Professional Documents

Culture Documents

Computer Numerical Control

Uploaded by

saisenthOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Computer Numerical Control

Uploaded by

saisenthCopyright:

Available Formats

COMPUTER NUMERICAL CONTROL (CNC) Definition Computer Numerical Control (CNC) is one in which the functions and motions

of a machine tool are controlled by means of a prepared program containing coded alphanumeric data. CNC can control the motions of the work piece or tool, the input parameters such as feed, depth of cut, speed and the functions such as turning spindle on/off, turning coolant on/off. Applications The applications of CNC include both for machine tool as well as non-machine tool areas. In the machine tool category, CNC is widely used for lathe, drill press, milling machine, grinding unit, laser, sheet-metal press working machine, tube bending machine etc. Highly automated machine tools such as turning center and machining center which change the cutting tools automatically under CNC control have been developed. In the non-machine tool category, CNC applications include welding machines (are and resistance), coordinate measuring machine, electronic assembly, tape laying and filament winding machines for composites etc. Advantages and Limitations The benefits of CNC are (1) high accuracy in manufacturing, (2) short production time, (3) greater manufacturing flexibility, (4) simpler fixturing, (5) contour machining (2 to 5 - axis machining), (6) reduced human error. The drawbacks include high cost, maintenance and the requirement of skilled part programmer. ELEMENTS OF A CNC A CNC system consists of three basic components (Figure 2): 1. Part program 2. Machine Control Unit (MCU) 3. Machine tool (lathe, drill press, milling machine etc) Part Program The part program is a detailed set of commands to be followed by the machine tool. Each command specifies a position in the Cartesian coordinate system (x, y, z) or motion (work piece travel or cutting tool travel), machining parameters and on/off function. Part programmers should be well versed with machine tools, machining processes, effects of process variables and limitations of CNC controls. The part program is written manually or by using computerassisted language such as APT (Automated Programming Tool).

Figure 2. A typical numerical control system for a milling machine Machine Control Unit The machine control unit (MCU) is a microcomputer that stores the program and executes the commands into actions by the machine tool. The MCU consists of two main units: the data processing unit (DPU) and the control loops unit (CLU). The DPU software includes control system software, calculation algorithms, translation software that converts the part program into a usable format for the MCU, interpolation algorithm to achieve smooth motion of the cutter, editing of part program (in case of errors and changes). The DPU processes the data from the part program and provides it to the CLU which operates the drives attached to the machine lead screws and receives feedback signals on the actual position and velocity of each one of the axis. A driver (dc motor) and a feedback device are attached to the lead screw. The CLU consists of the circuits for position and velocity control loops, deceleration and backlash take up, function controls such as spindle on/off.

Machine Tool The machine tool could be one of the following: lathe, milling machine, laser, plasma, coordinate measuring machine etc. Figure 3 shows that a right-hand coordinate system is used to describe the motions of a machine tool. There are three linear axes (x, y, z), three rotational axes (I, j, k) and other axes such as tilt. (O) are possible. For example, a 5-axis machine implies any combination of x, y, z, I, j, k and O.

Figure 3. Right-hand coordinate system used in drill press and lathe.

PRINCIPLES OF CNC Basic Length Unit (BLU) Each BLU unit corresponds to the position resolution of the axis of motion. For example, 1 BLU = 0.0001 means that the axis will move 0.0001 for every one electrical pulse received by the motor. The BLU is also referred to as Bit (binary digit) Pulse = BLU = Bit Point-to-Point System Point-to-point systems are those that move the tool or the work piece from one point to another and then the tool performs the required task. Upon completion, the tool (or work piece) moves to the next position and the cycle is repeated (Figure 4). The simplest example for this type of system is a drilling machine where the work piece moves. In this system, the feed rate and the path of the cutting tool (or work piece) have no significance on the machining process. The accuracy of positioning depends on the systems resolution in terms of BLU (basic length unit) which is generally between 0.001 and 0.0001.

Figure 4. Cutter path between holes in a point-to-point system

Example 1 The XY table of a drilling machine has to be moved from the point (1,1) to the point (6,3). Each axis can move at a velocity of 0.5/sec and the BLU is 0.0001, find the travel time and resolution. Travel time in X-axis is (6-1)/0.5 = 10 sec, in Y-axis is (3-1)/0.5=4 sec. Travel time = 10 sec Resolution = BLU = 0.0001

Continuous Path Systems (Straight cut and contouring systems) These systems provide continuous path such that the tool can perform while the axis are moving, enabling the system to generate angular surfaces, two-dimensional curves, or threedimensional contours. Example is a milling machine where such tasks are accomplished (Figure 5). Each axis might move continuously at a different velocity. Velocity error is significant in affecting the positions of the cutter (Figure 5). It is more important in circular contour cutting where one axis follows sine function while the other follows cosine function. Figure 6 illustrates point-to-point and continuous path for various machines.

Figure 5. (a) Continuous path cutting and (b) Position error caused by the velocity error Example 2 A CNC milling machine has to cut a slot located between the points (0,0) and (4,3) on the XYplane where the dimensions are in inches. If the speed along the slot is to be 0.1 in/sec, find the cutting time and axial velocities. Distance travelled along the slot = (16+9) = 5 Cutting time = 5/0.1 = 5- sec V = xV/(x + y )in = 4(0.1)/5 = 0.08 in/sec

X

V = yV(x

y

+ y )in = 3(0.1)/5 = 0.06 in/sec

If the velocity is Y-axis is off by 10%, what would be the new position? New velocity in y is 0.9 x 0.06 = 0.054 in/sec In 50 sec, the y- will move a distance [50(0.054)] = 2.7 in

Figure 6. Schematic illustration of drilling, boring, and milling with various paths. Interpolator The input speed of 1 in/sec in example 2 is converted into the velocity components by an interpolator called the linear interpolator whose function is to provide the velocity signals to x and y directions. Similarly, we have circular and parabolic interpolators. See Figure 7.

