Professional Documents

Culture Documents

Application of Labview For Undergraduate Lab Experiments On Materials Testing

Uploaded by

Azza AhmedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Application of Labview For Undergraduate Lab Experiments On Materials Testing

Uploaded by

Azza AhmedCopyright:

Available Formats

Main Menu

Session 2168

Application of LabVIEW for Undergraduate Lab Experiments On Materials Testing

Ismail I. Orabi University of New Haven

Abstract

This paper describes the implementation of LabVIEW, in a torsion experiment in the Mechanics Laboratory in the Mechanical Engineering Department at the University of New Haven, to allow the acquisition of real time data for display, analysis, control and storage. The input moment and the angle of twist are measured directly from torsion transducers. The real-time measurements and display acquired waveforms are displayed on a PC screen and the data associated with these waveforms are stored for later use. The aim is to be able to control and apply moment to a specimen, and collect data from the resulting deformation in the material. In the torsion test, the mechanical properties of the materials to a twisting moment are obtained by two transducers mounted on the bottom of the grips of the torsion machine. The torque and angle of twist are then acquired using LabVIEW software to obtain the yield shear stress, modulus of rigidity and the ultimate strength. The data acquisition system is provided using the following products from National Instruments: application programming interface; and LabVIEW, software development package. The Excel spreadsheet is used to analyze the results. This work demonstrates that instrumentation experience is greatly enhanced by integration LabVIEW into the Laboratory. The incorporation of computer data acquisitions into the undergraduate laboratory provides students with a valuable tool for data collection and analysis. Introduction The use of a computer to imitate an instrument or device is known as virtual instrumentation. One software development package used to create virtual instruments is LabVIEW (Laboratory Virtual Instrument Engineering Workbench). LabVIEW is a graphical programming language that, when used in conjunction with a data acquisition device and personal computer, allows the user to control devices, collect, manipulate and display data. Written code is not used in LabVIEW, instead graphical representations of the circuits are constructed which are called

Proceedings of the 2002 American Society of Engineering Education Annual Conference & Exposition Copyright 2002, American Society of Engineering Education

Main Menu

Main Menu

virtual instruments (VIs). These VIs are manipulated to perform the desired tasks at hand. The VIs (virtual instruments) in LabVIEW are run from their front panels. This is the panel with all of the controls and displays. Each front panel has an associated block diagram. This block diagram is built using the graphical programming language G. The components of the block diagram represent different structures, loops and functions. The wiring of the block diagram represents flow of data between these components. A VI becomes a sub VI when it is placed inside the block diagram of another VI. These sub VIs are analogous to sub routines, and allow layering and modularity of the VIs. Linear Elastic Theory [ 1] Elementary theory predicts a state of pure shear stress on the surface of a circular torsion member. Pure shear is defined as a state of shear stress in the absence of normal stresses.

On the surface of a circular torsion member (Figure 1) the state of shear stress (in the axial and circumferential directions) is given by:

where T is the applied torque, c is the radius and J is the polar moment of the cross-sectional area. For a solid circular member:

Although the shear stress equation above contains no elastic constants, review of the derivation will show that linear elastic theory was assumed. It is important to realize that pure shear stress can exist only for one orientation of the coordinate frame. For all other orientations normal stresses will exist, and at 45o to the pure shear axes we find principal stresses (and thus no shear stress). It is easy to show with Mohr's circle (Figure 3) that the principal stresses are equal tensile and compressive stresses with the same magnitude as the torsional shear stress. The conclusion is that the state of pure shear stress is equivalent to a

Proceedings of the 2002 American Society of Engineering Education Annual Conference & Exposition Copyright 2002, American Society of Engineering Education

Main Menu

Main Menu

biaxial state of equal tensile and compressive stresses oriented at 45 o to the pure shear axes (Figure 2).

