Professional Documents

Culture Documents

Shear Failure of Bolted Joints Lab Report

Uploaded by

boo hu0 ratings0% found this document useful (0 votes)

41 views1 pageOriginal Title

Bolt Shear Load

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

41 views1 pageShear Failure of Bolted Joints Lab Report

Uploaded by

boo huCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 1

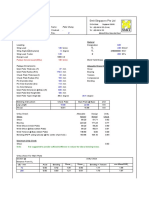

Shear Failure of Bolted Joints-- ME 372 Lab

Prepared by Leslie Tanner Input

Calculated For Right Angle Joint

Bolt Data

Number of Bolts N= 4

Distance between bolts s= 1 in Choose one, enter zero for

OR Bolt Circle Diameter D= 0 in other value

Angle between bolts (from Center) 90 degrees

Calculated Circle Radius ccr= 0.7071068 in

F

Nominal Bolt Diameter Dnom= 0.2500 in

Unthreaded Area 0.4900 in^2

Tensile Area At= 0.0318 in^2

Preload Torque 100 in-lbs (75% of Failure)

Friction Factor 0.2

Yield Strength Sy= 55 ksi

Ultimate Tensile Strength Su= 69 ksi Bolt Circle

F

Preload, Fi Fi= 2000 lbs

Shear Stress Area As= 0.0490874 in^2

Failure Torque Specimen 1 7657.9664 in-lbs

Specimen 2 7792.3167 in-lbs

Lever Arm

Structural Members Length, L

Yield Strength Sy= 40 ksi

Ultimate Tensile Strength Su= 72 ksi

Lever Arm Length L= 5 in

Relative Arm (of Load) Rad= 3.5355339 in

Results

Predicted Failure Force (based on Method)

Specimen 1: Failure Load 2166 lbs Ssy=Sy/2 Ssy=0.577Sy Ssu=0.67Su

Specimen 2: Failure Load 2204 lbs 669.01 745.28 1124.66 lbs

With Added Friction Force

731.77 808.04 1187.43 lbs

Tensile Load Component (F') 0.25 of total F

Torsional Load Component (F'') 1.767767 of total F

Greatest Shear (of total F) Gs= 2.017767 times F/As

Uniform Pressure Part

Pressure Circle Diameter Dia= 1.6642136 in

Max Pressure, Pa Pa= 919.43705 psi

Actuating Force, Fa Fa= 2000 lbs

Torque due to Friction T= 221.89514 in-lbs

Force to overcome the Friction Torque: 62.761424 lbs

You might also like

- Bolt Torque SpreadsheetDocument1 pageBolt Torque Spreadsheetboo huNo ratings yet

- Assignment 5 - Y-Joint FatigueDocument5 pagesAssignment 5 - Y-Joint Fatiguenallay17050% (1)

- Calculating Wind Load on a Dish AntennaDocument1 pageCalculating Wind Load on a Dish AntennadovermanNo ratings yet

- Bolt ConnectionsDocument36 pagesBolt Connectionsboo hu100% (1)

- Theory of Elasticity - Structural EngineeringDocument7 pagesTheory of Elasticity - Structural EngineeringVijay Aravind100% (1)

- Comp 2Document9 pagesComp 2YYo YudiNo ratings yet

- Tips For FEA AnalysisDocument6 pagesTips For FEA Analysissagar1503No ratings yet

- Beam 20031213Document8 pagesBeam 20031213John AlexanderNo ratings yet

- Section A: 2.1. Sling Design Load and SelectionDocument30 pagesSection A: 2.1. Sling Design Load and SelectionThomas StephenNo ratings yet

- FOUNDATION ANALYSISDocument14 pagesFOUNDATION ANALYSISJuli NirwantoNo ratings yet

- Lifting Davit Spreadsheet Structure (Robin)Document2 pagesLifting Davit Spreadsheet Structure (Robin)TsukomaruNo ratings yet

