Professional Documents

Culture Documents

Section A: 2.1. Sling Design Load and Selection

Uploaded by

Thomas StephenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section A: 2.1. Sling Design Load and Selection

Uploaded by

Thomas StephenCopyright:

Available Formats

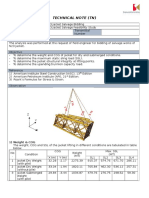

SECTION A

1. INTRODUCTION

. The purpose of the section A of this worksheet is to designa pile lifting padeye for the pile P2 in the

Gupkin jacket. The padeye on pile P2 will have to lift the combined weight of P1 and P2, and hence the

padeye on P2 is to be designed for 83.3t load. The padeye for P1 lifts 39t and the design for the P1

padeye is given in section B and the padeye for P3 which lifts 27.2t is given in section C.

2. SLING, SHACKLE AND PADEYE DESIGN

2.1. SLING DESIGN LOAD AND SELECTION

Doc G00A-ST-RPT-01-00137-107-00 Appendix A6-1 of A6-30 Rev :A

Unfactored sling design load (half the lift FUSDL := 1.1 0.5 83.3tonnef = 45.815 tonnef

weight+10%contingency)

Padeye design load Fsmax := 2 FUSDL = 91.63 tonnef

Sling breaking strength safety factor Sb := 4.0

Calculated sling breaking load FCRBL := Sb FUSDL = 183.26 tonnef

Lifting Angle 1 := 90deg

SLING SELECTION

Specification: Gaylin Koiswire 6 X 37 + FC type C (200kg/mm2) 56mm wire rope with 195 tonnef MBL

Diameter ds := 56mm

Minimum breaking strength FMBSL := 195tonnef

kg

Weight W s := 11.3

m

Doc G00A-ST-RPT-01-00137-107-00 Appendix A6-2 of A6-30 Rev :A

5.2.2. SHACKLE DESIGN LOAD AND SELECTION

Maximum load on shackle FSKL := FUSDL = 45.815 tonnef

SHACKLE SELECTION

Specification: Crosby G-2140 55t WLL shackle

Working load limit FWLL := 55tonnef

Pin diameter D := 57.2mm

Inside width B := 82.6mm

Inside length H := 197mm

Weight W sh := 23.6kg

Doc G00A-ST-RPT-01-00137-107-00 Appendix A6-3 of A6-30 Rev :A

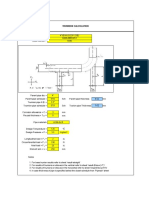

5.2.3. PADEYE DESIGN CALCULATIONS

PADEYE DIMENSIONS

Padeye Design Load 5

FPDL := Fsmax = 8.986 10 N

Radius of pin hole R h := 30mm

Use the following sizes of main, cheek and spacer plates

Item Radius Thickness

Main plate R m := 100mm t m := 50mm

Cheek plates R c1 := 60mm t c1 := 15mm

Yield stress of padeye steel Fy := 335MPa

Young's modulus 5

E := 2 10 MPa

Poisson's ratio := 0.3

Clearance available between cheek plate and

(

B - tm + 2 t c1 )

S := = 1.3 mm

shackle 2

D

Clearance between main plate and sling C 1 := R m - = 71.4 mm

2

C 2 := H - ds - C 1 = 69.6 mm

CHECK FOR BEARING STRESS

Reduction for bearing area 120 deg = 0.866

C r := sin

2

FPDL

Bearing stress b := = 226.747 MPa

( )

D t m + 2 tc1 C r

Allowable bearing stress ba := 0.9 Fy = 301.5 MPa

Check := "OK" if b < ba

"Redesign" otherwise

Check = "OK"

Doc G00A-ST-RPT-01-00137-107-00 Appendix A6-4 of A6-30 Rev :A

CHECK FOR HERTZ STRESS

FPDL

Load per unit length 4 kN

Phertz := = 1.123 10

tm + 2 t c1 m

Hertz stress

(2 R h - D )

h := Phertz E = 800.68 MPa

1-

( 2

) 2 RhD

Allowable hertz stress ha := 2.5 Fy = 837.5 MPa

Check := "OK" if h < ha

"Redesign" otherwise

Check = "OK"

CHECK FOR SHEAR STRESS

FPDL

Shear stress s :=

( ) (

2 R m - R h tm + 2 R c1 - R h t c1

)

s = 102.112 MPa

Allowable shear stress sa := 0.4 Fy = 134 MPa

Check := "OK" if s < sa

"Redesign" otherwise

Check = "OK"

FORCES ACTING ON CHEEK PLATE 1 WELD ds

FPDL tc1 FPDL 0.05 H -

Force acting on cheek plate 1 weld 2

R 1 := +

(tm + 2 tc1) (tm + 2 tc1)

R 1 = 263.397 kN

CHECK WELD BETWEEN MAIN PLATE AND CHEEK PLATE 1

Allowable weld shear stress (

sw := min 0.4 Fy , 0.3 70ksi = 134 MPa)

R1

Weld size required (fillet weld) Sw1 := = 14.75 mm

R c1 0.707 sw

Provide a fillet weld of 16 mm

Doc G00A-ST-RPT-01-00137-107-00 Appendix A6-5 of A6-30 Rev :A

5.2.4 CHECK PADEYE MAIN PLATE

COMBINED SECTIONAL PROPERTIES OF THE PADEYE MAIN PLATE AND STIFFENERS

Thickness of bottom stiffener plate t s1 := 0mm

Length of bottom stiffener plate ls1 := 0mm

2

Area of bottom stiffener plate As1 := 2 ls1 ts1 = 0 mm

Thickness of top stiffener plate t s2 := 0mm

Length of top stiffener plate ls2 := 0mm

2

Area of top stiffener plate As2 := 2 ls2 ts2 = 0 mm

Length of main plate Lm := 350mm

4 2

Area of main plate Am := Lm t m = 1.75 10 mm

4 2

Total cross section area At := Am + As1 + As2 = 1.75 10 mm

Finding the centroid(distance from the bottom stiffener plate)

