Professional Documents

Culture Documents

Design of Base Plate

Uploaded by

Walid KobroslyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Base Plate

Uploaded by

Walid KobroslyCopyright:

Available Formats

Design of Base Plate.

xls 1 of 4

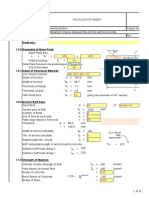

By : Dennis Dalaguan Checked : Gulfshade WALL PLATE (WP1) EFFECTIVE AREA METHOD DATA: D= (dia) t= pyp = fcu = 168 mm 10 mm 275 Mpa 35 Mpa

Client : CAT International

ID : Date:

12/20/10

BASEPLATE DESIGN BS 5950-1:2000 LOADS (Maximum for node 181 to 188) Pz = Mx = Vx = Vy = 14.724 kN (compression) 41.233 kN*m Values taken 7.958 kN from STAAD 14.19 kN Structural Analysis and Design

where: D = is the outside diameter of the column; T = is the flange & web thickness; p yp = is the design strength of the base plate; f cu = is the lower of the characteristic cube strengths of the concrete base and bedding material; Py = is the design uls axial load in the column. is the design uls moment in the column. is the design uls shear force along x direction in the column. is the design uls shear force along y direction in the column. is the largest perpendicular distance from the edge of the effective portion of the baseplate to the face of the column cross section Aeff = Effective cross sectional area Requirements for Axial Load q Pressure under base plate; Plate thickness provided; Base Plate Dimensions Provided; w = 0.6 fcu = tp = Dp = Bp = 21 Mpa 30 mm 275 mm 275 mm 4.13.2.2 Axial forces 4.13.2.3 Applied Moments M= Vx = Vy = c=

cactual = tp / (3 w / pyp)0.5 = 62.67832 mm 2 2 Aeff = [ (D/2+c) ] - [ (D/2-t-c) ] Aeff = 67187.19 mm

Effective base plate dimensions for concrete base design L= H= 275 mm 275 mm tp / (3 w / pyp)0.5 = (

Baseplate dimension is ok!!!

cp =

62.67832 mm

plastic c

4.13.2.3 Applied Moments

Design of Base Plate.xls 2 of 4

By : Dennis Dalaguan Checked : Gulfshade

Client : CAT International

ID : Date:

12/20/10

Py M

d1

a1

Pt

Bp

a2

M= Pt(a1)+C(a2) Pt = C-Py C= a1 = a2 = M= M= M= M= M= x = substituting:

d1 =

D p

38 mm

w(x)(D 2c) w(x)(D+2c) assume x < 2c+t 2c t 140.71 w= 84 Pt(a1) + C(a2) (C-Py)(a1)+C(a2) C(a1)-Py(a1)+C(a2) C(a1+a2)-Py(a1) w(x)(D+2c)(a1+a2)-Py(a1) [M+Py(a1)]/[w(D+2c)(a1+a2)] x= 31.28229 mm

21

< 2c + t

Mactual = 41233000 N*m Py = 14724 N D= 168 mm t= 10 mm C = 192714.2 N Pt = 207438.2 N

Design of Base Plate.xls 3 of 4

By : Dennis Dalaguan Checked : Gulfshade

Client : CAT International

ID : Date:

12/20/10

Check for Plate Thickness bending moment due to tension at neutral axis: MT = Pt x (a1- a2) = Mcap = 1.2 Pyp Z 4.2.5.1 11763822 N*mm where: Z= Pyp = b= b tp2 / 6 248 275

Mpa mm

tp = [( MT 6) / ( 1.2 Pyp b)]0.5 = 29.3675 mm < 30 mm OK Holding Down Bolt Design C ec Check Pull-out Capacity pe Bolt u out Capac ty per o t Maximum tension force per bolt; Ft = Pt/2 103.71911 kN Bolt Provided ; Dia = 24 Effective Dia = 21 Effective At = 346.36059 pt = 560 Pt = Pt = 0.8p 0 8 tA t 155.16954 kN mm mm mm Mpa

no. of bolts = bolt grade =

4 8.8

effective diameter after deduction for threading Effective area for tension tensile strength 6.6 Holding-down bolts SAFE