The surface shear strain associated with the axial-circumferential directions is given by:

Equipment setup The equipment was set up as shown in Figure 4. The VIs were written and run with LabVI 6.0 Student Edition. The Torsion VI worked in conjuction with the Tinius Olsen Lo-Torq Bench Model Testing machine . A serial interface is used to collect data from the 290 Display.

Proceedings of the 2002 American Society of Engineering Education Annual Conference & Exposition Copyright 2002, American Society of Engineering Education

Main Menu

Main Menu

Figure 4: Equipment setup The 290 Torsion Control VI , shown in Figures 5 and 6 interfaces with the Tinius Olsen Lo -Torq Bench Model Torsion Testing Machine with a Model 290 Display. This VI will collect the torque and twist angle data, calculate shear stress and shear strain and write all of this data to a file, which can be later opened with a spreadsheet program. The user must first enter a file name, to which the data will be saved, the time interval for the collection of data, and the diameter and length of the specimen.

Device Status Data

Torque vs. Twist Angle 1.0 Torque (Nm)

0.0000

Twist Angle (deg)

Not Collecting Data 0.5

Stop

0.0

0.00

Tiwst Angle (rad)

0.000

Shear Stress (MPa)

Parameter Input

File Name a:\test.xls eg: a:\test.xls

-0.5

0.0000

Shear Strain

-1.0 -1.0 Time Interval (sec) 10.00 I M P O R T A N T : -0.5 0.0 0.5 1.0

0.00000E+0

Diameter (mm)

0.0

Set the 290 Torsion Testing Device to SI units, and depress the CLEAR button before starting vi. Stop this vi with the Stop button on the vi, not the stop on the toolbar

Length (mm)

0.0

Figure 5 Front panel of the 290 Torsion Control VI

Proceedings of the 2002 American Society of Engineering Education Annual Conference & Exposition Copyright 2002, American Society of Engineering Education

Main Menu

Main Menu

The VI begins by zeroing the first channel and then collecting data from both channels of the Model 290 Display at the specified interval. This data is displayed in both numerical and graph form. The graph allows the user to observe the relationship between the applied torque and the angle of twist. The diameter and length of the specimen are utilized in the calculations of shear stress and shear strain.

1 [0..1]

Reads and Writes Data

Time Interval (sec)

6 Writing Data

1000 5 1 [0..1] Reads Data on Channel 2 Converts output to a decimal 1 number, and calculates values. Front panel indicator 25

Writes Header to File

Load

Torque vs. Twist Angle

3

Twist (deg)

Offset Length

Torque Shear Stress 500 points 0 Shear Strain Twist (rad)

Read Chan 2

[2]r

11

deg

Bytes to Read Read Time Port Number

T S 0 strain Clears the graph 0 rad at start

File Name

S=((T*P/180)*C)/(L/ 1000);R=T*P/180; C L P R

Writes Data to File

Shear Strain Tiwst Angle (rad) Length (mm) Twist Angle (deg)

transpose 0 0 stress append

Diameter (mm)

2000

Stop

Figure6 Block diagram for the 290 Torsion Control VI Depressing the Suspend button allows the user to interrupt the collection of data. With the Suspend on, the VI will write zeros to the file at the specified time interval. Depressing the Suspend button once more resumes the collection and writing of the data. The Stop button on the VI ends the collection of data and terminates the running of the VI.

Proceedings of the 2002 American Society of Engineering Education Annual Conference & Exposition Copyright 2002, American Society of Engineering Education

Main Menu

Main Menu

Results

During this experiment the LabVIEW software was constructed to allow the necessary experimental data to be computed and recorded into an excel spreadsheet. This stored data was analyzed by MS Excel. Figure 7 shows the relation between torque and the angle of twist for aluminum (6061 T651). Figure 8 indicates the relationship between shear stress and shear strain.