ts1 ts2 Lm

As1 + A s2 ts1 + Lm + + Am t s1 +

2 2 2

Xcent := = 175 mm

At

Doc G00A-ST-RPT-01-00137-107-00 Appendix A6-6 of A6-30 Rev :A

Since the padeye is symmetric, the centroid will lie in the middle of the main plate and hence the

position of the centroid along the Y axis need not be computed

Moment of inertia for inplane bending

3 2 2

t m Lm Lm t s1

3 8 4

IAA := + A m ts1 + - Xcent + 2 ls1 ts1 + 2 ls1 t s1 - Xcent ... = 1.786 10 mm

12 2 2

2

ts2

3

+ 2 ls2 ts2 + 2 ls2 t s2 ts1 + Lm + - Xcent

2

Moment of inertia for out of plane bending

3

Lm t m (

ts1 2 ls1 )3 (

ts2 2 ls2 )3 6 4

IBB := + + = 3.646 10 mm

12 12 12

8 4

Polar moment of inertia IPt := IAA + IBB = 1.823 10 mm

IAA

Section modulus for inplane bending ZAA :=

( )

max Xcent , ts1 + t s2 + Lm - Xcent

6 3

ZAA = 1.021 10 mm

IBB

Section modulus for out of plane bending ZBB :=

tm

max ls1 , ls2 ,

2

5 3

ZBB = 1.458 10 mm

As a design requirement , provide 5% padeye force in orthogonal out of plane direction

Horizontal shear force in out of plane orthogonal Fvc2 := 0.05 Fsmax = 44.929 kN

direction

Distance of centre of padeye hole from the vertical z pad1 := 150mm

shear plane of padeye

Horizontal distance from centre of padeye hole to z pad2 := 0mm

centre of sling diameter on inside of shackle bow

D ds

Vertical distance from centre of padeye hole to xpad := + H - sin ( 1) = 197.6 mm

centre of sling diameter on inside of shackle bow 2 2

Doc G00A-ST-RPT-01-00137-107-00 Appendix A6-7 of A6-30 Rev :A

FORCES AND MOMENTS ACTING AT INTERFACE OF THE PADEYE AND THE TUBULAR

Max tensile force on the padeye Fze := 0kN

Max shear force Fvc := Fsmax sin ( 1) = 898.583 kN

Fze

Axial stress in built up section axial := = 0 MPa

At

Position of the centre of padeye hole Lm2 := ts1 + Lm - R m = 0.25 m

Inplane bending ( )

MAA := Fvc z pad1 - Fze Lm2 - Xcent = 134.788 kN m

Out of plane bending ( )

MBB := Fvc2 z pad1 + z pad2 = 6.739 kN m

CHECK BENDING STRESSES

MAA

Actual inplane bending stress AA := = 132.037 MPa

ZAA

MBB

Actual out of plane bending stress BB := = 46.213 MPa

ZBB

Axial stress axial = 0 MPa

Adopting allowable axial and bending stress to be 0.6Fy conservatively

Doc G00A-ST-RPT-01-00137-107-00 Appendix A6-8 of A6-30 Rev :A

Allowable axial stress ca := 0.6Fy = 201 MPa

Allowable bending stress cb := 0.6Fy = 201 MPa

axial AA + BB

Combined stress ratio Fc := + = 0.887

ca cb

Total combined stress c := axial + AA + BB = 178.25 MPa less than

σcb

Check := "OK" if Fc < 1

"Redesign!" otherwise

Check = "OK"

CHECK SHEAR STRESSES

Fvc

Inplane shear stress vc := = 51.348 MPa

Lm t m

Allowable shear stress all := 0.4 Fy = 134 MPa

Adopting allowable axial and bending stress to be 0.6Fy conservatively

Check := "OK" if vc < all

"Redesign!" otherwise

Check = "OK"

vc

Unity Check UC := = 0.383

all

Doc G00A-ST-RPT-01-00137-107-00 Appendix A6-9 of A6-30 Rev :A

6. DESIGN SUMMARY

SLINGS

Sling No. Diameter Min. breaking strength

1 ds = 56 mm FMBSL = 195 tonnef

SHACKLES: Crosby G-2140 SHACKLE

Working load limit FWLL = 55 tonnef

Pin diameter D = 57.2 mm

Inside width B = 82.6 mm

Inside Height H = 197 mm

PADEYES

Main plate radius R m = 100 mm

Main plate thickness t m = 50 mm

Radius of padeye hole R h = 30 mm

Cheek plate radius R c1 = 60 mm

Cheek plate thickness t c1 = 15 mm

Cheek plate weld thickness Sw := 16mm

Length of stiffener plate 1 ls1 = 0 mm

Thickness of stiffener plate 1 t s1 = 0 mm

Length of stiffener plate 2 ls2 = 0 mm

Thickness of stiffener plate 2 t s2 = 0 mm

Doc G00A-ST-RPT-01-00137-107-00 Appendix A6-10 of A6-30 Rev :A

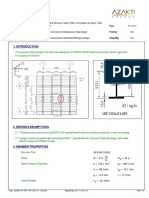

SECTION B

1. INTRODUCTION

. The purpose of the section B of this worksheet is to design a pile lifting padeye to lift the pile P1

designed to lift a total weight of 39t.

2. SLING, SHACKLE AND PADEYE DESIGN

2.1. SLING DESIGN LOAD AND SELECTION

Unfactored sling design load (half the lift FUSDL := 1.1 0.5 39tonnef = 21.45 tonnef

weight+10%contingency)

Padeye design load Fsmax := 2 FUSDL = 42.9 tonnef

Doc G00A-ST-RPT-01-00137-107-00 Appendix A6-11 of A6-30 Rev :A

Sling breaking strength safety factor Sb := 4.0

Calculated sling breaking load FCRBL := Sb FUSDL = 85.8 tonnef

Lifting Angle 1 := 90deg

SLING SELECTION

Specification: Gaylin Koiswire 6 X 37 + FC type B & CG (180 kg/mm2) 40mm wire rope with 92.2 tonnef