- Combined Footing Using Mathcad PrimeDocument6 pagesCombined Footing Using Mathcad PrimeYan YanNo ratings yet

- Clamp Design-2Document6 pagesClamp Design-2Harpreet SinghNo ratings yet

- Design of Stel Compression Members BS F950Document12 pagesDesign of Stel Compression Members BS F950Rotich VincentNo ratings yet

- CR4 - Thread - How To Calculate Flat Plate Thickness of Flat Bottom Storage Tank - PDFDocument3 pagesCR4 - Thread - How To Calculate Flat Plate Thickness of Flat Bottom Storage Tank - PDFInamullah KhanNo ratings yet

- Padeye Design AnalysisDocument8 pagesPadeye Design AnalysisMyatmyat SwewinNo ratings yet

- BMD SFDDocument3 pagesBMD SFDShrinath ShetNo ratings yet

- Elastic-Plastic Analysis of Simply Supported Rectangular Plates U PDFDocument178 pagesElastic-Plastic Analysis of Simply Supported Rectangular Plates U PDFTawsif AhmedNo ratings yet

- Section Properties:-: Try With Section Ixx Iyy ZXX Zyy A R R T TDocument4 pagesSection Properties:-: Try With Section Ixx Iyy ZXX Zyy A R R T TbuildconNo ratings yet

- C06-C09 Beam Connection Design CalculationsDocument7 pagesC06-C09 Beam Connection Design CalculationsKrish ChandNo ratings yet

- Anchor ForceDocument14 pagesAnchor ForceAdi Mulyadi100% (1)

- Evolution of Pile Shaft Capacity Over Time in Mari PDFDocument15 pagesEvolution of Pile Shaft Capacity Over Time in Mari PDFRazvan-Ionut SimionNo ratings yet

- Pin Base ModuleDocument16 pagesPin Base ModuleMd Ahsanul KabirNo ratings yet

- Transmission Line Design and Steel Pole StructuresDocument27 pagesTransmission Line Design and Steel Pole StructuresDanNo ratings yet

- Basic FEADocument12 pagesBasic FEAvikasNo ratings yet

- Fatigue Analysis and Repair of A High Mast Light Pole: SynopsisDocument14 pagesFatigue Analysis and Repair of A High Mast Light Pole: SynopsisjaffliangNo ratings yet

- Gujarat Transformers PVT - Ltd. E-Mail Copy: As Per IS 1180 - Level-2Document5 pagesGujarat Transformers PVT - Ltd. E-Mail Copy: As Per IS 1180 - Level-2THANGAVEL PNo ratings yet

- 4.3 1D ConnectionsDocument82 pages4.3 1D Connectionsjingyong123100% (1)

- USD T BeamDocument10 pagesUSD T BeammanowarNo ratings yet

- Beams On Elastic FoundationsDocument3 pagesBeams On Elastic FoundationsIgnatius SamrajNo ratings yet

- Vessel Side Shell Check CalculationsDocument5 pagesVessel Side Shell Check CalculationsShahir MeledathNo ratings yet

- WE-5-2 Fin Plate ConnectionDocument10 pagesWE-5-2 Fin Plate ConnectionPedro AlmeidaNo ratings yet

- #160 Lifting Fixture 38tons 020807Document14 pages#160 Lifting Fixture 38tons 020807halder_kalyan9216No ratings yet

- Padeye - 01Document9 pagesPadeye - 01ramNo ratings yet

- Eye Bolt CalculationDocument4 pagesEye Bolt CalculationAlok KumarNo ratings yet

- Tension Joints: Worked ExampleDocument23 pagesTension Joints: Worked ExampleSHADES 4 ALLNo ratings yet

- Comparision IS VS EURO PDFDocument7 pagesComparision IS VS EURO PDFRadhaKrishnanTNo ratings yet

