a large flat surface li+e a drafting table, a large des+, or your homes dining room table. ),orry -rs. .eader* With a large T'square, draw a series of equally spaced /oors auto and vertical lines across your drawing. The lines should be spaced in multiples of your drawing scale. The spacing you choose should stri+e a balance between speed and accuracy. The smaller the grid cells, the more calculations will need be performed but the higher the accuracy. The larger the grid cells, the fewer calculations will need to be performed the lower the accuracy will be. $ good compromise is to base the spacing on the average complexity of the 0ob site. In more complex areas the grid cells can be further subdivided so as to increase the accuracy in those portions of the drawing. Step ! " Calculating the e#isting elevations (or the corner of each grid cell, determine the existing elevation.

To do this accurately, ta+e a scale and find the shortest distance between two contours that form a line crossing through your corner. 1se the ratio of the distance between the contours and the distance from one contour to your corner to determine the elevation at the corner. (or example, if one contour is #2 feet, the next contour is #" feet, the distance between the contours is 34 feet and the distance from the #2 foot contour to the corner is 3" feet than the math loo+s li+e this, )(irst contour elevation ' second contour elevation* 5 )distance from first contour to corner 6 distance from first contour to second contour* 7 elevation of first contour 8 corner elevation 1sing the numbers in our example, )#" ' #2* 5 3" 6 34 7 #2 8 " 5 2.9 7 #2 8 3.& 7 #2 8 #3.&. If youre stripping topsoil from the site, ma+e sure to reduce the existing elevation by the thic+ness of the topsoil strip. Step $ " Calculating the proposed elevations .epeat step " above for all your proposed elevations. If your re'spreading topsoil or adding par+ing lot and building pads, ma+e sure to reduce the proposed elevation by the thic+ness of the topsoil re'spread or other man'made materials. Step % " Calculating the cut and ill depths (or the corner of each grid cell, subtract the existing elevation from the proposed elevation. ositive quantities are fill. :egative quantities are cut. Step & " Calculating the average cut' ill depth (or each grid cell, add the four corner cut or fill depths together and divide that sum by ;.2 to calculate the average cut or fill depth for that grid cell. Step ( " Calculating the cut or ill volume or each grid cell (or each grid cell, calculate the total cut or fill volume by multiplying the average cut or fill depth by the area of the grid cell. )To determine the area of the grid cell, multiply the length of one horizontal side by the length of one vertical side*. (inally, divide this number by "# in order to calculate cut and fill in cubic yards. :egative volumes are cut. ositive volumes are fill. Step ) " Calculate cut and ill volumes or the entire site <etermine the total cut for the site by adding up all of the negative volumes in every grid cell on the drawing. )=ou can record the cut as a positive number at this point.* Then determine the total fill for the site by adding up all the positive volumes in every grid cell on the drawing.

Step * " Calculating the import or e#port rom the site To determine the export from the site, subtract the fill from the cut. If the result is positive, this is the volume of soil that must be exported from the site. If the result is negative, this is the volume of soil that must be imported to the site. Final thoughts /all me simple but I li+e this method more than the cross'section method. I li+e it because all of my numbers are right on the drawing and its easy for anyone to see my math. Its very boring to do )I li+e to listen to boo+s on tape while I do all the calculations* but very reliable. ' >d

888888888888888888888888

The Cross-Section method

:ow the cross'section method is not my most favorite method for calculate cut and fill volumes but some of my colleagues li+e it and it is one of the widely accepted ways to calculate cut and fill so Im going to go ahead and teach it here anyway. Overview ?ow the cross'section method wor+s is that you draw a series of equally spaced horizontal lines across our site. $nd then for each cross'section you are going to plot out, on graph paper, a graph that shows the distance from the left edge of the drawing on the horizontal axis versus both the proposed and existing elevations on the vertical axis. We will then use the graph to figure out the calculate the cut area and fill area for each cross'section. !nce weve completed every cross'section, we will use the cut areas and fill areas and the distance between each cross'section to calculate cut and fill volumes for each pair of cross sections and then add them up for the whole 0ob. Tools youll need $ large flat surface bigger than your plan %& inch T'square, (airgate T%&T 33 x 3# graph paper, ,taples @93;4&& "; inch engineer scale, (airgate T>"; $ pencil )preferably mechanical* $ calculator or spreadsheet Step 1 " Cross-sectioning the drawing

