Professional Documents

Culture Documents

The Purpose of This Worksheet Is To Design The Stabbing Guides For The Piles Used in Gupkin MFP

Uploaded by

Thomas StephenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Purpose of This Worksheet Is To Design The Stabbing Guides For The Piles Used in Gupkin MFP

Uploaded by

Thomas StephenCopyright:

Available Formats

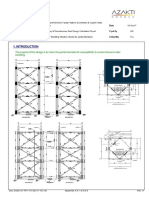

1.

INTRODUCTION

The purpose of this worksheet is to design the stabbing guides for the piles used in Gupkin MFP.

2. MATERIAL PROPERTIES

Yield Strength Fy := 345 MPa

Poission Ratio := 0.3

Young's Modulus 5

E := 2.10 10 MPa

Shear Modulus 4

G := 8 10 MPa

kg

Density s := 7850 3

m

Doc G00A-ST-RPT-01-00137-107-00 Appendix A7-1 of A7-3 Rev :A

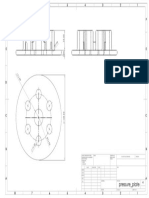

3. STABBING GUIDE PARAMETERS

Diameter D g := 961mm

Thickness t g := 20mm

4. DESIGN CHECKS FOR PILE STABBING GUIDE

The pile stabbing guide is checked against a horizontal load equal to 10% of the pile weight, which may

occur during the stabbing operation. The horizontal load is conservatively assumed to act at the bottom tip

of the stabbing guide. Since the stabbing operation is vertically straight, no other load needs to be

considered.

Lever arm of the horizontal load xg := 1500mm

Weight of the heaviest pile W g := 44.3tonnef

Moment on the stabbing guide section M g := 0.1 W g xg = 65.165 kN m

Doc G00A-ST-RPT-01-00137-107-00 Appendix A7-2 of A7-3 Rev :A

4

Moment of inertia of the stabbing guide section Ig := D - D g - 2 t g

64 g

( )4 = 6.547 109 mm 4

Ig

7 3

Section modulus Zg := = 1.363 10 mm

Dg

2

Mg

Maximum bending stress bend := = 4.782 MPa

Zg

Allowable bending stress all := 0.66Fy = 227.7 MPa

Check := "OK" if bend < all

"Redesign!" otherwise

Check = "OK"

bend

Unity Check UC := = 0.021

all

Doc G00A-ST-RPT-01-00137-107-00 Appendix A7-3 of A7-3 Rev :A

You might also like

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Appendix A3Document6 pagesAppendix A3Thomas Stephen100% (1)

- This Sheet Designs The Conductor Cone Guides Used in The MFP Jacket.Document3 pagesThis Sheet Designs The Conductor Cone Guides Used in The MFP Jacket.Thomas StephenNo ratings yet

- Appendix A1Document5 pagesAppendix A1Thomas Stephen100% (1)

- Appendix A2Document8 pagesAppendix A2Thomas StephenNo ratings yet

- Appendix A11Document3 pagesAppendix A11Thomas StephenNo ratings yet

- The Purpose of This Worksheet Is To Design The Welded Connection Between The Jacket Leg and Crownshim and The Piles and CrownshimDocument5 pagesThe Purpose of This Worksheet Is To Design The Welded Connection Between The Jacket Leg and Crownshim and The Piles and CrownshimThomas StephenNo ratings yet

- AXIALLY LOADED MEMBERS (Version 1)Document22 pagesAXIALLY LOADED MEMBERS (Version 1)Receb AgaNo ratings yet

- Section A: 2.1. Sling Design Load and SelectionDocument30 pagesSection A: 2.1. Sling Design Load and SelectionThomas StephenNo ratings yet

- Design of Coping Beam (Portal) : A. Basic DataDocument7 pagesDesign of Coping Beam (Portal) : A. Basic DataUzziel Abib GabiolaNo ratings yet

- Mathcad - C06-C3Document5 pagesMathcad - C06-C3Krish ChandNo ratings yet

- Machine Design Refresher PDFDocument122 pagesMachine Design Refresher PDFjoe125683% (6)