- BAEK Et Al. Fatigue Life Prediction Based On The Rainflow Cycle Counting Method For The End Beam of A Freight Car BogieDocument7 pagesBAEK Et Al. Fatigue Life Prediction Based On The Rainflow Cycle Counting Method For The End Beam of A Freight Car BogiePPNNo ratings yet

- Structural Linear BucklingDocument18 pagesStructural Linear BucklingKhusi1No ratings yet

- Tubular Welded JointsDocument6 pagesTubular Welded Jointsmyst3rioNo ratings yet

- WeldDocument43 pagesWeldAuggie AranzadoNo ratings yet

- Moment of InertiaDocument3 pagesMoment of InertiaFreed CreedNo ratings yet

- A Brief Overview of 2 Order (Or P-Delta) Analysis: ObjectiveDocument8 pagesA Brief Overview of 2 Order (Or P-Delta) Analysis: Objectiveanimesh91No ratings yet

- Fatigue of Steel StructuresDocument12 pagesFatigue of Steel Structuresshimic32000No ratings yet

- Design in Reinforced Concrete To BS 8110 1Document14 pagesDesign in Reinforced Concrete To BS 8110 1Anish KumarNo ratings yet

- Mathcad - Sandy SoilDocument1 pageMathcad - Sandy SoillsatchithananthanNo ratings yet

- Bearing CapacityDocument20 pagesBearing CapacityJhoan ParedesNo ratings yet

- Wind and Earthquake Analysis Results SummaryDocument8 pagesWind and Earthquake Analysis Results SummaryBrahim HammamiNo ratings yet

- Pipe Support2of 5Document1 pagePipe Support2of 5Anonymous fLgaidVBhz100% (1)

- WeldDocument7 pagesWeldMuhammad Akbar Faereza NugrahaNo ratings yet

- 10.23.1 1D ConnectionDocument21 pages10.23.1 1D Connectionjingyong123No ratings yet

- Fatigue AnalysisDocument2 pagesFatigue AnalysisZulham MochtarNo ratings yet

- Concrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part4-Blow Out Strength in TensionDocument3 pagesConcrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part4-Blow Out Strength in TensionVenu GopalNo ratings yet

- Member Stability CheckDocument3 pagesMember Stability CheckdamindaNo ratings yet

- Flexural Torsional BucklingDocument10 pagesFlexural Torsional BucklingAnonNo ratings yet

- Columns DesignDocument60 pagesColumns DesignifsrebraNo ratings yet

- Tower Foundation Design Drawing ReviewDocument2 pagesTower Foundation Design Drawing ReviewRupesh KhandekarNo ratings yet

- Welded JointsDocument30 pagesWelded JointsOmkar Kumar JhaNo ratings yet

- 134004-SEP-MEC-DAT-0004 Rev.B2 PDFDocument11 pages134004-SEP-MEC-DAT-0004 Rev.B2 PDFDhakshina KNo ratings yet

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsFrom EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNo ratings yet

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityFrom EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNo ratings yet

- Autus Bolt Torque CalculatorDocument2 pagesAutus Bolt Torque Calculatorboo huNo ratings yet

- Fastener DatasheetDocument3 pagesFastener DatasheetIbral De SilvaNo ratings yet

- Fastener DatasheetDocument3 pagesFastener DatasheetIbral De SilvaNo ratings yet

- Autus Bolt Torque CalculatorDocument2 pagesAutus Bolt Torque Calculatorboo huNo ratings yet

- Fundamentals of Torque TensionDocument12 pagesFundamentals of Torque TensionpuneetstudNo ratings yet

- Joint Analysis Excel DocumentDocument5 pagesJoint Analysis Excel Documentboo huNo ratings yet

- Review Design Guideline VDI2230fda PDFDocument15 pagesReview Design Guideline VDI2230fda PDFJORGRULESNo ratings yet

- Screw Threads #2Document221 pagesScrew Threads #2boo huNo ratings yet

- Analysis of Bolt TorquingDocument7 pagesAnalysis of Bolt TorquingAlessandro Serafini100% (1)

