Professional Documents

Culture Documents

Correcting An Angle of Loll

Uploaded by

Bharatiyulam0 ratings0% found this document useful (0 votes)

247 views6 pagesOriginal Title

Correcting an angle of loll

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

247 views6 pagesCorrecting An Angle of Loll

Uploaded by

BharatiyulamCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 6

CORRECTING AN ANGLE OF LOLL

During the course of a voyage the stability of the ship should be

closely monitored. It is recommended that a calculation of fluid

GM and a corresponding GZ curve be produced for the worst

anticipated condition. Calculations should be done for both

departure and anticipated arrival conditions, these being

adjusted to suit any changes that may take place as the voyage

progresses.

An angle of loll situation may arise in ships carrying timber

deck cargoes. Deck cargoes will absorb moisture causing G to

rise. Fuel and water will also be consumed from low down in

the ship raising G further due to the removal of weight from

low down in the ship and the introduction of free surfaces in

tanks that may have been initially full. These effects should be

accounted for. Poor tank management may cause excessive free

surface moments, leading to a similar loss of stability.

Unfortunately things do not always go to plan and mistakes

may be made in calculations. Any number of things might

happen such as a collision or a fire where water is introduced

into a compartment for fire fighting purposes.

Whatever the cause, a situation might arise whereby you find

that the ship is lying at an unexpected angle of inclination.

It is not possible to ascertain easily whether a ship is listed or

lolled and since the remedial action for each case is very

different it is essential that the cause of the inclination be

carefully investigated.

Correcting an angle of loll 1

(MAR Rev. 18/09/01)

The following procedures should be carefully observed:

1. Alter course to put the ship’s head into the

predominant waves.

If the ship is in a lolled situation it is essential that the ship

stays lolled to the same side. Wave action may cause the ship to

roll through the vertical to loll on the other side. This is a

dangerous situation since the ship will heel from the vertical of

it’s own accord and the momentum it will have in lolling over

to the other side may be sufficient to capsize it. In any event,

the ship will initially heel beyond the angle of loll before

settling at the angle of loll whereby cargo shift may result

which will worsen the situation further.

2. Check that port and starboard listing moments are

the same.

By verifying tank soundings and checking for cargo shift it

should be possible to account for any listing moments that may

cause the ship to be in a listed situation. If it is calculated that

there are no net listing moments then a case of instability may

be assumed and the ship will be lying at an angle of loll.

3. Check for slack tanks

In carrying out (2) above it should also be evident if there are

excessive free surface moments causing a loss of GM sufficient

enough to make the ship unstable. In this case a loll situation

may be confirmed.

Correcting an angle of loll 2

(MAR Rev. 18/09/01)

4. Take action to lower G (reduce KG)

It would be impractical to consider shifting weights on board

using ship’s lifting equipment at sea. If the ship has high ballast

tanks that are full then these may be emptied, discharging

ballast from the high side tank first - the greater vertical

distance between G of the ship and g of the weight being

discharged will ensure that the greatest lowering of G will

take place in the first instance.

Once the high side tank is empty the one on the low side may

then be emptied.

g

G

Correcting an angle of loll 3

(MAR Rev. 18/09/01)

5. Minimise Free surfaces

Having sounded all the tanks any that are slack will be

identified. Minimise the loss of GM due to free surface effect

by topping up low down ballast tanks and transferring fuel as

necessary. This action alone may remedy the situation.

6. Ballast tanks low down in the ship

Select a set of suitably subdivided double bottom tanks to

ballast. Ideally start with tanks that have the smallest free

surface areas to minimise the effects of free surface whilst

filling. The order of filling is as follows and must be strictly

adhered to:

(a) Start by filling the tank on the low side (No. 1) as

shown. Because of the introduction of more free

surfaces whilst filling the situation will initially

worsen.

Correcting an angle of loll 4

(MAR Rev. 18/09/01)

(b) When the first tank is completely full, fill the centre

tank (No. 2).

(c) When the centre tank is full, fill the final tank (No. 3)

(d) If G is lowered sufficiently then the ship should

complete in an upright condition (having initially

verified that the port and starboard moments were the

same).

The movement of G after completely filling each of the tanks is

as shown (ignoring the upward movement of G which arises as

a result of the introduced free surface at intermediate stages of

filling the tanks).

