Professional Documents

Culture Documents

Conductor Cone Guide Design Calculations

Uploaded by

Thomas StephenOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Conductor Cone Guide Design Calculations

Uploaded by

Thomas StephenCopyright:

Available Formats

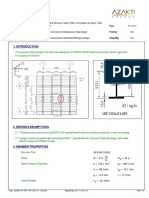

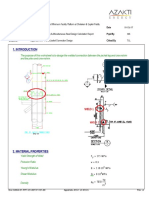

1.

INTRODUCTION

This sheet designs the conductor cone guides used in the MFP jacket..

2. MATERIAL PROPERTIES

Yield Strength Fy := 345 MPa

Poission Ratio := 0.3

Young's Modulus 5

E := 2.10 10 MPa

Shear Modulus 4

G := 8 10 MPa

kg

Density s := 7850 3

m

Doc G00A-ST-RPT-01-00137-107-00 Appendix A4-1 of A4-3 Rev :A

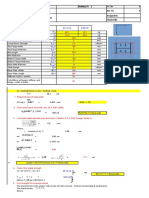

3. CONDUCTOR PARAMETERS

Diameter D c := 762mm

Thickness t c := 25mm

Length of conductor to be guided lc := 34.6m

4. DESIGN CHECKS FOR CONDUCTOR CONE GUIDE

Top diameter of the cone D t := 1152mm

Bottom diameter of the cone D b := 852mm

Thickness of the cone plate t p := 25mm

Cone angle := 45deg

The conductor cone would be supported by four 12 mm stiffener plates. Considering a section between the

stiffener plates, it will act as a conical plate with three sides fixed and one end free. For ease of design, the

plate is conservatively analysed to be a cantilever with the bottom end of the cone fixed. The conductor is

assumed to hit the guide on the free edge, and a horizontal load of 10% the weight of the conductor is also

considered in the design.

Average width of the plate section (taking the effective

(Dt + D b)

bp := = 786.969 mm

rectangular section of the cone) 4 2

Doc G00A-ST-RPT-01-00137-107-00 Appendix A4-2 of A4-3 Rev :A

2

Weight of the conductor W := D - D c - 2 t c

4 c

( )2 lc s g = 154.178 kN

Lever arm for the vertical force

(Dt - Db)

yv := = 150 mm

2

yh := yv tan ( ) = 150 mm

Lever arm for the horizontal force

Total moment on the plate M p := W yv + 0.1 W yh = 25.439 kN m

2

bp t p

4 3

Section modulus of the plate Zp := = 8.198 10 mm

6

Mp

Maximum bending stress bend := = 310.328 MPa

Zp

The cone guide is designed to yield and hence all := Fy = 345 MPa

allowable bending stress is

Check := "OK" if bend < all

"Redesign!" otherwise

Check = "OK"

bend

Unity Check UC := = 0.9

all

Doc G00A-ST-RPT-01-00137-107-00 Appendix A4-3 of A4-3 Rev :A

You might also like

- Appendix A1Document5 pagesAppendix A1Thomas Stephen100% (1)

- Appendix A3Document6 pagesAppendix A3Thomas Stephen100% (1)

- Appendix A2Document8 pagesAppendix A2Thomas StephenNo ratings yet

- Leg Protector Impact Load EstimationDocument3 pagesLeg Protector Impact Load EstimationThomas StephenNo ratings yet

- Design of Stabbing Guides for PilesDocument3 pagesDesign of Stabbing Guides for PilesThomas StephenNo ratings yet

- Appendix A1Document22 pagesAppendix A1Thomas StephenNo ratings yet

- Base plate design calculations and stressesDocument29 pagesBase plate design calculations and stressessatyakamNo ratings yet

- Design of End Plate ConnectionDocument2 pagesDesign of End Plate ConnectionAndro RebuyasNo ratings yet

- End Plate Conn. To Hollow Col. EC2 OKDocument26 pagesEnd Plate Conn. To Hollow Col. EC2 OKRaymond SabadoNo ratings yet

