Professional Documents

Culture Documents

Bio Degradable Sheets or Carry Bags

Uploaded by

foglaabhishekCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bio Degradable Sheets or Carry Bags

Uploaded by

foglaabhishekCopyright:

Available Formats

BIO DEGRADABLE SHEETS/CARRY BAGS Introduction: Low density polyethylene (LDPE) and linear low density polyethylene (LLDPE)

belong to polyethylene group of thermo-plastics. LDPE is generally the softest and least crystalline of all the polyethylene. LDPE has a unique combination of properties namely toughness, high impact strength, low-brittleness temperature, flexibility, processibility, film transparency, chemical resistance and having a density of 0.91 0.94. LDPE applications are mostly film based. The most common application areas are in general food packaging, milk pouches, industrial products, textiles, frozen foods, agriculture and horticulture section etc. LLDPE has all the advantages of LDPE together with the added benefit of low energy output which leads to a saving of over 20% in the manufacturing cost. The use of LLDPE has been predominantly in blends with LDPE as far as film extrusion is concerned. LLDPE and LDPE blended film are used for milk packaging, nursery bags, heavy duty sacks and general purpose bags. Market Potential: The unit is envisaged to manufacture LLDPE carry bags and LDPE sheets. The biggest advantage of using LLDPE is the possibility of down gauging of the film upto 30 percent or more with an improvement in the mechanical properties such as tensile strength, tear strength etc. The common sizes of plastic carry bags are 1 x 1 , 1 x 2, 1 x 3, 1 x and x . Different sizes LLDPE carry bags are required by grocery shops, stationary shops, textile shops, restaurant, bakery, pharmaceuticals shops, automobile spare parts shops etc. Conversion of LDPE is mostly in the form of a film with balanced orientation for better toughness. LDPE sheets generally come in rolls of size 100m x 2m and weight around 12 kg 14 kg. LDPE sheets are mostly required by tea gardens to be used as aprons by labour for plucking of tea leaves, by vegetables seller and for commercial as well as domestic use for protection from water/rainfall and for tea packaging along with jute bags etc. LDPE sheets also have a good potential outlet in the filed of agriculture and horticulture for several packaging and non packaging applications. Mention may be made here that products manufactured from granules are of A Grade quality with fine finish fetching high price, the products manufactured from mixing of granules and scraps are of Grade B quality with medium finished fetching medium price and the products manufacturing from scraps are of Grade C quality with average finish fetching low price. In view of recent ban on Grade B and Grade C quality finished products only A Grade quality finished products is considered for the purpose. Plant Capacity: The production basis for a typical tiny unit would be as under: Working hours/day : 8 (1 shift) Working days in a year : 300 Annual Production capacity : 45 MT (carry bags 30 MT, Sheets 15 MT) The unit has been assumed to operate at 70%, 80% and 90% of its installed capacity in the first, second and third year and onwards of its operation. Raw Material: The main raw materials required are LDPE/LLDPE granules and master batch (colour). The colour to be mixed with the raw materials is at the rate of around 2%. The requirement of LDPE/LLDPE granules, and master batch are as follows: LDPE/LLDPE granules : 45 MT Master batch : 920 Kg. The required raw materials are manufactured by Indian Petro-chemicals Limited (IPCL), Baroda. There exist authorized dealer of IPCL for whole of the N.E. region at Guwahati. The unit will have to tie-up with this authorized dealer for regular supply of raw materials including master batch.