(irst find a nice stable surface to place your drawing such as a large des+, drafting table or your dining room table )sorry -rs. .eader* and lay the drawing out nice and flat. Then ta+e your T'square and draw a series of horizontal lines across your drawing. They should be equally spaced and in multiples of your drawing scale. )That will ma+e the math easier.* The number of cross'sections required depends on how busy the drawing is. ,imple drawings require fewer cross'sections, more complex drawings require more cross'sections. It all depends on how accurate you want your estimate to be and how much time you are willing to spend doing the estimate. Step ! " +repare your graph paper 1sing your engineers scale, determine the total width of your drawing in feet. :ow find your drawing scale in the table below. Aoo+ to the right to find the number of feet per grid square to use on your 33 x 3#B paper. <rawing ,cale (eet per grid square on a %&B wide drawing and on 3#B wide paper 3C32 4 3C"2 32 3C%2 34 3C;2 "2 3C42 "4 3C&2 %2 3C92 ;2 3C322 42 3C"22 322

$long the bottom of your page, draw the horizontal axis and mar+ the distance every four grid squares. (or example, if I had a %2 scale drawing, the width of each grid square would be 34 feet. (or the vertical axis, you will need to determine the number of feet per grid square. To do that, examine the drawing and find both the lowest and highest elevations. (ind the difference between those two elevations and divide it by ;2 )the usable number of grid squares on the 33 inch side of the drawing*. .ound that number down to get a usable distance for each vertical grid square. (or example, if the high elevation was ## and low elevation was 43, the difference between the elevations would be "&. <ividing ;2 into "& gives us 2.&46grid square. 1sing 2.&4 would be an aw+ward number so lets rounded it down to 2.4. That means our vertical scale is 2.4 feet per grid square. :ow draw the vertical scale and mar+ the elevations every four grid squares.

$nd finally, reproduce this graph on enough new sheets of graph paper that you have one for every cross'section that youve drawn across the drawing. Step $ " ,etermine the area o each grid s-uare To calculate cut and fill volumes later, we will need to +now the area, in square feet, represented by each grid square. To determine that, multiply the grid cells width in feet by its height in feet. In the example in ,tep " above, the grid square was 34 feet across horizontally and 2.4 feet vertically. -ultiplying that out D. 34x2.4 gives us #.4 square feet for each grid square. Step % " Graph the e#isting sur ace Aay your engineers scale on the first cross'section with the zero mar+ on the left edge of the drawing and determine the distance to your first existing elevation. -ar+ that elevation and distance on your graph paper. .epeat for each existing elevation that crosses that horizontal cross'section line. !nce you reach the end of the line, go to each of the points you plotted and draw a line between them to show the existing surface. Step & " Graph the proposed sur ace Eo bac+ to the beginning of the horizontal line and determine the distance to your first proposed elevation. -ar+ that elevation and distance on your graph paper. .epeat for each proposed elevation that crosses the horizontal cross'section line. When you reach the end of the line go bac+ to the points you plotted and draw a line between them to show the proposed surface. Step ( " ,etermine the cut area :ow on each graph, find the section or sections where the existing surface is above the proposed surface. /ount the total number of full and partial squares in each of those sections. Then multiply the total number of grid squares you counted by the area of the grid square you determined in step % and record that on the graph paper. (or example, if you found "#." grid squares of cut, the total cut area would be "#." F #.4 8 "2;.2 square feet of cut area. Step ) " ,etermine the ill area :ow find the section or sections were the proposed surface is above the existing. /ount the total number of full or partial grid squares. Then multiply the total number of grid squares of fill by the area of a grid square and record that on the graph paper. (or example, if you found 3"G.3 grid squares of fill, the total fill area would be 3"G.3 F #.4 8 G&9."4 square feet of fill area. Step * " .epeat steps % through ) or each o the remaining hori/ontal cross-sections 1sing a new graph paper sheet for each horizontal cross'section repeat steps ; through #.

