Professional Documents

Culture Documents

Acceptance Criteria in Welding TableB

Uploaded by

anishk63360 ratings0% found this document useful (0 votes)

911 views1 pageCracks located in the weld metal or heat affected zone. Cracks shall not exceed 10% of the total. Undercut condition shall not create a notch in the undercut member.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCracks located in the weld metal or heat affected zone. Cracks shall not exceed 10% of the total. Undercut condition shall not create a notch in the undercut member.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

911 views1 pageAcceptance Criteria in Welding TableB

Uploaded by

anishk6336Cracks located in the weld metal or heat affected zone. Cracks shall not exceed 10% of the total. Undercut condition shall not create a notch in the undercut member.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

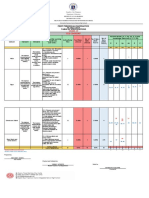

Defect ANSI A3.0 Definition Acceptance Criteria Defect ANSI A3.

0 Definition Acceptance Criteria

None Allowed.

Crack (weld) A crack located in 3 A groove melted 2. Base metal is greater than 0.25 inch in thickness:

the weld metal or Undercut a. Maximum depth of undercut shall be 1/32 inch

into the base metal

heat affected zone. 1 Weld metal crack adjacent to the weld b. Undercut must have a width no less than twice the

(continued) depth, i.e., the undercut condition shall not create a notch

2 Heat-affected-zone crack toe or weld root and

3 Base metal crack left unfilled by weld in the undercut member.

4 4 Crater crack metal. c. The length of undercut shall not exceed two inches

1 2 cumulative in any continuous 14 inch length of weld. For

continuous welds less than 24 inches in length, the

maximum cumulative length shall be in direct proportion to

The protrusion of The overlap condition shall not exceed 10% of the total Undercut this limit or one inch whichever is greater. (Example: for

Overlap Undercut

weld metal beyond weld length. an eight inch continuous length of weld, maximum

the weld toe or weld cumulative allowable undercut length is one inch.)

root. d. Melting of base metal on edges of material is not

Overlap considered to be undercut. It is acceptable provided:

(1) Weld seam meets the minimum size.

Overlap (2) Melting does not exceed 10% thickness for 10% of

Overlap weld length.

(3) Melting of corners is not considered to be undercut.

Melting shall not exceed 25% of material thickness

Contamination Cavity type 1. Maximum pore size shall be 1/16 inch diameter.

(porosity) discontinunities

formed by gas 2. Welds more than 12 inch long: There shall be no more

entrapment during than six pores for any twelve inch length of weld.

solidifacation or in a

Coldweld Weld metal does not None allowed.

thermal spray 3. Welds less than 12 inch long: There shall be Poor Penetration

deposit. proportionately less pores allowed (Example: A maximum penetrate the base metal Cold Weld

of six pores for six inches of weld.)

Good Penetration

Saw cut through weld

1. Base metal 0.25 inch and less in thickness:

Slag inclusion The surface of the The maximum depth of underfill shall be no greater than

Porosity Underfill weld metal is below 10% of the material thickness. The length of the undercut

the surface of the shall not exceed 10% of the weld length provided the weld

base metal seam meets minimum size.

Undercut A groove melted 1. Base metals 0.25 inch and less in thickness:

into the base metal a. The maximum depth of undercut shall be no greater 2. Base metal greater than 0.25 inch thickness:

adjacent to the weld than 10% of the material thickness which has the a. Maximum depth of underfill shall be 1/32 inch.

toe or weld root and undercut, the length of the undercut shall not exceed 10% b. The length of the underfill shall not exceed two inches

left unfilled by weld of weld length provided the weld seam meets minimum cumulative in any continuous 24 inch length of weld. For

metal. size. continuous welds less than 24 inches in length, the

Underfill

b. Maximum width of an undercut shall not exceed twice maximum cumulative length shall be in direct proportion to

the depth. Underfill this limit or one inch, whichever is greater. (Example: for

c. Melting of base metal on edges of material is not an eight inch continuous length of weld, maximum

Undercut considered to be undercut. It is acceptable provided: cumulative allowable underfill length is one inch.

