Professional Documents

Culture Documents

Base Plate Dan Anchor Bolt Calculation: Connection Design

Uploaded by

Surya FahmiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Base Plate Dan Anchor Bolt Calculation: Connection Design

Uploaded by

Surya FahmiCopyright:

Available Formats

SUBAN PHASE II GAS PROJECT No. : 02.

1362

Suban - South Sumatra Revision :

Detailed Engineering & Design Offsite Facilities & Permanet Camp Date : ###

Page :

Structure Calculation Grease - Wash Rack

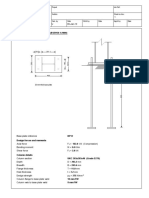

6.9 CONNECTION DESIGN

Base Plate dan Anchor Bolt Calculation

a. Base Plate

B

bf

tf m

P

column

Anchor bolts

Q

C d

tw

grouting

base plate

pedestal

n 0.8 bf n

Column WF 175X175X7.5X11

B = 300 mm

C = 300 mm

bf = 250 mm

d = 250 mm

tw = 9 mm

tf = 14 mm

Anchor Bolts A 307

Fy = 240 Mpa (yield stress)

f'c = 24.5 Mpa (concrete strength)

Loads (see attachment B)

Actual axial Load (P) = 26437 Kg

Actual shear load (Q) = 2751.2 Kg

fp = 0.35 f'c = 85.75 Kg/mm2 (fp = actual bearing pressure)

A1 = P / fp = 308.3 mm 2 (A1 = area of plate)

Take B x C = 90000 mm2

Check

D = 0.5 (0.95 d - 0.8 bf) = 18.75 mm

A2 > 1 P 2

= 10561 mm2 (A2 = Full cross-sectional area of concrete support)

A1 0.35 f'c

A2 > P = 15415 mm2

Prepared by PT. BITA HYUNDAI - THIESS

SUBAN PHASE II GAS PROJECT No. : 02.1362

Suban - South Sumatra Revision :

Detailed Engineering & Design Offsite Facilities & Permanet Camp Date : ###

Page :

Structure Calculation Grease - Wash Rack

0.7 f'c

Area require A2 = 15415 mm2

N= A2 + D = 142.91 < d = 225 mm

B= A2 = 107.87 < bf = 225 mm

N

Actual Bearing Pressure (fb)

fb = P = 0.2937 Kg/mm2 = 0.426 Kip/in2

BxC

Fb = 0.75 Fy = 1800 Kg/cm2 = 26.106 Kip/in2

a = bf - tw = 0.545

2( d - 2tf )

tp = 3 (bf-tw)2 fb = 0.8519 in = 21.64 mm (tp = thickness of plate)

4(1+3.2a ) Fb

3

Base plate thickness required is = 21.64 mm

Base plate thickness recommended is = 16 mm

b. Anchor Bolts

Anchor Bolts A 307

Fb = 0.6 Fy = 144 Mpa (allowable bending stress)

t = 86.4 Mpa (allowable shear stress)

s tu = 172.8 Mpa (allowable bearing stress)

Loads (see attachment B)

Actual shear load (Q) = 2751.2 Kg

Check for Shear

Try bolt (D) M 16 mm

numb of bolt (n) = 2

Ag = 1/4 p D2 = 201.06 mm2 (cross section area of bolt)

t = Q / n Ag

= 68.422 Mpa < t OK 0

Check for Bearing Plate

t = 16 mm (Base plate thickness recommended)

Atu = t x D = 256 mm2 (shear section area of bolt)

s tu = Q / n Atu

= 53.735 Mpa < s tu OK 0

Result :

Base plate and anchor bolt for Detail 1 (see attachment E drawing D-262-CS-025)

Base plate dimension : 300 X 300 X 16

Anchor bolt : 2 M 16

Prepared by PT. BITA HYUNDAI - THIESS

Prepared by PT. BITA HYUNDAI - THIESS

SUBAN PHASE II GAS PROJECT No. : 2.1362

Suban - South Sumatra Revision :

Detailed Engineering & Design Offsite Facilities & Permanet Camp Date : 10/25/04

Page :

Structure Calculation Grease - Wash Rack

Bolts Connection Calculation

Connection : Beam to Column

Q column WF 175x175x7.5x11

plate Beam WF 100x100x6x8

B1: WF 100X100X6X8 TO COLUMN

Bolt A 325

t = 126.5 Mpa (allowable shear stress)

s tu = 253 Mpa (allowable bearing stress)

Actual Loads

Q = 38659.3 N (Actual shear Load)

N = 6078.74 N (Actual axial load)

