Professional Documents

Culture Documents

Blind Flange Design Calculations

Uploaded by

guru22Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Blind Flange Design Calculations

Uploaded by

guru22Copyright:

Available Formats

DESIGN CALCULATIONS OF HEAT EXCHANGER

According to ASME Code, Sec. VIII, Div. 1, Edition 2001, Addenda 2002 / TEMA "R" 7th Edition 88. Designed by : Eng. Abdel Halim Galala, Design General Manager (Assistant)

Page : 76 of 136 Sheet : 1 of 6 Rev. : 0

Project : Design & Fabrication of Heat Exchanger for APRC Refinery Job No. : 7443-33 Dwg. No. : 7443-33-1A, Rev. 0 Exchanger : Residue Cooler, Type : AES, TEMA class : R

Sheet : 14

Date : 4.7.2003 Location : Alex. Client : APRC

Item : E-323A/B & E-514C/D

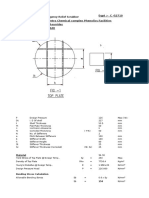

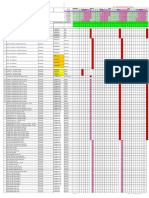

P. Flat Unstayed Circular Blind Flange(Channel Cover) Thickness (item no. 22) [UG-34 & Fig. UG-34 Sketch (j)] [Attached by Bolts] Subjected to internal pressure Blind Cover Material, Clad Metal : SB171 UNS No. C63000 ASME SA266 Class 2 Stud bolt material SA 193 Grade B7 o o F C Design Temperature 140 60 o o Min. Design Metal Temperature, MDMT F C 53.6 12 o o F C Bolt-up and Gasket Seating Temperature 86 30 Assume corrosion allowance, C [UG-25] 0.19685 INCH 5 MM Kg/CM2G Operating Pressure (tube side) 56.8182 PSIG 4 Internal Design Pressure, P (MAWP) 71.7082 PSIG 5.04826 Kg/CM2G Allowable Stress of Bolt Material, SB : * at design temp.(operating condition), Sb * or at atmospheric temp./bolt-up temp. (gasket seating), Sa Allowable Stress of Flange Material : * at design temp.(operating condition), SfH * or at atmospheric temp./bolt-up temp. (gasket seating), SfC [Table 1A , SubPart 1 , ASME Sec. II , Part D] Joint efficiency, E Bolt Hole, Flange outside diameter, A Bolt circut diameter (B.C.D.), 25000 25000 20000 20000 1 1.10236 26.9685 24.5276

INCH INCH INCH

PSIG PSIG PSIG PSIG

1760 1760 1408 1408

Kg/CM2G Kg/CM2G Kg/CM2G Kg/CM2G

28 685 623

MM MM MM

Fig. UG-34, Sketch (j) Figure (5)

No. of bolts Nominal bolt dia., dB Actual cross-sectional area of each bolt, Total actual cross-sectional area of bolts, Ab Flange face outer diameter Flange face inner diameter

[TEMA Table D-5]

28 1 0.551 15.428 22.1654 19

INCH INCH2 INCH INCH INCH

2

25.4 355.4832 9953.528 563 482.6

MM MM2 MM2

MM MM

DESIGN CALCULATIONS OF HEAT EXCHANGER

According to ASME Code, Sec. VIII, Div. 1, Edition 2001, Addenda 2002 / TEMA "R" 7th Edition 88. Designed by : Eng. Abdel Halim Galala, Design General Manager (Assistant)

Page : 77 of 136 Sheet : 2 of 6 Rev. : 0

Project : Design & Fabrication of Heat Exchanger for APRC Refinery Job No. : 7443-33 Dwg. No. : 7443-33-1A, Rev. 0 Exchanger : Residue Cooler, Type : AES, TEMA class : R