Figure 7.

Types of interpolation (a) linear, (b) continuous path approximated by incremental Straight lines, and (c) circular.

Incremental and Absolute systems CNC systems are further divided into incremental and absolute systems (Figure 8). In incremental mode, the distance is measured from one point to the next. For example, if you want to drill five holes at different locations, the x-position commands are x + 500, + 200, + -600, -300, -700, -300. As absolute system is one in which all the moving commands are referred from a reference point (zero point or origin). For the above case, the x-position referred from a reference point 9zero point or origin). For the above case, the x-position commands are x 500,700, 1300, 1000, 300, 0. (Figure 8). Both systems are incorporated in most CNC systems. For an inexperienced operator, it is wise to use incremental mode. (a). (b).

Figure 8. (a). Absolute versus incremental; In absolute positioning, the move is specified by X = 6, y = 8; in incremental, the move is specified by x=4, y=5 for the tool to be moved from (2,3) to (6,8) (b). Drilling 5-holes at different locations. The absolute system has two significant advantages over the incremental system. 1 Interruptions caused by, for example, tool breakage (or tool change, or checking the parts), would not affect the position at the interruption.

If a tool is to be replaced at some stage, the operator manually moves the table, exchanges the tool, and has to return the table to the beginning of the segment in which the interruption has occurred. In the absolute mode, the tool is automatically returned to the position. In incremental mode, it is almost impossible to bring it precisely to that location unless you repeat the part program. 2 Easy change of dimensional data

The incremental mode has two advantages over the absolute mode. 1. Inspection of the program is easier because the sum of position commands for each axis must be zero. A nonzero sum indicated an error. Such an inspection is impossible with the absolute system. 2. Mirror image programming (for example, symmetrical-geometry of the parts) is simple by changing the signs of the position commands. Open Loop Control System The open-loop control means that there is no feedback and uses stepping motors for driving the lead screw. A stepping motor is a device whose output shaft rotates through a fixed angle in response to an input pulse (Figure 9). The accuracy of the system depends on the motors ability to step through the exact number. The frequency of the stepping motor depends on the load torque. The higher the load torque, lower would be the frequency. Excessive load torque my occur in motors due to the cutting forces in machine tools. Hence, this system is more suitable for cases where the tool force does not exist (Example: laser cutting).

Figure 9.

Open loop control system

The stepping motor is driven by a series of electrical pulses generated by the MCU. Each pulse causes the motor to rotate a fraction of one revolution. The fraction is expressed in terms of the step angle, a, given by a = 360/N, degrees where N = number of pulses required for one revolution If the motor receives n number of pulses then the total angle, A = n (360/N), degrees In terms of the number of revolutions, it would be (n/N) If there is a 1:1 gear ratio between the motor and the lead screw, then the lead screw has (n/N) revolutions. If the pitch of lead screw is p (in/rev), then the distance travelled axially, say x, X = p(n/N) can be used to achieve a specified x-increment in a point-to-point system.

The pulse frequency, f, in pulses/sec determines the travel speed of the tool or the work piece. 60 f = N (RPM) where N = number of pulses per revolution. RPM = RPM of the lead screw. The travel speed, V, is then given by V = p (RPM) where p pitch in in/rev Example 3 A stepping motor has N = 150, p = 0.2/rev; If n = 2250 pulses, what is the distance travelled in x-direction? What should be the pulse frequency for a travel speed of 16 in./min? X = (0.2) (2250)/150 = 3 16 = 0.2 (rpm), from which, RPM = 80 f = (150) (80)/60 = 200 Hz

Example 4 A stepping motor of 200 steps per revolution is mounted on the lead screw of a drilling machine. If the pitch is 0.1 in/rev. a b a b What is the BLU? If the motor receives a pulse frequency of 2000 Hz, what is the speed of the table? BLU = 0.1/200 = 0.0005 Table speed = (p) (RPM) = (0.1) (60) (2000)/200 = t0 in/min

Closed-loop Control System Closed-loop NC systems are appropriate when there is a force resisting the movement of the tool/work piece. Milling and turning are typical examples. In these systems (Figure 10) the DC servomotors and feedback devices are used to ensure that the desired position is achieved. The feedback sensor used is an optical encoder shown in Figure 11. The encoder consists of a light source, a photo detector, and a disk containing a series of slots. The encoder is connected to the lead screw. As the screw turns, the slots cause the light to be seen by the photo detector as a series of flashes which are converted into an equivalent series of electrical pulses which are then used to characterize the position and the speed. The equations remain essentially the same as open-loop except that the angle between the slots in the disk is the step angle, a. Both the input to the control loop and the feedback signals are a sequence of pulses, each pulse representing a BLU unit. The two sequences are correlated by a comparator and gives a signal, by means of a digital-to-analog converter, (a signal representing the position error), to operate the drive motor (DC servomotor).

