Professional Documents

Culture Documents

Hand Calculation Method For Orifice Design

Uploaded by

Rapee PuaksungnoenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hand Calculation Method For Orifice Design

Uploaded by

Rapee PuaksungnoenCopyright:

Available Formats

Appendix B.

Hand Calculation Method for Orifice Design

Abstract

This appendix explains how to perform the calculations for orifice plate design by hand. For manual look-up of the orifice coefficient, S (given beta) or the diameter ratio, beta (given S), the following eight figures are provided: Figure B-1 Figure B-2 Figure B-3 Figure B-4 Figure B-5 Figure B-6 Flange Taps - 6 Inch Pipe Size (6.056 in.); S vs. Beta for Different RD Values (Based on Data from ISO 5167) Flange Taps; Pipe Size Corrections for S Values (Based on Data from ISO 5167) Radius Taps; S vs. Beta for Different R D Values (Based on Data from ISO 5167) Corner Taps; S vs. Beta for Different R D Values (Based on Data from ISO 5167) Pipe Taps; S vs. Beta for Different RD Values (Based on Data from ISO 5167) ASME Small Bore with Flange Taps; S vs. Beta for Different RD Values1 in. to 1-1/2 in. Pipe Size (Based on Data from "Fluid Meters: Their Theory and Application", 6th ed., 1971. Courtesy of ASME) ASME Small Bore with Corner Taps (.546 in.); S vs. Beta for Different RD Values1/2 in. Schedule 80 Pipe Size (Based on Data from "Fluid Meters: Their Theory and Application", 6th ed., 1971. Courtesy of ASME) Quadrant Edge Data; S and Thickness Ratio vs. Beta

Figure B-7

Figure B-8

Orifice calculation sheets have been prepared for guidance through the orifice calculation steps. Calculation sheets filled in with appropriate examples are attached. The four orifice calculation sheets are as follows: LIQUID, square-edge orifice, Form ICM-EF-59B (Figure B-9) LIQUID, quadrant-edge orifice, Form ICM-EF-59C (Figure B-10) GAS, square-edge orifice, Form ICM-EF-59D (Figure B-11) VAPOR/STEAM, square-edge orifice, Form ICM-EF-59E (Figure B-12)

Note that in these calculation sheets, the term "sharp edge" is used instead of "square-edge." Results of the hand calculations agree closely with the computer program ORIFICE. The two types of calculations that can be performed are orifice sizing and orifice reranging, except for quadrant-edge.

Chevron Corporation

B-1

July 1999

Appendix B

Instrumentation and Control Manual

B1.0

Calculation Procedure

1. Fill in the STREAM PROPERTY input blocks. TEMPERAURE PRESSURE ---degrees Fahrenheit for liquid and vapor/steam degrees Rankine = F + 460 for gas PSIA for gas and vapor -Gb at 60 F (Gb for water = 1.00) cu.ft./lb. for steam, use steam tables Ideal sp. gr. is used = M.W. gas/M.W. dry air = Zb Real sp. gr. LIQUID KINEMATIC VISCOSITY GAS AND VAPOR ABSOLUTE VISCOSITY 2. Fill in the FLOW RATE input blocks. UNITS: FULL SCALE: NORMAL: For liquid use BPD, BPH, GPM, or GPH. For vapor use lbs/hour; for gas use SCFH. Flow that creates a dp across the orifice taps equal to the maximum value of the dp transmitter range. For square-edge and ASME small-bore this should be the mid-range dp value, which equals .707 (full-scale flow rate) For quadrant-edge, equal to .333 (full-scale flow rate) --use centistokes use centipoise

LIQUID SPECIFIC GRAVITY

VAPOR/STEAM SPECIFIC GRAVITY --GAS SPECIFIC GRAVITY --

1/3 FS: 3.

