Professional Documents

Culture Documents

Dynamic Analysis and Structural Design of Turbine Generator Foundations

Uploaded by

Power PowerCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dynamic Analysis and Structural Design of Turbine Generator Foundations

Uploaded by

Power PowerCopyright:

Available Formats

- 1 -

DYNAMIC ANALYSIS AND STRUCTURAL DESIGN OF

TURBINE GENERATOR FOUNDATIONS

Dr. Arkady Livshits

IEC - Israel Electric Corporation Ltd, Israel

Nativ Ha-Or St, 1, POB 10, Haifa 31000, Israel

utz0d@iec.co.il

ABSTRACT

Turbine-generator foundation CAE is presented. Different types of foundations are

described. Dynamic behaviors of the foundations and sources of the dynamic loads are

discussed.

Modal analysis is required for frequencies separation verification. Very strict limits for

amplitude of vibrations at machine bearings shall be checked by harmonic forced vibration

analysis. Response spectrum analysis gives estimation of internal forces and displacements

due to seismic excitation. Structural design of the turbine generator foundation, made of

reinforced concrete, requires series of static analyses on various static and quasi-static loads.

ANSYS/CivilFEM software provides an effective computational environment to

perform all types of the analyses at once and to combine their results during the design

process. IEC developed CAE is used for in-house foundation design as well as for checking

and verification, when design is prepared by the machine manufacturer or by the third part.

Model generation with wide utilization of APDL capabilities is described. Different

types of finite elements are used for modeling concrete structures of the foundation,

supporting piles, machine parts and their connection to the foundation.

Design procedure in accordance with the relevant International and German, American

and Israeli Codes and Standards is discussed. Description of applied loads is presented.

Together with ordinary structural and environmental loads, specific machine loads for normal

operation condition as well as emergency loads are detailed. Load combinations for ultimate

state conditions as per IEC design practice are described.

Numerical results for "Tzafit" gas turbine generator foundation are presented.

INTRODUCTION

Growth of electricity consumption in the world in conjunction with strict

environmental requirements inspires during the last years come-back of traditional thermal

and combined cycle power plants. The concrete foundation supporting gas- and/or steam

turbine(s) and generator takes the central place among the power plant structures.

IEC owns about 60 power units with capacity ranges from tens to 575 MW. During

the last decade 10 new units have been constructed, 2 units are currently under construction, 3

units are in stage of detailed design and 3 another units are in stage of conceptual design and

technical specifications preparation. All these units have turbine-generator foundations of

- 2 -

different types and sizes depending on the capacity and type of power unit. There are four

main classes of built foundations:

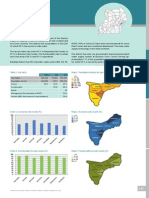

Gas Turbine - Generator Foundation (GTGF) for 3 Gas Turbine Units 230-270 MW

("Eshkol", "Alon-Tavor", "Tzafit")

Steam Turbine Generator Foundation (STGF) for 2 Combined Cycle Add-On Units

130 MW ("Eshkol", "Alon-Tavor")

Gas Turbine Steam Turbine Generator Foundation (GSTGF) for 5 Single Shaft

Combined Cycle Units 350-390 MW ("Gezer", "Hagit", "Haifa")

Steam Turbine Generator Foundation (TGF) for 2x575 MW Coal Fired Power

Station "Rutenberg-B"

The foundation design may be prepared in IEC Engineering Division or provided by

the machine manufacturer or by the third party. In any case, an effective modeling instrument

based on ANSYS/CivilFEM software is required for performing analyses and/or for checking

and verification of design obtained by alternative CAE.

CONCRETE TURBINE-GENERATOR FOUNDATION

The turbine-generator foundation (TGF) is a complex engineering structure. Different

types of foundations are used for different machines depending on their capacity, geometrical

sizes and constructional features.

Base Mat Foundation, the simplest type of the TGF, consists of reinforced concrete

plate 1.2 1.7 m thick. Base mat foundations are usually applied for small gas turbine units

with capacity up to 100 MW.

Pedestal Foundation consists of base mat of 1.8 2.0 m thickness and several

pedestals raised about 3.0 m. Pedestals support gas turbine frame and thick concrete walls of

about 5.0 m height support generator. Pedestal foundations are used for large gas turbine

units.

Tabletop Foundation consists of elevated concrete plates and beams supported by

columns and walls that transfer the loads to the base mat. This type of foundation is usually

used as STGF. For relatively small steam turbine of add-on units the thickness of the top plate

is about 1.5 m and base mat thickness is 2.0 m (Fig. 1). For large steam turbine of coal-fired

power station the thickness of the top plate is about 3.5 m and the base mat thickness may

reach 4.0 m. Top of the table in this case is about 16 18 m above the base mat top.