Figure 10. Closed loop control system

Figure 11. Optical Encoder (a) Device (b) Series of pulses emitted

Example 5 Consider a CNC worktable driven by a closed-loop control system consisting of a servomotor, lead screw, and optical encoder. The lead screw has a pitch, p = 0.2 and is coupled to the motor shaft with a screw to motor gear ration of 1:4. The encoder generates 150 pulses per revolution of the lead screw. If the number of pulses and the pulse rate received by the control system are 2250 and 200 Hz respectively, calculate a b c a b c Table Speed Motor speed in RPM Distance travelled by the table

V = p(RPM) = 0.2(RPM) = (0.2) (60 f)/N = (0.2) (60) (200)/150 = 16 in/min RPM of the lead screw = (60) (200)/(150) = 80 RPM of the motor = 320 x = p(n/N) = (0.2) (2250)/150 =3

Example 6 A de servomotor is coupled to a lead screw which drives the table of a CNC machine tool. A digital encoder, mounted at the end of the screw, emits 500 pulses per revolution. If the pitch is 5 mm per rev, and the motor rotates 600 rpm (1:1 gear ratio), calculate the a b c a b c Table speed BLU Frequency of pulses transmitted by the encoder V = p(RPM) = 5 (600) = 3000 mm/min = 3 m/min BLU = 5/500 = 0.01 mm RPM = 600 = (60f)/N -= 60 f/500 from which f = 5000 Hz

PRECISION IN CNC MACHINING The combined characteristics of the machine tool and the control determine the precision of positioning. Three critical measures of precision are: o o o Resolution Accuracy Repeatability

Control resolution (BLU) is the distance separating two adjacent points in the axis movement (the smallest change in the position). The electromechanical components of the positioning system that affect the resolution are the lead screw pitch, the gear ratio, and the step angle in the stepping motor (open loop) or the angle between the slots in the encoder (closed-loop). The control resolution for a 1:1 gear ratio of a stepped motor is, Resolution = p/N where p = pitch and N = 360/a. Features smaller than the control resolution could not be produced. resolution cannot exceed the control resolution. The programming

Accuracy of a CNC system depends on the resolution, the computer control algorithms and the machine inaccuracies. The inaccuracy due to the resolution is considered to be (1/2) BLU on the average. The control algorithm inaccuracy is due to the rounding off the errors in the computer which is insignificant. The machine inaccuracy could be due to several reasons (described below). The designer minimizes this inaccuracy to be under (1/2)BLU and hence Accuracy = (1/2) Resolution + Machining inaccuracy = BLU Repeatability is a statistical term associated with accuracy. It refers to the capability of a positioning system to return to a programmed point and is measured in terms of the errors associated with the programmed point. The deviation from the control point (error) usually follows a normal distribution in which case the repeatability may be given as +/- 3o where o is the standard deviation. The repeatability is always better than the accuracy. The mechanical inaccuracy can be considered as the repeatability. Figure 12 shows the difference between the accuracy and the repeatability, Machining Inaccuracy Cutting tool deflection, machine tool chatter, mechanical linkage between the lead screw and the tool and thermal deformations are the chief contributing factors. The lead screw transmits the power to the table or tool holder by means of a nut that engages the lead screw. This will create what is known as backlash due to the friction between the screw and the nut. If the nut consists of ball bearings, the friction is reduced. Thermal deformations are significant. For example, a temperature difference of 1 degree C along 1000 mm can cause an error of 0.01 mm.

PART PROGRAMMING FOR CNC The transfer of an engineering blueprint of a product to a part program can be performed manually using a calculator or with the assistance of a computer language. A part programmer must have an extensive knowledge of the machining processes and the capabilities of the machine tools. In this section, we describe how the part programmers execute manually the part programs. First, the machining parameters are determined. Second, the optimal sequence of operations is evaluated. Third, the tool path is calculated. Fourth, a program is written. Each line of the program, referred to as a block, contains the required data for transfer from one point to the next. A typical line for a program is given below. N100 G91 X -5.0 Y7.0 F100 S200 TO1 M03 (EOB) The significance of each term is explained below Sequence Number, N Consisting of typically three digits, its purpose is to identify the specific machining operation through the block number particularly when testing a part program. Preparatory Function, G It prepares the MCU circuits to perform a specific operation. The G-codes (some) are shown in Table 1. G91 implies incremental mode of operation. Dimension Words 1 2 3 Distance dimension words, X, Y, Z Circular dimension words, I, J, K for distance to the arc center Angular dimensions, A, B, C

While (1) and (3) are expressed either by incremental or absolute mode, (2) is always is given in incremental mode. All angular dimensions are specified in revolutions or degrees. In the above block, X moves a distance of 3 in. in the negative direction while Y moves a distance of 7 in. in the positive direction. Other axes remain stationary. In some systems, actual distances are used. In others, the dimension words are programmed in BLUs.

Federate, F It is expressed in in/min and is used in contouring or point-to-point or straight-cut systems. For example, a federate of F100 implies 100 in/min or 100 mm/min. Federates are independent of spindle speed. In linear motions, the federate of the cutting tool is not corrected for the cutter radius. But in circular motions, the federate should be corrected for the tool radius as follows: F= [(part contour radius + tool radius)/part contour radius] (required federate)

For cutting around the outside of a circle, the plus sign in the above equation is used and the federate is increased. For cutting around the inside of a circle, the minus sign is used and the federate is decreased. Example 8 See Figure 5(a). If the required federate is 6 in/min, part contour radius is 1.5 ins and the cutter diameter is 1 ins. What is the federate at the top and bottom circles? Feed rate at the top is to be 8 ins/min and at the bottom is to be 4 ins/min

Spindle speed, S Programmed in rev/min, it is expressed as RPM or by a three-digit code number that is related to the RPM. Tool word, T Consisting of a maximum of five digits, each cutting tool has a different code number. The tool is automatically selected by the automatic tool changer when the code number is programmed in a block. Miscellaneous Function, M Consisting of two digits, this word relates to the movement of the machine in terms of spindle on/off, coolant on/off etc. shown in Table 2. EOB The EOB character is used at the end of each block to complete a line.