Try bolt (D) M 16

numb of bolt (n) = 2

Check for shear

Ag = 1/4 p D2 = 201.056 mm2 (cross section area of bolt)

t = P / n Ag

= 97.32496 Mpa < t OK! 1

Check for bearing plate

t = 6 mm (Base plate thickness)

Atu = t x D = 96 mm2 (shear section area of bolt)

s tu = P / n Atu

= 203.8244 Mpa < s tu OK! 1

2

Use bolt 2 M 16

Result bolt connection Detail 4 : 2 M 16

(see attachment E drawing D-262-CS-026)

Prepareb by PT. BITA HYUNDAI - THIESS

SUBAN PHASE II GAS PROJECT No. : 2.1362

Suban - South Sumatra Revision :

Detailed Engineering & Design Offsite Facilities & Permanet Camp Date : 10/25/04

Page :

Structure Calculation Grease - Wash Rack

Connection : Rafter to Rafter

rafter T1

a1

M T2

a2

N T3

a3

T4 a4

10 mm

RafterWF 300x150x6.5x9

Bolt A 325

t = 126.5 Mpa (allowable shear stress)

s tu = 253 Mpa (allowable bearing stress)

s ta = 310 Mpa (allowable tension stress)

Actual Loads

Q = 87.72 kN (Actual shear Load)

N = 1.75 kN (Actual axial load)

M = 76.98 kNm (Actual moment load)

Try bolt (D) M 19

nx = 2 (numb of top both line)

n = 8 (numb of total both)

Check for shear

Ag = 1/4 p D2 = 283.520375 mm2 (cross section area of bolt)

t = Q / n Ag

= 0.77154949 Mpa < t OK! 1

Check for bearing plate

t = 7.5 mm (plate thickness)

Atu = t x D = 142.5 mm2 (shear section area of bolt)

s tu = Q / n Atu

= 1.53508772 Mpa < s tu OK! 1

Check for tension

Tension for one bolt by moment (Tam)

a1 = 0 mm T1 = 0.00 T M1 = 0 T

a2 = 80 mm T2 = 1.00 T M2 = 400 T

a3 = 80 mm T3 = 0.80 T M3 = 256 T

a4 = 80 mm T4 = 0.60 T M4 = 144 T

a5 = 80 mm T5 = 0.40 T M5 = 64 T

a6 = 80 mm T6 = 0.20 T M6 = 16 T

Sa = 400 mm SM = 880 T

Prepared by PT. BITA HYUNDAI _ THIESS

SUBAN PHASE II GAS PROJECT No. : 2.1362

Suban - South Sumatra Revision :

Detailed Engineering & Design Offsite Facilities & Permanet Camp Date : 10/25/04

Page :

Structure Calculation Grease - Wash Rack

7.7E+07 = 880 T

T = 87477 N

Tam = T/nx = 43738.636364 N

Tension for one bolt by normal (Tan)

Tan = N/n

= 10965 N

ST = Tam + Tan

= 54703.636364 N

Ata = 1/4 p (0.85D)2 = 204.843471 mm2 (cross section area of bolt)

s ta = T / Ata

= 267.050915 Mpa < s ta OK! 1

3

Use bolt 8 M 19

Result bolt connection for detail 8 : 8 M 19

(see attachment E drawing D-262-CS-026)

Prepared by PT. BITA HYUNDAI _ THIESS

SUBAN PHASE II GAS PROJECT No. : 2.1362

Suban - South Sumatra Revision :

Detailed Engineering & Design Offsite Facilities & Permanet Camp Date : 10/25/04

Page :

Structure Calculation Grease - Wash Rack

Connection : Rafter to Rafter

rafter T1

a1

M T2

a2

N T3

a3

T4 a4

10 mm

RafterWF 300x150x6.5x9

Bolt A 325

t = 126.5 Mpa (allowable shear stress)

s tu = 253 Mpa (allowable bearing stress)

s ta = 310 Mpa (allowable tension stress)

Actual Loads

Q = 38.66 kN (Actual shear Load)

N = 6 kN (Actual axial load)

M = 0.52 kNm (Actual moment load)

Try bolt (D) M 16

nx = 2 (numb of top both line)

n = 4 (numb of total both)

Check for shear

Ag = 1/4 p D2 = 201.056 mm2 (cross section area of bolt)

t = Q / n Ag

= 7.46060799 Mpa < t OK! 1

Check for bearing plate

t = 7.5 mm (plate thickness)