Fill in the ORIFICE DATA input blocks. TYPE OF ORIFICE PLATE ---TYPE OF TAPS ---PIPE INSIDE DIAMETER ORIFICE DIAMETER --Square-edge ASME small-bore Quadrant-edge Flange, radius, corner or pipe for square-edge Flange or corner only for ASME small-bore Flange for quadrant-edge Use 3 decimal places Entered for orifice re-ranging calculation

July 1999

B-2

Chevron Corporation

Instrumentation and Control Manual

Appendix B

-FULL SCALE DP --4. Fill in the CORRECTIONS FACTORS. Fa --

Use 3 decimal places Entered for orifice sizing calculation Standard value = 100 inches of water

Correction for thermal expansion of orifice meter at flowing temperature found in ASME MFC-3M Tables or API MPMS. Chapter 14.3/AGA-3. Gas expansion factor for mid-scale flow Y1 = correction based on upstream pressure Y2 = correction based on downstream pressure Look up in table or chart - use mid-range differential pressure (dp) Supercompressibility correction factor Rarely used in refinery calculations (usually set = 1.0) Look up in table or chart when used. Compressibility factor at 60F, 1 Atm Rarely used in refinery calculations (usually set = 1.0) Look up in table or chart when used.

--

Fpv

--

Zb

--

5.

Calculate Pipe Reynolds Number. Space is provided for values in equations. See examples on sheets provided.

6.

Calculate orifice size or dp range for square-edge or ASME small-bore orifice. Given h, Find d Fill in equations and solve for S. Look up beta ratio in table. Interpolation is necessary. Use Table in Figure B-2 to correct for pipe size other than 6-inches (2-12 inches). Use Reynolds number column that is closest to value calculated in step 5. Given d, Find h Calculate beta ratio. Look up S in table. Interpolation is necessary. Use Reynolds number that is closest to value calculated in Step 5. See examples on sheets provided.

7.

Calculation for quadrant-edge orifice size.

Chevron Corporation

B-3

July 1999

Appendix B

Instrumentation and Control Manual

Select a plate thickness, look up values from Figure B-8, and calculate the differential pressure h. If h is too large, make plate thicker; if too small, make plate thinner, and repeat calculation. h should equal about 100 inches of water. The permissible range of Reynolds numbers (at 1/3 full-scale flow) for a quadrant-edge orifice is a function of the beta ratio: beta ratio min. RD max. RD 0.2 670.0 17500.0 0.3 770.0 28000.0 0.4 630.0 45000.0 0.5 450.0 70000.0 0.6 320.0 85000.0

See example on calculation sheet provided.

July 1999

B-4

Chevron Corporation

Instrumentation and Control Manual

Appendix B

Fig. B-1

Flange Taps - 6 Inch Pipe Size (6.056 in.); S vs. Beta for Different RD Values (Based on Data from ISO 5167)

Chevron Corporation

B-5

July 1999

Appendix B

Instrumentation and Control Manual

Fig. B-2

Flange Taps; Pipe Size Corrections for S Values (Based on Data from ISO 5167)

July 1999

B-6

Chevron Corporation

Instrumentation and Control Manual

Appendix B

Fig. B-3

Radius Taps; S vs. Beta for Different RD Values (Based on Data from ISO 5167)

Chevron Corporation

B-7

July 1999

Appendix B

Instrumentation and Control Manual

Fig. B-4

Corner Taps; S vs. Beta for Different RD Values (Based on Data from ISO 5167)

July 1999

B-8

Chevron Corporation

Instrumentation and Control Manual

Appendix B

Fig. B-5

Pipe Taps; S vs. Beta for Different RD Values (Based on Data from ISO 5167)

Chevron Corporation

B-9

July 1999

Appendix B

Instrumentation and Control Manual

Fig. B-6

ASME Small Bore with Flange Taps; S vs. Beta for Different RD Values1 in. to 1-1/2 in. Pipe Size (Based on Data from "Fluid Meters: Their Theory and Application", 6th ed., 1971. Courtesy of ASME)

July 1999

B-10

Chevron Corporation

Instrumentation and Control Manual

Appendix B

Fig. B-7

ASME Small Bore with Corner Taps (.546 in.); S vs. Beta for Different RD Values1/2 in. Schedule 80 Pipe Size (Based on Data from "Fluid Meters: Their Theory and Application", 6th ed., 1971. Courtesy of ASME)