(diagram to be put on this page-front & back)

CONNECTION TO CNC PERIPHERALS y y y y 9CRT/MDI unit (M series) 7.2LCD/MDI unit (M series) 8.4LCD/MD1-unit (M series) Stand-alone type small MDI unit (M series)

English display

Symbol display

NSIC Explanation of the keyboard (Ref. keyboard Drawing) No 1 2 3 Name Power ON and OFF buttons o OFF 1 ON Reset key RESET START key OUTPUT START Soft keys (option) Explanation Press these buttons to turn CNC power ON and OFF. Press this key to reset the CNC, to cancel an alarm, etc. This key used to start MDI operation or automatic operation depending on the machine. This key is also used to output data to an Input/output unit. The soft keys have various functions, according to the applications. The soft key functions are displayed at the bottom of the CRT screen. Press these keys to input numeric and other characters. alphabetic,

5 6

Address and numeric keys N 4 INPUT key

When an address or a numerical key is pressed the data is input to the buffer and it is displayed on the CRT screen. To copy the data in the key input buffer to the offset register, etc., press the <IINPUT> key. This key is also used to input data from an input/output unit. Press this to delete the last character or symbol input to the key input buffer. Press these keys when editing the program. ALTER : Alteration INSERT : DELETE : Insertion Deletion

7 8

Cancel key CAN Program edit keys ALTER INSERT DELETE

9 10

Function keys PO8 PROG Cursor move keys Cursor [ ]

Press these keys to switch display screens for each function. There are two different cursor move keys. : This key is used to move the [ ] cursor in an upward or reverse

direction. The cursor is moved in small unit in the reverse direction [ ] : This key is used to move the cursor in an downward or forward direction. The cursor is moved in small unit in the forward direction. Two kinds of page change keys are described below. : This key is used to change over [ ] the page on the CRT screen in the reverse direction. [ ] : This key is used to change over the page on the CRT screen in the forward direction. [ ]

11

Page change keys PAGE [ [ ] ]

FUNCTION KEYS AND SOFT KEYS General Screen Operations 1 Press a function key on the CRT/MDI panel. The chapter selection soft keys that belong to the selected function appear. 2 Press one of the soft keys. The screen for the selected chapter appears. IF the soft key for a target chapter is not displayed, press the continuous menu key (next-menu key).In some cases,. additional chapters can be selected within a chapter.

3 To redisplay the previous soft keys, press the return key. The general screen display procedure is explained above. However, the actual display procedure varies from one screen to another. For details, see the description of individual operations. If the soft keys are not provided, press a key having the equivalent function to select the desired chapter. The functions of the soft key are automatically displayed, depending on the configuration. The functions are displayed, irrespective of the function configuration, if bit 7 of parameters 048 is specified accordingly.

Function Keys Function keys are provided to select the type of screen to be displayed. The following function keys are provided on the CRT/MDI panel: POS PRGM MENU OFFSET DGNOS/PARAM OPR ALARM AUX GRAPH Press this key to display the position screen Press this key to display the program screen Press this key to display the offset screen Press this key to display the parameter/diagnosis screen Press this key to display the alarm screen Press this key to display the graphics screen

NSIC 1.0 PART PROGRAMMING 1.1 PROGRAM Program is an encoded information giving co-ordinate values and other details which indicate how the tool should be moved in relation to a work piece in order to achieve a desired machining form. Program contains all the information for the machining of a component which is input to the con unit. The control unit provides control signal at the correct time and in correct sequence to the various drive units of the machine. The data given in a program block may be divided into two parts namely:1 Control Data 2 Dimensional Data Control Data include preparatory functions and miscellaneous functions which command the v functions like axes movement, tool change, etc. Dimensional data include the co-ordinate values of X, Y and Z axes. 1.2 AXIS AND MOTION NOMENCLATURE Right hand Cartesian co-ordinate system is used as a standard and it is always assumed that the cutting tool moves relative to the work piece:

X-Axis:- The X axis is always horizontal and is parallel to the work holding surface. Positive Xaxis is to the right when looking from the spindle towards the work piece. Z-Axis:- Z-Axis is the main machine spindle axis. The Z axis is positive in a direction away from work piece towards the spindle. Y-Axis:- The Y axis is perpendicular to both X and Z axis. The positive direction of Y axis is away from the spindle looking from spindle towards the work piece.

NSIC

(diagrams to be filled in this page)

NSIC

A,B & C are the rotary axes of motion around X, Y and Z axes respectively. Positive A, B and C in the direction which advances a right handed screw in the positive X, Y and Z axes respectively. 1.3 STRUCTURE OF A PART PROGRAM

A part program defines a sequence of machining operations. The information contained in the program can be dimensional or non-dimensional like speed, feed, auxiliary functions etc. The basic unit of part program input to the control is called a block. Each block contains adequate information for the machine to perform a movement or other functions. A block in turn is made up words and a word has a number of characters. All blocks are terminated by block end character A block may contain any or all of the following N0000 G00 X000.000 Y000.000 M00 S0000 T00 H00 F; (end of Optional block slip 1.3.1 BLOCK or SEQUENCE NUMBER

A block may have sequence number at its head. Sequence number are mainly used for the convenience of the operators in identifying the different operations. Block numbers are need not be consecutive and it is not a must to have a block number.