- Mathcad - Clip Angle ConnectionDocument8 pagesMathcad - Clip Angle ConnectionShobanBaabu ArumugamNo ratings yet

- Bellow As Per EJMA - 1Document2 pagesBellow As Per EJMA - 1966571016208No ratings yet

- Head Nozzle and Flange Calculation, DN100 (CF) Size NozzleDocument7 pagesHead Nozzle and Flange Calculation, DN100 (CF) Size Nozzleakın ersözNo ratings yet

- Design of Coping Beam (Portal) : A. Basic DataDocument7 pagesDesign of Coping Beam (Portal) : A. Basic DataUzziel Abib GabiolaNo ratings yet

- JEROME M. GUETA QUIZ 3 - Advance Steel DesignDocument105 pagesJEROME M. GUETA QUIZ 3 - Advance Steel DesignJerome M. GuetaNo ratings yet

- Square and Rectangular HSS and Box-Shaped Members: Material Proper TiesDocument2 pagesSquare and Rectangular HSS and Box-Shaped Members: Material Proper Tiesengineer.mmNo ratings yet

- Roller DesignDocument1 pageRoller Designjami sharat chandNo ratings yet

- Base Plate Design for Column Base ConnectionDocument6 pagesBase Plate Design for Column Base ConnectionThuyTranNo ratings yet

- By: Client: ID: Checked: Date: Wall Plate (Wp1) Effective Area Method BASEPLATE DESIGN BS 5950-1:2000Document4 pagesBy: Client: ID: Checked: Date: Wall Plate (Wp1) Effective Area Method BASEPLATE DESIGN BS 5950-1:2000Benjun BalbinNo ratings yet

- AISC2005 Anchor Bolt5 Pin Connection NewDocument6 pagesAISC2005 Anchor Bolt5 Pin Connection NewThuyTranNo ratings yet

- Section A: 2.1. Sling Design Load and SelectionDocument30 pagesSection A: 2.1. Sling Design Load and SelectionThomas StephenNo ratings yet

- Base Design (Blocks) - Commented On 26.09.2017Document4 pagesBase Design (Blocks) - Commented On 26.09.2017tsinghal_19No ratings yet

- Connection Design: Given DataDocument2 pagesConnection Design: Given Datasyed muneeb haiderNo ratings yet

- Design of Singly Reinforced Concrete BeamDocument4 pagesDesign of Singly Reinforced Concrete BeamAnton_Young_1962No ratings yet

- Bearing CheckDocument6 pagesBearing CheckdhanushkaNo ratings yet

- AISC2005 Anchor Bolt Version22042015 FixDocument8 pagesAISC2005 Anchor Bolt Version22042015 FixThuyTranNo ratings yet

- Design of Moment and Shear ConnectionDocument4 pagesDesign of Moment and Shear ConnectionAndro RebuyasNo ratings yet

- To Do - DS - LRFD - Supporting Beam - W8X18 - W8X18Document15 pagesTo Do - DS - LRFD - Supporting Beam - W8X18 - W8X18amitNo ratings yet

- Lesson 1 Exercises Problem No. 1Document2 pagesLesson 1 Exercises Problem No. 1Ariel GamboaNo ratings yet

- Lesson 1 Exercises Problem No. 1Document2 pagesLesson 1 Exercises Problem No. 1Ariel Gamboa100% (1)

- Appendix A9Document9 pagesAppendix A9Thomas StephenNo ratings yet

- To Do - DS-H - Supporting Beam - W8X18 - W8X18Document15 pagesTo Do - DS-H - Supporting Beam - W8X18 - W8X18amitNo ratings yet

- AXIALLY LOADED MEMBERS (Version 1)Document22 pagesAXIALLY LOADED MEMBERS (Version 1)Receb AgaNo ratings yet

- Design of Base PlateDocument4 pagesDesign of Base PlateBenjun Balbin100% (5)