Vibration isolators consisting of springs and dampers located at the top of columns below the

table plate are sometimes used to separate fundamental and operation frequencies and,

consequently, to prevent transmission of dynamic loads on supporting structures in normal

operation conditions.

Combined Foundation presents the combination of pedestal and tabletop foundations

placed on common base mat of approximately 2.5 3.0 m thick. Foundations of this type are

used for single-shaft combined cycle units when gas turbine, generator and steam turbine have

a common rotor axis.

In all types of TGF the base mat may rest directly on soil or may be supported by

piles. An adequate model of soil/piles in terms of equivalent spring coefficients and damping

parameters is very significant for the dynamic analysis of the TGF. Usually these parameters

are to be provided by a geotechnical consultant. Theoretical background and practical

recommendations for soil parameters estimation are presented in [1 3].

- 3 -

Figure 1: Table-Top Steam Turbine-Generator Foundation

Dynamic behaviors of the foundation play an important role in providing normal

operating conditions for the supported turbo-machine. The main source of dynamic forces in

the turbo-machine is mass eccentricity, when center mass of rotating parts does not coincide

with the center of rotation. Unbalanced masses of the rotor produce centrifugal forces that

lead to vibrations of the rotating turbo-machine foundation. At each bearing of the rotor (both

at turbine and at generator) the harmonic forces in any direction perpendicular to longitudinal

rotation axis are

2

) sin( ) (

e m P

t P t F

i i

i i

=

=

where

i

m = proportional part of rotating mass, supported by i-th bearing;

e = mass eccentricity;

f 2 = = circular operating frequency of the turbine-generator;

f = operating frequency ( 50

0

= f Hz at nominal turbine speed).

Very strict limits for amplitude of vibrations at machine bearings shall be checked by

harmonic forced vibration analysis.

Israel is a relatively strong earthquake area. TGF is a structure that supports heavy and

high elevated equipment. Therefore seismic forces are very significant for a proper and safe

design of the TGF. Dynamic response spectrum analysis gives an estimation of internal forces

and displacements due to seismic excitation.

The structural design of the turbine-generator foundation made of reinforced concrete

requires series of static analyses on various static and quasi-static loads.

- 4 -

MODEL DESCRIPTION

ANSYS/CivilFEM software provides an effective computational environment to

perform all types of the analyses at once and to combine their results during the design

process. It is IEC practice to use ANSYS for analysis and design of complex engineering

structures. Following this tradition, a special application for turbine generator foundation has

been developed after the concrete chimney ANSYS-based CAD [4]. This application is used

for in-house foundation design as well as for checking and verification, when design is

prepared by the machine manufacturer or by the third party.

Model generation widely utilizes APDL capabilities. 3-D grid of K-points serves as

basis for automatic generation process. Each one of the planar objects (base mat, pedestals,

vertical walls and top plate) is modeled as a carpet of Areas. Selection and Boolean operations

on the Areas are extensively used for sculpturing particular planar object to its realistic

configuration, taking into consideration openings, reentering and salient angles etc. Planar

object is modeled at its middle plane. Due to significant thickness of the base mat

discontinuities of model exist. For example, vertical wall or pedestal starts from the top of the

base mat when the mat is located below at a distance of half-thickness (Fig. 2). This distance

may reach 1/4 1/3 of the wall height. The same situation is with the top of piles located at

the bottom of the base mat. To account these eccentricities the RIGID REGION between

nodes of separate objects coinciding in horizontal plane are applied after the mesh generation.

Figure 2: Finite Element Model Generation

Different types of finite elements are used for modeling concrete structures of the

foundation. Element SHELL63 is used for planar objects, BEAM44 is used for columns and

beams. Different material properties (concrete grade B-30 for base mat and concrete grade B-

40 for elevated structures) as well as different real constants (plate thickness) are used for

different objects. Special attention in meshing process is paid to establish consistent local

coordinate systems for elements. It is important for right interpretation of analyses results.

- 5 -

The 3D spring elements COMBINE14 are used for modeling piles supporting base

mat. The node at the top of the pile is connected by RIGID REGION to coplanar node at the

midplane of the base mat.

The 3-D elements MASS21 without rotary inertia are used for modeling additional

masses obtained from the weight of machine parts and other equipment. Due to the fact that

machine to foundation mass ratio is about 1:3 1:5, differences between fundamental

frequencies with and without additional masses may be around 15%.

Non-structural nodes modeling machine bearing location at rotational axis elevation

are connected to the foundation by RIGID REGION.