G

G1

G3 G2

3 2 1

If the situation is not remedied then a second set of tanks must

be chosen for filling, the process is repeated.

Correcting an angle of loll 5

(MAR Rev. 18/09/01)

Note

Once a loll situation is confirmed only ever fill one tank at a

time.

Always start by filling the low side tank first.

The angle of loll may initially worsen because the introduced

free surfaces when initially starting to fill the tank may cause

a greater rise of G than the fall of G caused by the added

bottom weight. Hence the importance of filling small tanks

first.

If there is any doubt as to whether the ship is lolled or listed,

always assume it is a lolled situation and take appropriate

action.

When correcting a list it is sufficient to shift a weight to the

high side. This may be achieved by shifting weights on deck or

by transferring ballast from a listed side tank to a high side

tank. Alternatively, excess ballast from the listed side (possibly

low down in the ship) may be discharged.

To treat a loll situation in the same way would have disastrous

consequences for reasons already explained!

Correcting an angle of loll 6

(MAR Rev. 18/09/01)

You might also like

- Stability Theory With Ques and AnsDocument25 pagesStability Theory With Ques and AnsAnkit BatraNo ratings yet

- Stability of Ship While Dry DockingDocument3 pagesStability of Ship While Dry DockingT Vigneshwar0% (1)

- Factors Affecting GZ CurvesDocument11 pagesFactors Affecting GZ CurvesAbdallah Mansour100% (2)

- Orals SafetyDocument2 pagesOrals Safetycaptyashpal100% (3)

- 1a.3 - Bridge Watchkeeping LevelsDocument8 pages1a.3 - Bridge Watchkeeping LevelsRaghav SoodNo ratings yet

- Factors Affecting GZ CurvesDocument11 pagesFactors Affecting GZ CurvesBharatiyulam100% (3)

- B1b StabilityDocument17 pagesB1b StabilityDarwin Neil MoranoNo ratings yet

- Sqa Oow Navigation Answers For Theory PartDocument74 pagesSqa Oow Navigation Answers For Theory PartNelum Perera100% (1)

- Stability SqaDocument20 pagesStability SqaSujeet sharma100% (1)

- Chain RegisterDocument2 pagesChain RegisterSachin chaudharyNo ratings yet

- Ror (20791)Document60 pagesRor (20791)Aamir Sirohi100% (2)

- Stability Theory - OOW-2Document23 pagesStability Theory - OOW-2Lovepreet ShahNo ratings yet

- Loadicator RequirementsDocument6 pagesLoadicator RequirementsMariner's Circle100% (1)

- Function 1 OralsDocument71 pagesFunction 1 OralsTojo T VargheseNo ratings yet

- Magnetic Compass - Oral COCDocument10 pagesMagnetic Compass - Oral COCNaeem100% (1)

- OOW ORAL Flash Card NotesDocument98 pagesOOW ORAL Flash Card NotesTyrone Sharp100% (4)

- Part 18-Grain, Damage Control PlanDocument5 pagesPart 18-Grain, Damage Control Planaungthein_san100% (1)

- 3-Short Notes For Masters Oral ExamDocument461 pages3-Short Notes For Masters Oral ExamAlberto Neri100% (2)

- Orals MCQDocument9 pagesOrals MCQaungthein_sanNo ratings yet

- Stability MCA OOW June 2005Document6 pagesStability MCA OOW June 2005Tom Alex100% (1)

- Radar Plotting SheetDocument1 pageRadar Plotting SheetCl dubeyNo ratings yet

- 4 - ManevraDocument44 pages4 - ManevraIulian Sandru100% (1)

- Initial Transverse MetacentreDocument9 pagesInitial Transverse MetacentreBharatiyulam100% (1)

- NAVIGATION SolutionDocument40 pagesNAVIGATION SolutionMd Monir Hossain100% (2)

- Grain Loading Stability BookletDocument1 pageGrain Loading Stability Bookletshivajinarvekar50% (2)

- Oow Couse Information (Ljmu)Document23 pagesOow Couse Information (Ljmu)Rupesh KumarNo ratings yet

- GZ CurvesDocument30 pagesGZ CurvesUtkarsh Mane100% (3)