(1) Weld seam meets the minimum size.

(2) Melting does not exceed 10% thickness for 10% of

weld length.

(3) Melting of corners is not considered to be undercut.

Melting shall not exceed 25% of material thickness.

You might also like

- 10 Essential Books For Active TradersDocument6 pages10 Essential Books For Active TradersChrisTheodorou100% (2)

- Sheet MetalDocument23 pagesSheet Metalvenkatesh07590% (21)

- WIS5 - Appendix 2Document86 pagesWIS5 - Appendix 2Reza Fakhrizal100% (1)

- Wire Rope Information SheetDocument3 pagesWire Rope Information SheetThanos Kazakos100% (1)

- IBPS Clerk Pre QUANT Memory Based 2019 QuestionsDocument8 pagesIBPS Clerk Pre QUANT Memory Based 2019 Questionsk vinayNo ratings yet

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesNavanitheeshwaran Sivasubramaniyam100% (3)

- Department of Education: Income Generating ProjectDocument5 pagesDepartment of Education: Income Generating ProjectMary Ann CorpuzNo ratings yet

- Tolerances As Per Aws D1.1: Structural Welding CodeDocument34 pagesTolerances As Per Aws D1.1: Structural Welding Codeegy pureNo ratings yet

- Acceptance CriteriaDocument1 pageAcceptance CriteriaRamzi Dol Abdul Wahid50% (2)

- 008.rtfi Notes - OkDocument19 pages008.rtfi Notes - OkVivekanandan JNo ratings yet

- RT Acceptance Criteria For Welder Test According To ASME Sec IX (QW 191 1.2)Document20 pagesRT Acceptance Criteria For Welder Test According To ASME Sec IX (QW 191 1.2)Oscar Iván Duque DiazNo ratings yet

- ستيل ستركشرDocument73 pagesستيل ستركشرAws SamaNo ratings yet

- Acceptance Level TWI SampleDocument1 pageAcceptance Level TWI SampleFadhlan D Luffy100% (1)

- Participant Observation: Qualitative Research Methods: A Data Collector's Field GuideDocument17 pagesParticipant Observation: Qualitative Research Methods: A Data Collector's Field GuideMarta CabreraNo ratings yet

- Table 6 1 AWS D1 1 D1 1M 2010 PDFDocument1 pageTable 6 1 AWS D1 1 D1 1M 2010 PDFFu AdNo ratings yet

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesDudy Pindayana FirdausNo ratings yet

- Mark Magazine#65Document196 pagesMark Magazine#65AndrewKanischevNo ratings yet

- A Junk Project - An Income Generating ProjectDocument2 pagesA Junk Project - An Income Generating ProjectHercules Verdeflor ValenzuelaNo ratings yet

- VT Acceptance Criteria PDFDocument10 pagesVT Acceptance Criteria PDFKalaivel ThandavarayanNo ratings yet

- LG Sigma+EscalatorDocument4 pagesLG Sigma+Escalator강민호No ratings yet

- Visual Acceptance AWS D1.1 StructuralDocument1 pageVisual Acceptance AWS D1.1 StructuralPamungkasNo ratings yet

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesTanveer Rajput EngrNo ratings yet

- Saudi Aramco: Company General UseDocument8 pagesSaudi Aramco: Company General UseMasudhBashaNo ratings yet

- Villamaria JR Vs CADocument2 pagesVillamaria JR Vs CAClarissa SawaliNo ratings yet

- Q4 Music 6 Module 2Document15 pagesQ4 Music 6 Module 2Dan Paolo AlbintoNo ratings yet

- Tabla 8.1 para No Tubulares AWS D1.1 2020 PDFDocument1 pageTabla 8.1 para No Tubulares AWS D1.1 2020 PDFRONALD100% (1)

- Aws Table 8.1 MT PTDocument1 pageAws Table 8.1 MT PTSugianto Tan Lok AnNo ratings yet