Sheet : 14

Date : 4.7.2003 Location : Alex. Client : APRC

Item : E-323A/B & E-514C/D

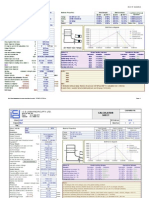

P. Flat Unstayed Circular Blind Flange (Channel Cover) Thickness (item no. 22) (cont.) [Attached by Bolts] [UG-34 & Fig. UG-34 Sketch (j)] Gasket Details: - Flat metal, jacketed asbestos filled, soft copp[er or brass - Outside diameter - Inside diameter = O.D - 2N - Width, N Gasket Dimensions: Basic gasket seating width, bO = N/2 [Table 2-5.2] Since bo > 1/4 ", Effective gasket seating width, b = 0.5 SQRT(bO) [Table [Table 2-5.1] Gasket Factor, m Min. Seating Stress, y [Table 2-5.1] Facing Sketch [Table 2-5.1] 0.125 22.0472 20.8661 0.59055 0.29528

INCH INCH INCH INCH INCH

3.175 560 530 15 7.5

MM MM MM MM MM

0.2717 INCH 3.5 6500 PSIG (1a); Column II

6.901087 MM 457.6

Kg/CM2G

Diameter at location of gasket load reaction, d ( d represnts G ) When bo is larger than 1/4", d = O.D.of gasket contact face - 2 b [Appendix 2-3]

21.5039

INCH

546.1978 MM

Factor depending upon method of attachment of head, C [Fig. UG-34, Sketch (j)] 0.3 Gasket moment arm, hG = (B.C.D - d)/2 = (C-G)/2 [Table 2-5.2] 1.51185

INCH

38.40109 MM

Calculating the Min. required Thickness of Blind Flange, t: [UG-34(c)(2)] t = d CP/SE +1.9W hG /SEd3 When using this formula, the thickness t shall be calculated for both operating conditions, and gasket seating, and the greater of the two values shall be used.

SA 193 Grade B7 o F 100 140 PSI 25000 ? ASME SA266 Class 2 o F 100 140 PSI 20000 ?

150 25000 200 20000

DESIGN CALCULATIONS OF HEAT EXCHANGER

According to ASME Code, Sec. VIII, Div. 1, Edition 2001, Addenda 2002 / TEMA "R" 7th Edition 88. Designed by : Eng. Abdel Halim Galala, Design General Manager (Assistant)

Page : 78 of 136 Sheet : 3 of 6 Rev. : 0

Project : Design & Fabrication of Heat Exchanger for APRC Refinery Job No. : 7443-33 Dwg. No. : 7443-33-1A, Rev. 0 Exchanger : Residue Cooler, Type : AES, TEMA class : R

Sheet : 14

Date : 4.7.2003 Location : Alex. Client : APRC

Item : E-323A/B & E-514C/D

P. Flat Unstayed Circular Blind Flange (Channel Cover) Thickness (item no. 22) (cont.)

[Attached by Bolts] [UG-34 & Fig. UG-34 Sketch (j)]

Calculating the total bolt load, W (for circular heads): 1. For operating conditions, the value of P shall be the design pressure, and the value of S at the design temperature and W from Formula (3) of 2-5(e) shall be used. Flange Design Bolt Load for circular heads, W [Appendix 2-5(e)] For operating conditions, W = Wm1 (3) Wm1 = H + Hp = 0.785 G2P + (2b x 3.14 GmP) (1) [Appendix 2-5(e35243.2 Flange thickness

t = d CP / SE + 1.9Wh G / SEd^ 3

lb INCH

15986.05 Kg 21.74301 MM

0.85602

2. For gasket seating, P equals zero, and the values of S at atmospheric and W from Formula (4) of 2-5(e) shall be used.

[UG-34(c)(2)]