DESIGN PROCEDURE

Codes and Standards

Turbo-generator foundations are unique because they may be subjected to significant

dynamic loads during operation in addition to ordinary structural design and environmental

loads. Therefore normative design documents shall cover all load types and shall establish

dynamic and static design criteria.

International Standard [5] limits unbalanced mass eccentricity and defines balance

quality grade in terms of product e . For gas and steam turbines balance quality grade G2.5

is to be applied which means that 5 . 2 = e mm/s.

International Standards [6, 7] and German normative [8] establish dynamic design

criteria in terms of permissible bearing vibration displacement amplitude or bearing root-

mean-square vibration velocity. For turbine with nominal operating frequency 50 Hz bearing

displacement amplitude is limited by 12.5 m (Zone Boundary A/B).

The only standard specifically addressed to machine foundation design is German

Standard [9]. The American Report [10] gives a good overview of all aspects of concrete

turbine-generator foundation design but it has no normative status.

The design of reinforced concrete structures shall be in accordance with requirements

of Israeli Standard [11], when seismic and wind loads are defined by [12] and [13]

respectively.

Modal Analysis

Dynamic behaviors of the foundation shall be firstly verified by modal analysis. All

modes with frequencies up to 60 2 . 1

0

= f Hz shall be extracted. Usually 30 40 modes are

enough. First 2 4 modes present rigid body translational (in horizontal plane) or

translational-rotational modes. Vertical translational mode is usually combined with flexural

modes. Only about 10 first modes have significant participation factor.

Frequency separation criteria shall be verified. For low-tuned foundation the

fundamental frequency shall be less than 40 8 . 0

0

= f Hz. If this condition is not met the

resonance may occur and the foundation should be resized.

- 6 -

Harmonic Forced Vibration Analysis

This analysis is required to verify dynamic design criteria for vibration due to rotor

unbalance forces in normal operation conditions. Sometimes the manufacturer provides

unbalance loads

0

i

P for nominal frequency

0

f at each bearing of turbine and generator

explicitly. In other cases

i

P shall be calculated on the basis of balanced quality grade.

Harmonic analysis is provided in frequency range

0 0

2 . 1 8 . 0 f f f , i.e. between 40

and 60 Hz. Unbalance forces are to be adjusted for operating frequency. Quadratic adjustment

( )

2

0

0

/ ) ( f f P f P

i i

=

shall be used when unbalance loads are defined explicitly, and the linear adjustment

0

0

/ ) ( f f P f P

i i

=

is applied in case of balanced quality grade usage.

These rotor unbalance loads may be acting with random distribution of relative phase

angle. Hence four cases are taken into consideration:

Vertical unbalance forces applied in-phase;

Vertical unbalance forces applied counter-phase;

Horizontal unbalance forces applied in-phase;

Horizontal unbalance forces applied counter-phase.

Damping ratio is assumed 0.02 as recommended in [9].

Response Spectrum Analysis

The evaluation of the seismic effect on TGF is based on the dynamic response

spectrum analysis. The design spectrum for all mode shapes and periods is derived from the

spectral amplification factor curves for horizontal seismic action, corresponding to

appropriate type of soil, as required in Israeli Standard [12] (Fig. 3). Notwithstanding its

relatively small area, Israel has zones that significantly differ one from another from

seismological point of view. The expected horizontal ground acceleration varies from about

0.1g at Mediterranean Sea shore to 0.3g near the Jordan Valley which is a part of the Syrian-

African fault line.

Figure 3: SI 413 Spectrum (for Soil Types S2, S3) vs. Site-Specific Response Spectrum

- 7 -

Additional magnification of ground acceleration known as site effect depends on local

geological structure. Due to the vital importance of power station normal functioning IEC

order seismological survey and seismic hazard assessments at each one of the new designed

power units. Site-specific response spectrum obtained as a result of the experimental survey

[14] is used in TGF design in addition to spectrum defined by Standard (Fig. 3).

SRSS method is used for the mode shapes combination.

Design Loads

The following static and quasi-static loads shall be taken into account in structural design of

the turbine-generator foundation.

Ordinary Structural Loads

SW - self weight of structures

DL - dead loads due to the weight of the turbo-machine and equipment

LL - live loads

PL - piping loads

TE - thermal expansion or friction forces

T - temperature

Normal Operation Loads

ST - shaft thrust

NT - normal torque

NP - pressure

CV - condenser vacuum loads

Emergency Loads

UF - rotor unbalance forces

CB - compressor loss-of-blade

TB - turbine loss-of-bucket

SC - generator short circuit or faulty synchronization

SP - shutdown pressure

FP - failure pressure

Installation Loads

ER - erection loads

CS - construction loads or shrinkage

Environmental Loads

EQ - seismic loads

WL - wind loads

SN - snow loads

SL - site-specific loads, for example swelling

- 8 -

Not all loads listed above are defined for each foundation. In fact the applied loads

depend on turbine type, machine configuration and manufacturer and on the site conditions.