60 56 52 48 44 40

Test Curve Curve extending to Yield Strength Values at the proportional Limit Values at the Yield Strength

TORQUE (Nm)

36 32 28 24 20 16 12 8 4 0 0 11 24 37 50 63 76 89 102 115 127 141 153 166 179 192 205 218

TWIST (Degree)

Graph 3

Figure 7: Torque and angle of twist diagram (6061-T651 ALUMINUM SPECIMEN)

Proceedings of the 2002 American Society of Engineering Education Annual Conference & Exposition Copyright 2002, American Society of Engineering Education

Main Menu

Main Menu

Test Curve Values at Proportional limit Value of Yield Strength at 0.2% offset

140 130 120 110 100

SHEAR STRESS (MPa)

90 80 70 60 50 40 30 20 10 0 0.000 0.004 0.008 0.013 0.017 0.021 0.025 0.030 0.034 0.038 0.043 0.047 0.052 0.056 0.060 0.065 0.069 0.073 SHEAR STRAIN (mm/mm) Graph 4

Figure 8: SHEAR STRESS VS SHEAR STRAIN (6061-T651 ALUMINUM SPECIMEN) Discussion Once the equipment was set up the VIs were easy to use, and in a matter of minutes the experiment had been executed and the data recorded. The data is displayed on the VI, and calculations are made using this data and parameters set by the user. Data and calculations are written to a file which can be opened using a spread sheet program such as MS Excel This saves considerable time over the method of using the 290 display to capture the signal, making the measurements of the data, and performing the calculations. Comparison of the results, as shown in Figures 7 and 8, indicate that the mechanical properties of Aluminum are comparable to the published data.

Proceedings of the 2002 American Society of Engineering Education Annual Conference & Exposition Copyright 2002, American Society of Engineering Education

Main Menu

Main Menu

Conclusions In this experiment, virtual instruments created with LabVIEW were used to investigate the mechanical properties of materials subjected to twisting load.. A LabVIEW VI and a number of subVIs were written for the experiment. The use of virtual instruments created with LabVIEW allows the user to quickly investigate and gather data, and also serves to introduce many students to the use of virtual instruments. The time student takes to complete the experiment are significantly reduced by using computer data acquisitions. This work demonstrates that the capability to rapidly acquire, display and analyze data provides a valuable tool to students.

Bibliography

1. 2. 3. 4. http://www.umr.edu/~be120/lessons/torsion/manual/index.html#theory Mechanics of Materials, by Higdon et al., 4th Ed., Wiley, 1985, pp 179-185, 196-199, 204-205. Mechanics of Materials, by Hibbeler, Macmillan, 1991, pp 171-182, pp 192-195, pp 232-236 Craig, R.R., and McConnell, L., "Virtual Instruments Revitalize an Undergraduate Measurements and Instrumentation Course, 1999 annual ASEE Conference Proceedings, Charlotte, NC, June 20 - 23, 1999 Neebel, D. J., Blandino, J. R., and Lawrence, D. J., " A Survey of Modern Computer -Based Experiments, Part No. 321884B-01, National Instruments, Austin, TX, March 1998. Smith, C.C., Lund, E.K. and Dahl, J.F., "Instrumentation and Digital Data Acquisition in Mechanical Engineering," 1994 ASEE Annual Conferenc Proceedings, Vancouver, BC., 1994 Eibeck, P.A., " Multimedia Courseware Support for the Instruction of Engineering Experimentation," Proceedings of Frontiers in Education 23 rd Annual conference, sponsored by ASEE and IEEE, Washington, D.C., Nov. 6-9, pp. 135-139, 1993. Smith, C.C., Heaton, H.S., and Queiroz, M., "Integration of Computer-Based Data Acquisition Systems into Undergraduate Instrumentation Laboratories, 1992 ASEE Annual Conference Proceedings, Toledo, Ohio, 1992

5. 6. 7.

8.