Chevron Corporation

B-11

July 1999

Appendix B

Instrumentation and Control Manual

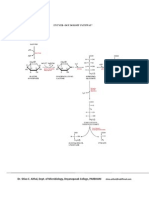

Fig. B-8

Quadrant Edge Data; S and Thickness Ratio vs. Beta

July 1999

B-12

Chevron Corporation

Instrumentation and Control Manual

Appendix B

Fig. B-9

Orifice Calculation SheetLiquid, Square-edge Orifice

Chevron Corporation

B-13

July 1999

Appendix B

Instrumentation and Control Manual

Fig. B-10 Orifice Calculation SheetLiquid, Quadrant-edge Orifice

July 1999

B-14

Chevron Corporation

Instrumentation and Control Manual

Appendix B

Fig. B-11 Orifice Calculation SheetGas, Square-Edge Orifice

Chevron Corporation

B-15

July 1999

Appendix B

Instrumentation and Control Manual

Fig. B-12 Orifice Calculation SheetVapor/Steam, Square-Edge Orifice

July 1999

B-16

Chevron Corporation

You might also like

- Orifice Sizing CalculationDocument24 pagesOrifice Sizing Calculationjamestpp67% (3)

- Control Valve Sizing Guide for Optimal Plant PerformanceDocument7 pagesControl Valve Sizing Guide for Optimal Plant PerformanceJojolasNo ratings yet

- Calculation of Orifice Plate Hole DiameterDocument3 pagesCalculation of Orifice Plate Hole DiameterhiuNo ratings yet

- Ansi Isa-S91.01-1995Document12 pagesAnsi Isa-S91.01-1995jf2587No ratings yet

- Valve Sizing CalculationDocument10 pagesValve Sizing CalculationJayesh Chandran100% (1)

- A Guide To Sizing Orifice Plate Flow MetersDocument4 pagesA Guide To Sizing Orifice Plate Flow Meterscldanghel4648No ratings yet

- Restriction Orifice (RO) - Flow Control InstrumentDocument8 pagesRestriction Orifice (RO) - Flow Control InstrumentAnonymous 2g4jKo5a7vNo ratings yet

- Industrial Flow MeasurementDocument244 pagesIndustrial Flow MeasurementRoxana Gligor100% (3)

- Use ISO 5167 To Find The Orifice Discharge Coefficient For An Orifice Flow MeterDocument10 pagesUse ISO 5167 To Find The Orifice Discharge Coefficient For An Orifice Flow MeterEuler CauchiNo ratings yet

- Orifice Plate CalculationDocument10 pagesOrifice Plate CalculationkswaghmareNo ratings yet

- Valve Magazine Fall-2006 PSVs SizingDocument5 pagesValve Magazine Fall-2006 PSVs Sizingpiolinwalls100% (1)

- Flow Meter Sizing MOSDocument11 pagesFlow Meter Sizing MOSra9622No ratings yet

- Restriction Orifice Sizing For A Minimum Recirculation LineDocument5 pagesRestriction Orifice Sizing For A Minimum Recirculation LineChemical.AliNo ratings yet

- Orifice Plate Flow MetersDocument4 pagesOrifice Plate Flow Metersvilaschinke123100% (2)

- Welding Defects and PreventionDocument2 pagesWelding Defects and PreventionVicky SinghNo ratings yet

- Standard BS 1042 - Part 1 - 1964Document116 pagesStandard BS 1042 - Part 1 - 1964MPChethan100% (2)

- Compressor Instrument and Control - 2Document63 pagesCompressor Instrument and Control - 2Alaa ShahwanNo ratings yet

- Yemen LNG Upstream Facilities Project: Phase 1 Process Design Basis ManualDocument23 pagesYemen LNG Upstream Facilities Project: Phase 1 Process Design Basis Manualabdoamer.2553No ratings yet

- InstruCalc8 QuickStart GuideDocument26 pagesInstruCalc8 QuickStart GuideBari Ipung Guntur100% (1)