Step 0 " ,etermine the cut volume (or each ad0acent pair of cross'sections, add the two cut areas together. :ow divide that number by two to determine the average cut area. (inally, multiply that average cut area by the distance between the two cross'sections. Thats your cut volume for that pair of cross'sections. .epeat this for each cross'section. Step 11 " ,etermine the ill volume (or each ad0acent pair of cross'sections, add the two fill areas together. :ow divide that number by " to determine the average fill area. (inally, multiply that average fill area by the distance between the two cross'sections. Thats your fill volume for that pair of cross'sections. .epeat this for each cross'section. Step 11 " ,etermine the total cut volume $dd up all the cut volumes you 0ust calculated to determine your total cut volume. Step 1! " ,etermine the total ill volume $dd up all the fill volumes you 0ust calculated to determine your total fill volume. Step 1$ " Calculating the import or e#port rom the site To determine the export from the site, subtract the fill from the cut. If the result is positive, this is the volume of soil that must be exported from the site. If the result is negative, this is the volume of soil that must be imported to the site. Some inal thoughts :ow do you see why I prefer to use the grid methodH If you have your cross'sections fairly close together, this method can be a very accurate way to calculate cut and fill. Iut its also very tedious and requires a lot of attention to detail. $nd because the cross'sections are not shown directly on the plan is very hard to double chec+ your wor+. Iut some people swear by it... Eo figureJ ' >d 888888888888888888888888 Calculating Cut and Fill with so tware

:ow both of those by hand methods will get you by if you are 0ust starting out or if you only have to bid a 0ob once in a while. Iut neither is particularly fast or accurate. If you calculate cut and fill by hand, youll be able to do maybe one or two 0obs today with accuracy somewhere around 32 to "2K. If you are serious about your wor+ or you need to calculate cut and fill for a lot of bids, you will need to use cut and fill software and a computer. The great thing about using cut and fill software is that it will increase your bidding speed three or four fold. Then instead of doing one bid a day, youll be able to cran+ out four bids in the same amount of time and with tighter numbers. Thats particularly important now when people are having to bid 32 or "2 0obs in order to win a single one. I 0ust cant tell you how much productivity are going to be using cut and fill software. Its li+e night and day difference. I used to spend an entire day or two ta+ing a single sheet. $nd even then, I was only withing 34K to 32K of the actual numbers. !nce I got my first cut and fill program, that time got cut in half. $nd not only was I faster but I was a lot more accurate. -ore li+e %K to 4K. That allowed us to be a lot tighter with our bids and not always leaving so much money on the table. Ill tell you, its a lot more comfortable putting in a bid +nowing how much cut and fill your are going to have versus +nowing within "2K what your real numbers are. ,o, heres my ta+e on buying software to calculate cut and fill pro0ectsC The +ros Its faster ' % to 4 times faster. Its more accurate ' %K to 4K vs. 34K to "2K It ma+es you far more productive. I cant stress this enough. Its easy for other people to chec+ your wor+. If you are the boss it ma+es it easier for you to chec+ your estimators wor+. Its much easier to update your cut and fill ta+eoff when change orders come in. It frees up a lot of your time to do more productive and profitable wor+. $nd if you have the proper equipment and software, it allows you ma+e a %'< model to allow automatic grading of your site. The Cons /ut and fill software costs money. =ou have to learn something new. It is a few days to a few hours of downtime learning a new piece of software. If you are a computer'phobe, you have to learn how to use one.

)$s for the cost, its really not that big a deal compared to what we get for your money. Im 0ust amazed the number of people who plead poverty in their business, and yet have the money for a new bass boat, $TL or new giant flatscreen TL.* What to loo+ for when you buy cut and fill software (irst, decide what you want the software to do for you. <o you want to calculate 0ust cut and fill volumesH <o you needed to figure out material quantities li+e asphalt, base course and concreteH <o you need to measure areas, length and countsH Then plan to spend between M%222 and M4222 on an on'screen cut and fill program. )an on N screen program will allow you to do your ta+eoff directly from a <( right on your computer screen* If youre wor+ing from paper plans, then plan to spend an extra M"%22'M"922 on a digitizer board. These are large electronic drafting boards that allow you to trace information from the paper plan into the software. These used to be all the rage, but now with onscreen ta+eoff <(s, they are not used that much anymore. If youre definitely going to be using E , hardware on your equipment, then plan between spending M9222 and M"2,222 on your cut and fill software. -a+e sure to wor+ closely with your E , equipment supplier so that you get exactly the right software to use their equipment. Its especially smart to buy all of your software and hardware from one company and that way when something goes wrong )because it will* only one company will be responsible to fix it. =ou dont want to companies pointing at each others hardware or software and saying O?ey, its the other guys problemJB .ecommendations aydirt ' If you need to generate %'< models for your machine control grading systems, then you should get both equipment and software from Trimble. that would be both the aydirt software and E/, G22 grade control systems. The aydirt software runs between M9222 and M32,222. If youre using $uto/$< drawings ma+e sure to get the Terra-odel software as well. That software is required to import and correct the $uto/$< files. >arthWor+s ' If you need an affordable and straightforward program to figure your cut and fill material quantities from on'screen drawings or paper plans, then get >arthWor+s from www.Tra+ware3.com. It is a very straightforward and easy to use program with lots of built'in help. I got up and running 0ust a couple hours, and was cran+ing outbid by the end day. $s I recall, they start around M%422. /opyright, "232 >dward Penney at httpC66www.calculatecutandfill.com6. $ll rights reserved