Biographical Information

ISMAIL I. ORABI, Professor of Mechanical Engineering at University of New Haven. He received his Ph.D. from Clarkson University, and his MS degree from the State University of New York and B.S. from Cairo Institute of Technology, all in Mechanical Engineering. In the past 10 years, He has established three Laboratories: the Materials Testing laboratory sponsored by the NSF, the Engineering Multimedia Laboratory supported by AT&T Foundation and the Space Dynamic Systems Lab funded by United Technologies and the Yankee Ingenuity of the State of Connecticut. He has published over 25 technical articles in refereed journals and conference proceedings. His research interests include dynamics of linear and nonlinear structural systems, numerical simulations and seismic analysis and design.

Proceedings of the 2002 American Society of Engineering Education Annual Conference & Exposition Copyright 2002, American Society of Engineering Education

Main Menu

You might also like

- Applied Metrology for Manufacturing EngineeringFrom EverandApplied Metrology for Manufacturing EngineeringRating: 5 out of 5 stars5/5 (1)

- Application of Labview For Undergraduate Lab Experiments On Materials TestingDocument8 pagesApplication of Labview For Undergraduate Lab Experiments On Materials TestingShahnewaz BhuiyanNo ratings yet

- Hyperworks FatigueDocument24 pagesHyperworks FatigueParis AdriánNo ratings yet

- Cutting Force Measurement of Electrical Jigsaw byDocument6 pagesCutting Force Measurement of Electrical Jigsaw byKhoaNguyễnNo ratings yet

- Zemko KapustovaDocument7 pagesZemko KapustovaMNNo ratings yet

- SYS Bolt ManualDocument64 pagesSYS Bolt ManualNoppolNorasriNo ratings yet

- He So Nen UonDocument7 pagesHe So Nen UonTran Van DaiNo ratings yet

- STAAD+PRO - NRC Verfication Manual 2005Document154 pagesSTAAD+PRO - NRC Verfication Manual 2005Jose Rojas-GuzmanNo ratings yet

- Design and Validation of XY Flexure Mechanism: Pratik M. Waghmare, Shrishail B. SollapurDocument5 pagesDesign and Validation of XY Flexure Mechanism: Pratik M. Waghmare, Shrishail B. SollapurbhageshlNo ratings yet

- Fatigue Analysis of A Shaft On AnsysDocument28 pagesFatigue Analysis of A Shaft On AnsysSatheesh SekarNo ratings yet

- Inicio Rapido-Undwedge TutorialDocument18 pagesInicio Rapido-Undwedge TutorialEddy Mamani GuerreroNo ratings yet

- Design and Construction of A Torsion Fatigue Machine: Torsion Fatigue Tests On Two Industrial Aluminum AlloysDocument15 pagesDesign and Construction of A Torsion Fatigue Machine: Torsion Fatigue Tests On Two Industrial Aluminum AlloysAyberk TürkNo ratings yet

- Digital Image Correlation For Tensile TestDocument9 pagesDigital Image Correlation For Tensile TestAli AbbarNo ratings yet

- Numerical Study On Stress Analysis of Curved BeamsDocument8 pagesNumerical Study On Stress Analysis of Curved BeamsIAEME PublicationNo ratings yet

- Intermediate Lab 4 Manual V2Document19 pagesIntermediate Lab 4 Manual V2Mohammed KhalidNo ratings yet

- Mechatronic Options For Increasing Productivity and Accuracy in ProductionDocument25 pagesMechatronic Options For Increasing Productivity and Accuracy in Productionmaitham100No ratings yet

- A Presentation On Final Year Project: Birla Institute of Technology Mesra (Ranchi)Document18 pagesA Presentation On Final Year Project: Birla Institute of Technology Mesra (Ranchi)Dhruv VashisthaNo ratings yet

- Use of Strain Gauge Rosette To Investigate Stress Concentration in Isotropic and Orthotropic Plate With Circular HoleDocument5 pagesUse of Strain Gauge Rosette To Investigate Stress Concentration in Isotropic and Orthotropic Plate With Circular HoleHako KhechaiNo ratings yet