NSIC 1.3.2 PREPARATORY FUNCTION

These are codes which prepare the machine to perform a particular function like positioning, contouring, canned cycles etc. The following are the important G codes which are used in general. G code G00 G01 G02 G03 G04 G10 G15 G16 G17 G18 G19 G20 G21 G27 G28 G29 G30 G40 G41 G42 G43 G44 G49 G52 G53 G54 to G59 G60 G61 G63 G64 G65 G68 G69 G73 G74 G80 G81 G82 Group 01 01 01 01 00 00 17 17 02 02 02 06 06 00 00 00 00 07 07 07 08 08 08 00 00 14 14 00 15 15 15 00 16 16 09 09 09 09 09 Function Positioning Linear interpolation Circular Interpolation CW Circular Interpolation CCW Dwell Data setting Polar co-ordinates command cancel Polar co-ordinates command. XY Plane selection XY Plane selection YZ Plane selection Input in inch Input in mm Reference point return check Reference point return Return from reference position 2nd, 3rd reference position return Cutter Compensation cancel Cutter radius compensation (Left0 Cutter compensation (Right) Tool length compensation (+v direction) Tool length compensation (-ve direction) Tool length compensation (cancel0 Local co-ordinate system setting Machine co-ordinate system setting Work piece co-ordinate system selection Single direction positioning Exact stop mode Tapping mode Cutting mode Macro call Co-ordinate rotation Co-ordinate rotation cancel Peck drilling cycle Counter tapping cycle Canned cycle cancel Drilling cycle Counter Boring cycle

G83 G84 G85 G86 G87 G88 G89 G90 G91 G92 G94 G95 G98 G99 Model G code 1.3.3

09 09 09 09 09 09 09 03 03 00 05 05 10 10

Peck drilling cycle Tapping cycle Boring cycle Boring cycle Back boring cycle Boring cycle Boring cycle Absolute command Incremental command Setting of work co-ordinate system Feed/min Feed/rev Return to initial point in canned cycle Return to R point in canned cycle

DIMENSIONING

Co-ordinates specifying the destination dimensions are programmed in two ways namely; a) Absolute dimension programming b) Incremental dimension programming Absolute Dimension Programming: In this system all dimensions are taken from a single point, called origin or work zero. In the Fig. shown all the dimensions are considered from the point O which is work zero. Absolute dimensions are programmed using the code G90. Command format: G90 X. Y. Z ;

NSIC Incremental Dimension Programming: In this system, the distance from previous tool position to the destination is given. Incremental programming is done using G91 command. G91: X Y.. Z; The fig. clearly shows, explains the difference between absolute and incremental dimensioning.

13.4 MISCELLANEOUS FUNCTIONS (M-CODES) These are the operations associated with the machine for functions other than positioning or contouring, like, coolant off and on, Spindle rotation etc. The following are the standard M-codes M00 M01 M02 M03 M04 M05 M06 M07 M09 M19 M20 M28 M29 M30 M45 M98 M99 Program stop (conditional) Program stop (conditional) End of program with return to program start Spindle rotation CW Spindle rotation CCW Spindle stop Tool change Coolant ON Coolant OFF Spindle orientation Spindle orientation release Rigid tap OFF Rigid tap ON End of program Tool unclamp, enable in MDI, HANDLE Mode (MCV-400) Sub program call Sub program end.

Optional M12 M13 M14 M15 M22 M23 M24 M25 M31 M46 M47 M48 M49 M52 M53 M54 M55 M80 M81 M82 M83 M89 M90 M91 M92 M93 M94 M97 Component clamp Component de-clamp Rotary table clamp Rotary table de-clamp Pallet-1 load Pallet-1 unload Pallet-2 load Pallet-2 unload Probe ON/OFF Auto door close Auto door open Flush coolant ON Flush coolant OFF High pr. Coolant -1(25 bar) ON High pr. Coolant -1(25 bar) OFF High pr. Coolant -2(65 bar) ON High pr. Coolant -2(65 bar) OFF Auto pallet change Enable pallet 1 transfer in auto mode Enable pallet 2 transfer in auto mode Enable both pallet transfer in auto mode Pallet 1 Sub program Pallet 2 Sub program Tool monitoring auto interface enable Tool monitoring Auto interface disable Tool monitoring AC enable during AID Tool monitoring AC disable during AID Part count

You might also like

- 4l80e Teardown Rebuild and InstallationDocument146 pages4l80e Teardown Rebuild and Installationobx4ever50% (2)

- RISK ASESSMENT For SKYLIGHTDocument23 pagesRISK ASESSMENT For SKYLIGHTadeoye Adeyemi100% (1)

- CNC AutomationDocument19 pagesCNC Automationsameersaurabh5No ratings yet

- Guide To ISO50001 PDFDocument43 pagesGuide To ISO50001 PDFJohn Rajesh67% (3)

- Production Flow AnalysisDocument24 pagesProduction Flow AnalysisSelva Shri NathNo ratings yet

- Accident Avoiding of Punching Machine - ReportDocument38 pagesAccident Avoiding of Punching Machine - ReportPrathmeshBhokari0% (1)

- Timber-framed homes guideDocument44 pagesTimber-framed homes guideMtkNo ratings yet

- Tata Steel Corporate PresentationDocument49 pagesTata Steel Corporate Presentationjyoti mahajanNo ratings yet

- Unit 5 MCQDocument9 pagesUnit 5 MCQDhanesh PawarNo ratings yet

- Electronic Payment Systems Security and Protocols ExplainedDocument36 pagesElectronic Payment Systems Security and Protocols ExplainedPaksmilerNo ratings yet