- Verificare Grinda MetalicaDocument2 pagesVerificare Grinda MetalicaVirginia Elena IordacheNo ratings yet

- Machine Design Refresher PDFDocument122 pagesMachine Design Refresher PDFJaypes ManzanoNo ratings yet

- Machine Design Refresher PDFDocument122 pagesMachine Design Refresher PDFJaypes ManzanoNo ratings yet

- Head Nozzle and Flange Calculation, DN100 (CF) Size NozzleDocument7 pagesHead Nozzle and Flange Calculation, DN100 (CF) Size Nozzleakın ersözNo ratings yet

- Parapet Mounted - 1800 Reach - Post and JibDocument3 pagesParapet Mounted - 1800 Reach - Post and Jibkiruba shankarNo ratings yet

- # Verification On Transom Profile: References CalculationsDocument1 page# Verification On Transom Profile: References CalculationsAzahar Bin HashimNo ratings yet

- Flange Analysis For Internal Pressure - ASME Section VIII, Division 1, Appendices 2 and S - 2004 EditionDocument1 pageFlange Analysis For Internal Pressure - ASME Section VIII, Division 1, Appendices 2 and S - 2004 Editionגרבר פליקסNo ratings yet

- Calc Steel Metal PerporatedDocument13 pagesCalc Steel Metal PerporatedOecoep Iteem100% (1)

- JEROME M. GUETA QUIZ 3 - Advance Steel DesignDocument105 pagesJEROME M. GUETA QUIZ 3 - Advance Steel DesignJerome M. GuetaNo ratings yet

- Appendix A9Document9 pagesAppendix A9Thomas StephenNo ratings yet

- To Do - DS-H - Supporting Beam - W8X18 - W8X18Document15 pagesTo Do - DS-H - Supporting Beam - W8X18 - W8X18amitNo ratings yet

- Assignment #5 (2013)Document2 pagesAssignment #5 (2013)clinton D'SouzaNo ratings yet

- To Do - DS - LRFD - Supporting Beam - W8X18 - W8X18Document15 pagesTo Do - DS - LRFD - Supporting Beam - W8X18 - W8X18amitNo ratings yet

- Mathcad - Angle Bracing Connected To A Gusset Plate On BeamDocument14 pagesMathcad - Angle Bracing Connected To A Gusset Plate On BeamValentinNo ratings yet

- Retaining Wall Problems: OuestionDocument14 pagesRetaining Wall Problems: OuestionAli AratNo ratings yet

- Retaining Wall Problems: OuestionDocument9 pagesRetaining Wall Problems: OuestionYusuf DuranNo ratings yet

- Project Sports Complex Date: V Max ActDocument2 pagesProject Sports Complex Date: V Max ActShanil BussooaNo ratings yet

- 3 1Document3 pages3 1Mark Arvin VelascoNo ratings yet

- Group 12 p1Document3 pagesGroup 12 p1SM WorldNo ratings yet

- STEEL POLE 14M & 16M 350 Dan (Flange Type)Document4 pagesSTEEL POLE 14M & 16M 350 Dan (Flange Type)Juragan IwalNo ratings yet

- Mathcad - Secondary Beam Design Opening-2Document2 pagesMathcad - Secondary Beam Design Opening-2mrnaeem76No ratings yet

- SC-S14006-PK02-FTCO-EXT-11 Rev. 01Document6 pagesSC-S14006-PK02-FTCO-EXT-11 Rev. 01Alaa Al-habashNo ratings yet

- Input Data: Package: Bridge Name: Pier Name: 1. General Input DataDocument7 pagesInput Data: Package: Bridge Name: Pier Name: 1. General Input DataTuanNo ratings yet

- Weld Check: I. Connection Properties Bridge IDDocument3 pagesWeld Check: I. Connection Properties Bridge IDJemicah YumenaNo ratings yet

- Input Data: Package: Bridge Name: Pier Name: 1. General Input DataDocument7 pagesInput Data: Package: Bridge Name: Pier Name: 1. General Input DataTuanNo ratings yet

- Spun Pile D400Document13 pagesSpun Pile D400Tri huỳnh100% (3)