MBL

Diameter ds := 40mm

Minimum breaking strength FMBSL := 92.2tonnef

kg

Weight W s := 5.75

m

Doc G00A-ST-RPT-01-00137-107-00 Appendix A6-12 of A6-30 Rev :A

5.2.2. SHACKLE DESIGN LOAD AND SELECTION

Maximum load on shackle FSKL := FUSDL = 21.45 tonnef

SHACKLE SELECTION

Specification: Crosby G-2140 30t WLL shackle

Working load limit FWLL := 30tonnef

Pin diameter D := 41.4mm

Inside width B := 60.5mm

Inside length H := 146mm

Weight W sh := 8.52kg

Doc G00A-ST-RPT-01-00137-107-00 Appendix A6-13 of A6-30 Rev :A

5.2.3. PADEYE DESIGN CALCULATIONS

PADEYE DIMENSIONS

Padeye Design Load 5

FPDL := Fsmax = 4.207 10 N

Radius of pin hole R h := 21.5mm

Use the following sizes of main, cheek and spacer plates

Item Radius Thickness

Main plate R m := 80mm t m := 35mm

Cheek plates R c1 := 60mm t c1 := 10mm

Yield stress of padeye steel Fy := 345MPa

Young's modulus 5

E := 2 10 MPa

Poisson's ratio := 0.3

Clearance available between cheek plate and

(

B - tm + 2 t c1 )

S := = 2.75 mm

shackle 2

D

Clearance between main plate and sling C 1 := R m - = 59.3 mm

2

C 2 := H - ds - C 1 = 46.7 mm

CHECK FOR BEARING STRESS

Reduction for bearing area 120 deg = 0.866

C r := sin

2

FPDL

Bearing stress b := = 213.346 MPa

( )

D t m + 2 tc1 C r

Allowable bearing stress ba := 0.9 Fy = 310.5 MPa

Check := "OK" if b < ba

"Redesign" otherwise

Check = "OK"

Doc G00A-ST-RPT-01-00137-107-00 Appendix A6-14 of A6-30 Rev :A

CHECK FOR HERTZ STRESS

FPDL kN

Load per unit length Phertz := = 7649.187

tm + 2 t c1 m

Hertz stress

(2 R h - D )

h := Phertz E = 693.51 MPa

1-

( 2

) 2 RhD

Allowable hertz stress ha := 2.5 Fy = 862.5 MPa

Check := "OK" if h < ha

"Redesign" otherwise

Check = "OK"

CHECK FOR SHEAR STRESS

FPDL

Shear stress s :=

( ) (

2 R m - R h tm + 2 R c1 - R h t c1

)

s = 74.659 MPa

Allowable shear stress sa := 0.4 Fy = 138 MPa

Check := "OK" if s < sa

"Redesign" otherwise

Check = "OK"

FORCES ACTING ON CHEEK PLATE 1 WELD ds

FPDL tc1 FPDL 0.05 H -

Force acting on cheek plate 1 weld 2

R 1 := +

(tm + 2 tc1) (tm + 2 tc1)

R 1 = 124.682 kN

CHECK WELD BETWEEN MAIN PLATE AND CHEEK PLATE 1

Allowable weld shear stress ( )

sw := min 0.4 Fy , 0.3 70ksi = 138 MPa

R1

Weld size required (fillet weld) Sw1 := = 6.78 mm

R c1 0.707 sw

Provide a fillet weld of 8 mm

Doc G00A-ST-RPT-01-00137-107-00 Appendix A6-15 of A6-30 Rev :A

5.2.4 CHECK PADEYE MAIN PLATE

COMBINED SECTIONAL PROPERTIES OF THE PADEYE MAIN PLATE AND STIFFENERS

Thickness of bottom stiffener plate t s1 := 0mm

Length of bottom stiffener plate ls1 := 0mm

2

Area of bottom stiffener plate As1 := 2 ls1 ts1 = 0 mm

Thickness of top stiffener plate t s2 := 0mm

Length of top stiffener plate ls2 := 0mm

2

Area of top stiffener plate As2 := 2 ls2 ts2 = 0 mm

Length of main plate Lm := 300mm

4 2

Area of main plate Am := Lm t m = 1.05 10 mm

4 2

Total cross section area At := Am + As1 + As2 = 1.05 10 mm

Finding the centroid(distance from the bottom stiffener plate)

ts1 ts2 Lm

As1 + A s2 ts1 + Lm + + Am t s1 +

2 2 2

Xcent := = 150 mm

At

Doc G00A-ST-RPT-01-00137-107-00 Appendix A6-16 of A6-30 Rev :A

Since the padeye is symmetric, the centroid will lie in the middle of the main plate and hence the

position of the centroid along the Y axis need not be computed

Moment of inertia for inplane bending

3 2 2

t m Lm Lm t s1

3 7 4

IAA := + A m ts1 + - Xcent + 2 ls1 ts1 + 2 ls1 t s1 - Xcent ... = 7.875 10 mm

12 2 2

2

ts2

3

+ 2 ls2 ts2 + 2 ls2 t s2 ts1 + Lm + - Xcent

2

Moment of inertia for out of plane bending

3

Lm t m (

ts1 2 ls1 )3 (

ts2 2 ls2 )3 6 4

IBB := + + = 1.072 10 mm

12 12 12

7 4

Polar moment of inertia IPt := IAA + IBB = 7.982 10 mm

IAA

Section modulus for inplane bending ZAA :=

(

max Xcent , ts1 + t s2 + Lm - Xcent

)

5 3

ZAA = 5.25 10 mm

IBB

Section modulus for out of plane bending ZBB :=

tm

max ls1 , ls2 ,

2

4 3

ZBB = 6.125 10 mm

As a design requirement , provide 5% padeye force in orthogonal out of plane direction

Horizontal shear force in out of plane orthogonal Fvc2 := 0.05 Fsmax = 21.035 kN

direction

Distance of centre of padeye hole from the vertical z pad1 := 150mm

shear plane of padeye

Horizontal distance from centre of padeye hole to z pad2 := 0mm

centre of sling diameter on inside of shackle bow

D ds

Vertical distance from centre of padeye hole to xpad := + H - sin ( 1) = 146.7 mm

centre of sling diameter on inside of shackle bow 2 2

Doc G00A-ST-RPT-01-00137-107-00 Appendix A6-17 of A6-30 Rev :A

FORCES AND MOMENTS ACTING AT INTERFACE OF THE PADEYE AND THE TUBULAR

Max tensile force on the padeye Fze := 0kN

Max shear force Fvc := Fsmax sin ( 1) = 420.705 kN

Fze

Axial stress in built up section axial := = 0 MPa

At

Position of the centre of padeye hole Lm2 := ts1 + Lm - R m = 0.22 m

Inplane bending ( )