You might also like

- Grid Method Contour LineDocument6 pagesGrid Method Contour LineMherlieNo ratings yet

- Contour SurveyingDocument14 pagesContour SurveyingAnkit JenaNo ratings yet

- Area and VolumeDocument34 pagesArea and VolumeQila Husin80% (5)

- GEOMATIC - LevelingDocument49 pagesGEOMATIC - LevelingAK4750% (2)

- Design of Horizontal and Vertical AlignmentDocument20 pagesDesign of Horizontal and Vertical AlignmentDharmesh ChandravadiyaNo ratings yet

- Calculation of Earthwork QuantityDocument8 pagesCalculation of Earthwork Quantitymkjailani100% (1)

- Chapter 2aDocument30 pagesChapter 2aSyazwi Hakimi0% (1)

- Spot Speed StudyDocument4 pagesSpot Speed StudyGeniuskuga Kugas0% (1)

- Celebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985From EverandCelebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985No ratings yet

- Cc206 - Bab 4 Ibs Score NewDocument27 pagesCc206 - Bab 4 Ibs Score NewAdron LimNo ratings yet

- Speed Spot StudiesDocument16 pagesSpeed Spot StudiesLuqman YusofNo ratings yet

- Lesson 5 - Levelling and ContouringDocument31 pagesLesson 5 - Levelling and ContouringBryan0% (2)

- Measuring Elevation Differences with Fly LevelingDocument12 pagesMeasuring Elevation Differences with Fly LevelingHonin AlshaerNo ratings yet

- Schmidt HammerDocument4 pagesSchmidt Hammerfarid_millerNo ratings yet

- Skid-Sand-Outflow ReportDocument11 pagesSkid-Sand-Outflow ReportAthirah Dinata100% (1)

- Table of Contents and Capacity AnalysisDocument10 pagesTable of Contents and Capacity AnalysisAzyan Afiqah100% (1)

- Final Exam HighwayDocument14 pagesFinal Exam HighwayzsNo ratings yet

- Case Study of EarthworkDocument5 pagesCase Study of EarthworkMuhammad Nuriqram0% (1)

- Example 6.1 - Slab-Simply Supported (One-Way) PDFDocument5 pagesExample 6.1 - Slab-Simply Supported (One-Way) PDFnur100% (1)

- Engineering Surveying Field Scheme ReportDocument6 pagesEngineering Surveying Field Scheme ReportMohafisto SofistoNo ratings yet

- Engineering SurveyDocument3 pagesEngineering SurveyDzira HadziraNo ratings yet

- Group 3 (Seksyen4)Document15 pagesGroup 3 (Seksyen4)alnzNo ratings yet

- Highway Geometric Design ElementsDocument93 pagesHighway Geometric Design ElementsGERA AMITH KUMARNo ratings yet

- GEOMATIC - Areas & VolumeDocument32 pagesGEOMATIC - Areas & VolumeAK47100% (1)

- Surveying AssignmentDocument21 pagesSurveying AssignmentSalman FarisNo ratings yet

- Failure analysis of retaining wall in VisakhapatnamDocument4 pagesFailure analysis of retaining wall in VisakhapatnamRaghavNo ratings yet