Atu = t x D = 120 mm2 (shear section area of bolt)

s tu = Q / n Atu

= 12.5 Mpa < s tu OK! 1

Check for tension

Tension for one bolt by moment (Tam)

a1 = 0 mm T1 = 0.00 T M1 = 0 T

a2 = 0 mm T2 = 0.00 T M2 = 0 T

a3 = 0 mm T3 = 0.00 T M3 = 0 T

a4 = 0 mm T4 = 0.00 T M4 = 0 T

a5 = 200 mm T5 = 1.00 T M5 = 350 T

a6 = 150 mm T6 = 0.43 T M6 = 64 T

Sa = 350 mm SM = 414 T

Prepared by PT. BITA HYUNDAI _ THIESS

SUBAN PHASE II GAS PROJECT No. : 2.1362

Suban - South Sumatra Revision :

Detailed Engineering & Design Offsite Facilities & Permanet Camp Date : 10/25/04

Page :

Structure Calculation Grease - Wash Rack

5.2E+05 = 414 T

T = 1255 N

Tam = T/nx = 627.5862069 N

Tension for one bolt by normal (Tan)

Tan = N/n

= 9665 N

ST = Tam + Tan

= 10292.586207 N

Ata = 1/4 p (0.85D)2 = 145.26296 mm2 (cross section area of bolt)

s ta = T / Ata

= 70.8548566 Mpa < s ta OK! 1

3

Use bolt 4 M 16

Result bolt connection for detail 8 : 4 M 16

(see attachment E drawing D-262-CS-026)

Prepared by PT. BITA HYUNDAI _ THIESS

SUBAN PHASE II GAS PROJECT No. : 2.1362

Suban - South Sumatra Revision :

Detailed Engineering & Design Offsite Facilities & Permanet Camp Date : 10/25/04

Page :

Structure Calculation Grease - Wash Rack

Connection : Rafter to Column

Q0

rafter

1 7

M0

a 2 8

e N0

3 9

4 10

5 11

6 12

RafterWF 400x200x8x13

Bolt A 325

t = 220 Mpa (allowable shear stress)

s ta = 413 Mpa (allowable tension stress)

Actual Loads

Q0 = 91.60 kN (Actual shear Load)

N0 = 16.34 kN (Actual axial load)

M0 = 88.10 kNm (Actual moment load)

Try bolt (D) M 19

nx = 2 (numb of top bolt line)

ny = 6

n = 12 (numb of total bolt)

e = 90 mm (eccentricity)

a = 12 0

= 0.21 rad

Nx

a Ny

Ny = N . Sin a

= 3.40 kN

Nx = N . Cos a

= 15.98 kN

Prepared by PT. BITA HYUNDAI _ THIESS

SUBAN PHASE II GAS PROJECT No. : 2.1362

Suban - South Sumatra Revision :

Detailed Engineering & Design Offsite Facilities & Permanet Camp Date : 10/25/04

Page :

Structure Calculation Grease - Wash Rack

Additional Loads due to Eccentricity

Q1 = Q0 + Ny = 94.99 kN

N1 = N0

+ Nx = 32.32 kN

M1 = M0 + Nx .e = 89.53 kNm

1. Check for shear

Ag = 1/4 p D2

= 283.52 mm2 (cross section area of bolt)

t = Q1 / (n . Ag)

= 27.92 Mpa < t = 220 Mpa OK!

2. Check for tension

T1

T2

y1

M1 T3 y2

N1 y3

y4

T4 y5

y6

T5

T6

y1 = 275 mm y7 = 275 mm

y2 = 165 mm y8 = 165 mm

y3 = 55 mm y9 = 55 mm

y4 = -55 mm y10 = -55 mm

y5 = -165 mm y11 = -165 mm

y6 = -275 mm y12 = -275 mm

∑y2 = 423500 mm2

Tension for one bolt by axial (Tan)

N1

Tan =

n

= 2.69 kN

Prepared by PT. BITA HYUNDAI _ THIESS

SUBAN PHASE II GAS PROJECT No. : 2.1362

Suban - South Sumatra Revision :

Detailed Engineering & Design Offsite Facilities & Permanet Camp Date : 10/25/04

Page :

Structure Calculation Grease - Wash Rack

Tension for one bolt by moment (Tam)