- How To Upload PsDocument16 pagesHow To Upload Psrohan sharmaNo ratings yet

- CNC NotesDocument21 pagesCNC NotesradhiostrokesNo ratings yet

- Design and Implementation of 3 Axis Linear Interpolation Controller in Fpga For CNC Machines and RoboticsDocument11 pagesDesign and Implementation of 3 Axis Linear Interpolation Controller in Fpga For CNC Machines and RoboticsIAEME Publication100% (1)

- Human Computer Interaction: Iv/Ii SemesterDocument61 pagesHuman Computer Interaction: Iv/Ii SemesterSuresh VanamalaNo ratings yet

- SnifferDocument14 pagesSnifferGangadhar KarriNo ratings yet

- Automatic Traffic Light Control UsingDocument35 pagesAutomatic Traffic Light Control UsingDilyalew DebreworkNo ratings yet

- CSE Lamp Technology ReportDocument15 pagesCSE Lamp Technology Reportphani raghavendraNo ratings yet

- Software Dev Life CycleDocument15 pagesSoftware Dev Life CycledepdneoNo ratings yet

- Smart Memories A Seminar Report: A.Rana Pratap (14761A0506)Document15 pagesSmart Memories A Seminar Report: A.Rana Pratap (14761A0506)Hari KrishNo ratings yet

- FINALGrid Computing Seminar ReportDocument34 pagesFINALGrid Computing Seminar ReportMiraj Kumar100% (3)

- Digital Watermarking PresentationDocument16 pagesDigital Watermarking PresentationNikhil DixitNo ratings yet

- Automatic Paper Cutting Using Geneva MechanismDocument4 pagesAutomatic Paper Cutting Using Geneva MechanismsankaramarayananNo ratings yet

- Smart Dustbin For Smart CityDocument11 pagesSmart Dustbin For Smart CityBommaraju Yogeswar krishna0% (1)

- Development of Four Wheel Steering System For A Car: K. Lohith, Dr. S. R. Shankapal, M. H. Monish GowdaDocument8 pagesDevelopment of Four Wheel Steering System For A Car: K. Lohith, Dr. S. R. Shankapal, M. H. Monish GowdaGaurav PandeyNo ratings yet

- Biological ComputerDocument10 pagesBiological ComputerAnkit MishraNo ratings yet

- Cse Diamond Chip Reportn PDFDocument18 pagesCse Diamond Chip Reportn PDFSanjay Kumar PrajapatiNo ratings yet

- Voice Recognition SystemDocument18 pagesVoice Recognition SystemArun Sharma75% (16)

- Seminar On CNC Machine: Submitted To: Submitted byDocument23 pagesSeminar On CNC Machine: Submitted To: Submitted byFaisal MaqsoodNo ratings yet

- New Seminar ReportDocument20 pagesNew Seminar ReportThockanattu Varkey MathewNo ratings yet

- Government Polytechnic College Nedumangadu: Snapdragon ProcessorsDocument17 pagesGovernment Polytechnic College Nedumangadu: Snapdragon ProcessorspremamohanNo ratings yet

- Pen PlotterDocument24 pagesPen PlotterMridul SethiNo ratings yet

- FDM 3D PrinterDocument23 pagesFDM 3D PrinterYuvraj MarneNo ratings yet

- Design and Fabrication of Prevention Kit For Driving Two Wheeler Without HelmetDocument2 pagesDesign and Fabrication of Prevention Kit For Driving Two Wheeler Without HelmetRajeshNo ratings yet

- Infini BandDocument22 pagesInfini Bandtarunr1No ratings yet

- Blockchain Technology and Its Impact On The Global EconomyDocument3 pagesBlockchain Technology and Its Impact On The Global EconomyIJAR JOURNALNo ratings yet

- What Is CNC Machine - Main Parts, Working, Block DiagramDocument3 pagesWhat Is CNC Machine - Main Parts, Working, Block DiagramShanuOlanikkalNo ratings yet

- Multi Sensor Write Up PaperDocument7 pagesMulti Sensor Write Up PaperTRIAD TECHNO SERVICESNo ratings yet

- Technical Seminar ReportDocument26 pagesTechnical Seminar ReportkrishanbharadwajvNo ratings yet

- Student Smart Identity CardDocument12 pagesStudent Smart Identity Cardkartikey mishraNo ratings yet

- Virtual Retinal Display Seminar Report 2001Document44 pagesVirtual Retinal Display Seminar Report 2001Smiely Ammu100% (1)

- Acs PDFDocument2 pagesAcs PDFAkshay PowarNo ratings yet

- Pune Summer Training ReportDocument34 pagesPune Summer Training ReportGaurav giriNo ratings yet

- Optical Mouse Seminar ReportDocument13 pagesOptical Mouse Seminar Reportkarloss_kark0% (1)

- MANET Seminar Report SummaryDocument28 pagesMANET Seminar Report SummaryDhairav PatelNo ratings yet

- Smart MemoryDocument19 pagesSmart MemoryShabnam AsNo ratings yet

- Computer Integrated Manufacturing Cat 1Document58 pagesComputer Integrated Manufacturing Cat 1Abid YusufNo ratings yet

- DTMF Controlled Robot Without MicrocontrollerDocument4 pagesDTMF Controlled Robot Without MicrocontrollershanofaNo ratings yet

- CAD CAM Unit - 3 PPT-ilovepdf-compressedDocument66 pagesCAD CAM Unit - 3 PPT-ilovepdf-compressedTaha SakriwalaNo ratings yet