Tension Capacity:

CHECK FOR COMBINED TENSION AND SHEAR OF HOLDING BOLTS VR = Fs = PS = (Vx + Vz)0.5 / no. of bolts = VR ps A s ; 6.3.2.1 General Effective area for shear shear strength SAFE 6.3.4.4 Combined Shear and Tension SAFE 4067.292 N

Effective As = 346.3606 mm ps = 375 Mpa Ps = 129885.2 N Fs/Ps + Ft/Pt 1.4 ; Fs/Ps + Ft/Pt =

0.6997389 1.4

CHECK FOR BEARING OF BOLT AND PLATE BEARING OF BOLT dtppbb Pbb = BEARING OF PLATE kbsdtppbs but Pbs 0.5kbsetppbs Pbs =

6.3.3.2 Bearing Capacity of bolt

6.3.3.3 Bearing Capacity of connected part

Design of Base Plate.xls 4 of 4

By : Dennis Dalaguan Checked : Gulfshade

Client : CAT International

ID : Date:

12/20/10

kbs = d= Effective dia = tp = pbb = pbs = e= Pbb = Pbs = or Pbs =

1 24 mm 21 mm 30 mm 1000 Mpa 460 Mpa 30 mm 630000 N 289800 N 207000 use Pbs =

for bolts in standard clearances holes diameter of bolt effective diameter after deduction for threading thickness of plate bearing strength bearing t b i strength, steel grade S275 th t l d end distance > 4067.292 N 207000 N > 4067.2923

SAFE SAFE

Length of Holding Down Bolt: Tensile Capacity, pT = 155.16954 kN = 34 885239 ki 34.885239 kips Minimum embedment length: Lemb = 17d Lemb = 408 mm Lproj = 50 mm tgrout = 50 mm tnut = twasher = tplate = 19 mm 4 mm 30 mm

based on AISC Steel Design Guide Series Column Base Plates - 2003 - Minimum Bolt Lengths and Edge Distances page 25

Total Length = Lemb + tnut+ twasher + tplate + tgrout + Lproj Total Length = 561 mm Figure: diam. 24mm

Threaded Part

275mm 38mm 38mm

38mm 561 Lemb = 408 mm 30mm thk diam. 27mm 275mm

38mm

Design Result/Conclusion: g Base Plate : 275mm x 275mm x 30mm thick A36 steel plate Anchor Bolts: 4pcs diam. 24 Grade 8.8 Anchor Bolts @ 561mm length bolt through

You might also like

- Design of Base PlateDocument4 pagesDesign of Base PlatesanggythaNo ratings yet

- Design of Base Plate For BS5950Document2 pagesDesign of Base Plate For BS5950dantevarias89% (19)

- BS5950 End Plate DesignDocument4 pagesBS5950 End Plate DesignSimon Lsm67% (3)

- End Plate DesignDocument4 pagesEnd Plate DesignAgnon Fung100% (4)

- Connection Design MomentDocument4 pagesConnection Design MomentAkshit Dhawan100% (1)

- Corbel BS8110Document3 pagesCorbel BS8110Nugraha BintangNo ratings yet

- RD, 1 RD, 2 RD, 3 RD, 4 RD, 5 RD, 6 RD, 7 RD, 8: Doc. ID-Code Rev. CategoryDocument25 pagesRD, 1 RD, 2 RD, 3 RD, 4 RD, 5 RD, 6 RD, 7 RD, 8: Doc. ID-Code Rev. CategoryHanuman Sharma83% (6)

- Design of Base PlateDocument166 pagesDesign of Base PlateAnonymous ciKyr0t86% (7)

- Design of Shear KeyDocument13 pagesDesign of Shear Keynhulugalla100% (1)