- 625 1Document12 pages625 1tuongnvNo ratings yet

- Paper-Rotating Bending Machine For High Cycle Fatigue TestingDocument7 pagesPaper-Rotating Bending Machine For High Cycle Fatigue TestingAlcidney Valério ChavesNo ratings yet

- Laboratory Handout Semester 1Document12 pagesLaboratory Handout Semester 1Taras GorevoiNo ratings yet

- CAD ANALYSIS LAB MANUAL 2015 S6 MechanicalDocument26 pagesCAD ANALYSIS LAB MANUAL 2015 S6 MechanicalKailas Sree Chandran100% (2)

- Procedure Title - Vickers Hardness Testing With The Mitutoyo MVK-H1 Microhardness TesterDocument12 pagesProcedure Title - Vickers Hardness Testing With The Mitutoyo MVK-H1 Microhardness TesterVitor100% (1)

- Slender Strut (Column) Buckling.: Control, Structure and Syntax of CalculationsDocument11 pagesSlender Strut (Column) Buckling.: Control, Structure and Syntax of CalculationsNageswar RaoNo ratings yet

- Articolo 202 PDFDocument16 pagesArticolo 202 PDFAntmavrNo ratings yet

- 3. مهم جداvery Important Conrod Reference and Experimental WorkDocument8 pages3. مهم جداvery Important Conrod Reference and Experimental WorkAhmed M. El-DyastyNo ratings yet

- Lab10 Tensile TestDocument12 pagesLab10 Tensile TestNur Syamiza Zamri100% (2)

- A Simple Unconsolidated Undrained Triaxial Compression Test EmulatorDocument5 pagesA Simple Unconsolidated Undrained Triaxial Compression Test EmulatorPlanta SeedNo ratings yet

- Lamdamap03044fu PDFDocument10 pagesLamdamap03044fu PDFSong BunrithNo ratings yet

- 2020 Numisheet Benchmark Study Uniaxial Tensile Tests SummaryDocument18 pages2020 Numisheet Benchmark Study Uniaxial Tensile Tests Summaryifb.mirzaNo ratings yet

- Calculation of Load Capacity of Gears in Random Varying Exploitation ConditionsDocument9 pagesCalculation of Load Capacity of Gears in Random Varying Exploitation ConditionsthisisjineshNo ratings yet

- MIcro End-Milling I - Wear and BreakageDocument18 pagesMIcro End-Milling I - Wear and BreakageanujNo ratings yet

- JMET Vol 7 No 2 Paper 1Document15 pagesJMET Vol 7 No 2 Paper 1Dustin WhiteNo ratings yet

- Using LabVIEW: Simulation Exciter of Devices JammingDocument11 pagesUsing LabVIEW: Simulation Exciter of Devices JammingInternational Journal of Basic and Applied ScienceNo ratings yet

- Signature Analysis of Cracked Cantilever BeamDocument13 pagesSignature Analysis of Cracked Cantilever BeamIAEME PublicationNo ratings yet

- Estimating The Uncertainty of Tensile Strength MeaDocument8 pagesEstimating The Uncertainty of Tensile Strength MeaSonja Kostić0% (1)

- FEA of Ellipsoidal Head Pressure Vessel - by - VikramDocument7 pagesFEA of Ellipsoidal Head Pressure Vessel - by - VikramaruatscribdNo ratings yet

- Maggi 2011Document6 pagesMaggi 2011Praveen PrasadNo ratings yet

- Surface & Coatings Technology: H.Y. Miao, S. Larose, C. Perron, Martin LévesqueDocument12 pagesSurface & Coatings Technology: H.Y. Miao, S. Larose, C. Perron, Martin LévesqueAhmed MabroukNo ratings yet

- Experimental and Numerical Analysis On Coil Springs Preset Plastic DeformationDocument5 pagesExperimental and Numerical Analysis On Coil Springs Preset Plastic DeformationRobinson Ferrari BarbosaNo ratings yet