So, loads CV and FP are specific for the steam turbine and do not exist in gas turbine.

Thermal Expansion loads can be developed at the turbine-generator supports from

mechanical resistance to the thermal movement of the turbine-generator. It is a self-balanced

system of forces with a net resultant force equal to zero, producing only internal forces in the

foundation.

Shaft Thrust is an axial load on the foundation produced from the flow momentum

change through the gas turbine.

Normal Torque is generally applied to the foundation as a couple of vertical static

forces.

Condenser Vacuum is the load from the vacuum pull of the condenser on the steam

turbine.

Unbalance Forces are static equivalent forces which correspond to the maximum

allowable rotor vibration amplitudes (Zone Boundary C/D). This load is calculated as a

function of the rotor weight and usually assumed as 57 times of the rotor support reaction at

each bearing. Separate load steps are produced for in-phase, as well as for alternating counter-

phase unbalanced forces applied in vertical and in horizontal directions.

Loss of Blade (Bucket) of the turbine may produce a large dynamic forces rotating

with the rotor. This load is normally defined by the turbine manufacturer as an equivalent

static load.

Short Circuit moment is bi-harmonic function of time with descending amplitude

( ) ( ) ( )

2 1 0

/

2

/

1

/

0

2 sin sin

a t a t a t

e A t e A t e A t M

+ =

Equivalent quasi-static load, equal to the maximum of the time-dependent short circuit

moment, may be used for structural design purposes. According to [9] a dynamic load factor

of 1.7 should be used for the static equivalent short circuit moment.

Shrinkage effect is considered by a uniformly temperature drop from the ambient

temperature for all the elements above the top of the base mat. Shrinkage shall be taken into

account because the pedestals and walls are concreted later than the base mat.

It should be noted that some design loads produce several load steps differ by

direction of the load action.

Load Combinations

Following load combinations for ultimate state conditions are used for structural

design in accordance with requirements of the Israeli Concrete Code [11].

1.2 (SW + DL)

1.4 (SW + DL) + 1.6 LL + 1.6 TE + 1.6 (ST + NT + NP)

1.4 (SW + DL) + 1.6 LL + 1.6 TE + 1.6 (ST + NT + NP) + 1.6 SL

1.4 (SW + DL) + 1.6 LL + 1.6 (TE + T) + 1.6 (ST + NT + NP)

1.4 (SW + DL) + 1.6 LL + 1.6 TE + 1.6 (ST + NT + NP) + 1.6 UF

1.4 (SW + DL) + 1.6 LL + 1.6 TE + 1.6 (NT + NP) + 1.6 SP

- 9 -

1.4 (SW + DL) + 1.6 LL + 1.6 TE + 1.6 (ST + NT) + 1.4 CB

1.4 (SW + DL) + 1.6 LL + 1.6 TE + 1.6 (ST + NT) + 1.4 TB

1.4 (SW + DL) + 1.6 LL + 1.6 TE + 1.6 (ST + NT) + 1.4*1.7 SC

1.4 (SW + DL) + 1.2 LL + 1.2 (ST + NT + NP) + 1.2 W

1.4 (SW + DL) + 1.4 W

1.2 (SW + DL) + 1.4 W

1.0 (SW + DL) + 1.0 LL+ 1.0 TE + 1.0 (ST + NT + NP) + 1.0 EQ

1.0 (SW + DL) + 1.0 EQ

1.4 SW + 1.6 CS

1.2 (SW + DL) + 1.6 SL

Load factor consistent with a live load applies for normal operation loads and for

emergency loads that may occur from time to time during the machine life. Load factor

consistent with a dead load applies for emergency loads of catastrophic character CB, TB, SC

that have a very low probability of occurrence during the life of the machine. In contrast to

normal operation loads, the emergency loads are not considered acting concurrently with

other emergency loads and with accidental environmental loads.

The required amount of reinforcement is calculated by CivilFEM standard procedure.

CALCULATION EXAMPLE

"Tzafit" gas turbine generator foundation (Fig. 4) is of pedestal type. The base mat of

2.0 m thickness has a length of 38.0 m and width varies from 11.0 to 16.0 m. Three pedestals

supporting gas turbine frame and exhaust diffuser have a height of 2.85 m and thickness

varies from 0.75 to 2.0 m. Five connected vertical walls supporting generator have a height of

about 4.7 m and thickness varies from 0.6 to 1.6 m. Center line of the rotor is located at

elevation 5.4 m above top of the base mat. The base mat is supported by 55 piles of 0.8 m

diameter and of 22 m length arranged in diamond grid.