- Tolerance As Per AWS D1.1Document3 pagesTolerance As Per AWS D1.1milind bedarkarNo ratings yet

- Visual Inspection Acceptance Criteria (See: ProhibitionDocument1 pageVisual Inspection Acceptance Criteria (See: ProhibitionSaptarshi MandalNo ratings yet

- Cuadro de Inspeccion VisualDocument1 pageCuadro de Inspeccion VisualCESAR CHAVEZNo ratings yet

- Aceptance Criteria For Visual-2Document2 pagesAceptance Criteria For Visual-2ayuNo ratings yet

- Aws - D1.1M - 2020 - Llo 268Document1 pageAws - D1.1M - 2020 - Llo 268santiago cruzNo ratings yet

- API 1104 NDT AcceptanceDocument1 pageAPI 1104 NDT AcceptanceErAnisAlamNo ratings yet

- VT 2020Document2 pagesVT 2020stixxx420No ratings yet

- Steel CordDocument20 pagesSteel CordrajksharmaNo ratings yet

- Acceptence CriteriaDocument1 pageAcceptence CriteriaPraviBeetlesNo ratings yet

- Preheat Welding Document For Truck Bodies PDFDocument10 pagesPreheat Welding Document For Truck Bodies PDFCarlos LoboNo ratings yet

- Visual Inspection Acceptance CriteriaDocument2 pagesVisual Inspection Acceptance CriteriaJohn TerryNo ratings yet

- Acceptance PDFDocument2 pagesAcceptance PDFTijieichSuprihantoNo ratings yet

- Precision Plastic Industries PVT - LTDDocument1 pagePrecision Plastic Industries PVT - LTDsonu007adakNo ratings yet

- Cracking in Flexural Member Deflection in Flexural Member Eff I M I I Effective Moment Inertia Instantaneous and Long Term DeflectionDocument20 pagesCracking in Flexural Member Deflection in Flexural Member Eff I M I I Effective Moment Inertia Instantaneous and Long Term DeflectionMohamed AbdNo ratings yet

- 008rtfi Notes Okdoc CompressDocument19 pages008rtfi Notes Okdoc CompressShahid IqbalNo ratings yet

- Tis 0003 Webbing Straps and Ratchets Issue 1 British SteelDocument2 pagesTis 0003 Webbing Straps and Ratchets Issue 1 British SteelJuan AlfaroNo ratings yet

- Precision Plastic Industries PVT - LTDDocument1 pagePrecision Plastic Industries PVT - LTDsonu007adakNo ratings yet

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesShubham ShuklaNo ratings yet

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesShankar Pl GowdaNo ratings yet

- Acceptance Criteria of Weld DefectsDocument17 pagesAcceptance Criteria of Weld DefectsvikasNo ratings yet

- Tabla 8.1 Soldadura de Acero InoxidableDocument1 pageTabla 8.1 Soldadura de Acero InoxidableJuan Alberto Lopez SanchezNo ratings yet

- AWS D1 1-D1 1M-2015 Criterios de Inspeccion VisualDocument1 pageAWS D1 1-D1 1M-2015 Criterios de Inspeccion VisualGilberto ZamudioNo ratings yet

- Bag Filter Cage InspectionDocument3 pagesBag Filter Cage InspectionAhmad Nil ForoushanNo ratings yet

- CT String Design Methodology For Extended Reach ApplicationsDocument25 pagesCT String Design Methodology For Extended Reach ApplicationsPheng Kit WongNo ratings yet

- API 1104 Defects Acceptance Criteria FinalDocument3 pagesAPI 1104 Defects Acceptance Criteria FinalAbdul Wajid AliNo ratings yet

- CSR Acceptable CriteriaDocument6 pagesCSR Acceptable CriteriaRenju RameshwithuNo ratings yet

- Weld Acceptance StandardDocument2 pagesWeld Acceptance StandardLalit Bom Malla100% (2)

- Busduct Welds - Acceptance StandardDocument3 pagesBusduct Welds - Acceptance StandardSURENDRA NARAYANNo ratings yet