MAA := Fvc z pad1 - Fze Lm2 - Xcent = 63.106 kN m

Out of plane bending ( )

MBB := Fvc2 z pad1 + z pad2 = 3.155 kN m

CHECK BENDING STRESSES

MAA

Actual inplane bending stress AA := = 120.202 MPa

ZAA

MBB

Actual out of plane bending stress BB := = 51.515 MPa

ZBB

Axial stress axial = 0 MPa

Adopting allowable axial and bending stress to be 0.6Fy conservatively

Doc G00A-ST-RPT-01-00137-107-00 Appendix A6-18 of A6-30 Rev :A

Allowable axial stress ca := 0.6Fy = 207 MPa

Allowable bending stress cb := 0.6Fy = 207 MPa

axial AA + BB

Combined stress ratio Fc := + = 0.83

ca cb

Total combined stress c := axial + AA + BB = 171.716 MPa less than

σcb

Check := "OK" if Fc < 1

"Redesign!" otherwise

Check = "OK"

CHECK SHEAR STRESSES

Fvc

Inplane shear stress vc := = 40.067 MPa

Lm t m

Allowable shear stress all := 0.4 Fy = 138 MPa

Adopting allowable axial and bending stress to be 0.6Fy conservatively

Check := "OK" if vc < all

"Redesign!" otherwise

Check = "OK"

vc

Unity Check UC := = 0.29

all

Doc G00A-ST-RPT-01-00137-107-00 Appendix A6-19 of A6-30 Rev :A

6. DESIGN SUMMARY

SLINGS

Sling No. Diameter Min. breaking strength

1 ds = 40 mm FMBSL = 92.2 tonnef

SHACKLES: Crosby G-2140 SHACKLE

Working load limit FWLL = 30 tonnef

Pin diameter D = 41.4 mm

Inside width B = 60.5 mm

Inside Height H = 146 mm

PADEYES

Main plate radius R m = 80 mm

Main plate thickness t m = 35 mm

Radius of padeye hole R h = 21.5 mm

Cheek plate radius R c1 = 60 mm

Cheek plate thickness t c1 = 10 mm

Cheek plate weld thickness Sw := 8mm

Length of stiffener plate 1 ls1 = 0 mm

Thickness of stiffener plate 1 t s1 = 0 mm

Length of stiffener plate 2 ls2 = 0 mm

Thickness of stiffener plate 2 t s2 = 0 mm

Doc G00A-ST-RPT-01-00137-107-00 Appendix A6-20 of A6-30 Rev :A

SECTION C

1. INTRODUCTION

. The purpose of the section C of this worksheet is to design a pile lifting padeye to lift the pile P3

designed to lift a total weight of 27.2t.

2. SLING, SHACKLE AND PADEYE DESIGN

2.1. SLING DESIGN LOAD AND SELECTION

Unfactored sling design load (half the lift FUSDL := 1.1 0.5 27.2tonnef = 14.96 tonnef

weight+10%contingency)

Padeye design load Fsmax := 2 FUSDL = 29.92 tonnef

Doc G00A-ST-RPT-01-00137-107-00 Appendix A6-21 of A6-30 Rev :A

Sling breaking strength safety factor Sb := 4.0

Calculated sling breaking load FCRBL := Sb FUSDL = 59.84 tonnef

Lifting Angle 1 := 90deg

SLING SELECTION

Specification: Gaylin Koiswire 6 X 37 + FC type C (200 kg/mm2) 31.5mm wire rope with 61.8 tonnef

MBL

Diameter ds := 31.5mm

Minimum breaking strength FMBSL := 61.8tonnef

kg

Weight W s := 3.57

m

Doc G00A-ST-RPT-01-00137-107-00 Appendix A6-22 of A6-30 Rev :A

5.2.2. SHACKLE DESIGN LOAD AND SELECTION

Maximum load on shackle FSKL := FUSDL = 14.96 tonnef

SHACKLE SELECTION

Specification: Crosby G-2140 18t WLL shackle

Working load limit FWLL := 18tonnef

Pin diameter D := 35.6mm

Inside width B := 51.6mm

Inside length H := 119.1mm

Weight W sh := 5.31kg

Doc G00A-ST-RPT-01-00137-107-00 Appendix A6-23 of A6-30 Rev :A

5.2.3. PADEYE DESIGN CALCULATIONS

PADEYE DIMENSIONS

Padeye Design Load 5

FPDL := Fsmax = 2.934 10 N

Radius of pin hole R h := 19mm

Use the following sizes of main, cheek and spacer plates

Item Radius Thickness

Main plate R m := 60mm t m := 30mm

Cheek plates R c1 := 40mm t c1 := 8mm

Yield stress of padeye steel Fy := 345MPa

Young's modulus 5

E := 2 10 MPa

Poisson's ratio := 0.3

Clearance available between cheek plate and

(

B - tm + 2 t c1 )

S := = 2.8 mm

shackle 2

D

Clearance between main plate and sling C 1 := R m - = 42.2 mm

2

C 2 := H - ds - C 1 = 45.4 mm

CHECK FOR BEARING STRESS

Reduction for bearing area 120 deg = 0.866

C r := sin

2

FPDL

Bearing stress b := = 206.892 MPa

( )

D t m + 2 tc1 C r

Allowable bearing stress ba := 0.9 Fy = 310.5 MPa

Check := "OK" if b < ba

"Redesign" otherwise

Check = "OK"