- 23 SQA NAV Gangaram Theory-1Document23 pages23 SQA NAV Gangaram Theory-1kumarNo ratings yet

- Stability Sqa Oow Wed - 8 February 2017Document6 pagesStability Sqa Oow Wed - 8 February 2017Stelios TheodorouNo ratings yet

- Fse On Ship StabilityDocument34 pagesFse On Ship StabilityVinodh KumarNo ratings yet

- Grain CalculationDocument11 pagesGrain CalculationWunna Tint Way100% (2)

- Oral Question MateDocument7 pagesOral Question Matewanazizwanmad100% (3)

- Bouy FlashcardsDocument14 pagesBouy FlashcardsTushar Rathod100% (2)

- SQA BM SQA Answers 2005-2012 NewDocument60 pagesSQA BM SQA Answers 2005-2012 NewRahul Saini50% (2)

- CH 05 Circumpolar BodiesDocument2 pagesCH 05 Circumpolar BodiesAmit Pandey100% (2)

- Ship S Stability PDFDocument17 pagesShip S Stability PDFKalaivani PeriyasamyNo ratings yet

- GRAINCALCNCBDocument8 pagesGRAINCALCNCBwaleedyehia100% (1)

- Rendezvous ProblemDocument4 pagesRendezvous ProblemTachy Cho100% (1)

- Ship HandlngDocument3 pagesShip Handlngcaptyashpal100% (4)

- Orals MetDocument3 pagesOrals MetcaptyashpalNo ratings yet

- Marine Gyro Compasses For Ships OfficersDocument82 pagesMarine Gyro Compasses For Ships OfficersCarlie West100% (2)

- Change in Trim Due To Change in DensityDocument4 pagesChange in Trim Due To Change in Densitygipanaul60% (5)

- Stability Notes:-Bulk Grain CargoesDocument2 pagesStability Notes:-Bulk Grain CargoesSankar Ganesh100% (1)

- Dynamic UKC CalculationDocument10 pagesDynamic UKC CalculationCagatay alpNo ratings yet

- Celestial Navigation Notes 2019 v1.1Document15 pagesCelestial Navigation Notes 2019 v1.1Ashish100% (1)

- SMSS-994 Answer KeyDocument3 pagesSMSS-994 Answer KeyAmir SoleimanyNo ratings yet

- OOW Oral - July 2011Document5 pagesOOW Oral - July 2011Lau EscamillaNo ratings yet

- 1MFG Function 1Document176 pages1MFG Function 1Rohit RajNo ratings yet

- Abort Point and Point of No Return in Voyage PlanningDocument5 pagesAbort Point and Point of No Return in Voyage Planninglanguyentuelam100% (2)

- Ship Stability NomenclatureDocument6 pagesShip Stability NomenclatureRoderick EstrellaNo ratings yet

- 2nd Mate Past Question Papers Till Nov18 1Document143 pages2nd Mate Past Question Papers Till Nov18 1arbaazNo ratings yet

- 2MFG - MMD Ques Set Till July 2018 PDFDocument327 pages2MFG - MMD Ques Set Till July 2018 PDFindumarnicaraguaNo ratings yet

- Ship Magnetism and the Magnetic Compass: The Commonwealth and International Library of Science, Technology, Engineering and Liberal Studies: Navigation and Nautical CoursesFrom EverandShip Magnetism and the Magnetic Compass: The Commonwealth and International Library of Science, Technology, Engineering and Liberal Studies: Navigation and Nautical CoursesRating: 5 out of 5 stars5/5 (3)

- Oral Preparation Watch Keeper Deck Mates: Question and Answer GuidelinesFrom EverandOral Preparation Watch Keeper Deck Mates: Question and Answer GuidelinesRating: 5 out of 5 stars5/5 (1)

- Collisions at Sea: Volume 1: Liability and the Collision RegulationsFrom EverandCollisions at Sea: Volume 1: Liability and the Collision RegulationsNo ratings yet

- Marine Gyro-Compasses and Automatic Pilots: A Handbook for Merchant Navy OfficersFrom EverandMarine Gyro-Compasses and Automatic Pilots: A Handbook for Merchant Navy OfficersRating: 5 out of 5 stars5/5 (1)