- Compressor ControlDocument47 pagesCompressor ControlFabbrox100% (2)

- ISA 75.21 Process Data Presentation For Control Valves PDFDocument18 pagesISA 75.21 Process Data Presentation For Control Valves PDFjose luis100% (1)

- Process Control Valve EngineeringDocument294 pagesProcess Control Valve EngineeringRAMSAHARE MALLAH100% (2)

- Control Valve Selection GuideDocument8 pagesControl Valve Selection Guidewalidderbel1981No ratings yet

- Design and CFD Analysis of Orifice Plate at Different Velocity RatiosDocument69 pagesDesign and CFD Analysis of Orifice Plate at Different Velocity RatiosMohammad Ehraz AliNo ratings yet

- Essential Process Control For Chemical Engineers PDFDocument208 pagesEssential Process Control For Chemical Engineers PDFcgoveia9No ratings yet

- PID SymbolDocument18 pagesPID SymbolAli AbdNo ratings yet

- Engineering Standard for Control ValvesDocument11 pagesEngineering Standard for Control Valvesrahul.ril1660No ratings yet

- Valve Sizing Worksheet InstructionsDocument14 pagesValve Sizing Worksheet Instructionsmilton1987No ratings yet

- Thermowell and Immersion Probe Installation GuideDocument7 pagesThermowell and Immersion Probe Installation GuideBEN ADEGBULUNo ratings yet

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsFrom EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsRating: 5 out of 5 stars5/5 (1)

- As 2360.1.1-1993 Measurement of Fluid Flow in Closed Conduits Pressure Differential Methods - Measurement UsiDocument10 pagesAs 2360.1.1-1993 Measurement of Fluid Flow in Closed Conduits Pressure Differential Methods - Measurement UsiSAI Global - APACNo ratings yet

- FLUOR - New Delhi: Flow Instruments (Part-1)Document20 pagesFLUOR - New Delhi: Flow Instruments (Part-1)Tirado Melchor Angel Miguel100% (2)

- Instrument Air SizingDocument2 pagesInstrument Air Sizingmilton1987100% (1)

- Instrument Level Sketches PDFDocument8 pagesInstrument Level Sketches PDFJoyNo ratings yet

- Milk Cheese and Butter 1894Document458 pagesMilk Cheese and Butter 1894osvaldoreneNo ratings yet

- Open Vessel Level Calculation GuideDocument11 pagesOpen Vessel Level Calculation GuideAnurag GuptaNo ratings yet

- Orifice Plate Sizing PDFDocument18 pagesOrifice Plate Sizing PDFalexmuchmure2158No ratings yet

- Steel Industry PackageDocument9 pagesSteel Industry Packagebatung144100% (1)

- Pipeline Vs Piping - All About PipelinesDocument6 pagesPipeline Vs Piping - All About Pipelinesjulian2282254No ratings yet

- Orifice PlateDocument18 pagesOrifice PlateAshvani Shukla100% (2)

- PIP PCEFL001 Flow Measurement GuidelinesDocument28 pagesPIP PCEFL001 Flow Measurement GuidelinesMax AdamsonNo ratings yet

- Flow Coefficient (CV) and Calculation of Flow Through ValvesDocument7 pagesFlow Coefficient (CV) and Calculation of Flow Through ValvesMikeCroNo ratings yet

- Flow Measurement Criteria - PIPDocument16 pagesFlow Measurement Criteria - PIPKarthik ChockkalingamNo ratings yet

- JERES-J-901 Instrument Air Supply SystemsDocument13 pagesJERES-J-901 Instrument Air Supply SystemsMahi IndraNo ratings yet

- Magnetic Flow Meters: Law of Electromagnetic Induction. Magmeters Can Detect TheDocument6 pagesMagnetic Flow Meters: Law of Electromagnetic Induction. Magmeters Can Detect TheMichelle MenciasNo ratings yet

- Orifice Calc: GasDocument4 pagesOrifice Calc: GasJames R. Lawrence Sr.100% (6)