M1 . Yi

Tam =

∑y2

Tam1 = 58.14 kN Tam7 = 58.14 kN

Tam2 = 34.88 kN Tam8 = 34.88 kN

Tam3 = 11.63 kN Tam9 = 11.63 kN

Tam4 = -11.63 kN Tam10 = -11.63 kN

Tam5 = -34.88 kN Tam11 = -34.88 kN

Tam6 = -58.14 kN Tam12 = -58.14 kN

y = 4.73 x - 12.738

Ta = Tan + Tam

Tam1 Ta1

Tam2 Ta2

Tam3

Ta3

= Tan + =

y = -12.74 mm

Tam4 Ta4

Tam5 Ta5

Tam6 Ta6

Ta1 = 60.83 kN Ta7 = 60.83 kN

Ta2 = 37.58 kN Ta8 = 37.58 kN

Ta3 = 14.32 kN Ta9 = 14.32 kN

Ta4 = -8.93 kN Ta10 = -8.93 kN

Ta5 = -32.19 kN Ta11 = -32.19 kN

Ta6 = -55.45 kN Ta12 = -55.45 kN

Ata = 1/4 p (0.85 D)2

= 204.84 mm2 (cross section area of bolt)

s ta = Ta1 / Ata

= 296.97 Mpa < s ta = 413 Mpa OK!

3. Combination Shear and Tension

si = √ s ta2 + 3 t2

= 300.88 Mpa < s ta = 413 Mpa OK!

Prepared by PT. BITA HYUNDAI _ THIESS

SUBAN PHASE II GAS PROJECT No. : 2.1362

Suban - South Sumatra Revision :

Detailed Engineering & Design Offsite Facilities & Permanet Camp Date : 10/25/04

Page :

Structure Calculation Grease - Wash Rack

4. Bearing Plate Thickness (t)

Steel BJ 37

fy = 240 Mpa

si = 134 Mpa (allowable combination tension&shear stress)

Ta1

287.7 mm Ta2

177.7 mm

Ta3

67.7 mm

y = -12.74 mm

-152.3 mm -42.3 mm Ta4

-262.3 mm Ta5

Ta6

M compression = (Ta4x-42.3) + (Ta5x-152.3) + (Ta6x-262.3)

= 19.82 kNm

M tension = (Ta1x287.7) + (Ta2x177.7) + (Ta3x67.7)

= 25.15 kNm ==> to be considered

Plate Thickness (t) :

t = √ (6.Mtension / 1000.si)

= 33.51 mm , use thickness = 7.5 mm

5. Check for bearing plate

t = 7.5 mm (plate thickness)

Atu = txD

= 142.5 mm2 (shear section area of bolt)

s tu = Q / n Atu

= 9.55 Mpa <si OK!

Use bolt 12 M 19

Prepared by PT. BITA HYUNDAI _ THIESS

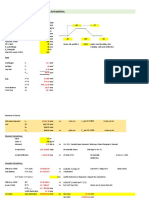

1

Y X

275 60.83

165 37.58

55 14.32

-55 -8.93

-165 -32.19

-275 -55.45

2.6931 0

Prepared by PT. BITA HYUNDAI _ THIESS

Chart Title

300

250

f(x) = 4.730025567x - 12.7383519775

200

150

100

50

00

-80.00 -60.00 -40.00 -20.00 -50 0.00 20.00 40.00 60.00 80.00

-100

-150

-200

-250

-300

Prepared by PT. BITA HYUNDAI _ THIESS

1

###

Prepared by PT. BITA HYUNDAI _ THIESS

60.00 80.00

Prepared by PT. BITA HYUNDAI _ THIESS

SUBAN PHASE II GAS PROJECT No. :

Suban - South Sumatra Revision :

Detailed Engineering & Design Offsite Facilities & Permanet Camp Date :

Page :

Structure Calculation Grease - Wash Rack

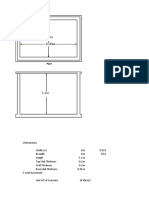

6.9 CONNECTION DESIGN

Base Plate dan Anchor Bolt Calculation

a. Base Plate

B

bf

tf m

P

column

Anchor bolts

Q

C d

tw

grouting

base plate

pedestal

n 0.8 bf n

Column WF 175X175X7.5X11

B = 250 mm

C = 250 mm

bf = 200 mm

d = 200 mm

tw = 8 mm

tf = 12 mm

Anchor Bolts A 307

Fy = 240 Mpa (yield stress)

f'c = 24.5 Mpa (concrete strength)

Loads (see attachment B)

Actual axial Load (P) = 11872 Kg

Actual shear load (Q) = 1532.1 Kg

fp = 0.35 f'c = 85.75 Kg/mm2 (fp = actual bearing pressure)

A1 = P / fp = 138.44 mm 2 (A1 = area of plate)

Take B x C = 62500 mm2

Check

D = 0.5 (0.95 d - 0.8 bf) = 15 mm

A2 > 1 P 2

= 3066.7 mm2 (A2 = Full cross-sectional area of concrete support)

A1 0.35 f'c

A2 > P = 6922.2 mm2

Prepared by PT. BITA HYUNDAI - THIESS

SUBAN PHASE II GAS PROJECT No. :