- Hollow This-Walled Section of Uniform ThicknessDocument2 pagesHollow This-Walled Section of Uniform ThicknessEng-CalculationsNo ratings yet

- Mathcad - Angle Bracing Connected To Gusset Plate On ColumnDocument13 pagesMathcad - Angle Bracing Connected To Gusset Plate On ColumnValentinNo ratings yet

- Design of Singly Reinforced Concrete BeamDocument4 pagesDesign of Singly Reinforced Concrete BeamAnton_Young_1962No ratings yet

- Control Perimeters For Punching Shear @2dDocument4 pagesControl Perimeters For Punching Shear @2dpravin awalkondeNo ratings yet

- Triangle Beam B1Document6 pagesTriangle Beam B1sallysel90No ratings yet

- ASME SEC. VIII Div. 2 Ed. 2013 Buckling 4.4.5Document3 pagesASME SEC. VIII Div. 2 Ed. 2013 Buckling 4.4.5mechengg01No ratings yet

- 1) in This Load Management Significance of Load Case - 1 & 2 (SW-SUM & STG-SUM) Is Not Understood. Could You Please Explain What Does This Signifies?Document10 pages1) in This Load Management Significance of Load Case - 1 & 2 (SW-SUM & STG-SUM) Is Not Understood. Could You Please Explain What Does This Signifies?Ashish GNo ratings yet

- Section Properties: Design of Padeye As Per Aisc 360-2005Document5 pagesSection Properties: Design of Padeye As Per Aisc 360-2005Fadil WimalaNo ratings yet

- Reference Calculations OutputDocument2 pagesReference Calculations OutputGirinathNo ratings yet

- Design of Steel I-Section (BS5950)Document3 pagesDesign of Steel I-Section (BS5950)gertjaniNo ratings yet

- Bellow As Per EJMA - 1Document2 pagesBellow As Per EJMA - 1966571016208No ratings yet

- 2.1 Shear Force - Stress and StrainDocument15 pages2.1 Shear Force - Stress and StrainTooling ganesh0% (1)

- Lesson 1 Exercises Problem No. 1Document2 pagesLesson 1 Exercises Problem No. 1Ariel Gamboa100% (1)

- Lesson 1 Exercises Problem No. 1Document2 pagesLesson 1 Exercises Problem No. 1Ariel GamboaNo ratings yet

- Design of Bearing Replacement SchemeDocument10 pagesDesign of Bearing Replacement SchemeShivendra KumarNo ratings yet

- Raft Footing DesignDocument7 pagesRaft Footing DesignPrakash ShresthaNo ratings yet

- Calculation For Transsport BoxDocument9 pagesCalculation For Transsport Boxthanhtrung87No ratings yet

- Mathcad - Primary Beam Lap Splice CalculationDocument4 pagesMathcad - Primary Beam Lap Splice Calculationmrnaeem76No ratings yet

- Calculation Sheet Connection New Column To ExistingDocument4 pagesCalculation Sheet Connection New Column To ExistingDamar BudiNo ratings yet

- Tower - 3D Model Builder 7.0 - x64 Edition Registered To Bios Radimpex - WWW - Radimpex.rsDocument1 pageTower - 3D Model Builder 7.0 - x64 Edition Registered To Bios Radimpex - WWW - Radimpex.rsKenan AvdusinovicNo ratings yet

- Strength Calculation Report-3X49Document3 pagesStrength Calculation Report-3X49SalauddinAnsariNo ratings yet

- Appendix A5Document4 pagesAppendix A5Thomas StephenNo ratings yet

- Nylon Carpet. Harrington Catalogue.2022 - 2022-09-20T105330.316Document36 pagesNylon Carpet. Harrington Catalogue.2022 - 2022-09-20T105330.316Thomas StephenNo ratings yet

- New Floating Fish Farm Off Changi Aims To Produce More Seafood Than Traditional Coastal Farms - TODAYonline PDFDocument27 pagesNew Floating Fish Farm Off Changi Aims To Produce More Seafood Than Traditional Coastal Farms - TODAYonline PDFThomas StephenNo ratings yet