254

Process: LDPE/LLDPE films are manufactured by extrusion process. Plastic extrusion is basically defined as converting plastic powder or granules into a continuous uniform melt and forcing this melt through a die which yields a desired shape. Any thermo-plastic product required in length of uniform cross-section is extruded. The basic process steps involved are Mixing of colours with granules. Feeding of colour mixed granules into the hopper. Heating of these mixed raw materials in an extruder. Passing of molten raw materials through dies to get desired shape. Cooling and winding of film. Making of desired size Sheets/Bags and sorting. Packing and despatch. In India a indigenous technology for LDPE, LLDPE products manufacturing is provided by a good number of organizations like Central Institute of Plastic Engineering & Technology (CIPET). Machinery: The major equipment required by the unit are shown below. The equipment has been selected keeping in view the capacity and other process considerations. Brimco Model BRHM -40 Plant and equipment for extrusion of LDPE/LLDPE film which consists of the main assembles Low base extruder, spiral type die set, air cooling ring, blower for cooling, take up tower, surface winder and electrical control panel - (1 No.). Punches suitable for dies of 50mm and 80mm for processing LLDPE with air ring insert (2 Nos.) Snap winding mechanism and cutting system (1 No.). BSL -450 bottom Seal and both end seal bag making machine (for carry bags) (1 No.). 0.7 KW air compressor as well as compressed air pipe system ( 1 No.). Tool kits (2 sets). Mention may be made here that Brimco Model BRHM- 40 is suitable for processing LDPE, LLDPE & HMHDPE by accordingly changing the dies, punch etc. which can be fitted on the same machine Location: The suitable locations for the project may be Guwahati, Jorhat, Tinsukia, Silchar, Biswanath Chariali in Assam. Jorabat/ Byrnihat in Meghalaya. Naharlagun in Arunachal Pradesh. Dimapur in Nagalan. Imphal in Manipur Kolasib in Mizoram1 Infrastructure: The basic infrastructure required are : Land : 4,400 sq.ft. Building : 520 sq.ft. Power : 111.04 Kwh per day. Water : 1600 Ltr. Per day. Manpower : 10 Nos. [Administrative (4), Factory Staff (6)], Total Capital Requirement: The total capital requirement including fixed capital and working capital is estimated at Rs 47.50 lakhs as follows. Of this, the project cost comprising fixed capital and margin money on working capital is Rs 41.20 lakhs. A. Fixed Capital: (Rs in lakh) Land 2.50 Building 8.50 Machinery 20.00 Miscellaneous fixed assets 3.80 Preliminary and pre-operative expenses 2.20 Total (A) 37.00 =====

255

B.

Working Capital: Raw materials Finished goods Working expenses Receivables

2 months 3 weeks 1 month 2 weeks Total (B)

5.00 3.00 0.50 2.00 10.50 ==== Total (A)+(B) 47.50 Rs 6.30 lakhs Rs 4.20 lakhs Rs 10.50 lakhs ===========

Note: Working capital may be financed as: Bank Finance Margin Money

.. ..

Means of Finance: The project cost of Rs 41.20 lakhs including margin money for working capital may be financed as under: Promoters contribution (35%) . Rs 14.40 lakhs Term Loan (65%) . Rs 26.80 lakhs Rs 41.20 lakhs =========== Operating Expenses: The annual operating expenses are estimated at Rs 42.90 lakhs (70% capacity utilization) as given below: (Rs in lakhs) 1. Raw materials 30.00 2. Utilities 0.80 3. Wages & Salaries 3.40 4. Overheads 1.35 5. Selling expenses @ 1.5% on annual sales 0.75 6. Interest on term loan 3.70 7. Interest on Bank Finance for Working Capital (14%) 0.90 8. Depreciation @10% 2.00 42.90 ====== Sales Realization: The estimated average ex-factory sales realization from the sale of carry bags & sheet is Rs 150/- per Kg. carry bags/sheets of Grade-I quality. Based on this the annual sales realization is estimated to be Rs 67.50 lakhs and at 70% capacity utilization the same is Rs 47.25 lakhs. Profitability: Based on the sales realization and the operating expenses, the profit would be Rs 4.35 lakhs per year (70% capacity utilization). This works out to a return on investment of 11%. The plant will break even at 56% of the rated capacity. Highlight: The major highlights of the project are as follows: Total capital requirement Promoters contribution Annual sales realization (70% cap.) Annual operating expenses (70% cap.) Annual profit (pre-tax) Pre-tax Return on Sales Break Even Point No.of persons employed

: : : : : : : :

Rs 47.50 lakhs Rs 14.40 lakhs Rs 47.25 lakhs Rs 42.90 lakhs Rs 4.35 lakhs 10 % 56% 10

256

List of Machinery Suppliers: 1. M/s R.H. Windsor (India) Ltd. E-6 UZ Road, Thane Industrial Estate, Thane 400 604 1.