Suban - South Sumatra Revision :

Detailed Engineering & Design Offsite Facilities & Permanet Camp Date :

Page :

Structure Calculation Grease - Wash Rack

0.7 f'c

Area require A2 = 6922.2 mm2

N= A2 + D = 98.2 < d = 225 mm

B= A2 = 70.491 < bf = 225 mm

N

Actual Bearing Pressure (fb)

fb = P = 0.1899 Kg/mm2 = 0.2755 Kip/in2

BxC

Fb = 0.75 Fy = 1800 Kg/cm2 = 26.106 Kip/in2

a = bf - tw = 0.5455

2( d - 2tf )

tp = 3 (bf-tw)2 fb = 0.5456 in = 13.86 mm (tp = thickness of plate)

4(1+3.2a ) Fb

3

Base plate thickness required is = 13.86 mm

Base plate thickness recommended is = 16 mm

b. Anchor Bolts

Anchor Bolts A 307

Fb = 0.6 Fy = 144 Mpa (allowable bending stress)

t = 86.4 Mpa (allowable shear stress)

s tu = 172.8 Mpa (allowable bearing stress)

Loads (see attachment B)

Actual shear load (Q) = 1532.1 Kg

Check for Shear

Try bolt (D) M 16 mm

numb of bolt (n) = 2

Ag = 1/4 p D2 = 201.06 mm2 (cross section area of bolt)

t = Q / n Ag

= 38.103 Mpa < t OK 0

Check for Bearing Plate

t = 16 mm (Base plate thickness recommended)

Atu = t x D = 256 mm2 (shear section area of bolt)

s tu = Q / n Atu

= 29.924 Mpa < s tu OK 0

Result :

Base plate and anchor bolt for Detail 1 (see attachment E drawing D-262-CS-025)

Base plate dimension : 250 X 250 X 16

Anchor bolt : 2 M 16

Prepared by PT. BITA HYUNDAI - THIESS

02.1362

10/25/04

Anchor bolts

base plate

Prepared by PT. BITA HYUNDAI - THIESS

02.1362

10/25/04

= thickness of plate)

Prepared by PT. BITA HYUNDAI - THIESS

SUBAN PHASE II GAS PROJECT No. : 2.1362

Suban - South Sumatra Revision :

Detailed Engineering & Design Offsite Facilities & Permanet Camp Date : 10/25/04

Page :

Structure Calculation Grease - Wash Rack

Bolts Connection Calculation

Connection : Beam to Column

Q column WF 175x175x7.5x11

plate Beam WF 100x100x6x8

B1: WF 100X100X6X8 TO COLUMN

Bolt A 325

t = 126.5 Mpa (allowable shear stress)

s tu = 253 Mpa (allowable bearing stress)

Actual Loads

Q = 21750 N (Actual shear Load)

N = 4.65 N (Actual axial load)

Try bolt (D) M 16

numb of bolt (n) = 2

Check for shear

Ag = 1/4 p D2 = 201.056 mm2 (cross section area of bolt)

t = P / n Ag

= 54.09113 Mpa < t OK! 1

Check for bearing plate

t = 6 mm (Base plate thickness)

Atu = t x D = 96 mm2 (shear section area of bolt)

s tu = P / n Atu

= 113.2813 Mpa < s tu OK! 1

2

Use bolt 2 M 16

Result bolt connection Detail 4 : 2 M 16

(see attachment E drawing D-262-CS-026)

Prepareb by PT. BITA HYUNDAI - THIESS

You might also like

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Bearing CheckDocument6 pagesBearing CheckdhanushkaNo ratings yet

- BP2Document3 pagesBP2insane88No ratings yet

- Client Comment Response - DG FoundationDocument7 pagesClient Comment Response - DG FoundationAnnelzNo ratings yet

- STR 237Document144 pagesSTR 237kavin patel100% (1)

- Wind CalculatorDocument12 pagesWind Calculatorilyasmd7No ratings yet

- Welded & Pinned Connection Design CalculationDocument14 pagesWelded & Pinned Connection Design CalculationPrakash Singh RawalNo ratings yet

- REINFORCEMENT CALCULATION FOR 1000MM THICK CF1Document3 pagesREINFORCEMENT CALCULATION FOR 1000MM THICK CF1ARUNKUMAR KNo ratings yet

- 2 ConnectionDocument18 pages2 Connectionssikha100% (1)

- Calculate area, centroid and moment of inertiaDocument77 pagesCalculate area, centroid and moment of inertiaAmit Kumar PaulNo ratings yet