- Report EsteemDocument14 pagesReport EsteemNur Hazimah100% (1)

- Road Design BasicsDocument13 pagesRoad Design BasicsLJD211100% (1)

- Infiltration Rate and Infiltration TestDocument7 pagesInfiltration Rate and Infiltration TestThomas CroweNo ratings yet

- Cut and Fill PresentationDocument23 pagesCut and Fill PresentationMuhammad Faiz bin Ahmad Shafi63% (8)

- Geometric Design of Highways for EngineersDocument39 pagesGeometric Design of Highways for EngineersZeleke TaimuNo ratings yet

- g20 Setting OutDocument8 pagesg20 Setting OutMohd AmranNo ratings yet

- Surveying Control Points and Levelling MethodsDocument37 pagesSurveying Control Points and Levelling MethodsVikash Peerthy0% (2)

- Hazen-Williams Formula For Water FlowDocument13 pagesHazen-Williams Formula For Water FlowSeroKeretaMasaroWidiar100% (1)

- Setting Out GEO200Document48 pagesSetting Out GEO200asunanesha0% (1)

- Structural Design of Flexible Pavement-ATJ 5-85 Pindaan 2013Document38 pagesStructural Design of Flexible Pavement-ATJ 5-85 Pindaan 2013Mohammad Yunus Salehi50% (2)

- Assignment EsteemDocument3 pagesAssignment EsteemHani BarjokNo ratings yet

- Project Report Topic: Analysis of Statically Determinate BeamDocument22 pagesProject Report Topic: Analysis of Statically Determinate BeamMARVINNo ratings yet

- Pavement Thickness Design ProcedureDocument29 pagesPavement Thickness Design Proceduremustafurade1No ratings yet

- Esteem PlusDocument261 pagesEsteem PlusLun Ding50% (2)

- Two Peg TestDocument2 pagesTwo Peg TestTidus FarronNo ratings yet

- Pavements DesignDocument21 pagesPavements DesignRamil S. ArtatesNo ratings yet

- 5 PPT GD of ROADSDocument58 pages5 PPT GD of ROADSMudduKrishna shettyNo ratings yet

- Chapter 1 IntroductionDocument36 pagesChapter 1 IntroductionCpt ShinodaNo ratings yet

- Map 3 Introduction To True & Apparent Dip and Thickness of BedDocument1 pageMap 3 Introduction To True & Apparent Dip and Thickness of BedSyazli EimranNo ratings yet

- Highway Chapter 2 Road ClassificationDocument24 pagesHighway Chapter 2 Road ClassificationIr Ahmad NazriNo ratings yet

- Highway Geometric Design PrinciplesDocument91 pagesHighway Geometric Design PrinciplesSolomon DesalegnNo ratings yet

- Lab 6 Manual LosDocument11 pagesLab 6 Manual LosAmar Aizad100% (1)

- Spot Speed Study Lab ReportDocument8 pagesSpot Speed Study Lab ReportMuhammad ArbainNo ratings yet

- Compaction ReportDocument6 pagesCompaction ReportharinderNo ratings yet

- Project Hydraulics and HydrologyDocument17 pagesProject Hydraulics and HydrologyEiyra NadiaNo ratings yet

- Integrated Design ProjectDocument34 pagesIntegrated Design ProjectFarhanah Binti Faisal100% (2)

- Labsheet 4 Tacheometry PDFDocument3 pagesLabsheet 4 Tacheometry PDFLogarithemNo ratings yet

- CVG3109 Lab Vane Shear Test 2014Document9 pagesCVG3109 Lab Vane Shear Test 2014Terry Jenkins100% (2)

- SUG596 - Field Scheme II (Engineering Survey)Document60 pagesSUG596 - Field Scheme II (Engineering Survey)mruzainimf90% (10)

- Chapter 4.0 Geometric Design of Highway and Streets - Sept2016Document256 pagesChapter 4.0 Geometric Design of Highway and Streets - Sept2016dzikryds50% (2)

- Ce 404-Sec11Document20 pagesCe 404-Sec11Yasser AlghrafyNo ratings yet

- Planning - Cut & Fill, Site GradingDocument6 pagesPlanning - Cut & Fill, Site GradingMelodyFranciscoNo ratings yet