- Notching On BeamsDocument5 pagesNotching On BeamsRRussel CastroNo ratings yet

- Min Max Steel Reinforcement For SlabDocument1 pageMin Max Steel Reinforcement For SlabRodel, Jr. NatividadNo ratings yet

- Nema Rn1 1998Document1 pageNema Rn1 1998AXEL OMAR SANCHEZNo ratings yet

- Welded Connection - 3Document18 pagesWelded Connection - 3Ravi RawatNo ratings yet

- Auger BoringDocument6 pagesAuger BoringVipin GuptaNo ratings yet

- Nuclear Power Engineering (MEE 2027) : Fall Semester (2020-2021)Document13 pagesNuclear Power Engineering (MEE 2027) : Fall Semester (2020-2021)AllNo ratings yet

- LRAD Datasheet 2000XDocument2 pagesLRAD Datasheet 2000XOkkar MaungNo ratings yet

- Liquid Chlorine SdsDocument7 pagesLiquid Chlorine SdsIPKL RS BHAYANGKARA KEDIRINo ratings yet

- Morse Potential CurveDocument9 pagesMorse Potential Curvejagabandhu_patraNo ratings yet

- Footing - f1 - f2 - Da RC StructureDocument42 pagesFooting - f1 - f2 - Da RC StructureFrederickV.VelascoNo ratings yet

- The International Poker RulesDocument2 pagesThe International Poker RulesOutontheBubbleNo ratings yet

- Internal Analysis: Pertemuan KeDocument15 pagesInternal Analysis: Pertemuan Kekintan utamiNo ratings yet

- 3rd Page 5Document1 page3rd Page 5api-282737728No ratings yet

- Restaurant Report Card: February 9, 2023Document4 pagesRestaurant Report Card: February 9, 2023KBTXNo ratings yet

- Practical Cs Xii Mysql 2022-23 FinalDocument9 pagesPractical Cs Xii Mysql 2022-23 FinalHimanshu GuptaNo ratings yet

- The Piano Lesson Companion Book: Level 1Document17 pagesThe Piano Lesson Companion Book: Level 1TsogtsaikhanEnerelNo ratings yet

- Intervensi Terapi Pada Sepsis PDFDocument28 pagesIntervensi Terapi Pada Sepsis PDFifan zulfantriNo ratings yet

- ArcGIS Shapefile Files Types & ExtensionsDocument4 pagesArcGIS Shapefile Files Types & ExtensionsdanangNo ratings yet

- III.A.1. University of Hawaii at Manoa Cancer Center Report and Business PlanDocument35 pagesIII.A.1. University of Hawaii at Manoa Cancer Center Report and Business Planurindo mars29No ratings yet

- Revised Final Quarter 1 Tos-Rbt-Sy-2022-2023 Tle-Cookery 10Document6 pagesRevised Final Quarter 1 Tos-Rbt-Sy-2022-2023 Tle-Cookery 10May Ann GuintoNo ratings yet

- Using The Monopoly Board GameDocument6 pagesUsing The Monopoly Board Gamefrieda20093835No ratings yet

- CoSiO2 For Fischer-Tropsch Synthesis Comparison...Document5 pagesCoSiO2 For Fischer-Tropsch Synthesis Comparison...Genesis CalderónNo ratings yet

- MECANISMOS de Metais de TransicaoDocument36 pagesMECANISMOS de Metais de TransicaoJoão BarbosaNo ratings yet

- Lesson: The Averys Have Been Living in New York Since The Late NinetiesDocument1 pageLesson: The Averys Have Been Living in New York Since The Late NinetiesLinea SKDNo ratings yet

- Agile ModelingDocument15 pagesAgile Modelingprasad19845No ratings yet

- TW BT 01 - Barstock Threaded Type Thermowell (Straight) : TWBT - 01Document3 pagesTW BT 01 - Barstock Threaded Type Thermowell (Straight) : TWBT - 01Anonymous edvYngNo ratings yet