- Anchor Bolt Design CalculationsDocument64 pagesAnchor Bolt Design CalculationsSiva baalanNo ratings yet

- Bolt Grade (GR - Bolt) No. of Bolts N NRXNC Dia. of Bolts D With Hole DH at Gauge 'G' X/Crs Sw1 Sw1 (TYP at FLG.) SW SWDocument124 pagesBolt Grade (GR - Bolt) No. of Bolts N NRXNC Dia. of Bolts D With Hole DH at Gauge 'G' X/Crs Sw1 Sw1 (TYP at FLG.) SW SWAsaru DeenNo ratings yet

- Steel Column FOR SCRIBDDocument8 pagesSteel Column FOR SCRIBDdarshika.jaganiNo ratings yet

- Insert Plate DesignDocument8 pagesInsert Plate DesignPiyushNo ratings yet

- Base Plate Uc152x152x23Document2 pagesBase Plate Uc152x152x23sonofalexanderNo ratings yet

- Splice ConnectionUC 254X254X73Document1 pageSplice ConnectionUC 254X254X73PavanGuptaNo ratings yet

- 8224 Grating No HeaderDocument69 pages8224 Grating No HeadervishalnalwarNo ratings yet

- ReportTank 12.0m DiaDocument17 pagesReportTank 12.0m DiasuheilbugsNo ratings yet

- Column Base PlateDocument3 pagesColumn Base PlatePurnima ArkalgudNo ratings yet

- Base Plate & Anchor Bolt - BP1Document20 pagesBase Plate & Anchor Bolt - BP1munishant1No ratings yet

- 3PB Pilecap DesignDocument3 pages3PB Pilecap DesignJONAS NGNo ratings yet

- Design of rigid connection detail 85Document215 pagesDesign of rigid connection detail 85Umer AziqNo ratings yet

- Connection No: 34: LOADS (Worst Case Group No.112 & Element No.1120800)Document10 pagesConnection No: 34: LOADS (Worst Case Group No.112 & Element No.1120800)Stephen JamesNo ratings yet

- Steel BeamDocument12 pagesSteel BeamV.m. RajanNo ratings yet

- Chirai Anjar Rigid Pavement Design As Per IRC 58 2011Document60 pagesChirai Anjar Rigid Pavement Design As Per IRC 58 2011chetan c patilNo ratings yet

- Design of Ring Girder SupportDocument3 pagesDesign of Ring Girder Supportvishal guptaNo ratings yet

- Circular WeldDocument12 pagesCircular WeldJohn Paul UmaliNo ratings yet

- Base Plate Design - Rev-0Document8 pagesBase Plate Design - Rev-0KINGSUK PALNo ratings yet

- R.R. Rojo and Associates: Anchor Bolt Design The Anchor Rod Design Is AdequateDocument10 pagesR.R. Rojo and Associates: Anchor Bolt Design The Anchor Rod Design Is AdequateMarkNo ratings yet

- Crane Beam Web Splice DesignDocument7 pagesCrane Beam Web Splice DesignCrystal JaneNo ratings yet

- Design Criteria/Design Check For Star Deck Sheet (44/130)Document2 pagesDesign Criteria/Design Check For Star Deck Sheet (44/130)Advanced Structural EngineeringNo ratings yet

- Steeltek ConnectionDocument5 pagesSteeltek ConnectioncadsultanNo ratings yet

- Tubular SectionDocument15 pagesTubular SectionOuseppachan AmbookenNo ratings yet

- Chequred PlateDocument2 pagesChequred PlateKumar Prasanna HNNo ratings yet

- RAM Connection Input With CommentsDocument6 pagesRAM Connection Input With CommentsAhmed Saeed OokaNo ratings yet

- Design of Non Composite Beams With Large OpeningsDocument73 pagesDesign of Non Composite Beams With Large OpeningsbalaNo ratings yet

- Angle-Weld Length CalculationsDocument28 pagesAngle-Weld Length CalculationsrammohanNo ratings yet

- Rafter-Column Bracing DesignDocument3 pagesRafter-Column Bracing Design4geniecivilNo ratings yet

- Design Report For 300m3 Rectangular ReservoirsDocument37 pagesDesign Report For 300m3 Rectangular ReservoirsARSENo ratings yet

- 111.872 KN Section Properties B 203.1 D 203.2 T 11 T 7.24Document7 pages111.872 KN Section Properties B 203.1 D 203.2 T 11 T 7.24ItsmejanuNo ratings yet

- Design of column splice plates and weldsDocument4 pagesDesign of column splice plates and weldsNiraj Shinde100% (1)

