Professional Documents

Culture Documents

Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)

Uploaded by

bismarckandresOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)

Uploaded by

bismarckandresCopyright:

Available Formats

(03/08)

Sketches, Production Drawings, Weld Symbols, or Written Description

should show the general arrangement of the parts to be welded. Where

applicable, the details of weld groove may be specified.

[At the option of the manufacturer, sketches may be attached to illustrate

joint design, weld layers, and bead sequence (e.g., for notch toughness

procedures, for multiple process procedures, etc.)]

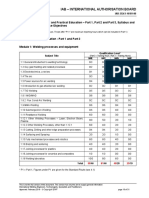

QW-482 SUGGESTED FORMAT FOR WELDING PROCEDURE SPECIFICATIONS (WPS)

(See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)

Company Name

Welding Procedure Specification No.

By

Date Supporting PQR No.(s)

Welding Process(es) Type(s)

Revision No. Date

JOINTS (QW-402) Details

Joint Design

*BASE METALS (QW-403)

P-No.

Specification and type/grade or UNS Number

OR

OR

Group No. to P-No. Group No.

to Specification and type/grade or UNS Number

Chem. Analysis and Mech. Prop.

to Chem. Analysis and Mech. Prop.

Thickness Range:

Base Metal: Groove Fillet

Other

*FILLER METALS (QW-404) 1 2

*Each base metal-filler metal combination should be recorded individually.

Spec. No. (SFA)

AWS No. (Class)

F-No.

A-No.

Size of Filler Metals

Weld Metal

Thickness Range:

Groove

Fillet

Electrode-Flux (Class)

Flux Trade Name

Consumable Insert

Other

Backing: Yes No

(Refer to both backing and retainers)

(Automatic, Manual, Machine, or Semi-Automatic)

Backing Material (Type)

Metal

Nonmetallic

Nonfusing Metal

Other

Root Spacing

Maximum Pass Thickness

1

/

2

inch (13 mm)

(Yes) (No)

Filler Metal Product Form

Supplemental Filler Metal

Flux Type

INMOBILIARIA DEL SURESTE SA DE CV SOCIEDAD INTERNACIONAL DE INGENIEROS

WPS-INDUSA-023 05/03/2012 PQR-INDUSA-003-2012

001 05/03/2012

SMAW (Shielded Metal Arc Welding) Manual

V-SENCILLA

Sin Respaldo 1/8" 1/16", Con Respaldo 3/16" 1/16"

Opcional ---

Acero al Carbono, M1, P1, o S1- Grupo 1,2 3

1 1 2 1 1 2

ASME SA 53 Gr. B

ASME SA 53 Gr. B

---

---

1/8" hasta 1 1/2" ---

---

5.1

A5.1

3

1

1/8" Y 3/32"

varilla revestida

---

---

---

---

---

---

---

---

PRINT SAVE

QW-482 (Back)

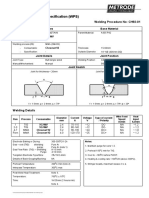

POSITIONS (QW-405)

WPS No. Rev.

Position(s) of Groove

Position(s) of Fillet

PREHEAT (QW-406)

Preheat Temperature, Minimum

ELECTRICAL CHARACTERISTICS (QW-409)

TECHNIQUE (QW-410)

String or Weave Bead

Orifice, Nozzle, or Gas Cup Size

Initial and Interpass Cleaning (Brushing, Grinding, etc.)

Method of Back Gouging

Oscillation

Contact Tube to Work Distance

Multiple or Single Pass (Per Side)

Multiple or Single Electrodes

Electrode Spacing

Peening

Other

Tungsten Electrode Size and Type

Interpass Temperature, Maximim

Preheat Maintenance

(Continuous or special heating, where applicable, should be recorded)

Welding Progression: Up

POSTWELD HEAT TREATMENT (QW-407)

GAS (QW-408)

Percent Composition

Gas(es)

(Pure Tungsten, 2% Thoriated, etc.)

Mode of Metal Transfer for GMAW (FCAW)

Other

(Spray Arc, Short Circuiting Arc, etc.)

(Mixture) Flow Rate

Temperature Range

Time Range

Shielding

Trailing

Backing

Down

(07/10)

Amps and volts, or power or energy range, should be recorded for each electrode size, position, and thickness, etc.

Other

Other

Other

Other

Pulsing Current Heat Input (max.)