- Davit CalcDocument4 pagesDavit CalcrustamriyadiNo ratings yet

- Balok Kolom Braced UnDocument3 pagesBalok Kolom Braced UnIkbal ImanudinNo ratings yet

- Idn - 3Document6 pagesIdn - 3Anh KyNo ratings yet

- SPT Girder L 38.75m, S 2.26m (43 Strands) - 0507Document53 pagesSPT Girder L 38.75m, S 2.26m (43 Strands) - 0507Trần Dinh BảoNo ratings yet

- STRESSING CALCULATIONS - Malbogon BridgeDocument1 pageSTRESSING CALCULATIONS - Malbogon BridgeRay Vincent Agorita FriasNo ratings yet

- Baseplate-Kolom wf250Document79 pagesBaseplate-Kolom wf250Gary JonathanNo ratings yet

- S2 Slab Calculation PDFDocument1 pageS2 Slab Calculation PDFashishNo ratings yet

- 5.design of Isolated FootingDocument4 pages5.design of Isolated FootingMadhubalaNo ratings yet

- Design of Rafter by LSD: Loading: Beam-9, Shelter-B, L/C: 214Document3 pagesDesign of Rafter by LSD: Loading: Beam-9, Shelter-B, L/C: 214Ayush GargNo ratings yet

- Monorail Crane Girder CalculationDocument4 pagesMonorail Crane Girder Calculationrony100% (1)

- Engr Vic (LRFD Sample)Document173 pagesEngr Vic (LRFD Sample)Victor DlreyesNo ratings yet

- Clip Angle Connection: Design ForcesDocument3 pagesClip Angle Connection: Design ForcesSIVAKUMARNo ratings yet

- End Plate Conn. To Hollow Col. EC2Document26 pagesEnd Plate Conn. To Hollow Col. EC2Raymond SabadoNo ratings yet

- Design of One-way SlabDocument4 pagesDesign of One-way SlabAnton_Young_1962No ratings yet

- Design of tension member calculationDocument1 pageDesign of tension member calculationchaNo ratings yet

- Loads:: Donnees de Calcul ChargesDocument6 pagesLoads:: Donnees de Calcul ChargesAdekimi EmmanuelNo ratings yet

- 05a - HORIZONTAL BRACEDocument10 pages05a - HORIZONTAL BRACEShyamontika Choudhury ChakrabartiNo ratings yet

- Project:-Location: - Design Code: Date Revision Client IS 800: 2007 Designed byDocument1 pageProject:-Location: - Design Code: Date Revision Client IS 800: 2007 Designed bySantosh BapuNo ratings yet

- Moment Connection AnalysisDocument5 pagesMoment Connection AnalysisKrish ChandNo ratings yet

- Doubly Reinforced BeamDocument2 pagesDoubly Reinforced BeamG.DhanabalNo ratings yet

- Channel Design AISCDocument9 pagesChannel Design AISCRajveer SinghNo ratings yet

- Design stairway from EL 1500 to 6500Document10 pagesDesign stairway from EL 1500 to 6500Thomas StephenNo ratings yet

- End-Plate-Design BS CodeDocument15 pagesEnd-Plate-Design BS CodeRaymond SabadoNo ratings yet

- Anchor Bolt - AISC ASDDocument7 pagesAnchor Bolt - AISC ASDameyyammaiNo ratings yet

- Chapter 5Document107 pagesChapter 5Keantai RinaNo ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Nylon Carpet. Harrington Catalogue.2022 - 2022-09-20T105330.316Document36 pagesNylon Carpet. Harrington Catalogue.2022 - 2022-09-20T105330.316Thomas StephenNo ratings yet

- New Floating Fish Farm Off Changi Aims To Produce More Seafood Than Traditional Coastal Farms - TODAYonline PDFDocument27 pagesNew Floating Fish Farm Off Changi Aims To Produce More Seafood Than Traditional Coastal Farms - TODAYonline PDFThomas StephenNo ratings yet