- Thesis Packet TracerDocument52 pagesThesis Packet TracerHashmat MohamadNo ratings yet

- Seminar Report On Bluetooth 5Document19 pagesSeminar Report On Bluetooth 5sudhakarreddy jNo ratings yet

- NC, CNC and DNCDocument7 pagesNC, CNC and DNCaqtu12fuc67% (3)

- BASIC DIFFERENCES BETWEEN COUPLINGS, CLUTCHES AND BRAKESDocument41 pagesBASIC DIFFERENCES BETWEEN COUPLINGS, CLUTCHES AND BRAKESKadiyam VijayNo ratings yet

- 07-Fabrication of Mini Hydraulic Pipe ViceDocument3 pages07-Fabrication of Mini Hydraulic Pipe ViceVignesan Mech100% (2)

- Decision Review System (DRS)Document17 pagesDecision Review System (DRS)Dhruv Pawar100% (1)

- RFID Advantages and Disadvantages for Library ManagementDocument6 pagesRFID Advantages and Disadvantages for Library ManagementahmedNo ratings yet

- CAD/CAE Applications in BiomedicineDocument12 pagesCAD/CAE Applications in BiomedicineManoj DhageNo ratings yet

- Ilovepdf Merged PDFDocument24 pagesIlovepdf Merged PDFSumana Sri UdumulaNo ratings yet

- Biometrics PPT FinalDocument19 pagesBiometrics PPT FinalRama SudhaNo ratings yet

- Design and Optimisation of 3 Axis CNC Wood Carving Machine 2Document4 pagesDesign and Optimisation of 3 Axis CNC Wood Carving Machine 2International Journal of Innovative Science and Research Technology100% (1)

- Course Title: Computer Hardware Networking Lab Course Code: Period/Week: 5 Periods/Semester:90 Course ObjectivesDocument1 pageCourse Title: Computer Hardware Networking Lab Course Code: Period/Week: 5 Periods/Semester:90 Course ObjectivesUnaise EkNo ratings yet

- METHOD STUDY FOR COST REDUCTIONDocument68 pagesMETHOD STUDY FOR COST REDUCTIONzakirno19248No ratings yet

- 04 NC CNC & DNC System-1Document23 pages04 NC CNC & DNC System-1Arsa Damara PNo ratings yet

- Office Skill Competencie Needed by Secretaries For Effective Job PerformanceDocument14 pagesOffice Skill Competencie Needed by Secretaries For Effective Job PerformanceJoseph JboyNo ratings yet

- Computer Graphics: Presented By: Yogesh Nagaraj NaikDocument26 pagesComputer Graphics: Presented By: Yogesh Nagaraj Naikಯೋಗೇಶ್ ಪಿNo ratings yet

- Pendolina System For Railway ComfortDocument23 pagesPendolina System For Railway ComfortSmileyNo ratings yet

- Obstacle Avoiding Robot Lab Project ReportDocument27 pagesObstacle Avoiding Robot Lab Project Reportyaswanth yashuNo ratings yet

- CNC ManualDocument49 pagesCNC ManualThiagarajan VenugopalNo ratings yet

- Computer Numerical Control INDRADocument11 pagesComputer Numerical Control INDRAIndra Blue'DuatujuhNo ratings yet

- Fms 1Document32 pagesFms 1saisenthNo ratings yet

- MRP Material Requirements PlanningDocument2 pagesMRP Material Requirements PlanningsaisenthNo ratings yet

- Application of Low Cost Inhibitors To Reduce Rate of Corrosion in Rail Passenger CoachesDocument9 pagesApplication of Low Cost Inhibitors To Reduce Rate of Corrosion in Rail Passenger CoachessaisenthNo ratings yet

- CH 1 and 2 Product Design and Development (#1)Document12 pagesCH 1 and 2 Product Design and Development (#1)VinodVermaNo ratings yet

- PhilosophyDocument1 pagePhilosophysaisenthNo ratings yet

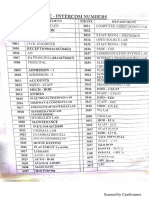

- Intercom Numbers PDFDocument1 pageIntercom Numbers PDFsaisenthNo ratings yet

- Mechanical Department Overview and Future PlansDocument2 pagesMechanical Department Overview and Future PlanssaisenthNo ratings yet

- 5,5 Notes On Routing in ManufacturingDocument2 pages5,5 Notes On Routing in ManufacturingsaisenthNo ratings yet

- 5.2 Notes On Production CycleDocument2 pages5.2 Notes On Production CyclesaisenthNo ratings yet

- Application of Low Cost Inhibitors To Reduce Rate of Corrosion in Rail Passenger CoachesDocument9 pagesApplication of Low Cost Inhibitors To Reduce Rate of Corrosion in Rail Passenger CoachessaisenthNo ratings yet

- 8 Assignment QP Key Sample ScriptDocument10 pages8 Assignment QP Key Sample ScriptsaisenthNo ratings yet

- Request To Send PapersDocument1 pageRequest To Send PaperssaisenthNo ratings yet

- Academic Calender 2018-19-To Hods (6484)Document10 pagesAcademic Calender 2018-19-To Hods (6484)saisenthNo ratings yet

- 12 WorkstationdesignDocument31 pages12 WorkstationdesignsaisenthNo ratings yet

- Saveetha School of Engineering Automobile Engineering Credit SystemDocument112 pagesSaveetha School of Engineering Automobile Engineering Credit SystemsaisenthNo ratings yet

- CamScanner App Scans Documents EasilyDocument2 pagesCamScanner App Scans Documents EasilysaisenthNo ratings yet