Weld

Pass(es)

Current

Type and

Polarity

Energy or

Power

(Range)

Wire Feed

Speed

(Range)

Amps

(Range)

Volts

(Range)

Travel

Speed

(Range)

Other

(e.g., Remarks, Com-

ments, Hot Wire

Addition, Technique,

Torch Angle, etc.) Process

Classifi-

cation

Filler Metal

Diameter

INDUSA-023 001

TODAS

Ascendente ---

---

---

Opcional 1100 a 1200 F

Opcional, 1 hora por pulgada (minimo 15 minutos)

---

50F, 175F t > 1.000"

50F, 175F t > 1.000", 500F

no se requiere especial o continuo

---

--- --- ---

--- --- ---

--- --- ---

--- --- ---

---

---

---

Raiz (1)

Raiz (1)

Relleno

Relleno

Relleno

Relleno(2)

SMAW

SMAW

SMAW

SMAW

SMAW

SMAW

E6010

E6010

E7018

E7018

E7018

E7018

3/32"

1/8"

3/32"

1/8"

5/32"

3/16"

DCEP

DCEP

DCEP

DCEP

DCEP

DCEP

40-80

75-125

70-100

115-165

150-220

200-275

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

(1) Una capa adicional es

permitida

(2) Solo en posicin plana

y horizontal

--- ---

---

---

---

Cualquiera

---

Limpieza incial Quimica o Mecanica, la union debe estar libre de humedad antes de soldar

Entre pasos solamente limpieza mecnica

Mecnico temirco cuando sea requerido

---

---

---

---

---

No esta Permitido

---

PRINT SAVE

You might also like

- The Complete Guide to Telephone Interview Questions and AnswersFrom EverandThe Complete Guide to Telephone Interview Questions and AnswersNo ratings yet

- Electrode Equivalaent NumbersDocument2 pagesElectrode Equivalaent NumbersRamdas100% (2)

- 30 12 14 Expediting Report GoodrichGasketsDocument2 pages30 12 14 Expediting Report GoodrichGasketsjasmineamma100% (1)

- Review of GTAW Welding ParametersDocument14 pagesReview of GTAW Welding Parameterskervyn SáenzNo ratings yet

- T, K & Y Shape Joint Steel StructureDocument23 pagesT, K & Y Shape Joint Steel StructurePrabu VenkatNo ratings yet

- BV Inspection Report - NitolDocument3 pagesBV Inspection Report - NitolMr. JahirNo ratings yet

- Welding in Pipelines - PV - StructureDocument6 pagesWelding in Pipelines - PV - StructureanshumanNo ratings yet

- Shielding GasesDocument27 pagesShielding GasesvarunNo ratings yet

- WPQ Sunil Yadav W-13 PQR 003 Smaw - PipeDocument1 pageWPQ Sunil Yadav W-13 PQR 003 Smaw - Pipeharshileng3992100% (1)

- ButtWelding Is 11790 1986Document11 pagesButtWelding Is 11790 1986kathir1965No ratings yet

- Add02 1060.1Document14 pagesAdd02 1060.1Diego Calderón AlvaradoNo ratings yet

- Dye Penetrant Inspection - Wikipedia, The Free EncyclopediaDocument5 pagesDye Penetrant Inspection - Wikipedia, The Free Encyclopediaviswamanoj100% (1)

- Module3 - Welding ProcessesDocument155 pagesModule3 - Welding ProcessesPurvesh NanavatiNo ratings yet

- WI & CERT Kelas EDocument22 pagesWI & CERT Kelas EKevin ArmandoNo ratings yet

- Astm A 986 - 2016 PDFDocument3 pagesAstm A 986 - 2016 PDFEmmanuel BoquetNo ratings yet

- IWE SyllabusDocument4 pagesIWE Syllabusmdasifkhan2013No ratings yet

- Visual Testing of Welds.Document9 pagesVisual Testing of Welds.maheshNo ratings yet

- ASMEDocument38 pagesASMEshazanNo ratings yet

- Technofibre International SDN BHD: Welder Qualification Test Reord (WQT)Document1 pageTechnofibre International SDN BHD: Welder Qualification Test Reord (WQT)dandiar1100% (1)

- PRES TIG Hot Wire Narrow Gap Welding enDocument25 pagesPRES TIG Hot Wire Narrow Gap Welding enRavishankarNo ratings yet

- JTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackDocument19 pagesJTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackWarren LeeNo ratings yet

- Long Seam and Circumference Seam SetupDocument4 pagesLong Seam and Circumference Seam SetupAlesol EquipmentNo ratings yet

- Welding Defects: Ganesan V Assistant Manager-TSD D&H Secheron Electrodes PVT - LTDDocument49 pagesWelding Defects: Ganesan V Assistant Manager-TSD D&H Secheron Electrodes PVT - LTDPrakash RajNo ratings yet

- WI-INSP-07 R2 Work Instruction-Inspection of PumpsDocument5 pagesWI-INSP-07 R2 Work Instruction-Inspection of PumpsRakesh MishraNo ratings yet