- Active StructureDocument1 pageActive StructureThomas StephenNo ratings yet

- Appendix A5Document4 pagesAppendix A5Thomas StephenNo ratings yet

- Developing affordable feed for seabass aquacultureDocument4 pagesDeveloping affordable feed for seabass aquacultureThomas StephenNo ratings yet

- Appendix A5Document4 pagesAppendix A5Thomas StephenNo ratings yet

- Appendix A1Document22 pagesAppendix A1Thomas StephenNo ratings yet

- Section A: 2.1. Sling Design Load and SelectionDocument30 pagesSection A: 2.1. Sling Design Load and SelectionThomas StephenNo ratings yet

- Appendix A3Document8 pagesAppendix A3Thomas StephenNo ratings yet

- Design stairway from EL 1500 to 6500Document10 pagesDesign stairway from EL 1500 to 6500Thomas StephenNo ratings yet

- The Purpose of This Worksheet Is To Design The Welded Connection Between The Jacket Leg and Crownshim and The Piles and CrownshimDocument5 pagesThe Purpose of This Worksheet Is To Design The Welded Connection Between The Jacket Leg and Crownshim and The Piles and CrownshimThomas StephenNo ratings yet

- Appendix A9Document9 pagesAppendix A9Thomas StephenNo ratings yet

- Pressure - Plate - Sheet1Document1 pagePressure - Plate - Sheet1Thomas StephenNo ratings yet

- Input Parameters: 1.1. Input Surface Areas 1.1.1. Above Mudline Without Corrosion Protection CoatingDocument6 pagesInput Parameters: 1.1. Input Surface Areas 1.1.1. Above Mudline Without Corrosion Protection CoatingThomas StephenNo ratings yet

- Pressure - Plate - Sheet1Document1 pagePressure - Plate - Sheet1Thomas StephenNo ratings yet

- SECTIONDocument1 pageSECTIONpavaniitm2006No ratings yet

- Project Manager Gantt ChartDocument16 pagesProject Manager Gantt ChartThomas StephenNo ratings yet

- Structural Analysis Report - Detention Steel Doors PMSD-5000Document62 pagesStructural Analysis Report - Detention Steel Doors PMSD-5000Thomas StephenNo ratings yet

- SP11-FE-SPC-WHP - A - B-OU-1001 Fire and Blast Partitions Rev.0Document17 pagesSP11-FE-SPC-WHP - A - B-OU-1001 Fire and Blast Partitions Rev.0Thomas StephenNo ratings yet

- Is.4991.1968 - 0-BLAST RESISTANT STRUCTURES PDFDocument43 pagesIs.4991.1968 - 0-BLAST RESISTANT STRUCTURES PDFgirishNo ratings yet

- HTB Tender Assisted Drilling Unit Makers ListDocument15 pagesHTB Tender Assisted Drilling Unit Makers ListThomas StephenNo ratings yet

- Blast Design Considerations for Structural EngineersDocument21 pagesBlast Design Considerations for Structural EngineersFrancisco Garrido100% (1)

- Is.4991.1968 - 0-BLAST RESISTANT STRUCTURES PDFDocument43 pagesIs.4991.1968 - 0-BLAST RESISTANT STRUCTURES PDFgirishNo ratings yet

- Gen Ed Answer Key (A)Document7 pagesGen Ed Answer Key (A)Antonette Escarpe TorcinoNo ratings yet

- Management Foreign BodyDocument6 pagesManagement Foreign BodyRahmatia SyukrinaNo ratings yet

- Ship Construction: Second Mates - HANDOUTDocument117 pagesShip Construction: Second Mates - HANDOUTmaneeshNo ratings yet

- Well Rounded.: 360 CassetteDocument12 pagesWell Rounded.: 360 CassetteMonty Va Al MarNo ratings yet