- Base Plate - FixedDocument4 pagesBase Plate - Fixedbhaskardharani80% (5)

- Connection Design SheetDocument47 pagesConnection Design SheetStephen James100% (1)

- Base Plate Design Fixed RevisedDocument8 pagesBase Plate Design Fixed RevisedEngDbt80% (5)

- Base PlateDocument12 pagesBase PlateD SRINIVAS100% (1)

- Evo Design - Structural Design: Calculation SheetDocument7 pagesEvo Design - Structural Design: Calculation SheetAnand.5No ratings yet

- Design of Grating For PlatformDocument5 pagesDesign of Grating For Platformvj8584100% (2)

- Base Plate Design BSDocument4 pagesBase Plate Design BSvinujohnpanickerNo ratings yet

- Base PlateDocument45 pagesBase PlateMuhammed Ali60% (5)

- Design of Anchor Bolt - Rev.ADocument8 pagesDesign of Anchor Bolt - Rev.AcivilaskarNo ratings yet

- Base Plate Design BS CodeDocument3 pagesBase Plate Design BS CodeFodor ZoltanNo ratings yet

- Base Plate Design - BS CodeDocument3 pagesBase Plate Design - BS Codemicheleling669667% (3)

- Design of Isolated FootingDocument10 pagesDesign of Isolated Footingramdev panditNo ratings yet

- Design of Steel I-Section (BS5950)Document6 pagesDesign of Steel I-Section (BS5950)Rachelle C. Abanes50% (4)

- Beam Ledge DesignDocument2 pagesBeam Ledge Designauatipu100% (1)

- Circular Base PlateDocument4 pagesCircular Base PlateErnesto Feliciano Basurto Galvez100% (1)

- Base Plate and Anchor Bolt DesignDocument9 pagesBase Plate and Anchor Bolt DesignShaikh Muhammad Ateeq100% (2)

- Beam-Column Using Double Angle CleatDocument7 pagesBeam-Column Using Double Angle CleatNur Syahira100% (1)

- Typ-Base PlateDocument11 pagesTyp-Base PlateManoj Jaiswal100% (2)

- Calculation Sheet: Base Plate & Anchor Bolt Design - Moment Connection Base Plate DataDocument1 pageCalculation Sheet: Base Plate & Anchor Bolt Design - Moment Connection Base Plate DataLaurence Arcon Banal0% (1)

- Steel DesignDocument14 pagesSteel DesignNordin AhmadNo ratings yet

- Anchor Bolt DesignDocument18 pagesAnchor Bolt Designbhaskardharani78% (9)

- Purlin Check - Member PropertiesDocument6 pagesPurlin Check - Member PropertiesKaren Sia100% (1)

- MOMENT EndplateDocument10 pagesMOMENT EndplateALPHYL BALASABASNo ratings yet

- Base Plate DesignDocument32 pagesBase Plate DesignGautam Sharma50% (2)

- Anchor Bolt BiAxialDocument10 pagesAnchor Bolt BiAxialALPHYL BALASABASNo ratings yet

- Aluminium DesignDocument9 pagesAluminium Designikanyu79No ratings yet

- Anchor Bolt and Circular Base Plate Design As Per BS 5950Document16 pagesAnchor Bolt and Circular Base Plate Design As Per BS 5950Shamim Ahsan ZuberyNo ratings yet

- Base Plate Design To BS8110Document8 pagesBase Plate Design To BS8110Bridgy mcbridgeNo ratings yet

- By: Client: ID: Checked: Date: Wall Plate (Wp1) Effective Area Method BASEPLATE DESIGN BS 5950-1:2000Document4 pagesBy: Client: ID: Checked: Date: Wall Plate (Wp1) Effective Area Method BASEPLATE DESIGN BS 5950-1:2000Benjun BalbinNo ratings yet

- Design of Base PlateDocument258 pagesDesign of Base PlateNguyen Duc CuongNo ratings yet

- Design of Base PlateDocument11 pagesDesign of Base PlateSherwin CairoNo ratings yet