- Welder NIMI Q 2Document30 pagesWelder NIMI Q 2Mahesh SonarNo ratings yet

- Handbook - Filler Metal ASTM SteelsDocument1 pageHandbook - Filler Metal ASTM SteelsadelNo ratings yet

- 0301e - Guidebook For Inspectors - 2018-3Document6 pages0301e - Guidebook For Inspectors - 2018-3FranciscoNo ratings yet

- Digital Marketing StratergyDocument10 pagesDigital Marketing StratergyhasinyNo ratings yet

- QW 442 A Number PDFDocument1 pageQW 442 A Number PDFMadidj_2014No ratings yet

- OneCIS - ASME CA Connect BrochureDocument20 pagesOneCIS - ASME CA Connect BrochureBayu Jatmiko0% (1)

- 2.2 - NDEP-C1574-5-6-7-8 - Rev.0 NDE Procedures Book PDFDocument59 pages2.2 - NDEP-C1574-5-6-7-8 - Rev.0 NDE Procedures Book PDFGeorge JhonsonNo ratings yet

- Book - Vol.1&2 - BasicsAndQuality - 22junDocument82 pagesBook - Vol.1&2 - BasicsAndQuality - 22junlth770310No ratings yet

- Asme Sect. Ix Part QW Art. I 2005 PDFDocument12 pagesAsme Sect. Ix Part QW Art. I 2005 PDFarlyNo ratings yet

- Weldability of MaterialsDocument5 pagesWeldability of MaterialsclnNo ratings yet

- Heat Treatment of SteelDocument3 pagesHeat Treatment of SteelKristine ReyesNo ratings yet

- WPS, PQR, WPQDocument2 pagesWPS, PQR, WPQESL100% (1)

- St. Joseph'S College of Engineering: Chennai 119Document43 pagesSt. Joseph'S College of Engineering: Chennai 119Praba KaranNo ratings yet

- WPS AWS TemplateDocument3 pagesWPS AWS TemplateMohd SaffririzalNo ratings yet

- Final Welding of Ti Alloys and MG AlloysDocument32 pagesFinal Welding of Ti Alloys and MG AlloysArjyajyoti GoswamiNo ratings yet

- World Lecture Hall: Useful Links For EngineersDocument9 pagesWorld Lecture Hall: Useful Links For Engineerssandi1111No ratings yet

- Welding Procedure Specification (WPS)Document3 pagesWelding Procedure Specification (WPS)Jignasa ShahNo ratings yet

- Gas Metal Arc WeldingDocument52 pagesGas Metal Arc WeldingBalakumarNo ratings yet

- Auditing Oof Welding Under ASME Section IXDocument21 pagesAuditing Oof Welding Under ASME Section IXsabahiraqNo ratings yet

- QW-452.3 Groove-Weld Diameter Limits: 2011A Section IxDocument1 pageQW-452.3 Groove-Weld Diameter Limits: 2011A Section IxdhasdjNo ratings yet

- Introduction To Welding - MetallurgyDocument15 pagesIntroduction To Welding - Metallurgyramkishore_87100% (1)

- Welding Questionaire: Duties and Responsibilities of Welding InspectorDocument9 pagesWelding Questionaire: Duties and Responsibilities of Welding InspectormohamedqcNo ratings yet

- 08 PawDocument30 pages08 PawAnupam KushwahaNo ratings yet

- Spatter Reduction ChecklistDocument6 pagesSpatter Reduction ChecklistJorge perezNo ratings yet

- WPS - 021Document13 pagesWPS - 021MAT-LIONNo ratings yet

- Asme 9 DatosDocument47 pagesAsme 9 Datosvichu_villamarNo ratings yet

- List of Welders and Welding Operators: Project No - Equipment Name: Tag No.Document1 pageList of Welders and Welding Operators: Project No - Equipment Name: Tag No.Hanuman RaoNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKAnonymous Ij6VfaNo ratings yet

- Cladding PDFDocument6 pagesCladding PDFlibid_rajNo ratings yet

- AutomationDocument5 pagesAutomationashfaq_ahmed_7No ratings yet

- Sample Editable WPSDocument2 pagesSample Editable WPSsbmmlaNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)mohammadNo ratings yet

- ASME WPS-PQR-WQT CombinedDocument6 pagesASME WPS-PQR-WQT CombinedStan HonNo ratings yet

- 3 BodyPart Edcb3a5f Eede 445f A423 Ea2f5809c15eDocument6 pages3 BodyPart Edcb3a5f Eede 445f A423 Ea2f5809c15emayank0738No ratings yet

- Draft 1 Smash AqmDocument35 pagesDraft 1 Smash AqmMeghan GhoneNo ratings yet

- En 42Document2 pagesEn 42Meghan GhoneNo ratings yet

- Boiler Syllabus PDFDocument9 pagesBoiler Syllabus PDFMeghan GhoneNo ratings yet