- Electrostatic Energy EE 141 NotesDocument13 pagesElectrostatic Energy EE 141 NotesdanielsandriaNo ratings yet

- Cantilever BeamDocument5 pagesCantilever Beamkiran_wakchaureNo ratings yet

- Vibration BookDocument152 pagesVibration Bookrez_babu7430No ratings yet

- Lecture 3 - Drained and Undrained BehaviorDocument19 pagesLecture 3 - Drained and Undrained BehaviorAmr Elshanawany100% (1)

- CVEN 5161 Advanced Mechanics of Materials I: Instructor: Kaspar J. WillamDocument38 pagesCVEN 5161 Advanced Mechanics of Materials I: Instructor: Kaspar J. WillamFaridehNo ratings yet

- Mechanical Separations: Unit OperationDocument5 pagesMechanical Separations: Unit Operationعبداللە عمر ابراهیمNo ratings yet

- 00 Silabus Fisika BatuanDocument2 pages00 Silabus Fisika BatuanIla FadilaNo ratings yet

- 1687800284mod 1 Question BankDocument2 pages1687800284mod 1 Question BanknishadyunasNo ratings yet

- Module No. 6Document22 pagesModule No. 6Allysa Mariethony CastilloNo ratings yet

- 2ND Floor BeamDocument5 pages2ND Floor BeamDynna GanteNo ratings yet

- Linear Motion NotesDocument22 pagesLinear Motion NotesVarshLok100% (1)

- 3201 EmtDocument109 pages3201 EmtRoy VeseyNo ratings yet

- Impulse Steam Turbine OperationDocument9 pagesImpulse Steam Turbine OperationBharaniNo ratings yet

- The Fluid Mechanics of Cleaning and Decontamination of SurfacesDocument25 pagesThe Fluid Mechanics of Cleaning and Decontamination of SurfacesSarah HakikiNo ratings yet

- OrbitsDocument2 pagesOrbitsPantsik GrifoiNo ratings yet

- Soil Elastic Young Modulus ValuesDocument12 pagesSoil Elastic Young Modulus Valuesusman100% (3)

- 08 Tension TestDocument54 pages08 Tension TestQuang Le100% (1)

- Design of Buildings For Earthquake Resistance According To Eurocode 8 - Part 1Document53 pagesDesign of Buildings For Earthquake Resistance According To Eurocode 8 - Part 1babuliuNo ratings yet

- Ia Dyn Chapter5Document5 pagesIa Dyn Chapter5WarishaNo ratings yet

- G ForcesDocument4 pagesG ForcesSaam SaakNo ratings yet

- Astm E6Document12 pagesAstm E6Nacer KisyNo ratings yet

- TIP Fluid Mechanics GuideDocument34 pagesTIP Fluid Mechanics GuideRechvelen MacaparNo ratings yet

- 14met32 Engineering Thermodynamics Two MarksDocument18 pages14met32 Engineering Thermodynamics Two MarksAbubakkar SiddiqNo ratings yet

- CRSI Manual To Design RC Diaphragms - Part9Document4 pagesCRSI Manual To Design RC Diaphragms - Part9Adam Michael GreenNo ratings yet

- 최신대학물리학 5판 Ch2Document35 pages최신대학물리학 5판 Ch2아기상어No ratings yet

- Damage Detection Using ANSYS: A Study of Crack Effects on Turbine Blade Natural FrequenciesDocument86 pagesDamage Detection Using ANSYS: A Study of Crack Effects on Turbine Blade Natural FrequenciesAHMAD GHARABLINo ratings yet

- ConclusionDocument4 pagesConclusionali amerNo ratings yet

- Wind Actions On Signboards According To Eurocode 1 Part 4Document2 pagesWind Actions On Signboards According To Eurocode 1 Part 4mkaynak76No ratings yet