Figure 4: "Tzafit" Gas Turbine Generator Foundation

- 10 -

Equipment weight is about 950 tons when foundation self-weight is approximately

3000 tons, that provides machine-to-foundation mass ratio less than 1:3.

Finite-element model consists of 4200 SHELL63 elements, 165 COMBIN14 elements

and 50 MASS21 elements (Fig. 5). Total number of 37 modes has been extracted. First 3

modes are the rigid body modes in horizontal plane with frequencies 2.76 to 3.10 Hz. It gives

a good correlation with the single-degree-of-freedom model frequency estimation of 2.90 Hz.

The first significant flexural mode (5

th

mode in full set) is presented on Figure 6.

1

X

Y

Z

Tzafit Gas Turbine Generator Foundation

JUN 20 2005

16:16:07

ELEMENTS

Figure 5: "Tzafit" GTGF Finite Element Model

1

MN

MX

X

Y

Z

Tzafit Gas Turbine Generator Foundation

0

.008851

.017702

.026553

.035404

.044254

.053105

.061956

.070807

.079658

JUN 20 2005

17:43:19

NODAL SOLUTION

STEP=1

SUB =5

FREQ=5.991

USUM (AVG)

RSYS=0

DMX =.079658

SMX =.079658

Figure 6: "Tzafit" GTGF 5

th

Natural Mode of Vibration

- 11 -

Rotor unbalance forces 3 . 4

2 1

= = P P tons at the generator collector-end (

1

P ) and

turbine-end (

2

P ) bearings and 6 . 6

4 3

= = P P tons at the turbine forward- (

3

P ) and aft- (

4

P )

bearings have been provided by manufacturer. Results of dynamic analysis for horizontal

loads applied in counter-phase are presented on Figure 7.

Figure 7: "Tzafit" GTGF Vibration Amplitudes at Bearing under Horizontal Unbalance

Forces applied in Counter-Phase. Damping 0.02.

CONCLUSIONS

ANSYS/CivilFEM software provides an efficient tool for dynamic analysis and

structural design of the turbine-generator foundations. Analyses features and design procedure

have been described in details. Developed turbine-generator foundation CAE is extensively

used in IEC design practice. Example of the real project has been presented.

REFERENCES

[1] Bowels, J.E., "Foundation Analysis and Design", 5th Edition, McGraw-Hill, 1996

[2] Whitman, R.V., "Soil-Structure Interaction", Seismic Design for Nuclear Power

Plants, MIT, 1969, pp. 245-269

[3] Wolf, J.P., "Simple Physical Models for Foundation Dynamics", Dynamic Soil-

Structure Interaction, Elsevier Science B.V., 1998, pp. 1-70

[4] Livshits, A., "Concrete Chimney Analysis and Design: FE Models and ANSYS-based

CAD", ANSYS Conference Proceedings, Pittsburgh, 1998

- 12 -

[5] ISO 1940-1 (1993) Mechanical Vibration Balance Quality Requirements of Rigid

Rotors Part 1: Determination of Permissible Residual Unbalance

[6] ISO 10816-1 (1995) Mechanical Vibration Evaluation of Machine Vibration by

Measurements on Non-Rotating Parts Part 1: General Guidelines

[7] ISO 10816-2 (2001) Mechanical Vibration Evaluation of Machine Vibration by

Measurements on Non-Rotating Parts Part 2: Land-Based Steam Turbines and

Generators in Excess of 50 MW

[8] VDI 2056 (1964) Evaluation of Mechanical Vibration of Machines

[9] DIN 4024 Part 1 (1988) Machine Foundations: Flexible Structures Supporting

Machines with Rotating Masses

[10] ACI 351.3R (2004) Foundations for Dynamic Equipment

[11] SI 466 Part 1 (2003) Concrete Code: General Principles

[12] SI 413 (1998/2004) Design Provisions for Earthquake Resistance of Structures

[13] SI 414 (1982) Characteristic Loads in Buildings: Wind Loads

[14] Zaslavsky, Y., Gitterman, Y., Shapira, A., "Site Response Estimations in Israel using

Weak Motion Measurements", Proceeding of the 5

th

International Conference on

Seismic Zonation, Nice, 1995, pp.1713-1722

You might also like

- Turbo Generator Foundation 922Document19 pagesTurbo Generator Foundation 922cardreadreNo ratings yet

- Zhong Design of Foundations For Large Dynamic Equipment in A High Seismic Region 2013 PDFDocument12 pagesZhong Design of Foundations For Large Dynamic Equipment in A High Seismic Region 2013 PDFasgharNo ratings yet