P S [Appendix 2-5(e)] Flange Design Bolt Load for circular heads, W For gasket seating, W = 0.5(Am + Ab) Sa (4) Total required cross-sectional area of bolts, Am = Max (Am1,Am2) Required bolt load under atmospheric temp.conditions, Wm2 = 3.14bGy * Total cross-sectional area of bolts at root of thread requiired Am1 = Wm1/ Sb at operating conditions , * Total cross-sectional area of bolts at root of thread required gasket seating, Am2 = Wm2/ Sa Total required cross-sectional area of bolts, Am = Max (Am1,Am2) For gasket seating, W = 0.5(Am + Ab) Sa (4)

0 20000

PSIG PSIG

0 1408

Kg/CM2G Kg/CM2G

(2) 119246

lb

54089.04 Kg

1.40973

INCH2

909.4991 MM2

4.76983 4.76983 252473 1.29857 1.29857 1.29921 2.00787 2.48031

INCH2 INCH2

3077.304 MM2 3077.304 MM2 114519.9 Kg 32.98372 MM 32.98372 MM 33 MM 51 MM 63 MM

lb

INCH INCH INCH INCH INCH

t = d CP / SE + 1 .9Wh G / SEd^ 3

t = max. of t of operating and gasket seating Use t without corrosion allowance Use t for construction including R.F. N.B. Check which the deflection is considered a governing thickness or not. The deflection is ehe governing thickness

DESIGN CALCULATIONS OF HEAT EXCHANGER

According to ASME Code, Sec. VIII, Div. 1, Edition 2001, Addenda 2002 / TEMA "R" 7th Edition 88. Designed by : Eng. Abdel Halim Galala, Design General Manager (Assistant)

Page : 79 of 136 Sheet : 4 of 6 Rev. : 0

Project : Design & Fabrication of Heat Exchanger for APRC Refinery Job No. : 7443-33 Dwg. No. : 7443-33-1A, Rev. 0 Exchanger : Residue Cooler, Type : AES, TEMA class : R

Sheet : 14

Date : 4.7.2003 Location : Alex. Client : APRC

Item : E-323A/B & E-514C/D

P. Flat Unstayed Circular Blind Flange (Channel Cover) Thickness (item no. 22) (cont.) [Attached by Bolts] [UG-34 & Fig. UG-34 Sketch (j)]

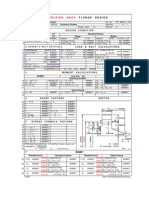

CONCLUSION:

FLANGE SUMMARY Flange thickness (without C.A.) Use t for construction including R.F. For a proper design of flange : 1. You have to make a check for flange deflection. 1.29857 2.04724

INCH INCH

32.98372 MM 52 MM

GASKET SUMMARY Gasket width, N Required cross-sectional of bolts, Am Actual cross-sectional area of bolts, Ab BOLT SUMMARY No. of bolts Size of bolt (the bolt size is represented by its actual cross-sectional area) Bolt hole dia. Total required cross-sectional area of bolts, Am Total actual cross-sectional area of bolts, Ab Actual cross-sectional area of bolt, [TEMA TABLE D-5]

0.59055 4.76983 15.428

INCH INCH2 INCH2

15 MM 3077.304 MM2 9953.528 MM2

28 1 1.125 4.76983 15.428 0.551

Bolt

INCH INCH INCH2 INCH2 INCH2

25.4 28.575 3077.304 9953.528 355.4832

MM MM

MM2 MM2 MM2

Since the actual bolt area Ab > The required bolt area Am, the bolts are adequately enough. N.B. When using bolt with size Total required cross-sectional area of bolts, Am Total ctual cross-sectional area of bolts, Ab Actual cross-sectional area of bolt, [TEMA TABLE D-5] Since the actual bolt area Ab < The required bolt area Am, the bolts are inadequately enough. Edge distance, E from drawing = 1/2 (A - C) Min. Edge distance, E (for bolt size 0.75") Min. Edge distance, E (for bolt size 1") Min. edge distance, E (for bolt size 1-1/8") [TEMA Table D-5] Min. Edge distance, E (for bolt size 1.25") 0.75 4.76983 8.456 0.302 INCH INCH2 INCH2 INCH2 NA