- Sample Formal Laboratory ReportDocument20 pagesSample Formal Laboratory ReportYesset KuspekovNo ratings yet

- Cutting Force Measurements in Conventional LatheDocument4 pagesCutting Force Measurements in Conventional LatheArpanNo ratings yet

- ColdSteel Manual V120Document87 pagesColdSteel Manual V120Terry CheukNo ratings yet

- Qiang Liu and Weiming GaiDocument6 pagesQiang Liu and Weiming GaiMarimuthu VijayanNo ratings yet

- SDC Brochure v4.0Document16 pagesSDC Brochure v4.0Yarko YurechkoNo ratings yet

- Displacement and Stress Analysis of Suspension Systems Using Ansys IJERTV7IS030152Document4 pagesDisplacement and Stress Analysis of Suspension Systems Using Ansys IJERTV7IS030152PFENo ratings yet

- Study On High-Rise Structure With Oblique Columns Etabs, Gen, SapDocument7 pagesStudy On High-Rise Structure With Oblique Columns Etabs, Gen, SapMaad Ahmed Al-MaroofNo ratings yet

- Axial Turbine FEADocument8 pagesAxial Turbine FEAcena3135No ratings yet

- NI ELVIS Enter The LabddsDocument10 pagesNI ELVIS Enter The Labddstotal4321No ratings yet

- Tensile TestDocument6 pagesTensile Testkinwai5557100% (1)

- PR 2303Document4 pagesPR 2303Karthik Srinivas0% (1)

- MEL311Document281 pagesMEL311Shiri ShaNo ratings yet

- CAT - Computer - Aided - Testing - in - Automation - of - Stability - TestsDocument7 pagesCAT - Computer - Aided - Testing - in - Automation - of - Stability - TestsOscar GomezNo ratings yet

- Deformation Analysis of A 3-Axis Gantry System: AbstractDocument4 pagesDeformation Analysis of A 3-Axis Gantry System: AbstractŽan PjerNo ratings yet

- Modal Analysis of Cantilever Beam Structure Using Finite Element Analysis and Experimental AnalysisDocument8 pagesModal Analysis of Cantilever Beam Structure Using Finite Element Analysis and Experimental AnalysisAJER JOURNALNo ratings yet

- Lab#10 PressureDocument9 pagesLab#10 PressureRehman ButtNo ratings yet

- Fatigue Analysis of Welded Components: Designer’s Guide to the Structural Hot-Spot Stress ApproachFrom EverandFatigue Analysis of Welded Components: Designer’s Guide to the Structural Hot-Spot Stress ApproachRating: 5 out of 5 stars5/5 (1)

- Cancer ModellingDocument15 pagesCancer ModellingAzza Ahmed100% (1)

- Is It An Agent, or Just A Program?: A Taxonomy For Autonomous AgentsDocument15 pagesIs It An Agent, or Just A Program?: A Taxonomy For Autonomous AgentsAzza AhmedNo ratings yet

- Power Management of A Stand-Alone Wind/Photovoltaic/Fuel Cell Energy SystemDocument11 pagesPower Management of A Stand-Alone Wind/Photovoltaic/Fuel Cell Energy SystemAzza AhmedNo ratings yet

- 1 Storder N LodeDocument5 pages1 Storder N LodeAzza AhmedNo ratings yet

- EMOC 208 Installation of VITT For N2 Cylinder FillingDocument12 pagesEMOC 208 Installation of VITT For N2 Cylinder Fillingtejcd1234No ratings yet

- Colchicine - British Pharmacopoeia 2016Document4 pagesColchicine - British Pharmacopoeia 2016Social Service (V)100% (1)

- Online Examination System For AndroidDocument7 pagesOnline Examination System For AndroidSri Sai UniversityNo ratings yet