- Wind Load Analysis: Sustain Wind Pressure For 15' HeightDocument4 pagesWind Load Analysis: Sustain Wind Pressure For 15' HeightSumon RoyNo ratings yet

- Project Calculation Sheets Eng. Check.: Sec. 1 Shear TorsionDocument2 pagesProject Calculation Sheets Eng. Check.: Sec. 1 Shear TorsionmaheshbandhamNo ratings yet

- Metal Sheet Calculations for 44-195 ProfileDocument29 pagesMetal Sheet Calculations for 44-195 ProfileAnonymous HkX2aE9FxNo ratings yet

- Moment Connection - Beam SpliceDocument3 pagesMoment Connection - Beam SpliceSh MNNo ratings yet

- CSE 362 Design of Steel Structures Section Properties and CapacitiesDocument19 pagesCSE 362 Design of Steel Structures Section Properties and CapacitiesRufus ChengNo ratings yet

- Beam DesignDocument8 pagesBeam DesignFaraaz FaisalNo ratings yet

- DG Consulting EngineersDocument8 pagesDG Consulting EngineersThakshayani SellavelNo ratings yet

- Steeltek ConnectionDocument5 pagesSteeltek ConnectionSudip ShresthaNo ratings yet

- Skylight StructureDocument16 pagesSkylight Structuremsiddiq1No ratings yet

- Beam Design TorsionDocument20 pagesBeam Design Torsionmailmaverick8167100% (1)

- Eccentric-Footing 2Document5 pagesEccentric-Footing 2Yash GoyalNo ratings yet

- Design of Fire Brick Wall FootingDocument4 pagesDesign of Fire Brick Wall FootingSATISH GAIKWADNo ratings yet

- Base Plate Design CapacitiesDocument4 pagesBase Plate Design CapacitiesSrishti Project Consultants0% (1)

- Column Design AnalysisDocument18 pagesColumn Design AnalysisSurya FahmiNo ratings yet

- Design of Base PlateDocument11 pagesDesign of Base PlateSherwin CairoNo ratings yet

- BASEPLATE INPUTDocument258 pagesBASEPLATE INPUTNguyen Duc CuongNo ratings yet

- Design of Base Plate 1Document2 pagesDesign of Base Plate 1Andro RebuyasNo ratings yet

- Column ConnectionDocument14 pagesColumn Connectionabhi aroteNo ratings yet

- Anchor Bolt& Base Plate DesignDocument28 pagesAnchor Bolt& Base Plate Designtirentyren1No ratings yet

- BridgeT BeamDocument23 pagesBridgeT BeamMochammad Syafi UddinNo ratings yet

- WelcomeDocument5 pagesWelcomeCatNo ratings yet

- Get Started With DropboxDocument10 pagesGet Started With DropboxYan HakimNo ratings yet

- Oil Storage - Structural CalculationDocument24 pagesOil Storage - Structural CalculationSurya FahmiNo ratings yet

- Devi Wijayanti-BPN-ZUBCTT-CGK-FLIGHT - RETURNINGDocument2 pagesDevi Wijayanti-BPN-ZUBCTT-CGK-FLIGHT - RETURNINGSurya FahmiNo ratings yet

- CostDocument1 pageCostSurya FahmiNo ratings yet

- Book 145Document2 pagesBook 145Surya FahmiNo ratings yet

- Table: Cold Formed Design 2 - PMM Details - Aisi-Lrfd96 Frame Designsect Designtype Combo Location Pu Mumajor MuminorDocument23 pagesTable: Cold Formed Design 2 - PMM Details - Aisi-Lrfd96 Frame Designsect Designtype Combo Location Pu Mumajor MuminorSurya FahmiNo ratings yet

- Column Design AnalysisDocument18 pagesColumn Design AnalysisSurya FahmiNo ratings yet

- Weld CalculationDocument3 pagesWeld CalculationSurya FahmiNo ratings yet

- BFFFDocument20 pagesBFFFSurya FahmiNo ratings yet

- Joint displacements and reactions tableDocument6 pagesJoint displacements and reactions tableSurya FahmiNo ratings yet

- Loading Atap 1Document12 pagesLoading Atap 1Surya FahmiNo ratings yet

- Weld CalculationDocument3 pagesWeld CalculationSurya FahmiNo ratings yet

- STC STRUCTURAL CALCULATION BEAM DESIGNDocument26 pagesSTC STRUCTURAL CALCULATION BEAM DESIGNSurya FahmiNo ratings yet

- Commercial property areas and costsDocument2 pagesCommercial property areas and costsSurya FahmiNo ratings yet