1.22047 0.8125 1.0625 1.125 1.25

INCH INCH INCH INCH INCH

31 20.6375 26.9875 28.575 31.75

MM MM MM MM MM

DESIGN CALCULATIONS OF HEAT EXCHANGER

According to ASME Code, Sec. VIII, Div. 1, Edition 2001, Addenda 2002 / TEMA "R" 7th Edition 88. Designed by : Eng. Abdel Halim Galala, Design General Manager (Assistant)

Page : 80 of 136 Sheet : 5 of 6 Rev. : 0

Project : Design & Fabrication of Heat Exchanger for APRC Refinery Job No. : 7443-33 Dwg. No. : 7443-33-1A, Rev. 0 Exchanger : Residue Cooler, Type : AES, TEMA class : R

Sheet : 14

Date : 4.7.2003 Location : Alex. Client : APRC

Item : E-323A/B & E-514C/D

P. Flat Unstayed Circular Blind Flange (Channel Cover) Thickness (item no. 22) (cont.) [Attached by Bolts] [UG-34 & Fig. UG-34 Sketch (j)] Actual Bolt spacing, B (c/c) from drawing 2.74622 INCH Min. Bolt spacing, B (for bolt size 0.75") 1.75 INCH Min. Bolt spacing, B (for bolt size 7/8") [TEMA Table D-5] 2.0625 INCH Min. Bolt spacing, B (for bolt size 1") 2.25 INCH Min. Bolt spacing, B (for bolt size 1-1/8") 2.5 INCH Min. Bolt spacing, B (for bolt size 1-1/4") 2.8125 INCH Max. Recommended bolt spacing, Bmax = 2 dB + 6 t / (m + 0.5) [TEMA RCB 3.94882 INCH Check for Flat Channel Cover Deflection [TEMA RCB-9.21] The effective thickness of a flat channel cover shall be the thickness at the bottom of the pass partition groove (or the face if there is no groove) minus corrosion allowance in excess of groove depth. The thickness is to be at least that required by the appropriate Code formula and thicker if required to meet proper deflection criteria. The recommended limit for channel cover deflection is: 0.03" for nominal diameters thru 24" 0.03 INCH 0.125% of nominal diameters (nominal diameter/800) for larger sizes 0.025 INCH 20 INCH Nominal diameter = Shell ID + 2 ts A method for calculating of channel cover deflection at the center, Y is:

G Y = 0.0435G 3 P+0.5S B A B h G ET 3

69.75387 44.45 52.3875 57.15 63.5 71.4375 100.3

MM MM MM MM MM MM MM

0.762 0.635 508

MM MM MM

)

INCH PSI INCH PSIG PSIG INCH2 INCH 546.1978 MM

2214784.07 Kg/CM G

2

Where

G = Gasket load reaction diameter as defined by the Code 21.5039 E = Modulus of elasticity at design temperature [ASME Sec.II,Part D, TM-31460000 T = Thickness under consideration (minus groove and C.A.) 1.29921 P = Design pressure 71.7082 SB = Allowable bolting stress at design temperature (Wm1) 25000 AB =Actual total cross-sectional root area of bolts 15.428 hG = Radial distance from diameter G to bolt circle 1.51185

33 5.04826 25000 9953.528 38.40109

MM

Kg/CM2G Kg/CM2G

MM2 MM

If the calculated deflection is greater than the recommended limit, the deflection may be reduced by acceptance methods such as: (a) Increase channel cover thickness by the cube root of the ratio of calculated deflection to the recommended limit. (b) Use of strong backs. (c) Change type of construction. Note: For single pass channels, or others in which there is no pass partition gasket seal against the channel cover, no deflection criteria need be considered.