- Appendix A5Document4 pagesAppendix A5Thomas StephenNo ratings yet

- A Feed For Seabass: Aldon, E. TDocument4 pagesA Feed For Seabass: Aldon, E. TThomas StephenNo ratings yet

- Active StructureDocument1 pageActive StructureThomas StephenNo ratings yet

- Appendix A1Document22 pagesAppendix A1Thomas StephenNo ratings yet

- Project Manager Gantt ChartDocument16 pagesProject Manager Gantt ChartThomas StephenNo ratings yet

- Appendix A3Document8 pagesAppendix A3Thomas StephenNo ratings yet

- Pressure - Plate - Sheet1Document1 pagePressure - Plate - Sheet1Thomas StephenNo ratings yet

- Section A: 2.1. Sling Design Load and SelectionDocument30 pagesSection A: 2.1. Sling Design Load and SelectionThomas StephenNo ratings yet

- The Purpose of This Worksheet Is To Design The Stairway From EL (+) 1500 To EL (+) 6500 From The Boatlanding To The JacketDocument10 pagesThe Purpose of This Worksheet Is To Design The Stairway From EL (+) 1500 To EL (+) 6500 From The Boatlanding To The JacketThomas StephenNo ratings yet

- The Purpose of This Worksheet Is To Design The Welded Connection Between The Jacket Leg and Crownshim and The Piles and CrownshimDocument5 pagesThe Purpose of This Worksheet Is To Design The Welded Connection Between The Jacket Leg and Crownshim and The Piles and CrownshimThomas StephenNo ratings yet

- Appendix A9Document9 pagesAppendix A9Thomas StephenNo ratings yet

- Project Heavy Tender Barge (HTB) Tender Assisted Drilling Unit Title Appendix 3-Makers List 01 Doc No. 1196-101-SPE-0001 Date 11.22.2011Document15 pagesProject Heavy Tender Barge (HTB) Tender Assisted Drilling Unit Title Appendix 3-Makers List 01 Doc No. 1196-101-SPE-0001 Date 11.22.2011Thomas StephenNo ratings yet

- SECTIONDocument1 pageSECTIONpavaniitm2006No ratings yet

- Pressure - Plate - Sheet1Document1 pagePressure - Plate - Sheet1Thomas StephenNo ratings yet

- Input Parameters: 1.1. Input Surface Areas 1.1.1. Above Mudline Without Corrosion Protection CoatingDocument6 pagesInput Parameters: 1.1. Input Surface Areas 1.1.1. Above Mudline Without Corrosion Protection CoatingThomas StephenNo ratings yet

- SP11-FE-SPC-WHP - A - B-OU-1001 Fire and Blast Partitions Rev.0Document17 pagesSP11-FE-SPC-WHP - A - B-OU-1001 Fire and Blast Partitions Rev.0Thomas StephenNo ratings yet

- Structural Analysis Report - Detention Steel Doors PMSD-5000Document62 pagesStructural Analysis Report - Detention Steel Doors PMSD-5000Thomas StephenNo ratings yet

- Is.4991.1968 - 0-BLAST RESISTANT STRUCTURES PDFDocument43 pagesIs.4991.1968 - 0-BLAST RESISTANT STRUCTURES PDFgirishNo ratings yet

- Is.4991.1968 - 0-BLAST RESISTANT STRUCTURES PDFDocument43 pagesIs.4991.1968 - 0-BLAST RESISTANT STRUCTURES PDFgirishNo ratings yet

- Blast Design OswaldDocument21 pagesBlast Design OswaldFrancisco Garrido100% (1)

- Theory of Earth Pressure and Bearing CapacityDocument10 pagesTheory of Earth Pressure and Bearing CapacityNicu MIHALACHENo ratings yet

- Applications of TrigonometryDocument15 pagesApplications of TrigonometrynabilakNo ratings yet

- Chapter 15 (Read-Only)Document35 pagesChapter 15 (Read-Only)Mai Anh ThưNo ratings yet