- Foundation Design For Vibrating Machines PDFDocument2 pagesFoundation Design For Vibrating Machines PDFSheiss Nabi50% (2)

- Machine Foundation DesignDocument44 pagesMachine Foundation DesignNimish Prabhukhanolkar75% (4)

- Design Charts For Machine FoundationDocument22 pagesDesign Charts For Machine Foundationroy1zhou100% (2)

- Machine Foundations-3Document34 pagesMachine Foundations-3yedida v r aviswanadhNo ratings yet

- Machine Foundation Dr. BhatiaDocument172 pagesMachine Foundation Dr. BhatiaBalaji HariNo ratings yet

- SPC-0804.02-40.11 Rev D2 Design of Machine FoundationsDocument11 pagesSPC-0804.02-40.11 Rev D2 Design of Machine Foundationskamalsingla3100% (5)

- Dynamic and Static Analysis of Turbogenerator FoundationDocument120 pagesDynamic and Static Analysis of Turbogenerator Foundationerabhijeetanand100% (1)

- Design of Dynamically Loaded Foundations For Pumps and Compressors-Belovolova - ArinaDocument38 pagesDesign of Dynamically Loaded Foundations For Pumps and Compressors-Belovolova - ArinaAmrut BhattNo ratings yet

- Block FoundationDocument16 pagesBlock FoundationMai Kawayapanik100% (7)

- Design of Foundations For Dynamic LoadsDocument446 pagesDesign of Foundations For Dynamic LoadsJose Luis Velasco Cadavid100% (49)

- Machine Foundation Digital Assignment 2: (1) Types of Machines, Capacity, Operating FrequencyDocument40 pagesMachine Foundation Digital Assignment 2: (1) Types of Machines, Capacity, Operating Frequencyyedida v r aviswanadh100% (2)

- Analysis of Frame Type Machine Foundations Thesis-ShaguftaDocument76 pagesAnalysis of Frame Type Machine Foundations Thesis-Shaguftaimamta100% (1)

- 08 Dynamic Analysis of Pile Supported Machine FoundationDocument6 pages08 Dynamic Analysis of Pile Supported Machine FoundationYati R. TankNo ratings yet

- Machine Vibration FoundationDocument17 pagesMachine Vibration FoundationAdigwe George ChimaNo ratings yet

- Dynamic Analysis of Machine FoundationDocument15 pagesDynamic Analysis of Machine FoundationSMT VIETNAMNo ratings yet

- Design of Machine Foundations Part 2Document39 pagesDesign of Machine Foundations Part 2Keshav VaityNo ratings yet

- Design of Equipment FoundationsDocument28 pagesDesign of Equipment Foundationsapi-379773793% (42)

- Block FoundationDocument3 pagesBlock Foundationdsananda67% (3)

- Dynamic Analysis of Pump Block Foundation - VaidyanathanDocument5 pagesDynamic Analysis of Pump Block Foundation - VaidyanathanShamik GhoshNo ratings yet

- Design of Structures & Foundations For Vibrating MachinesDocument212 pagesDesign of Structures & Foundations For Vibrating MachinesOvidiu Genteanu97% (30)

- Machine Foundation AnalysisDocument39 pagesMachine Foundation AnalysisramirovillegasNo ratings yet

- Foundation Vibration Analysis: A Strength of Materials ApproachFrom EverandFoundation Vibration Analysis: A Strength of Materials ApproachRating: 3 out of 5 stars3/5 (2)

- A Comprehensive Database of Tests on Axially Loaded Piles Driven in SandFrom EverandA Comprehensive Database of Tests on Axially Loaded Piles Driven in SandNo ratings yet

- Compr FDN JPDocument7 pagesCompr FDN JPSilvestreNo ratings yet

- This Is A Case Study of Multiple: May/June 2009Document6 pagesThis Is A Case Study of Multiple: May/June 2009Anonymous mcHqIfbnV1No ratings yet

- Design and Construction of Machine Foundations - Code of PracticeDocument12 pagesDesign and Construction of Machine Foundations - Code of PracticeMalar ManoharanNo ratings yet

- Dynamic Analysis of Turbo Generator MachDocument6 pagesDynamic Analysis of Turbo Generator MachJorge VallejosNo ratings yet

- TB FoundationAndSkidDesignDocument4 pagesTB FoundationAndSkidDesigndicktracy11100% (1)

- TG Foundation 316Document19 pagesTG Foundation 316Deepu PillaiNo ratings yet

- Design of Turbo-Generator Foundations: C.Ravishankar, C. Channakeshava, B. Sreehari Kumar, G V RaoDocument8 pagesDesign of Turbo-Generator Foundations: C.Ravishankar, C. Channakeshava, B. Sreehari Kumar, G V RaoAlastair KerrNo ratings yet