- Tanker Disasters: IMO's Places of Refuge and the Special Compensation Clause; Erika, Prestige, Castor and 65 CasualtiesFrom EverandTanker Disasters: IMO's Places of Refuge and the Special Compensation Clause; Erika, Prestige, Castor and 65 CasualtiesNo ratings yet

- Code of Safe Working Practices for Merchant Seafarers: Consolidated edition (incorporating amendments 1-6)From EverandCode of Safe Working Practices for Merchant Seafarers: Consolidated edition (incorporating amendments 1-6)No ratings yet

- Sila Silpam NuvveDocument204 pagesSila Silpam NuvveBharatiyulamNo ratings yet

- NATUECO Book PDFDocument112 pagesNATUECO Book PDFpuvichandranNo ratings yet

- Kabeer Suktimuktavali Sankara Sreeramarao 1960Document76 pagesKabeer Suktimuktavali Sankara Sreeramarao 1960BharatiyulamNo ratings yet

- Horticultural Society, Hyderabad - Diary 2022Document476 pagesHorticultural Society, Hyderabad - Diary 2022BharatiyulamNo ratings yet

- Nature Book PDFDocument2 pagesNature Book PDFBharatiyulam100% (1)

- Vaaradhi With SEVA OrgDocument10 pagesVaaradhi With SEVA OrgBharatiyulamNo ratings yet

- Antioxidant SSR PDFDocument81 pagesAntioxidant SSR PDFBharatiyulamNo ratings yet

- Power Train Components MJHDocument17 pagesPower Train Components MJHBharatiyulamNo ratings yet

- EPU of Bio-Pesticides PDFDocument170 pagesEPU of Bio-Pesticides PDFBharatiyulamNo ratings yet

- Welcome: SEVA Org. & BharatiyulamDocument20 pagesWelcome: SEVA Org. & BharatiyulamBharatiyulamNo ratings yet

- Okka Rupayee Chaalu BharatiyulamDocument2 pagesOkka Rupayee Chaalu BharatiyulamManindar KumarNo ratings yet

- Bharatiyulam Invitation For You On Facebook Forward ItDocument1 pageBharatiyulam Invitation For You On Facebook Forward ItBharatiyulamNo ratings yet

- Online Seat Booking For ExaminationDocument6 pagesOnline Seat Booking For ExaminationBharatiyulam100% (1)

- Meo Examination Part-Check ListDocument2 pagesMeo Examination Part-Check ListArun PrasadNo ratings yet

- Prevention of Static ElectricityDocument1 pagePrevention of Static ElectricityBharatiyulamNo ratings yet

- PRESTIGEDocument3 pagesPRESTIGEBharatiyulamNo ratings yet

- PollutionDocument12 pagesPollutionBharatiyulamNo ratings yet

- Overseas Cadet ProgrammesDocument3 pagesOverseas Cadet ProgrammesBharatiyulamNo ratings yet

- MCA Stability BookletDocument19 pagesMCA Stability BookletBharatiyulam0% (1)

- Petroleum OilDocument5 pagesPetroleum OilgunapalshettyNo ratings yet

- The Magnetic Compass CardDocument148 pagesThe Magnetic Compass CardBharatiyulamNo ratings yet

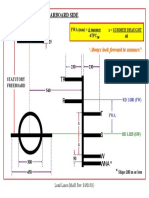

- Load Line DiagramDocument1 pageLoad Line DiagramBharatiyulamNo ratings yet

- Mca Formula SheetDocument4 pagesMca Formula SheetBharatiyulamNo ratings yet

- Oil SpillsDocument5 pagesOil SpillsBharatiyulamNo ratings yet

- Navigation FormulaeDocument1 pageNavigation FormulaeBharatiyulam100% (1)

- The M. S. (Load Line) Regulations 1998 (Amended 2000)Document4 pagesThe M. S. (Load Line) Regulations 1998 (Amended 2000)BharatiyulamNo ratings yet

- MAM - I, Question BankDocument8 pagesMAM - I, Question BankBharatiyulamNo ratings yet