- Welding Pipeline HandbookDocument63 pagesWelding Pipeline Handbookchanchai T100% (9)

- Restrictive OrificeDocument11 pagesRestrictive Orificeligia hancu100% (1)

- Design and Analysis of OrificesDocument46 pagesDesign and Analysis of Orificesbkkbrazil0% (1)

- Small Bore Orifice For Gas FlowDocument4 pagesSmall Bore Orifice For Gas FlowMarc EdwardsNo ratings yet

- ISO Standard for Cone Meters Flow MeasurementDocument2 pagesISO Standard for Cone Meters Flow MeasurementAjay Chodankar60% (5)

- 377 Series Trip Valves: Product BulletinDocument3 pages377 Series Trip Valves: Product BulletinIsmail AhmadNo ratings yet

- Instrumentation GPSA HandbookDocument6 pagesInstrumentation GPSA HandbookmusaveerNo ratings yet

- Distributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979From EverandDistributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979T. J. HarrisonNo ratings yet

- WonderfulDocument2 pagesWonderfulSHAIK AHMED JAWADNo ratings yet

- Pressure Drop CalcualtionDocument11 pagesPressure Drop CalcualtionDuong ThaoNo ratings yet

- Gas lift design finalDocument57 pagesGas lift design finalZehron ChemicalsNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: DescriptionDocument31 pagesAspen Exchanger Design and Rating Shell & Tube V10: DescriptionCHELSEE VALENTINA SANCHEZ MUÑOZNo ratings yet

- Compact High-Pressure Internal Gear Pumps Dimension SheetDocument28 pagesCompact High-Pressure Internal Gear Pumps Dimension SheetcotteNo ratings yet

- ASME B16.5 Flange StandardDocument4 pagesASME B16.5 Flange StandardMohamed FayedNo ratings yet

- Gate Valve Class T Size 2 inDocument2 pagesGate Valve Class T Size 2 inIrfan IsmailNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: DescriptionDocument29 pagesAspen Exchanger Design and Rating Shell & Tube V10: DescriptionCHELSEE VALENTINA SANCHEZ MUÑOZNo ratings yet

- Ratio Controller: HD Fire Protect Pvt. Ltd. Technical DataDocument8 pagesRatio Controller: HD Fire Protect Pvt. Ltd. Technical DataDarshAwadNo ratings yet

- 03 - Hot Tap Quest 16 InchDocument2 pages03 - Hot Tap Quest 16 InchSaiKumarNo ratings yet

- Fire Pump Test Meter: Gerand EngineeringDocument5 pagesFire Pump Test Meter: Gerand EngineeringPIYARAT SUWANNAKHANo ratings yet

- Los Grandes Enigmas LarousseDocument224 pagesLos Grandes Enigmas LarousseValentina Pizarro VieiraNo ratings yet

- Folleto Valvula EknDocument2 pagesFolleto Valvula EknosvaldoreneNo ratings yet

- Ames' Guide To Self-Instruction in Practical and Artistic PenmanshipDocument63 pagesAmes' Guide To Self-Instruction in Practical and Artistic Penmanshiphoudoken100% (17)

- Link Expired - How to Resend or RenewDocument1 pageLink Expired - How to Resend or RenewKarina Paz AlvesNo ratings yet

- Real Heat Engines and RefrigeratorsDocument11 pagesReal Heat Engines and RefrigeratorsMario MikulandraNo ratings yet

- N52 Grade Neodymium Magnets DataDocument1 pageN52 Grade Neodymium Magnets DataSteve HsuNo ratings yet

- Green Inhibitors For Steel Corrosion in Acidic Environment - State of ArtDocument21 pagesGreen Inhibitors For Steel Corrosion in Acidic Environment - State of Artanisa sutifanyNo ratings yet

- Recyclingand Reuseof TextileDocument47 pagesRecyclingand Reuseof TextileRey100% (1)

- Msds - Marpozol W-505 (GHS) Eng 130409Document5 pagesMsds - Marpozol W-505 (GHS) Eng 130409Syafarul Mohammad100% (1)