- Paper 67Document10 pagesPaper 67rowatersNo ratings yet

- 2003 Design of A New Axial Flux Permanent Magnet Generator For Hybrid Electric VehiclesDocument5 pages2003 Design of A New Axial Flux Permanent Magnet Generator For Hybrid Electric VehiclesFazal Karim MahsudNo ratings yet

- 2007 Case StudyDocument7 pages2007 Case StudyRiddhima MukherjeeNo ratings yet

- A Model For Yawing Dynamic Optimization of A Wind Turbine StructureDocument9 pagesA Model For Yawing Dynamic Optimization of A Wind Turbine StructureRevan TaeNo ratings yet

- Shaft Diameter PDFDocument8 pagesShaft Diameter PDFrusruleti100% (1)

- 05 Nucleus PAKDocument5 pages05 Nucleus PAKEngr Muhammad Mansoor AshrafNo ratings yet

- Vibration Based Wind Turbine Tower Foundation Design Utilizing Soil-Foundation-Structure InteractionDocument8 pagesVibration Based Wind Turbine Tower Foundation Design Utilizing Soil-Foundation-Structure InteractionCristi BrebanNo ratings yet

- Insertion Loss Models For Evaluating The PerformanDocument9 pagesInsertion Loss Models For Evaluating The Performansoumyajit maityNo ratings yet

- Divarchini (WWW - Civil100.20r.ir)Document7 pagesDivarchini (WWW - Civil100.20r.ir)x620No ratings yet

- MEAS D 17 02252R1 4 Split MergeDocument27 pagesMEAS D 17 02252R1 4 Split MergeAditya DoyaleNo ratings yet

- Internship ReportDocument31 pagesInternship ReportVisa Meena2351No ratings yet

- Effect of Using Bracing Members in Reducing Thermal Effects in Long BuildingsDocument13 pagesEffect of Using Bracing Members in Reducing Thermal Effects in Long BuildingspadashtNo ratings yet

- Intorduction To Power Engineering - 4 GeneratorsDocument26 pagesIntorduction To Power Engineering - 4 Generatorssyedsalmanali91No ratings yet

- Ijert Ijert: Analysis and Design of Transmission Line Tower 220 KV: A Parametric StudyDocument6 pagesIjert Ijert: Analysis and Design of Transmission Line Tower 220 KV: A Parametric Studyswapnil_dreamzNo ratings yet

- Structural Modification of A Steam Turbine BladeDocument7 pagesStructural Modification of A Steam Turbine BladeEMS CommerceNo ratings yet

- 492 FerreiraDocument6 pages492 FerreiraRonald LiemNo ratings yet

- CT2 2012 Foundations and Skids Large High Speed RecipsDocument4 pagesCT2 2012 Foundations and Skids Large High Speed RecipsAnonymous xcFcOgMiNo ratings yet

- Machine FoundationDocument10 pagesMachine FoundationDeepak SolankiNo ratings yet

- Energy Efficiency Assessment of Four Designs of Vertical Axis and Drag Differential Wind TurbinesDocument9 pagesEnergy Efficiency Assessment of Four Designs of Vertical Axis and Drag Differential Wind TurbinesLopez D NikkoNo ratings yet

- 2017 IET SSI Offshore Wind TurbinesDocument16 pages2017 IET SSI Offshore Wind TurbinesMarcus Girão de MoraisNo ratings yet

- Design and Off-Design Analysis of A Tesla Turbine Utilizing CO2 As Working FluidDocument6 pagesDesign and Off-Design Analysis of A Tesla Turbine Utilizing CO2 As Working Fluidbillthegunm0% (1)

- Thermal Analysis of Gas Turbine BladeDocument46 pagesThermal Analysis of Gas Turbine BladeManepalli HarshavardhananNo ratings yet

- Influence of Elastic Foundation Structures On The Rotor DynamicsDocument8 pagesInfluence of Elastic Foundation Structures On The Rotor DynamicsVodanh Tieutot100% (1)

- RE Unit 4Document16 pagesRE Unit 4PALAK GARGNo ratings yet

- Vibrational Analysis of Composite Twisted PlatesDocument2 pagesVibrational Analysis of Composite Twisted PlatesraghuNo ratings yet

- Project Work - Excitation SystemDocument58 pagesProject Work - Excitation SystemKaranki DineshNo ratings yet

- machine design, Vol.5 (2013) No.2, ISSN 1821-1259 pp. 79-82: Reducers For Main Drives Оf Rolling MillsDocument4 pagesmachine design, Vol.5 (2013) No.2, ISSN 1821-1259 pp. 79-82: Reducers For Main Drives Оf Rolling Millsrazen_inNo ratings yet