Doc G00A-ST-RPT-01-00137-107-00 Appendix A6-24 of A6-30 Rev :A

CHECK FOR HERTZ STRESS

FPDL kN

Load per unit length Phertz := = 6378.586

tm + 2 t c1 m

Hertz stress

(2 R h - D )

h := Phertz E = 889.755 MPa

1-

( 2

) 2 RhD

Allowable hertz stress ha := 2.5 Fy = 862.5 MPa

Check := "OK" if h < ha

"Redesign" otherwise

Check = "Redesign"

CHECK FOR SHEAR STRESS

FPDL

Shear stress s :=

( ) (

2 R m - R h tm + 2 R c1 - R h t c1

)

s = 93.683 MPa

Allowable shear stress sa := 0.4 Fy = 138 MPa

Check := "OK" if s < sa

"Redesign" otherwise

Check = "OK"

FORCES ACTING ON CHEEK PLATE 1 WELD ds

FPDL tc1 FPDL 0.05 H -

Force acting on cheek plate 1 weld 2

R 1 := +

(tm + 2 tc1) (tm + 2 tc1)

R 1 = 83.99 kN

CHECK WELD BETWEEN MAIN PLATE AND CHEEK PLATE 1

Allowable weld shear stress ( )

sw := min 0.4 Fy , 0.3 70ksi = 138 MPa

R1

Weld size required (fillet weld) Sw1 := = 6.85 mm

R c1 0.707 sw

Provide a fillet weld of 8 mm

Doc G00A-ST-RPT-01-00137-107-00 Appendix A6-25 of A6-30 Rev :A

5.2.4 CHECK PADEYE MAIN PLATE

COMBINED SECTIONAL PROPERTIES OF THE PADEYE MAIN PLATE AND STIFFENERS

Thickness of bottom stiffener plate t s1 := 0mm

Length of bottom stiffener plate ls1 := 0mm

2

Area of bottom stiffener plate As1 := 2 ls1 ts1 = 0 mm

Thickness of top stiffener plate t s2 := 0mm

Length of top stiffener plate ls2 := 0mm

2

Area of top stiffener plate As2 := 2 ls2 ts2 = 0 mm

Length of main plate Lm := 250mm

2

Area of main plate Am := Lm t m = 7500 mm

2

Total cross section area At := Am + As1 + As2 = 7500 mm

Finding the centroid(distance from the bottom stiffener plate)

ts1 ts2 Lm

As1 + A s2 ts1 + Lm + + Am t s1 +

2 2 2

Xcent := = 125 mm

At

Doc G00A-ST-RPT-01-00137-107-00 Appendix A6-26 of A6-30 Rev :A

Since the padeye is symmetric, the centroid will lie in the middle of the main plate and hence the

position of the centroid along the Y axis need not be computed

Moment of inertia for inplane bending

3 2 2

t m Lm Lm t s1

3 7 4

IAA := + A m ts1 + - Xcent + 2 ls1 ts1 + 2 ls1 t s1 - Xcent ... = 3.906 10 mm

12 2 2

2

ts2

3

+ 2 ls2 ts2 + 2 ls2 t s2 ts1 + Lm + - Xcent

2

Moment of inertia for out of plane bending

3

Lm t m (

ts1 2 ls1 )3 (

ts2 2 ls2 )3 5 4

IBB := + + = 5.625 10 mm

12 12 12

7 4

Polar moment of inertia IPt := IAA + IBB = 3.963 10 mm

IAA

Section modulus for inplane bending ZAA :=

(

max Xcent , ts1 + t s2 + Lm - Xcent

)

5 3

ZAA = 3.125 10 mm

IBB

Section modulus for out of plane bending ZBB :=

tm

max ls1 , ls2 ,

2

4 3

ZBB = 3.75 10 mm

As a design requirement , provide 5% padeye force in orthogonal out of plane direction

Horizontal shear force in out of plane orthogonal Fvc2 := 0.05 Fsmax = 14.671 kN

direction

Distance of centre of padeye hole from the vertical z pad1 := 150mm

shear plane of padeye

Horizontal distance from centre of padeye hole to z pad2 := 0mm

centre of sling diameter on inside of shackle bow

D ds

Vertical distance from centre of padeye hole to xpad := + H - sin ( 1) = 121.15 mm

centre of sling diameter on inside of shackle bow 2 2

Doc G00A-ST-RPT-01-00137-107-00 Appendix A6-27 of A6-30 Rev :A

FORCES AND MOMENTS ACTING AT INTERFACE OF THE PADEYE AND THE TUBULAR

Max tensile force on the padeye Fze := 0kN

Max shear force Fvc := Fsmax sin ( 1) = 293.415 kN

Fze

Axial stress in built up section axial := = 0 MPa

At

Position of the centre of padeye hole Lm2 := ts1 + Lm - R m = 0.19 m

Inplane bending ( )

MAA := Fvc z pad1 - Fze Lm2 - Xcent = 44.012 kN m

Out of plane bending ( )

MBB := Fvc2 z pad1 + z pad2 = 2.201 kN m

CHECK BENDING STRESSES

MAA

Actual inplane bending stress AA := = 140.839 MPa

ZAA

MBB

Actual out of plane bending stress BB := = 58.683 MPa

ZBB

Axial stress axial = 0 MPa

Adopting allowable axial and bending stress to be 0.6Fy conservatively

Doc G00A-ST-RPT-01-00137-107-00 Appendix A6-28 of A6-30 Rev :A

Allowable axial stress ca := 0.6Fy = 207 MPa

Allowable bending stress cb := 0.6Fy = 207 MPa

axial AA + BB

Combined stress ratio Fc := + = 0.964

ca cb

Total combined stress c := axial + AA + BB = 199.522 MPa

Check := "OK" if Fc < 1

"Redesign!" otherwise

Check = "OK"