- Materials Used in Automotive Manufacture and Material Selection Using Ashby ChartsDocument15 pagesMaterials Used in Automotive Manufacture and Material Selection Using Ashby ChartsHanumantNo ratings yet

- 1976-Morito - Transition From External To Internal Oxidation in Fe-Si Alloy As A Function of Oxygen Potential of The Ambient AtmosphereDocument4 pages1976-Morito - Transition From External To Internal Oxidation in Fe-Si Alloy As A Function of Oxygen Potential of The Ambient AtmosphereDavid Hernández EscobarNo ratings yet

- Chemical Injection SkidDocument6 pagesChemical Injection SkidRaheel SultanNo ratings yet

- Ganoderma laccase optimizationDocument9 pagesGanoderma laccase optimizationRajeshKumarNo ratings yet

- Entner Duodroff PathwayDocument2 pagesEntner Duodroff PathwayDr. SHIVA AITHALNo ratings yet

- Heavy Metal Contamination: An Alarming Threat To Environment and Human HealthDocument23 pagesHeavy Metal Contamination: An Alarming Threat To Environment and Human HealthMalik HopeNo ratings yet

- E 4575 Dry Ice Solid Carbon Dioxide Safety Data Sheet SdsDocument9 pagesE 4575 Dry Ice Solid Carbon Dioxide Safety Data Sheet Sdsjohnpatt888No ratings yet

- Green Angle EnviroTech Pvt. Ltd. Company ProfileDocument33 pagesGreen Angle EnviroTech Pvt. Ltd. Company Profilep364364No ratings yet

- Safety Data Sheet: Masteremaco S 5400ciDocument10 pagesSafety Data Sheet: Masteremaco S 5400ciSolomon AhimbisibweNo ratings yet

- Thermoplastic Gas Pressure Pipe, Tubing, and Fittings: Standard Specification ForDocument20 pagesThermoplastic Gas Pressure Pipe, Tubing, and Fittings: Standard Specification ForAndres Camilo BenitezNo ratings yet

- Mineral WebquestDocument3 pagesMineral Webquestapi-268569185No ratings yet

- Erba URIC ACID DESDocument2 pagesErba URIC ACID DEShexamed bme100% (1)

- Hawe Hydraulic Oil RecommendationsDocument13 pagesHawe Hydraulic Oil RecommendationsJako MishyNo ratings yet

- Heavy Oil Upgrading - A Key Solution For Heavy Oil Upstream and Midstream Operations - IVANHOE ENERGY PDFDocument44 pagesHeavy Oil Upgrading - A Key Solution For Heavy Oil Upstream and Midstream Operations - IVANHOE ENERGY PDFGustavo Gonzalez ServaNo ratings yet

- Manufacturing and Metal Working Process ClassificationDocument5 pagesManufacturing and Metal Working Process ClassificationPeeka Prabhakara RaoNo ratings yet

- Compressor Disk Corrosion Problems and Solutions - SermetelDocument13 pagesCompressor Disk Corrosion Problems and Solutions - SermetelKatNo ratings yet

- 2074 1 2015 AMD2 Reff2020Document16 pages2074 1 2015 AMD2 Reff2020ocsspectroNo ratings yet

- SodaPDF-converted-Exercise No. 7 - Soil Sample Collection and PreparationDocument30 pagesSodaPDF-converted-Exercise No. 7 - Soil Sample Collection and PreparationJacky Lou GermanoNo ratings yet

- 2 MS ElectrochemistryDocument7 pages2 MS ElectrochemistrysachinNo ratings yet

- Us03cicv21 Unit3Document28 pagesUs03cicv21 Unit3ashokNo ratings yet

- Ankit Topic - Using Cast Iron For Machine PartsDocument12 pagesAnkit Topic - Using Cast Iron For Machine PartsAnkit BhadesiaNo ratings yet

- Sloss Industries 1062235 M2234300 EX351 V 2Document1 pageSloss Industries 1062235 M2234300 EX351 V 2DanielDeFrancescoNo ratings yet