- Sabiha Gokcen International AirportDocument2 pagesSabiha Gokcen International AirportSumejaZukićNo ratings yet

- Speech Notes - Building NationsDocument5 pagesSpeech Notes - Building NationsAnonymous ptVOSrGNo ratings yet

- ASTM A234 A234M 23 - UnlockedDocument7 pagesASTM A234 A234M 23 - Unlockedrashid isaar0% (1)

- Chapter 8Document25 pagesChapter 8aung0024No ratings yet

- Staircase Pressurization Fan, What Is The Equation To Calculate The Air Flow and Static Pressure For Fan - Bayt PDFDocument3 pagesStaircase Pressurization Fan, What Is The Equation To Calculate The Air Flow and Static Pressure For Fan - Bayt PDFDesigner ForeverNo ratings yet

- ContinueDocument2 pagesContinuePramod RaghuNo ratings yet

- Abul Hassan Haveli Case StudyDocument10 pagesAbul Hassan Haveli Case StudyAyush RawatNo ratings yet

- Mold Cooling SystemDocument8 pagesMold Cooling SystemImedooImedNo ratings yet

- High-Workability Concrete High-Workability ConcreteDocument43 pagesHigh-Workability Concrete High-Workability ConcreteF Azam Khan AyonNo ratings yet

- Mobile Crane or Boom Truck Checklist Rev4Document2 pagesMobile Crane or Boom Truck Checklist Rev4maomontes100% (2)

- FAS Data-Sheet Vantage-Seal PDFDocument10 pagesFAS Data-Sheet Vantage-Seal PDFVictor Flores ResendizNo ratings yet

- Dow ELITE 5220G Enhanced Polyethylene ResinDocument2 pagesDow ELITE 5220G Enhanced Polyethylene Resinusman3549606No ratings yet

- Short Column DesignDocument7 pagesShort Column DesignNelsonDay100% (2)

- Boq Package 4-Mep Rumus1Document413 pagesBoq Package 4-Mep Rumus1Muhammad Iqbal ArdhiansyahNo ratings yet

- Is 4031-7 (1988) - Methods of Physical Tests For Hydraulic Cement, Part 7 - Determination of Compressive Strength of Masonry CementDocument4 pagesIs 4031-7 (1988) - Methods of Physical Tests For Hydraulic Cement, Part 7 - Determination of Compressive Strength of Masonry CementApurv PatelNo ratings yet

- SAF-03 Plant BuildingsDocument19 pagesSAF-03 Plant Buildingsluke100% (2)

- Change in Spaces: Adaptive Reuse From Residential To CommercialDocument33 pagesChange in Spaces: Adaptive Reuse From Residential To CommercialkeerthanaNo ratings yet

- Myron Braced TubeDocument7 pagesMyron Braced TubeAnass QawasmiNo ratings yet

- Koehler Rheology v1Document32 pagesKoehler Rheology v1ShriNo ratings yet

- Caterpillar Disassembly and Assembly Transmission 950g and 962g Wheel LoaderDocument20 pagesCaterpillar Disassembly and Assembly Transmission 950g and 962g Wheel Loaderpatrick100% (40)

- ButalejaDocument4 pagesButalejaSamuel WagemaNo ratings yet

- Excel Tulangan Slab On Pile 3Document2 pagesExcel Tulangan Slab On Pile 3panduNo ratings yet

- Construction AgreementDocument8 pagesConstruction AgreementChristopher JavierNo ratings yet

- SAEP-352 - Welding Procedures Review and Approval PDFDocument14 pagesSAEP-352 - Welding Procedures Review and Approval PDFsilvrsurfr637No ratings yet

- Sanitary Check ListDocument36 pagesSanitary Check ListankurNo ratings yet

- Steel Tanks For Fire ProtectionDocument21 pagesSteel Tanks For Fire ProtectionCkaal74No ratings yet

- 5 RFP Vol III Feasibility Report Part IIDocument40 pages5 RFP Vol III Feasibility Report Part IIAnil Kumsr T BNo ratings yet

- FRA MV Cable TerminationsDocument1 pageFRA MV Cable Terminationsmohamed1303No ratings yet

- Design and Analysis of Composite Drive Shaft For Automotive Application IJERTV3IS110410Document8 pagesDesign and Analysis of Composite Drive Shaft For Automotive Application IJERTV3IS110410frindgeNo ratings yet

- Neca 600 (Medium Voltage Cable)Document42 pagesNeca 600 (Medium Voltage Cable)UET MAIN100% (1)

- CATALOG 4660-Thermoplastic HoseDocument339 pagesCATALOG 4660-Thermoplastic HoseJose Antonio GomezNo ratings yet