- Welding Basics 2Document0 pagesWelding Basics 2alwaysanybodyNo ratings yet

- KontolDocument144 pagesKontolAnonymous ssieDC50% (2)

- Transmi Finals Set BDocument10 pagesTransmi Finals Set BKerwin TejucoNo ratings yet

- Strategy - Apple Inc - Project PPT (Recovered)Document16 pagesStrategy - Apple Inc - Project PPT (Recovered)Jayesh GoswamiNo ratings yet

- Power Distribution and Utilization - Updated2020 - Spring 2021Document4 pagesPower Distribution and Utilization - Updated2020 - Spring 2021Ahad MunawarNo ratings yet

- BM207 Design of Electronic CirsuitsDocument2 pagesBM207 Design of Electronic CirsuitsnidalNo ratings yet

- HF100 Ver.1.6.pdf Service Manual WebridgedDocument28 pagesHF100 Ver.1.6.pdf Service Manual WebridgedErnesto AcostaNo ratings yet

- Current Electricity-1 JEE Main and AdvancedDocument8 pagesCurrent Electricity-1 JEE Main and Advancedbibhas_samantaNo ratings yet

- Onkyo Stereo Receiver Remote Control CodesDocument16 pagesOnkyo Stereo Receiver Remote Control CodesRonnie EvansNo ratings yet

- Practical Guide To InstrumentationDocument12 pagesPractical Guide To InstrumentationradiobrunoNo ratings yet

- Installers Manual Sliding Door AutomationDocument55 pagesInstallers Manual Sliding Door AutomationSidney Moraes AlvesNo ratings yet

- HCPL-7800A: Isolation AmplifierDocument9 pagesHCPL-7800A: Isolation AmplifierkarkonNo ratings yet

- gp2000 ProfaceDocument7 pagesgp2000 ProfacedombanNo ratings yet

- An Autonomous Flight Safety SystemDocument12 pagesAn Autonomous Flight Safety SystemWoofyNo ratings yet

- CMR Techincal Campus Department of Ece Iv B.Tech Ece-Radar Systems (A, B, C) A.Y-2018-2019: QUESTION BANK Unit Iii Part-A Answer The FollowingDocument3 pagesCMR Techincal Campus Department of Ece Iv B.Tech Ece-Radar Systems (A, B, C) A.Y-2018-2019: QUESTION BANK Unit Iii Part-A Answer The FollowingSindhureddyNo ratings yet

- Lesson 3 - FiltersDocument29 pagesLesson 3 - FiltersRennel MallariNo ratings yet

- Mitsubishi E500 ManualDocument202 pagesMitsubishi E500 ManualChaitanya TrivediNo ratings yet

- Chapter13 Transceiver Design ExampleDocument72 pagesChapter13 Transceiver Design ExampleNikunj ShahNo ratings yet

- EN VEGACAL 62 4... 20 Ma HART Two WireDocument60 pagesEN VEGACAL 62 4... 20 Ma HART Two WireVõ HòaNo ratings yet

- Leonova Diamond TD Sheet 2Document10 pagesLeonova Diamond TD Sheet 2Ahmed Mohamed HassanNo ratings yet

- MM3000 User ManualDocument11 pagesMM3000 User ManualTiffany DacinoNo ratings yet

- Areva Ieee MnitDocument37 pagesAreva Ieee Mnitsmilehood99No ratings yet

- Electrical Thumb RuleDocument24 pagesElectrical Thumb RulemkdholkiyaNo ratings yet

- Lab 7 Power Electronics by Muhammad Husnain AliDocument6 pagesLab 7 Power Electronics by Muhammad Husnain AliMuhammad HusnainNo ratings yet

- Support ProfessionalDocument2 pagesSupport ProfessionalscriNo ratings yet

- IEEE STD 259-1999 PDFDocument18 pagesIEEE STD 259-1999 PDFEdwin CapdepomtNo ratings yet

- 80 US - Compact - 010295 - 01 - 10 (1) - KritechDocument2 pages80 US - Compact - 010295 - 01 - 10 (1) - KritechBudikaPaisokCipuikPWElfaAriyanNo ratings yet

- Smart Voltage Stabilizer Using PIC16F877ADocument8 pagesSmart Voltage Stabilizer Using PIC16F877AAswathy CjNo ratings yet

- P30series (메뉴얼)Document72 pagesP30series (메뉴얼)Luân ThànhNo ratings yet

- Modulation and Multiplexing Schemes in Satellite CommunicationsDocument7 pagesModulation and Multiplexing Schemes in Satellite CommunicationsSUNILNo ratings yet

- Group 8 Final Manuscript 1Document41 pagesGroup 8 Final Manuscript 1Reymond Clark AdasaNo ratings yet