DESIGN CALCULATIONS OF HEAT EXCHANGER

According to ASME Code, Sec. VIII, Div. 1, Edition 2001, Addenda 2002 / TEMA "R" 7th Edition 88. Designed by : Eng. Abdel Halim Galala, Design General Manager (Assistant)

Page : 81 of 136 Sheet : 6 of 6 Rev. : 0

Project : Design & Fabrication of Heat Exchanger for APRC Refinery Job No. : 7443-33 Dwg. No. : 7443-33-1A, Rev. 0 Exchanger : Residue Cooler, Type : AES, TEMA class : R

Date : 4.7.2003

Location : Alex.

Sheet : 14

Client : APRC

Item : E-323A/B & E-514C/D

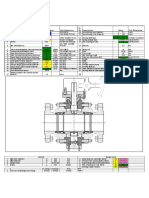

P. Flat Unstayed Circular Blind Flange (Channel Cover) Thickness (item no. 22) (cont.) [Attached by Bolts] [UG-34 & Fig. UG-34 Sketch (j)] The calculated deflection is

Y = G E T3

(0.0435 G

P + 0.5 S B AB hG

0.10054 0.03

INCH INCH

2.553795 MM 0.762 MM

The recommended deflection limit Since the calculated deflection exceeds the recommended deflection, we have to increase the flange tickness by the cubic root of the ratio of deflections,

Tassumed = T +

3

Ycalculated [TEMA RCB-9.21] Yrecommended

2.88948

INCH

73.39285 MM

Y =

Easier approach : 1. Assume T,

G 0.0435 G 3 P + 0.5 S B AB hG E T3

0.00914

INCH

0.232149 MM

1.88283

Y = G 0.0435 G 3 P + 0.5 S B AB hG E T3

INCH INCH INCH

47.824

MM

2. Find Calculated deflection

3. Recommended deflection limit

0.03303 0.03 OK 1.88283 1.88976

0.839054 MM 0.762 MM

4. Compare the calculated deflection with the recommended deflection

The minimum thickness of channel cover at bottom of pass partition is The thickness neglecting corrosion allowance is Conclusion : Checking of Deflection The min. thickness of channel cover to resist the internal pressure is Where the min. thickness of channel cover to avoid deflection is The min. thickness of channel cover as derived from drawings is The flange thickness increased by Tthickness including groove depth ( 5 MM) Overall thickness including raised faces & groove depth Max. Working Pressure, MWP at New (cold) & Operating (corroded) at New (cold) P = SE t2 /d2 c - 1.9 W hG / d3 c at Operating (corroded) P = SE t2 /d2 c - 1.9 W hG / d3 c

INCH INCH

47.824 48

MM MM

1.33858 1.88976 1.9685 0.07874 2.08661 2.48031

INCH INCH INCH INCH INCH INCH

34 48 50 2 53 63

MM MM MM MM MM MM

104.094 104.094

PSIG PSIG

2 7.328196 Kg/CM G 2 7.328196 Kg/CM G

You might also like

- Body Flange Design-Appx-2Document4 pagesBody Flange Design-Appx-2Matthieu100% (1)

- Flat Head Calculation (Based On Ug 34)Document2 pagesFlat Head Calculation (Based On Ug 34)rustamriyadiNo ratings yet

- Blind Flange DesignDocument1 pageBlind Flange DesignSachin5586No ratings yet

- Blind Flange Thickness Calculation Under 40 CharactersDocument6 pagesBlind Flange Thickness Calculation Under 40 Charactersshazan0% (1)

- Blind Flange Thickness CalculationDocument3 pagesBlind Flange Thickness CalculationKannapiran Krishnamoorthy75% (4)

- Loads On FlangesDocument16 pagesLoads On Flangesccoollest100% (3)

- Pd5500 Flange CalculationDocument6 pagesPd5500 Flange CalculationMakrand SakpalNo ratings yet

- ASME V111 Div2 APP 3 Flanges Stress Calculation in ExcelDocument16 pagesASME V111 Div2 APP 3 Flanges Stress Calculation in ExcelPanya Purahong100% (1)

- Bolt Torque ASME B16.5 Flanges - Spiral Wound GasketsDocument31 pagesBolt Torque ASME B16.5 Flanges - Spiral Wound Gasketsbakelly100% (5)