CHECK SHEAR STRESSES

Fvc

Inplane shear stress vc := = 39.122 MPa

Lm t m

Allowable shear stress all := 0.4 Fy = 138 MPa

Adopting allowable axial and bending stress to be 0.6Fy conservatively

Check := "OK" if vc < all

"Redesign!" otherwise

Check = "OK"

vc

Unity Check UC := = 0.283

all

Doc G00A-ST-RPT-01-00137-107-00 Appendix A6-29 of A6-30 Rev :A

6. DESIGN SUMMARY

SLINGS

Sling No. Diameter Min. breaking strength

1 ds = 31.5 mm FMBSL = 61.8 tonnef

SHACKLES: Crosby G-2140 SHACKLE

Working load limit FWLL = 18 tonnef

D = 35.6 mm

Inside width B = 51.6 mm

H = 119.1 mm

PADEYES

Main plate radius R m = 60 mm

Main plate thickness t m = 30 mm

Radius of padeye hole R h = 19 mm

Cheek plate radius R c1 = 40 mm

Cheek plate thickness t c1 = 8 mm

Cheek plate weld thickness Sw := 8mm

Length of stiffener plate 1 ls1 = 0 mm

Thickness of stiffener plate 1 t s1 = 0 mm

Length of stiffener plate 2 ls2 = 0 mm

Thickness of stiffener plate 2 t s2 = 0 mm

Doc G00A-ST-RPT-01-00137-107-00 Appendix A6-30 of A6-30 Rev :A

You might also like

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Stiffener Check For Pipe SupportDocument5 pagesStiffener Check For Pipe SupportSai Sushank100% (1)

- Ducting Stress Analysis Report ReviewDocument81 pagesDucting Stress Analysis Report ReviewDaya AlamFarabiNo ratings yet

- Front End Engineering Design (FEED) for Gas Lift Compression Project Pipeline DesignDocument14 pagesFront End Engineering Design (FEED) for Gas Lift Compression Project Pipeline Designsutomo rochmandaNo ratings yet

- Wind Turbine Foundation Design StepsDocument9 pagesWind Turbine Foundation Design StepsRamachandran Sundararaman100% (1)

- OBS InstallationDocument6 pagesOBS InstallationFaridah ZahraNo ratings yet

- Input Data: Trench - CoverDocument20 pagesInput Data: Trench - CoverEl riza annamlNo ratings yet

- Padeye - 01Document9 pagesPadeye - 01ramNo ratings yet

- Mathcad - Sandy SoilDocument1 pageMathcad - Sandy SoillsatchithananthanNo ratings yet

- Transmission Line Design and Steel Pole StructuresDocument27 pagesTransmission Line Design and Steel Pole StructuresDanNo ratings yet

- App 10 Longitudial Shear 2 UC 283Document3 pagesApp 10 Longitudial Shear 2 UC 283yuNo ratings yet

- Lifting Analysis Report - Mahadi KurniawanDocument31 pagesLifting Analysis Report - Mahadi KurniawanDian SasNo ratings yet

- Padeye Design CheekDocument1 pagePadeye Design CheekPawan ShettyNo ratings yet

- PLEM Pile Drivability PDFDocument49 pagesPLEM Pile Drivability PDFTharach JanesuapasaereeNo ratings yet

- Padeye Design AnalysisDocument8 pagesPadeye Design AnalysisMyatmyat SwewinNo ratings yet

- Clamp Design-2Document6 pagesClamp Design-2Harpreet SinghNo ratings yet

- Calculation of DavitDocument2 pagesCalculation of DavitpiziyuNo ratings yet

- Vessel Side Shell Check CalculationsDocument5 pagesVessel Side Shell Check CalculationsShahir MeledathNo ratings yet

- NODE PLATE STRESS CALCULATIONDocument14 pagesNODE PLATE STRESS CALCULATIONparvej0% (1)

- ABS Fatigue Life Assessment 2014Document1 pageABS Fatigue Life Assessment 2014Fandy SipataNo ratings yet

- FOUNDATION ANALYSISDocument14 pagesFOUNDATION ANALYSISJuli NirwantoNo ratings yet

- Shear Failure of Bolted Joints Lab ReportDocument1 pageShear Failure of Bolted Joints Lab Reportboo huNo ratings yet

- Input Parameters: 1.1. Input Surface Areas 1.1.1. Above Mudline Without Corrosion Protection CoatingDocument6 pagesInput Parameters: 1.1. Input Surface Areas 1.1.1. Above Mudline Without Corrosion Protection CoatingThomas StephenNo ratings yet

- DANA-Technical Note (TN)Document8 pagesDANA-Technical Note (TN)Samsul Imran BahromNo ratings yet

- Fatigue Analysis of AL SHAHEEN Field Crown PlateDocument9 pagesFatigue Analysis of AL SHAHEEN Field Crown PlateRajat KatyalNo ratings yet

- Torispherical Cone With KnuckleDocument2 pagesTorispherical Cone With KnuckleSajal KulshresthaNo ratings yet

- Lifting Analysis Preview)Document4 pagesLifting Analysis Preview)Faisal AjaNo ratings yet

- Appendix e (Sacs Output)Document6 pagesAppendix e (Sacs Output)Tran Van DaiNo ratings yet

- Subsee Suction Pile Installation AnalysisDocument11 pagesSubsee Suction Pile Installation AnalysisKen KennyNo ratings yet

- BOX Sec-Beam-Column-AiscDocument6 pagesBOX Sec-Beam-Column-AiscWintun73No ratings yet

- Foundation 1 Design ReportDocument18 pagesFoundation 1 Design Reportyolittle shiNo ratings yet

- Dent Depth CalculationDocument1 pageDent Depth CalculationSai SushankNo ratings yet

- Pt. Tripatra Engineering: Calculation SheetDocument6 pagesPt. Tripatra Engineering: Calculation SheetriandiNo ratings yet

- Calculation Note Stabbing Guide Design Design Code Check:Api RP 2A Check For Tubular Ø 323.9 X 12.70 Due To Boatlanding InstallationDocument8 pagesCalculation Note Stabbing Guide Design Design Code Check:Api RP 2A Check For Tubular Ø 323.9 X 12.70 Due To Boatlanding InstallationSai SushankNo ratings yet

- CS-Guide CalculationDocument27 pagesCS-Guide Calculationduf fuNo ratings yet

- Vedeld 2 - VIV Fatigue CalculationDocument36 pagesVedeld 2 - VIV Fatigue Calculationmobin_turkNo ratings yet

- Tips For FEA AnalysisDocument6 pagesTips For FEA Analysissagar1503No ratings yet