- Baseplate-Kolom wf250Document79 pagesBaseplate-Kolom wf250Gary JonathanNo ratings yet

- Base Plate Dan Anchor Bolt Calculation: Connection DesignDocument21 pagesBase Plate Dan Anchor Bolt Calculation: Connection DesignSurya FahmiNo ratings yet

- This Sheet Designs The Conductor Cone Guides Used in The MFP Jacket.Document3 pagesThis Sheet Designs The Conductor Cone Guides Used in The MFP Jacket.Thomas StephenNo ratings yet

- Standard BaseplateDocument133 pagesStandard BaseplateMohamad AmirulbaharudinNo ratings yet

- Steeltek Connection GeneralDocument5 pagesSteeltek Connection GeneralcadsultanNo ratings yet

- Joint Check 1Document9 pagesJoint Check 1abin100% (1)

- One Way SlabDocument9 pagesOne Way SlabJane RoNo ratings yet

- Crack Width Check BS5400 4Document6 pagesCrack Width Check BS5400 4amirNo ratings yet

- Crack Width Check BS5400 4 4Document6 pagesCrack Width Check BS5400 4 4Marvin MalicdemNo ratings yet

- Crack Width Check BS5400 4Document6 pagesCrack Width Check BS5400 4Anonymous 1HFV185Sl4No ratings yet

- Crack Width Check BS5400 4Document6 pagesCrack Width Check BS5400 4Dushyant GuptaNo ratings yet

- Crack Width Check BS5400 4Document6 pagesCrack Width Check BS5400 4Parthiban ArivazhaganNo ratings yet

- Steel Bunker DesignDocument13 pagesSteel Bunker Designsreenivasulu chenchugariNo ratings yet

- Sheet 3Document1 pageSheet 3Vasanth KumarNo ratings yet

- Calculation Base Plate EMDEKIDocument6 pagesCalculation Base Plate EMDEKIjunarkoNo ratings yet

- A.2 MC Conexion PIPE A W6x22Document7 pagesA.2 MC Conexion PIPE A W6x22Vivaldi ChangraNo ratings yet

- Singly Reinforced Beam in Excel FormatDocument6 pagesSingly Reinforced Beam in Excel FormatVEERKUMARNo ratings yet

- Anchor Bolt& Base Plate DesignDocument28 pagesAnchor Bolt& Base Plate Designtirentyren1No ratings yet

- Design 1-Way One End Continuous SlabDocument9 pagesDesign 1-Way One End Continuous SlabRbcabajes ButalonNo ratings yet

- Quality of Materials:: Large Moment Base Plate Design AISC LRFD - MethodeDocument7 pagesQuality of Materials:: Large Moment Base Plate Design AISC LRFD - MethodejunarkoNo ratings yet

- Base Plate & Anchor Bolts DesignDocument8 pagesBase Plate & Anchor Bolts DesignBenjun Balbin100% (2)

- Structural Reviewer (Q&A)Document196 pagesStructural Reviewer (Q&A)Lance Laron100% (8)

- Fillet Weld (Design) WELDED CONNECTIONSDocument11 pagesFillet Weld (Design) WELDED CONNECTIONS0600697No ratings yet

- Load Combinations - AISC-ASDDocument1 pageLoad Combinations - AISC-ASDBenjun Balbin80% (5)

- By: Client: ID: Checked: Date: Wall Plate (Wp1) Effective Area Method BASEPLATE DESIGN BS 5950-1:2000Document4 pagesBy: Client: ID: Checked: Date: Wall Plate (Wp1) Effective Area Method BASEPLATE DESIGN BS 5950-1:2000Benjun BalbinNo ratings yet

- Plantas Con Madre Plants That Teach and PDFDocument15 pagesPlantas Con Madre Plants That Teach and PDFJetNo ratings yet