- Blind Thickness CalculatorDocument2 pagesBlind Thickness Calculatorckd71175% (4)

- FLANGEDocument1 pageFLANGEscrbdgharavi50% (2)

- Design of Flanges - Full-Face Gasket 2010Document29 pagesDesign of Flanges - Full-Face Gasket 2010bakelly100% (2)

- Design of Flat Head For HydrotestDocument12 pagesDesign of Flat Head For HydrotestSAGARNo ratings yet

- Blind Flange CalculationDocument12 pagesBlind Flange CalculationrajarajanNo ratings yet

- Flange Analysis ASME Section VIII Div 1 Appendices 2 S 2004Document1 pageFlange Analysis ASME Section VIII Div 1 Appendices 2 S 2004Lava SatNo ratings yet

- Ring Flange CalculationDocument3 pagesRing Flange CalculationLuizNo ratings yet

- FlangeCalc AS1210 v1.5Document28 pagesFlangeCalc AS1210 v1.5Ben100% (1)

- Asme Viii CalcsDocument20 pagesAsme Viii CalcsSriram VjNo ratings yet

- CHORD lENGTH cALCULATIONDocument4 pagesCHORD lENGTH cALCULATIONmukesh50% (2)

- FlangeCalculationASMEVIII Version5Document13 pagesFlangeCalculationASMEVIII Version5madodandembe100% (3)

- Flange Pad CalcsDocument4 pagesFlange Pad CalcstomNo ratings yet

- Flange CalculationsDocument5 pagesFlange CalculationsswapnavattemNo ratings yet

- Reinforcement Pad DesignDocument3 pagesReinforcement Pad DesignAkshat JainNo ratings yet

- Section VIII CalDocument19 pagesSection VIII CalPradeep Kothapalli100% (1)

- Flange CalculationsDocument3 pagesFlange CalculationssanjaysyNo ratings yet

- Sight Glass Flange AnalysisDocument4 pagesSight Glass Flange AnalysisOmil Rastogi0% (2)

- Design Calculation Anchor Flange - ASME VIII Div 1 App.2Document3 pagesDesign Calculation Anchor Flange - ASME VIII Div 1 App.2losmoscasbr100% (2)

- Flange Calculation Sheet..Document2 pagesFlange Calculation Sheet..nguyenquoc198850% (2)

- Blind Flange Calculation11Document3 pagesBlind Flange Calculation11jaymuscatNo ratings yet

- Flange Input CalcDocument12 pagesFlange Input CalcdharwinNo ratings yet

- Nozzle Reinforcing Calculations For A Pressure Vessel Design - by Abdel Halim GalalaDocument5 pagesNozzle Reinforcing Calculations For A Pressure Vessel Design - by Abdel Halim Galalapaary100% (2)

- Sample FLG CalcDocument6 pagesSample FLG CalcameyyammaiNo ratings yet

- Input EchoDocument6 pagesInput EchohgagNo ratings yet

- HEAT EXCHANGER DESIGN CALCULATIONSDocument8 pagesHEAT EXCHANGER DESIGN CALCULATIONSanishNo ratings yet

- Left blind flange stress analysis and designDocument6 pagesLeft blind flange stress analysis and designkamardheen majithNo ratings yet

- CK Tourqe CalculationDocument7 pagesCK Tourqe Calculationamit amity100% (1)

- DatasheetDocument2 pagesDatasheetnirmalNo ratings yet

- Blind flange design calculationDocument4 pagesBlind flange design calculationmukesh100% (2)

- Flange DesignDocument6 pagesFlange DesignDinesh VaghelaNo ratings yet

- Mechanical Data Sheet for Tank DesignDocument1 pageMechanical Data Sheet for Tank Designsafar bahariNo ratings yet