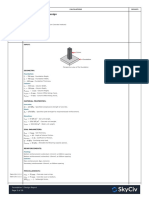

- Skyciv Foundation Design: InputDocument19 pagesSkyciv Foundation Design: InputNaim ZeinounNo ratings yet

- 150 VV 1010 Davit CalculationDocument3 pages150 VV 1010 Davit Calculationdraj1875977No ratings yet

- 4.75 Tonne Padeye Design AnalysisDocument4 pages4.75 Tonne Padeye Design AnalysissereNo ratings yet

- Mathcad - Laydown Area Deck PlateDocument3 pagesMathcad - Laydown Area Deck PlatePradeep ChitluriNo ratings yet

- Comp 2Document9 pagesComp 2YYo YudiNo ratings yet

- 02-Lifting Operation Planning Checklist - Lifting Freon Bottle To E-House Roof TopDocument6 pages02-Lifting Operation Planning Checklist - Lifting Freon Bottle To E-House Roof TopImam Saja DechNo ratings yet

- ENGI 8673 Subsea Pipeline Engineering Lecture 17 ExampleDocument3 pagesENGI 8673 Subsea Pipeline Engineering Lecture 17 ExampleThyago de LellysNo ratings yet

- Wind Pressure Calculation As per SP-1275Document7 pagesWind Pressure Calculation As per SP-1275Siva baalanNo ratings yet

- Support Leg DesignDocument4 pagesSupport Leg DesignSiva baalanNo ratings yet

- Petroleum Regeneration and Processing Facility: Anchor Force CalculationDocument8 pagesPetroleum Regeneration and Processing Facility: Anchor Force CalculationPrasadNo ratings yet

- Bending Moment Diagram CalculationDocument97 pagesBending Moment Diagram CalculationCharles HutabaratNo ratings yet

- Fatigue AnalysisDocument2 pagesFatigue AnalysisZulham MochtarNo ratings yet

- SEISMIC ANALYSIS KazzincDocument14 pagesSEISMIC ANALYSIS KazzincArees KhambattaNo ratings yet

- FEA Analysis For Hull MEG Storage Tank T-5601AB - Rev 01Document52 pagesFEA Analysis For Hull MEG Storage Tank T-5601AB - Rev 01jahiranazriNo ratings yet

- Soroosh and Nowrooz Integrated Development Project: SO EST AN Spp1 55000 D0Document54 pagesSoroosh and Nowrooz Integrated Development Project: SO EST AN Spp1 55000 D0AnjuNo ratings yet

- Technical Evaluation HAM BAKERDocument1 pageTechnical Evaluation HAM BAKEReko123No ratings yet

- Dog Plate & Tubular Support Subsea Template DesignDocument4 pagesDog Plate & Tubular Support Subsea Template DesignAkhmad Syahroni100% (1)

- ABB - Cálculo de Esfuerzos PDFDocument14 pagesABB - Cálculo de Esfuerzos PDFRogelio RevettiNo ratings yet

- Slot Expansion CalculationDocument1 pageSlot Expansion CalculationSarfaraz KhanNo ratings yet

- Trunnion Calcualtion SheetDocument22 pagesTrunnion Calcualtion SheetAbhijit50% (2)

- Head Nozzle and Flange Calculation, DN100 (CF) Size NozzleDocument7 pagesHead Nozzle and Flange Calculation, DN100 (CF) Size Nozzleakın ersözNo ratings yet

- Appendix A1Document5 pagesAppendix A1Thomas Stephen100% (1)

- Conductor Cone Guide Design CalculationsDocument3 pagesConductor Cone Guide Design CalculationsThomas StephenNo ratings yet

- Appendix A5Document4 pagesAppendix A5Thomas StephenNo ratings yet

- Appendix A5Document4 pagesAppendix A5Thomas StephenNo ratings yet

- Active StructureDocument1 pageActive StructureThomas StephenNo ratings yet

- Nylon Carpet. Harrington Catalogue.2022 - 2022-09-20T105330.316Document36 pagesNylon Carpet. Harrington Catalogue.2022 - 2022-09-20T105330.316Thomas StephenNo ratings yet

- Developing affordable feed for seabass aquacultureDocument4 pagesDeveloping affordable feed for seabass aquacultureThomas StephenNo ratings yet

- Appendix A3Document6 pagesAppendix A3Thomas Stephen100% (1)

- Appendix A2Document8 pagesAppendix A2Thomas StephenNo ratings yet

- Appendix A1Document22 pagesAppendix A1Thomas StephenNo ratings yet

- New Floating Fish Farm Off Changi Aims To Produce More Seafood Than Traditional Coastal Farms - TODAYonline PDFDocument27 pagesNew Floating Fish Farm Off Changi Aims To Produce More Seafood Than Traditional Coastal Farms - TODAYonline PDFThomas StephenNo ratings yet

- Appendix A1Document5 pagesAppendix A1Thomas Stephen100% (1)

- Conductor Cone Guide Design CalculationsDocument3 pagesConductor Cone Guide Design CalculationsThomas StephenNo ratings yet

- Appendix A1Document5 pagesAppendix A1Thomas Stephen100% (1)

- Input Parameters: 1.1. Input Surface Areas 1.1.1. Above Mudline Without Corrosion Protection CoatingDocument6 pagesInput Parameters: 1.1. Input Surface Areas 1.1.1. Above Mudline Without Corrosion Protection CoatingThomas StephenNo ratings yet

- Appendix A3Document8 pagesAppendix A3Thomas StephenNo ratings yet

- Design of Stabbing Guides for PilesDocument3 pagesDesign of Stabbing Guides for PilesThomas StephenNo ratings yet

- The Purpose of This Worksheet Is To Design The Welded Connection Between The Jacket Leg and Crownshim and The Piles and CrownshimDocument5 pagesThe Purpose of This Worksheet Is To Design The Welded Connection Between The Jacket Leg and Crownshim and The Piles and CrownshimThomas StephenNo ratings yet

- Project Manager Gantt ChartDocument16 pagesProject Manager Gantt ChartThomas StephenNo ratings yet

- Design stairway from EL 1500 to 6500Document10 pagesDesign stairway from EL 1500 to 6500Thomas StephenNo ratings yet