- Physics PDFDocument42 pagesPhysics PDFashNo ratings yet

- Appendix A-ShapeDocument10 pagesAppendix A-ShapeAhmadMoaazNo ratings yet

- GPT CalculationDocument2 pagesGPT CalculationWan MahiramNo ratings yet

- GPT OgiDocument2 pagesGPT OgiWan MahiramNo ratings yet

- Austroads: Guide To Road Design Part 3 Geometric DesignDocument374 pagesAustroads: Guide To Road Design Part 3 Geometric Design268586660% (5)

- BS ListDocument7 pagesBS ListWan Mahiram100% (1)

- ResintechHDPEsewerpipe-superiormaterialforsewerconstructionDocument14 pagesResintechHDPEsewerpipe-superiormaterialforsewerconstructionJonNo ratings yet

- New Sewerage Works Approval Procedures For Low RiskDocument19 pagesNew Sewerage Works Approval Procedures For Low RiskWan Mahiram100% (1)

- Spiral Hdpe Flat GatesDocument2 pagesSpiral Hdpe Flat GatesWan MahiramNo ratings yet

- Excel:earthwork Manual SpreadsheetDocument14 pagesExcel:earthwork Manual SpreadsheetWan MahiramNo ratings yet

- The Installation Process of HDPE Sewer Pipes and Actual Site ConditionsDocument12 pagesThe Installation Process of HDPE Sewer Pipes and Actual Site ConditionsSK NGNo ratings yet

- AGRD06-10 Guide To Road Design Part 6 Roadside Design Safety and BarriersDocument266 pagesAGRD06-10 Guide To Road Design Part 6 Roadside Design Safety and BarriersRamadan DurakuNo ratings yet

- Measurement and Earthwork CalculationDocument5 pagesMeasurement and Earthwork CalculationGawesha DissanayakeNo ratings yet

- EarthworkDocument26 pagesEarthworkWan MahiramNo ratings yet

- Authorities Approval Status (25!09!16)Document12 pagesAuthorities Approval Status (25!09!16)Wan MahiramNo ratings yet

- Notification For Connection To Public SewerDocument3 pagesNotification For Connection To Public SewerMohamad AmirulbaharudinNo ratings yet

- Lysaght Bondek User GuideDocument12 pagesLysaght Bondek User GuideSiu SiuNo ratings yet

- Sports PA BrochureF AD B11 V13Document16 pagesSports PA BrochureF AD B11 V13Wan MahiramNo ratings yet

- Osd 1Document4 pagesOsd 1Wan Mahiram100% (1)

- Sports Personal Accident InsuranceDocument6 pagesSports Personal Accident InsuranceWan MahiramNo ratings yet

- Sewer Hydraulic CalculationDocument3 pagesSewer Hydraulic CalculationWan Mahiram100% (3)

- Infraworks Colouring For SubmissionDocument7 pagesInfraworks Colouring For SubmissionWan MahiramNo ratings yet

- REPORT Earthworks PDFDocument7 pagesREPORT Earthworks PDFWan MahiramNo ratings yet

- AUTHORITY SUBMISSION GUIDEDocument3 pagesAUTHORITY SUBMISSION GUIDEWan Mahiram100% (4)

- Civil 3d Best PracticesDocument210 pagesCivil 3d Best Practicescosty2882100% (1)

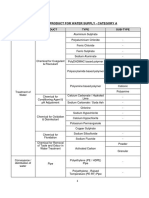

- Product Grouping Under Category A For Water Supply ProductDocument6 pagesProduct Grouping Under Category A For Water Supply ProductWan MahiramNo ratings yet

- L-Shape Wall Mar13Document2 pagesL-Shape Wall Mar13Wan MahiramNo ratings yet

- DR Quek Time Area KL - MSMA2Document5 pagesDR Quek Time Area KL - MSMA2Wan MahiramNo ratings yet

- Drainage Inspection Checklist ProjectDocument1 pageDrainage Inspection Checklist ProjectWan Mahiram100% (3)

- Cas Sambungan TNBDocument11 pagesCas Sambungan TNBsofyanshahNo ratings yet

- Need Statement Guide JKRDocument89 pagesNeed Statement Guide JKRKhairuddin Ismail67% (12)

- U Shape Drain Mar13Document4 pagesU Shape Drain Mar13Wan MahiramNo ratings yet