- Design of Saddle Supports & Stresses in Vessel On Two Saddles Using ZICK's Method - by Abdel Halim GalalaDocument16 pagesDesign of Saddle Supports & Stresses in Vessel On Two Saddles Using ZICK's Method - by Abdel Halim GalalaRaymond Metselaar83% (6)

- Appendix 2) : Optional Type Flange (Fig. 2-4 (8) )Document18 pagesAppendix 2) : Optional Type Flange (Fig. 2-4 (8) )hardik5818No ratings yet

- WELD NECK BODY FLANGE DESIGN CALCULATIONDocument30 pagesWELD NECK BODY FLANGE DESIGN CALCULATIONravielb9873No ratings yet

- Part-Uhx (U-Tube) .Document5 pagesPart-Uhx (U-Tube) .AKSHAY BHATKARNo ratings yet

- N1 FLG Flange Calculation ReportDocument4 pagesN1 FLG Flange Calculation ReportAnonymous AyDvqgNo ratings yet

- Calc' Diesel Fuel (Rev)Document10 pagesCalc' Diesel Fuel (Rev)joko_tm02No ratings yet

- Job No. Item No: Doc. No. Tag No. Client Fine Filter Skid FD-38063A/B Bharat Heavy Electricals LimitedDocument3 pagesJob No. Item No: Doc. No. Tag No. Client Fine Filter Skid FD-38063A/B Bharat Heavy Electricals LimitedgauravNo ratings yet

- Examples E4.16.1/E4.6.1 and E4.6.2 BPVC VIII-1: ASME PTB-4-2013Document15 pagesExamples E4.16.1/E4.6.1 and E4.6.2 BPVC VIII-1: ASME PTB-4-2013ordenador90No ratings yet

- Special nitrile rubber rod seal packingsDocument2 pagesSpecial nitrile rubber rod seal packingsTeddy NsNo ratings yet

- Weld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersDocument25 pagesWeld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersLipika GayenNo ratings yet

- WELD NECK BODY FLANGE DESIGN CALCULATION DATADocument25 pagesWELD NECK BODY FLANGE DESIGN CALCULATION DATALipika GayenNo ratings yet

- Bolt TorqueDocument5 pagesBolt TorqueTarunNo ratings yet

- Blind Flange Design for 8-Inch PipeDocument2 pagesBlind Flange Design for 8-Inch PipeGohar ZamanNo ratings yet

- Ssv/prop/72/22-01, Rev.0Document10 pagesSsv/prop/72/22-01, Rev.0parveshNo ratings yet

- Roundness Check Record of 1St Shell CourseDocument1 pageRoundness Check Record of 1St Shell CourseRhannie GarciaNo ratings yet

- Pressure VesselDocument6 pagesPressure VesselKiranNo ratings yet

- F-0201 Special Blind Calculation (N9)Document2 pagesF-0201 Special Blind Calculation (N9)rustamriyadiNo ratings yet

- Flange DesignDocument26 pagesFlange Designresume Fi-1401No ratings yet

- Buffer Vessel Data SheetDocument4 pagesBuffer Vessel Data SheetUmair A. KhanNo ratings yet

- Flange Excel NewDocument26 pagesFlange Excel NewvikasNo ratings yet

- Blind Flange Design Calculations - by Abdel Halim GalalaDocument6 pagesBlind Flange Design Calculations - by Abdel Halim GalalaNirmalraj Manoharan67% (3)

- Design of Pressure Vessel (Int & Ext)Document394 pagesDesign of Pressure Vessel (Int & Ext)api-3824026100% (8)

- API 650 Tank Nozzle Stand OutDocument8 pagesAPI 650 Tank Nozzle Stand OutmadodandembeNo ratings yet

- Above Ground Storage Tank OperaDocument98 pagesAbove Ground Storage Tank OperaNirmalraj Manoharan0% (1)

- NORTHERN ARIZONA UNIVERSITY - Technical Standards: Project XX - XXX.XXX - Project NameDocument69 pagesNORTHERN ARIZONA UNIVERSITY - Technical Standards: Project XX - XXX.XXX - Project NameMEHDI FARROKHINo ratings yet