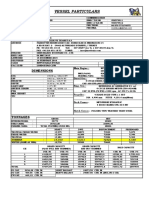

- Final Ince Tokyo Ship ParticularsDocument1 pageFinal Ince Tokyo Ship ParticularsSupplyNo ratings yet

- Stability Assessment Methods (Deterministic and Probabilistic)Document29 pagesStability Assessment Methods (Deterministic and Probabilistic)Md. Ashfaq SiddiqueeNo ratings yet

- A.184 Mod.3: Heavy Weight TorpedoDocument2 pagesA.184 Mod.3: Heavy Weight TorpedoPutra AdamNo ratings yet

- Questions For 1e InterviewDocument3 pagesQuestions For 1e InterviewThiet Pham100% (1)

- Puli Q88Document7 pagesPuli Q88ImmorthalNo ratings yet

- PONTA DA MADEIRA (PDM) Port - Line Up 30-MAY-2022Document6 pagesPONTA DA MADEIRA (PDM) Port - Line Up 30-MAY-2022Capital Shipping ServicesNo ratings yet

- Wreck SitesDocument10 pagesWreck SitespokerdazNo ratings yet

- Thales UMS 4110Document2 pagesThales UMS 4110Anonymous BrUMhCjbiBNo ratings yet

- Semi SubmersibleDocument23 pagesSemi SubmersibleSrinivasan RajenderanNo ratings yet

- Local Media4291495270671487859Document2 pagesLocal Media4291495270671487859Dimasalang PerezNo ratings yet

- CV Servinus Un PDFDocument2 pagesCV Servinus Un PDFWenNo ratings yet

- Soal PertaminaDocument4 pagesSoal PertaminaRio Cahyo PratamaNo ratings yet

- Haldia Draft Sep 2020Document2 pagesHaldia Draft Sep 2020Mohit DhaulNo ratings yet

- General Arrangement PDFDocument33 pagesGeneral Arrangement PDFJeesonAntonyNo ratings yet

- BC Midship Section MeasuringDocument1 pageBC Midship Section MeasuringΑλέξης ΚριτσωτάκηςNo ratings yet

- Frank Morley GurneyDocument2 pagesFrank Morley GurneyAnnette EdwardsNo ratings yet

- Dictionary of Shipping TermsDocument64 pagesDictionary of Shipping TermsseitancornelNo ratings yet

- Navsea 9997 1 83Document9 pagesNavsea 9997 1 83Anbarasan AnandhanNo ratings yet

- Special Upgrades Special Upgrades: Kraken Missile Kaos Polarizing MineDocument2 pagesSpecial Upgrades Special Upgrades: Kraken Missile Kaos Polarizing MineLouis Duranleau-HendrickxNo ratings yet

- Contoh CV Pelaut Baru Keren PDFDocument2 pagesContoh CV Pelaut Baru Keren PDFMuhammad IchsanNo ratings yet

- Hal Vo Deck Plan 050822Document9 pagesHal Vo Deck Plan 050822sherbetNo ratings yet

- Critical Areas of Structural Concerns On Bulk Carriers / Dry Cargo ShipsDocument5 pagesCritical Areas of Structural Concerns On Bulk Carriers / Dry Cargo ShipsHUNG LE THANHNo ratings yet

- Demurrage CalculationsDocument1 pageDemurrage CalculationsJuan Ramón FuentesNo ratings yet

- Reviewer in SEAM 2 MidtermDocument13 pagesReviewer in SEAM 2 MidtermJazmin Goloso100% (1)

- Shiporganization 13276162475818 Phpapp01 120126162058 Phpapp01Document57 pagesShiporganization 13276162475818 Phpapp01 120126162058 Phpapp01Krishna Das KotaNo ratings yet

- Ship OrganizationDocument15 pagesShip OrganizationCatalin Apetre100% (1)

- Ecareg Reporting RequirementsDocument3 pagesEcareg Reporting RequirementsDane WandererNo ratings yet

- US Navy Submarine Casualties Booklet 1966Document268 pagesUS Navy Submarine Casualties Booklet 1966david_bober_2100% (3)

- 03 BulkheadDocument9 pages03 BulkheadLucky BoatNo ratings yet

- Guidelines For Iws MSC Circ 1348Document6 pagesGuidelines For Iws MSC Circ 1348Ignacio SantanaNo ratings yet