- SPWM Vs SVMDocument11 pagesSPWM Vs SVMpmbalajibtechNo ratings yet

- GSM BSC6000 Performance StatisticsDocument72 pagesGSM BSC6000 Performance StatisticsAli AlshwalNo ratings yet

- Highway Journal Feb 2023Document52 pagesHighway Journal Feb 2023ShaileshRastogiNo ratings yet

- Konsep Negara Hukum Dalam Perspektif Hukum IslamDocument11 pagesKonsep Negara Hukum Dalam Perspektif Hukum IslamSiti MasitohNo ratings yet

- Stellite 6 FinalDocument2 pagesStellite 6 FinalGumersindo MelambesNo ratings yet

- Consequences of Self-Handicapping: Effects On Coping, Academic Performance, and AdjustmentDocument11 pagesConsequences of Self-Handicapping: Effects On Coping, Academic Performance, and AdjustmentAlliah Kate SalvadorNo ratings yet

- Approximate AnalysisDocument35 pagesApproximate AnalysisSyahir HamidonNo ratings yet

- Rubric For Audio Speech DeliveryDocument2 pagesRubric For Audio Speech DeliveryMarie Sol PanganNo ratings yet

- Dark Energy Survey DES CollaborationDocument38 pagesDark Energy Survey DES CollaborationgeorgcantorNo ratings yet

- Remediation of AlphabetsDocument34 pagesRemediation of AlphabetsAbdurahmanNo ratings yet

- Car Section 2 Series (H) Part-IiDocument6 pagesCar Section 2 Series (H) Part-Iipandurang nalawadeNo ratings yet

- General Introduction: 1.1 What Is Manufacturing (MFG) ?Document19 pagesGeneral Introduction: 1.1 What Is Manufacturing (MFG) ?Mohammed AbushammalaNo ratings yet

- Volvo HU 803Document8 pagesVolvo HU 803GiegloNo ratings yet

- Neural Computing and ApplicationsDocument49 pagesNeural Computing and ApplicationsLine PhamNo ratings yet

- Eea2a - HOLIDAY HOMEWORK XIIDocument12 pagesEea2a - HOLIDAY HOMEWORK XIIDaksh YadavNo ratings yet

- Cryptography Lab DA-1Document19 pagesCryptography Lab DA-1Gautam Thothathri 19MIC0092No ratings yet

- Real Options BV Lec 14Document49 pagesReal Options BV Lec 14Anuranjan TirkeyNo ratings yet

- Bomba Manual Hidraulica - P 19 LDocument2 pagesBomba Manual Hidraulica - P 19 LBruno PachecoNo ratings yet

- 103-Article Text-514-1-10-20190329Document11 pages103-Article Text-514-1-10-20190329Elok KurniaNo ratings yet

- 27 Points of Difference Between Personnel Management & HRDDocument2 pages27 Points of Difference Between Personnel Management & HRDMurtaza Ejaz33% (3)

- Dashrath Nandan JAVA (Unit2) NotesDocument18 pagesDashrath Nandan JAVA (Unit2) NotesAbhinandan Singh RanaNo ratings yet

- EUCLIDDocument3 pagesEUCLIDNandini MouryaNo ratings yet

- Hospital Furniture: Project Profile-UpdatedDocument7 pagesHospital Furniture: Project Profile-UpdatedGaurav GuptaNo ratings yet

- SUNGLAO - TM PortfolioDocument60 pagesSUNGLAO - TM PortfolioGIZELLE SUNGLAONo ratings yet

- Python Cheat Sheet-1Document8 pagesPython Cheat Sheet-1RevathyNo ratings yet

- Basics PDFDocument21 pagesBasics PDFSunil KumarNo ratings yet

- English ID Student S Book 1 - 015Document1 pageEnglish ID Student S Book 1 - 015Williams RoldanNo ratings yet

- Reclaimer PDFDocument8 pagesReclaimer PDFSiti NurhidayatiNo ratings yet

- BypassGoldManual PDFDocument6 pagesBypassGoldManual PDFBrad FrancNo ratings yet