- Book 1Document2 pagesBook 1Surya FahmiNo ratings yet

- Book 1Document2 pagesBook 1Surya FahmiNo ratings yet

- 1 PB PDFDocument11 pages1 PB PDFaldo surya pratamaNo ratings yet

- Ms 01 140Document74 pagesMs 01 140Prateek RajNo ratings yet

- (Paul M. S. Monk) Physical Chemistry UnderstandinDocument3 pages(Paul M. S. Monk) Physical Chemistry UnderstandinAshwani kumar SinghNo ratings yet

- CJ1M Programming ManualDocument381 pagesCJ1M Programming ManualherpadianaNo ratings yet

- FCL Shipment Specific Quotation For BRIDGESTONE AMERICAS INCDocument3 pagesFCL Shipment Specific Quotation For BRIDGESTONE AMERICAS INCmustova81No ratings yet

- Industrial Training IntroductionDocument1 pageIndustrial Training Introductionsgurjar07No ratings yet

- Behavior of Connected and Unconnected Back-to-Back Walls For Bridge ApproachesDocument10 pagesBehavior of Connected and Unconnected Back-to-Back Walls For Bridge Approachessalar salarNo ratings yet

- Minimizing Penalty in Industrialpower Factor Correction by Engaging Apfc UnitDocument15 pagesMinimizing Penalty in Industrialpower Factor Correction by Engaging Apfc UnitabellNo ratings yet

- Chapter2 AligningSelectionProjectsDocument36 pagesChapter2 AligningSelectionProjectsZeynep SenerNo ratings yet

- Mendeley Data - Lowbrasys Brake Wear Cycle - 3h LACTDocument3 pagesMendeley Data - Lowbrasys Brake Wear Cycle - 3h LACTMini VargheseNo ratings yet

- Download Engineering Mathematics Textbook from EasyEngineering.netDocument828 pagesDownload Engineering Mathematics Textbook from EasyEngineering.netAzhagesvaran TamilselvamNo ratings yet

- Basic CourseDocument97 pagesBasic CourseAhmed KhairyNo ratings yet

- For Student-General Chemistry I - Module 6 - Phan Tai HuanDocument41 pagesFor Student-General Chemistry I - Module 6 - Phan Tai HuanEsat Goceri100% (1)

- Operations ManualDocument534 pagesOperations ManualAlthea Joy Castor SobretodoNo ratings yet

- Internal II BEEE QPDocument1 pageInternal II BEEE QPsivaNo ratings yet

- Intermittent Fasting Facts and Myths: Metabolic Benefits of Intermittent FastingDocument4 pagesIntermittent Fasting Facts and Myths: Metabolic Benefits of Intermittent FastingIJAR JOURNALNo ratings yet

- Ch02 World Trade An Overview 1Document32 pagesCh02 World Trade An Overview 1XIKAMNo ratings yet

- Datasheet GenDocument2 pagesDatasheet GenEdgar Bonilla MuñozNo ratings yet

- Plant Coordination and ControlDocument13 pagesPlant Coordination and ControlMarilyn GumeyiNo ratings yet

- Group 3 Safety Issues in ICTDocument15 pagesGroup 3 Safety Issues in ICTRoseAnnNo ratings yet

- Eating Healthily: People's Mixed ViewsDocument2 pagesEating Healthily: People's Mixed ViewsTbb GajahMada MagetanNo ratings yet

- ANALYSIS OF TRANSFORMER OIL TESTING USING GAS CHROMATOGRAPHY METHODDocument9 pagesANALYSIS OF TRANSFORMER OIL TESTING USING GAS CHROMATOGRAPHY METHODmuhammad yaminNo ratings yet

- Structural Dyanmics-Anna University Q PaperDocument7 pagesStructural Dyanmics-Anna University Q PaperVijay AravindNo ratings yet

- Fine ArtsDocument12 pagesFine Artsatul prajapatiNo ratings yet

- UNIVERGE SV9100 Hardware Manual - Issue 9.1Document574 pagesUNIVERGE SV9100 Hardware Manual - Issue 9.1TonyNo ratings yet

- Water Cycle Cer 002Document2 pagesWater Cycle Cer 002api-434008934No ratings yet

- Nike Run Club 5K Training PlanDocument25 pagesNike Run Club 5K Training PlanSalvador0% (1)

- Liugong 938l Wheel Loader Parts ManualDocument20 pagesLiugong 938l Wheel Loader Parts Manualviolet100% (56)

- Jazz Band LiteratureDocument4 pagesJazz Band LiteratureJohnny LaounNo ratings yet

- Learning Activity Sheet In: Computer Systems ServicingDocument12 pagesLearning Activity Sheet In: Computer Systems ServicingCarvalds 0315No ratings yet