List of Raw Materials Suppliers: M/s Mittal Station Works, 12/3297, Agrapura Roshampura Road, Subji Mandi, New Delhi 110 007

2.

M/s British Plastic & Engineering Works 89.2, Block A, Naraina Industrial Area, Phase-1, New Delhi 110 028

2.

M/s R.K. Traders, 43, A, Dilshad Garden, G.T. Road, Sahodora, New Delhi M/s Indian Petrochemicals Corpn.Ltd. 33A, Chowringhee Road, 3rd floor, Kolkata 700 071 M/s Swastic Plastics, 24/25, Roopchand Roy Street, Kolkata 700 001

3.

4.

M/s Oswal Engineering Corpn. 142/48 S.V. Road, Ghaswala Industrial Estate, Jogeswari (West) Mumbai 400 102 M/s Kwality Engineering works, 48A, Muktaram Babu Street, Kolkata 700 007

3.

4.

257

You might also like

- 02 ECS Lect Ecommerce Business Models ConceptsDocument20 pages02 ECS Lect Ecommerce Business Models ConceptsfoglaabhishekNo ratings yet

- NewItem 150 PlasticsWasteDocument47 pagesNewItem 150 PlasticsWasteYovitaAyuningtyasNo ratings yet

- Chinese Words 02AUG2013Document11 pagesChinese Words 02AUG2013foglaabhishekNo ratings yet

- Pumpo PumpDocument2 pagesPumpo PumpfoglaabhishekNo ratings yet

- The Art of War, by Sun Tzu 1Document96 pagesThe Art of War, by Sun Tzu 1foglaabhishekNo ratings yet

- Research Project: BY-Abhishek Fogla Dharmendra Banthia Nimisha Mittal Pooja Sureka Shruti RampuriaDocument24 pagesResearch Project: BY-Abhishek Fogla Dharmendra Banthia Nimisha Mittal Pooja Sureka Shruti RampuriafoglaabhishekNo ratings yet

- Timbuk 2Document6 pagesTimbuk 2foglaabhishekNo ratings yet

- RegressionDocument3 pagesRegressionfoglaabhishekNo ratings yet

- 1823973Document12 pages1823973foglaabhishekNo ratings yet

- StatisticsDocument6 pagesStatisticsfoglaabhishekNo ratings yet

- TallyDocument4 pagesTallyfoglaabhishekNo ratings yet

- Dell 10KDocument125 pagesDell 10Kreny_wenNo ratings yet

- CH - 08 Cap BudgetingDocument54 pagesCH - 08 Cap BudgetingfoglaabhishekNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Emerson Mentor MP ManualDocument182 pagesEmerson Mentor MP ManualiampedrooNo ratings yet

- GL Career Academy Data AnalyticsDocument7 pagesGL Career Academy Data AnalyticsDeveloper GuideNo ratings yet

- TR60 RIGID ENG. 6/13/03 10:38 AM Page 1: Performance DataDocument2 pagesTR60 RIGID ENG. 6/13/03 10:38 AM Page 1: Performance Databayu enasoraNo ratings yet

- How To Install 64 Bits IDES On 32 Bits OSDocument1 pageHow To Install 64 Bits IDES On 32 Bits OSMuhammad JaveedNo ratings yet

- Design of Footing R1Document8 pagesDesign of Footing R1URVESHKUMAR PATELNo ratings yet

- Learning Plans in The Context of The 21 ST CenturyDocument29 pagesLearning Plans in The Context of The 21 ST CenturyHaidee F. PatalinghugNo ratings yet