- EOS Tuning 1671172242Document34 pagesEOS Tuning 1671172242ASKY PNo ratings yet

- A Method For Determining The Convective Heat Transfer Coefficient During Immersion FryingDocument14 pagesA Method For Determining The Convective Heat Transfer Coefficient During Immersion FryingAna María TorresNo ratings yet

- Taguchi Method Lecture 02Document39 pagesTaguchi Method Lecture 02DrMohamed MansourNo ratings yet

- Natural Snow BuildingsDocument17 pagesNatural Snow BuildingsStrannik RuskiNo ratings yet

- Industrial Refrigeration TrainerDocument2 pagesIndustrial Refrigeration TrainerEugine BalomagaNo ratings yet

- An Intuitive Guide To Linear Algebra - BetterExplainedDocument25 pagesAn Intuitive Guide To Linear Algebra - BetterExplainedvkk intensiveNo ratings yet

- Work Power Energy Faculty Copy Yw3bPNODocument92 pagesWork Power Energy Faculty Copy Yw3bPNOSamridh GuptaNo ratings yet

- Precision Stretch Forming of Metal For Precision AssemblyDocument404 pagesPrecision Stretch Forming of Metal For Precision AssemblyMadalin NitaNo ratings yet

- Geography Skills HandbookDocument16 pagesGeography Skills HandbookGa SunshineNo ratings yet

- Example PDFDocument280 pagesExample PDFivoryhornNo ratings yet

- MMP 2 Mansoor Sultan: First PortionDocument6 pagesMMP 2 Mansoor Sultan: First PortionMansoor AslamNo ratings yet

- Pump Performance Datasheet: Operating Conditions LiquidDocument1 pagePump Performance Datasheet: Operating Conditions LiquidFabian A NeiraNo ratings yet

- Probabilistic Structural Dynamics: Parametric vs. Nonparametric ApproachDocument39 pagesProbabilistic Structural Dynamics: Parametric vs. Nonparametric Approachejzuppelli8036No ratings yet

- Lecture 25 - Steady-State Behavior of Markov ChainsDocument10 pagesLecture 25 - Steady-State Behavior of Markov ChainsK VirtuosoNo ratings yet

- Power Factor Sizing GuideDocument6 pagesPower Factor Sizing GuideMatt SmithNo ratings yet

- Engineering Mechanics DynamicsDocument2 pagesEngineering Mechanics DynamicsMallene EhurangoNo ratings yet

- Kami Export - Ashton Gopaul - FL - 8.P - 8.4 - ClassifyingMatter - INTERVENTION - IndependentPracticeDocument2 pagesKami Export - Ashton Gopaul - FL - 8.P - 8.4 - ClassifyingMatter - INTERVENTION - IndependentPracticeAshton GopaulNo ratings yet

- Turning Points of Quadratic Graphs Questions MMEDocument6 pagesTurning Points of Quadratic Graphs Questions MMECCSC124-Soham MaityNo ratings yet

- Fenper Lanjut #4TurbulentTransport 2020Document26 pagesFenper Lanjut #4TurbulentTransport 2020Aji Ridho PangestuNo ratings yet

- ST-1 2Document8 pagesST-1 2Omar Dr.No ratings yet

- Tes Master List of IMTE 2019 Back UpDocument120 pagesTes Master List of IMTE 2019 Back UprommyfebriNo ratings yet

- Nature and Structures of Academic TextDocument28 pagesNature and Structures of Academic TextPhoebe GarciaNo ratings yet

- 8 Physics HA 1Document2 pages8 Physics HA 1Royalty EmpireNo ratings yet

- Topic 5 - Curvilinear Motion - 2Document17 pagesTopic 5 - Curvilinear Motion - 2Eugene GarbosaNo ratings yet

- 03 Assignment IIDocument23 pages03 Assignment IIAnurag AgarwalNo ratings yet

- Jresv66cn1p25 A1bDocument8 pagesJresv66cn1p25 A1bum usuarioNo ratings yet

- W2 - Q1 - Math8B - Basic Geometric ConstructionsDocument4 pagesW2 - Q1 - Math8B - Basic Geometric ConstructionsFNERVEZ, DENISE T.No ratings yet