- Leg Protector Impact Load EstimationDocument3 pagesLeg Protector Impact Load EstimationThomas StephenNo ratings yet

- Pressure - Plate - Sheet1Document1 pagePressure - Plate - Sheet1Thomas StephenNo ratings yet

- Appendix A9Document9 pagesAppendix A9Thomas StephenNo ratings yet

- SP11-FE-SPC-WHP - A - B-OU-1001 Fire and Blast Partitions Rev.0Document17 pagesSP11-FE-SPC-WHP - A - B-OU-1001 Fire and Blast Partitions Rev.0Thomas StephenNo ratings yet

- HTB Tender Assisted Drilling Unit Makers ListDocument15 pagesHTB Tender Assisted Drilling Unit Makers ListThomas StephenNo ratings yet

- SECTIONDocument1 pageSECTIONpavaniitm2006No ratings yet

- Blast Design Considerations for Structural EngineersDocument21 pagesBlast Design Considerations for Structural EngineersFrancisco Garrido100% (1)

- Structural Analysis Report - Detention Steel Doors PMSD-5000Document62 pagesStructural Analysis Report - Detention Steel Doors PMSD-5000Thomas StephenNo ratings yet

- Pressure - Plate - Sheet1Document1 pagePressure - Plate - Sheet1Thomas StephenNo ratings yet

- Is.4991.1968 - 0-BLAST RESISTANT STRUCTURES PDFDocument43 pagesIs.4991.1968 - 0-BLAST RESISTANT STRUCTURES PDFgirishNo ratings yet

- Is.4991.1968 - 0-BLAST RESISTANT STRUCTURES PDFDocument43 pagesIs.4991.1968 - 0-BLAST RESISTANT STRUCTURES PDFgirishNo ratings yet

- Room Ac BrochureDocument41 pagesRoom Ac BrochuredplasNo ratings yet

- Design and Analysis of Biomass Pyrolysis BriquetteDocument8 pagesDesign and Analysis of Biomass Pyrolysis BriquetteJohnCris B. FornilosNo ratings yet

- ETABS Composite Column Design: ETABS 18.0.2 License # 1PJPHBGNRCE4GAWDocument2 pagesETABS Composite Column Design: ETABS 18.0.2 License # 1PJPHBGNRCE4GAWIvan PorrasNo ratings yet

- Sizing Electric Transformers PDFDocument2 pagesSizing Electric Transformers PDFrajnikNo ratings yet

- Guidelines For Structural Design: Dr. Moonis ZaheerDocument29 pagesGuidelines For Structural Design: Dr. Moonis ZaheerAninda Ghosh ParthaNo ratings yet

- Guidelines For Slurry PipingDocument6 pagesGuidelines For Slurry PipingAatish ChandrawarNo ratings yet

- Design of Monorail BeamDocument5 pagesDesign of Monorail BeamcadsultanNo ratings yet

- CG-107-F Bulk EarthworksDocument1 pageCG-107-F Bulk EarthworksJose AmorimNo ratings yet

- Gypsum Board FRDocument2 pagesGypsum Board FRKhaled Abdel SalamNo ratings yet

- Structural Design of Buried Corrugated Polyethylene Pipes: R. K. M. EDocument9 pagesStructural Design of Buried Corrugated Polyethylene Pipes: R. K. M. EElvi PapajNo ratings yet

- Grattec Eng 2010Document16 pagesGrattec Eng 20104U6ogj8b9snylkslkn3nNo ratings yet

- Irrigation Materials, Tools, Equipment and Structures: What I Need To KnowDocument10 pagesIrrigation Materials, Tools, Equipment and Structures: What I Need To KnowAlmira Mendez100% (2)

- Practices For Grounding and Bonding of Cable Trays - EEPDocument5 pagesPractices For Grounding and Bonding of Cable Trays - EEPSaraswatapalitNo ratings yet

- American Standard Rate ListDocument39 pagesAmerican Standard Rate ListAkhilesh Vikram SinghNo ratings yet

- NUBERG General TradingDocument1 pageNUBERG General TradingNexus Inspectorate Private LimitedNo ratings yet

- Wood Frame Construction GuideDocument144 pagesWood Frame Construction GuideRoland CepedaNo ratings yet

- 327101-C-BOD-0001, Rev.01 PDFDocument54 pages327101-C-BOD-0001, Rev.01 PDFGokulprabhuNo ratings yet

- 2016 Test Paper-1 SolutionsDocument11 pages2016 Test Paper-1 SolutionsHari PrasadNo ratings yet

- Umri Road Work Done-1Document162 pagesUmri Road Work Done-1DPRE PIU ADILABADNo ratings yet

- Design Primer For Hot ClimateDocument16 pagesDesign Primer For Hot ClimateHiren SavaliyaNo ratings yet

- SCI P292 SecureDocument222 pagesSCI P292 Secureg1g1ng100% (1)

- Core and Shell DesignDocument2 pagesCore and Shell Designmohamad5357No ratings yet

- Basic Boiler Construction GuideDocument8 pagesBasic Boiler Construction GuideIonescu FlorinNo ratings yet

- Molding Recommendations and Defect PreventionDocument3 pagesMolding Recommendations and Defect PreventionFaez Feakry100% (2)

- Astm d4065 PDFDocument7 pagesAstm d4065 PDFradziNo ratings yet

- 5fc5275d6e1cd14138c012f5 - Matsui MC BrochureDocument4 pages5fc5275d6e1cd14138c012f5 - Matsui MC BrochurePedro Del AngelNo ratings yet

- Advanced Ceramics - The New Frontier in Modern-Day Technology: Part IDocument9 pagesAdvanced Ceramics - The New Frontier in Modern-Day Technology: Part IAbdi EphremNo ratings yet

- 234 2852 PDFDocument8 pages234 2852 PDFOmar Faruqe ArmanNo ratings yet

- Some Notes About Corrosion Coupons InstallationDocument23 pagesSome Notes About Corrosion Coupons InstallationHadi VeyseNo ratings yet

- Short Circuit CalculationDocument57 pagesShort Circuit CalculationBrenda Naranjo MorenoNo ratings yet