- Jigoku Shoujo Eikyuu No SonzaiDocument166 pagesJigoku Shoujo Eikyuu No Sonzaiapi-224188021No ratings yet

- Beyond Schein DentalDocument9 pagesBeyond Schein DentaltomdietzlerNo ratings yet

- Bio-Sil ULTRA 1050: Medically Pure Platinum-Cured Silicone Tubing With An Ultra-Smooth Inner SurfaceDocument2 pagesBio-Sil ULTRA 1050: Medically Pure Platinum-Cured Silicone Tubing With An Ultra-Smooth Inner SurfaceLari GrossiNo ratings yet

- Experiment# 3 Projectile Motion (Tasks 3 and 4)Document18 pagesExperiment# 3 Projectile Motion (Tasks 3 and 4)Hafiz MuhammadNo ratings yet

- MFJ-854 RF MeterDocument5 pagesMFJ-854 RF MeterHappyJoeNo ratings yet

- Essay - DnaDocument2 pagesEssay - Dnaapi-243852896No ratings yet

- 6 Health Benefits of Bitter MelonDocument7 pages6 Health Benefits of Bitter Melonlove sardualNo ratings yet

- When Ceramic Sociology Meets Material SCDocument10 pagesWhen Ceramic Sociology Meets Material SCJosé Renato TeixeiraNo ratings yet

- Chapter 14 Chemical EquilibriumDocument29 pagesChapter 14 Chemical EquilibriumlynloeNo ratings yet

- Fire and Blast in The Future OffshoreDocument45 pagesFire and Blast in The Future OffshoredrgNo ratings yet

- NPT Pipe Thread Sizes and TapersDocument1 pageNPT Pipe Thread Sizes and TapersRajesh J BharadwajNo ratings yet

- IP Modulator User's Guide - Oct - 09Document68 pagesIP Modulator User's Guide - Oct - 09reivajjwNo ratings yet

- FT Aeroterme GEADocument15 pagesFT Aeroterme GEACrisTimNo ratings yet

- Wily Walnut BRAIN SQUEEZERS Vol.1Document116 pagesWily Walnut BRAIN SQUEEZERS Vol.1tarzaman88% (8)

- Memories of HomeDocument14 pagesMemories of HomeMary Francis Edmer SayconNo ratings yet

- Cell Structure ActivityDocument4 pagesCell Structure ActivitysharksiedNo ratings yet

- General Biology 1: Go Fast, or Slow Down?Document23 pagesGeneral Biology 1: Go Fast, or Slow Down?Mikhael OiraNo ratings yet

- The Storage Handling and Transportation of Ammonium Nitrate Based Fertilisers 2015Document58 pagesThe Storage Handling and Transportation of Ammonium Nitrate Based Fertilisers 2015Minh Đức TạNo ratings yet

- Week 7: Nurses Role in Disaster: Home Mitigation and PreparednessDocument10 pagesWeek 7: Nurses Role in Disaster: Home Mitigation and PreparednessRose Ann LacuarinNo ratings yet

- Basics of Scientific Writing, Scientific Research, and Elementary Data AnalysisDocument12 pagesBasics of Scientific Writing, Scientific Research, and Elementary Data Analysisburhan sabirNo ratings yet

- Is There Bitcoin Atm Mexicali Baja California - Google SearchDocument1 pageIs There Bitcoin Atm Mexicali Baja California - Google Searchannejessica396No ratings yet

- Let Us Discover: Hairdressing-Grade 11Document5 pagesLet Us Discover: Hairdressing-Grade 11cherry d.bandolaNo ratings yet

- Kyle 106 - 119 - 131 - 141Document1 pageKyle 106 - 119 - 131 - 141Gerson SouzaNo ratings yet

- EU Food Label GuidanceDocument99 pagesEU Food Label GuidanceMunteanu CristianNo ratings yet

- Fault Codes: STO U AndriivDocument3 pagesFault Codes: STO U AndriivAtochkavNo ratings yet