- Asper School of Business 9.613 Using Information Technology Part-Time MBA, December 2001 Instructor: Bob TravicaDocument13 pagesAsper School of Business 9.613 Using Information Technology Part-Time MBA, December 2001 Instructor: Bob TravicasaisenthNo ratings yet

- 12 WorkstationdesignDocument31 pages12 WorkstationdesignsaisenthNo ratings yet

- Me2252 MT1 Unit1Document23 pagesMe2252 MT1 Unit1saisenthNo ratings yet

- 2 Casting FormingDocument56 pages2 Casting FormingMohana KrishnanNo ratings yet

- Cellular Manufacturing Systems - Lecture Series 8: Ie 3265 Pom R. R. Lindeke, PHD Spring 2005Document42 pagesCellular Manufacturing Systems - Lecture Series 8: Ie 3265 Pom R. R. Lindeke, PHD Spring 2005saisenthNo ratings yet

- Electrical Notes - PvsDocument84 pagesElectrical Notes - PvssaisenthNo ratings yet

- Cellular Manufacturing Systems - Lecture Series 8: Ie 3265 Pom R. R. Lindeke, PHD Spring 2005Document42 pagesCellular Manufacturing Systems - Lecture Series 8: Ie 3265 Pom R. R. Lindeke, PHD Spring 2005saisenthNo ratings yet

- Electrical Notes - PvsDocument84 pagesElectrical Notes - PvssaisenthNo ratings yet

- Cim Syl SpuDocument2 pagesCim Syl SpusaisenthNo ratings yet

- 7 Production Planning ControlDocument20 pages7 Production Planning Controlmaanish000No ratings yet

- Group Technology in MFG SystemsDocument14 pagesGroup Technology in MFG SystemssanoojsiddikhNo ratings yet

- Coding and ClassificationDocument6 pagesCoding and ClassificationsaisenthNo ratings yet

- Cim Two Mark Que With AnsDocument7 pagesCim Two Mark Que With AnssaisenthNo ratings yet

- Ppcunit1 1Document1 pagePpcunit1 1saisenthNo ratings yet

- Drilling PDFDocument32 pagesDrilling PDFاحمد عمر حديدNo ratings yet

- CRM TemplateDocument17 pagesCRM TemplateAli MohamedNo ratings yet

- AVS Sevice Desk and Desk Side Support SOODocument28 pagesAVS Sevice Desk and Desk Side Support SOOCuong Duong DinhNo ratings yet

- Instruction Manual: SpecificationsDocument16 pagesInstruction Manual: SpecificationsJorge L. ContrerasNo ratings yet

- Richa Industries Wins First Rail Over Bridge Project For Railways (Company Update)Document2 pagesRicha Industries Wins First Rail Over Bridge Project For Railways (Company Update)Shyam SunderNo ratings yet

- Benefits of Cycling: Lessons from Top Cycling NationsDocument42 pagesBenefits of Cycling: Lessons from Top Cycling NationsZuniAsihNo ratings yet

- Ch11Integer Goal ProgrammingDocument54 pagesCh11Integer Goal ProgrammingAngelina WattssNo ratings yet

- Introduction To PMBOK - 2014Document49 pagesIntroduction To PMBOK - 2014'babi MulugetaNo ratings yet

- AD 302: Tightening of Ordinary Bolts: Sci Advisory DeskDocument2 pagesAD 302: Tightening of Ordinary Bolts: Sci Advisory DeskLightninWolf32No ratings yet

- Data Sheet 3196 MT-i - 3X4-13 - 130 m3h X 47 M GBQ - 49.991 - 14Document10 pagesData Sheet 3196 MT-i - 3X4-13 - 130 m3h X 47 M GBQ - 49.991 - 14Vinícius Toni MartinsNo ratings yet

- TSB WK PDFDocument4 pagesTSB WK PDFfulltransmissionNo ratings yet

- MBA 6011 Partial Mod 19 2013Document11 pagesMBA 6011 Partial Mod 19 2013sumithaps66469No ratings yet

- Exercise - Quality ToolsDocument10 pagesExercise - Quality ToolsĐức TrungNo ratings yet

- Mastercam 2023 Lathe enDocument3 pagesMastercam 2023 Lathe en정동현No ratings yet

- Stockdale Method Roundabout PDFDocument50 pagesStockdale Method Roundabout PDFAnonymous O7BzqVvmINo ratings yet

- Portable Machine MM2000iDocument3 pagesPortable Machine MM2000ijromero_rpgNo ratings yet

- Training On Industrial Engineering Basics For RMGDocument2 pagesTraining On Industrial Engineering Basics For RMGSalil BiswasNo ratings yet

- Dennis Resume 2009Document7 pagesDennis Resume 2009440grafixNo ratings yet

- Metering For Linemen: Current TransformersDocument3 pagesMetering For Linemen: Current TransformersEBENo ratings yet

- Industrial Training: Muhammad Amiruddin Bin Hassan 161382895 Ry44 - Integrated Electronic Alps Electric (M) SDN BHDDocument17 pagesIndustrial Training: Muhammad Amiruddin Bin Hassan 161382895 Ry44 - Integrated Electronic Alps Electric (M) SDN BHDAmiruddin HassanNo ratings yet

- Infineon FS30R06XL4 IGBT DatasheetDocument10 pagesInfineon FS30R06XL4 IGBT Datasheetmv_gearNo ratings yet

- General Considerations For Residential Considerations in Singapore Residential PropertyDocument54 pagesGeneral Considerations For Residential Considerations in Singapore Residential PropertyhosamlockNo ratings yet