- Stellant DualDocument3 pagesStellant DualAlexandra JanicNo ratings yet

- Whats New in ASME B31 3Document15 pagesWhats New in ASME B31 3Anonymous qhVGVpNo ratings yet

- DESIGN OF PRESSURE VESSEL Full Report DEDocument48 pagesDESIGN OF PRESSURE VESSEL Full Report DELuis Muñoz100% (1)

- LT2A - 15 - Krisna Surya Pamungkas - SolderDocument2 pagesLT2A - 15 - Krisna Surya Pamungkas - SolderMuhammad Hanif HidayatNo ratings yet

- Plastering Checklist PDFDocument1 pagePlastering Checklist PDFabdelmjidNo ratings yet

- Tripole University: Glass-Ceramic "MME660"Document3 pagesTripole University: Glass-Ceramic "MME660"amnajamNo ratings yet

- 52 Week PPM Planner Template-15 Jul 14Document26 pages52 Week PPM Planner Template-15 Jul 14safetydellNo ratings yet

- Project Report Group 4Document28 pagesProject Report Group 4Akame TakashitaNo ratings yet

- Micro Project MRSDocument13 pagesMicro Project MRS너사랑No ratings yet

- Unit G Punchlist ItemsDocument8 pagesUnit G Punchlist ItemsjhecyNo ratings yet

- 347R-14 Guide To Formwork For ConcreteDocument40 pages347R-14 Guide To Formwork For ConcreteJacky Leong100% (1)

- Mtech Thesis New (ZnO)Document59 pagesMtech Thesis New (ZnO)Tirthankar MohantyNo ratings yet

- 150 KV Substation Cost EstimationDocument21 pages150 KV Substation Cost EstimationMuhammadFajar100% (1)

- Coating DefectsDocument36 pagesCoating DefectsPageduesca RouelNo ratings yet

- Installation Manual: R410A Split SeriesDocument14 pagesInstallation Manual: R410A Split Serieswarick mNo ratings yet

- Reinforcing Detailing of RCCDocument40 pagesReinforcing Detailing of RCCThamaraiselvan Ramadoss100% (1)

- Is.8042.1989 White Cement SpecificationsDocument18 pagesIs.8042.1989 White Cement SpecificationsLucky KhanNo ratings yet

- (0000+) Comparison of Static Pushover and Dynamic Analyses Using RC BuildingDocument11 pages(0000+) Comparison of Static Pushover and Dynamic Analyses Using RC BuildingmgdarioNo ratings yet

- Natural Rubber VulcanizationDocument3 pagesNatural Rubber VulcanizationAbraha AbadiNo ratings yet

- How To Size A Room Air Conditioner PDFDocument3 pagesHow To Size A Room Air Conditioner PDFKo PaukNo ratings yet

- MODULE 3 - Pertinent Building Laws and RegulationsDocument45 pagesMODULE 3 - Pertinent Building Laws and RegulationsCammyNo ratings yet

- G-R 25Document27 pagesG-R 25Duncan VanderwallNo ratings yet

- Code Requirements Critical Dimension PDFDocument4 pagesCode Requirements Critical Dimension PDFSong phamNo ratings yet

- Fluid Mechanics PDFDocument48 pagesFluid Mechanics PDFrakib hasanNo ratings yet

- Housekeeping ScheduleDocument2 pagesHousekeeping ScheduleZeyya Nikka Cordova Pingad100% (1)

- Aropol LP 67400Document2 pagesAropol LP 67400Ahmed ZamanNo ratings yet

- Aditi VosDocument1 pageAditi VosXELIXCELINNo ratings yet

- Astm A451Document4 pagesAstm A451Đoàn Thoại Đông TriềuNo ratings yet

- Quality Control - Works Inspection: Base Coat For WallDocument1 pageQuality Control - Works Inspection: Base Coat For WallParasNo ratings yet