- ElectronicsDocument3 pagesElectronicsashishkumar218No ratings yet

- CH 4 Data CommDocument4 pagesCH 4 Data CommHenna ShainaNo ratings yet

- A9K CatalogueDocument152 pagesA9K CatalogueMohamed SaffiqNo ratings yet

- Jerry Hill's Letter To Bijan Sartipi, Director, District 4 CaltransDocument1 pageJerry Hill's Letter To Bijan Sartipi, Director, District 4 CaltransSabrina BrennanNo ratings yet

- Web 2.0: Dynamic Web PagesDocument12 pagesWeb 2.0: Dynamic Web PagesAra PantaleonNo ratings yet

- Cbse PMT 2012Document33 pagesCbse PMT 2012Vishal RamakrishnanNo ratings yet

- Manual PC Soundcard Scope 1.4.5Document17 pagesManual PC Soundcard Scope 1.4.5NatashaKillerNo ratings yet

- Programming Bayes Rule OptionalDocument17 pagesProgramming Bayes Rule OptionalajuhaseenNo ratings yet

- Skytrain Avia Services: Emergency Procedures ManualDocument32 pagesSkytrain Avia Services: Emergency Procedures ManualEndro RastadiNo ratings yet

- 007-013558-001 SAS PCE SPE With Support For HSM PSE2 Integration Feature Documentation RevCDocument43 pages007-013558-001 SAS PCE SPE With Support For HSM PSE2 Integration Feature Documentation RevCpietoeNo ratings yet

- 2019 All PDFDocument27 pages2019 All PDFvishesh bhatiaNo ratings yet

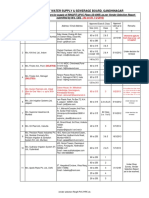

- GWSSB Vendor List 19.11.2013Document18 pagesGWSSB Vendor List 19.11.2013sivesh_rathiNo ratings yet

- Doing Hot Work On Gas ShipDocument5 pagesDoing Hot Work On Gas ShipAnonymous icnhaNsFNo ratings yet

- IEM PI A401 - ANNEXE - Design & Site ExperienceDocument5 pagesIEM PI A401 - ANNEXE - Design & Site ExperienceapiplajengilaNo ratings yet

- MJ4502 High-Power PNP Silicon TransistorDocument4 pagesMJ4502 High-Power PNP Silicon Transistorjoao victorNo ratings yet

- Emergency LightingDocument32 pagesEmergency LightingIsmet HizyoluNo ratings yet

- Siemens Engineering Manual V7Document338 pagesSiemens Engineering Manual V7Jeremy Branch100% (2)

- Ex-Cell XR2750 Pressure Washer Operation ManualDocument16 pagesEx-Cell XR2750 Pressure Washer Operation Manualj_wilson85No ratings yet

- Applying Six Sigma at 3MDocument13 pagesApplying Six Sigma at 3MdchNo ratings yet

- BurnerDocument4 pagesBurnerAhmed Mohamed KhalilNo ratings yet

- TD Quintolubric 888 68Document2 pagesTD Quintolubric 888 68Haitham YoussefNo ratings yet

- Coastal DefenceDocument112 pagesCoastal DefenceMorvin BudhanNo ratings yet

- 06-901 Keyed Input SwitchesDocument4 pages06-901 Keyed Input Switchesmajed al.madhajiNo ratings yet

- BIOS 203: Free Energy Methods Tom MarklandDocument23 pagesBIOS 203: Free Energy Methods Tom MarklandNemanja ĐokovićNo ratings yet

- Component Modeling - HDocument5 pagesComponent Modeling - HVasu IyerNo ratings yet

- Elevator Traffic Analysis - Passanger Elevators Option-1Document5 pagesElevator Traffic Analysis - Passanger Elevators Option-1Amit GuptaNo ratings yet

- Paket TrainingDocument20 pagesPaket TrainingLukman AriyantoNo ratings yet