- Field and Laboratory Evaluation of A Soft Clay Southern IraqDocument14 pagesField and Laboratory Evaluation of A Soft Clay Southern Iraqvidyaranya_bNo ratings yet

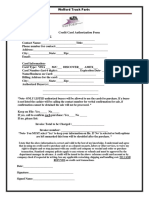

- Credit Card Authorization Form WoffordDocument1 pageCredit Card Authorization Form WoffordRaúl Enmanuel Capellan PeñaNo ratings yet

- Slup 230Document24 pagesSlup 230Jelena TodorovicNo ratings yet

- Practicewith Argument Athletesas ActivistsDocument30 pagesPracticewith Argument Athletesas ActivistsRob BrantNo ratings yet

- Program of ActivitiesDocument2 pagesProgram of ActivitiesVon Limuel LopezNo ratings yet

- n4 HandoutDocument2 pagesn4 HandoutFizzerNo ratings yet

- Typical Cable Laying Details For Direct Buried, Low Tension CablesDocument9 pagesTypical Cable Laying Details For Direct Buried, Low Tension CableslataNo ratings yet

- Hypothesis Testing Random MotorsDocument8 pagesHypothesis Testing Random MotorsLinn ArshadNo ratings yet

- Summative Test in Foundation of Social StudiesDocument2 pagesSummative Test in Foundation of Social StudiesJane FajelNo ratings yet

- 22 Thành NG Quen Thu C Trên Ielts - FirefighterDocument2 pages22 Thành NG Quen Thu C Trên Ielts - FirefighterNinh NguyễnNo ratings yet

- Permanent Magnet Motor Surface Drive System: Maximize Safety and Energy Efficiency of Progressing Cavity Pumps (PCPS)Document2 pagesPermanent Magnet Motor Surface Drive System: Maximize Safety and Energy Efficiency of Progressing Cavity Pumps (PCPS)Carla Ayelen Chorolque BorgesNo ratings yet

- Antenna Systems - Standard Format For Digitized Antenna PatternsDocument32 pagesAntenna Systems - Standard Format For Digitized Antenna PatternsyokomaNo ratings yet

- Career Orientation QuestionnaireDocument5 pagesCareer Orientation QuestionnaireApple May100% (1)

- 448 Authors of Different Chemistry BooksDocument17 pages448 Authors of Different Chemistry BooksAhmad MNo ratings yet

- College of Engineering Cagayan State UniversityDocument16 pagesCollege of Engineering Cagayan State UniversityErika Antonio GutierrezNo ratings yet

- Emcee Script For Recognition DayDocument3 pagesEmcee Script For Recognition DayRomeo Jr. LaguardiaNo ratings yet

- Capacity Analysis of Kashmir Highway IslamabadDocument71 pagesCapacity Analysis of Kashmir Highway Islamabadm saadullah khanNo ratings yet

- 1.2 The Basic Features of Employee's Welfare Measures Are As FollowsDocument51 pages1.2 The Basic Features of Employee's Welfare Measures Are As FollowsUddipta Bharali100% (1)

- Myers Briggs Type Indicator-2Document1 pageMyers Briggs Type Indicator-2api-261818438No ratings yet

- Headlight Washer System: Current Flow DiagramDocument3 pagesHeadlight Washer System: Current Flow DiagramLtBesimNo ratings yet

- Afa Coursework ExamplesDocument6 pagesAfa Coursework Examplesiuhvgsvcf100% (2)

- Performance Comparison of VxWorks Linux RTAI and Xenomai in A Hard Real-Time ApplicationDocument5 pagesPerformance Comparison of VxWorks Linux RTAI and Xenomai in A Hard Real-Time ApplicationsatyanaryanakNo ratings yet

- Green ThumbDocument2 pagesGreen ThumbScarlet Sofia Colmenares VargasNo ratings yet

- Control System PPT DO1Document11 pagesControl System PPT DO1Luis AndersonNo ratings yet