Professional Documents

Culture Documents

06 - Nickel and Its Alloys

06 - Nickel and Its Alloys

Uploaded by

yaswanth19920 ratings0% found this document useful (0 votes)

6 views16 pagesOriginal Title

06_Nickel and Its Alloys

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views16 pages06 - Nickel and Its Alloys

06 - Nickel and Its Alloys

Uploaded by

yaswanth1992Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 16

Suranaree University of Technology May-Aug 2007

Nickel and its alloys

Nickel and its alloys

Subjects of interest

Objectives/Introduction

Production of nickel and nickel alloys

Commercially pure nickel

Nickel-copper alloys (Monels)

Nickel-chromium alloys

Nickel-base superalloys

Single crystal castings of nickel-base

superalloys

Lecture 6

Tapany Udomphol

Suranaree University of Technology May-Aug 2007

Objectives

Objectives

This chapter provides fundamental knowledge of

different methods of productions of nickel alloys and the

use of various types of nickel alloys.

The influences of alloy composition and microstructure

on chemical and mechanical properties of nickel alloys will

be discussed in relation to its applications.

Tapany Udomphol

Suranaree University of Technology May-Aug 2007

Introduction

Introduction

Properties

Silvery shiny appearance

High toughness and ductility

Good high and low

temperature strength

High oxidation resistance

Good corrosion resistance

Ferro-magnetic

Relatively high cost

Not mixed with cheap

alloying elements.

Limitations

Nickel

Ni

Crystal structure FCC

Atomic number 28

Atomic weight 58.71

Density (g.cm

-3

) 8.89

Melting point (

o

C) 1455

28

58.71

FCC

Tapany Udomphol

Suranaree University of Technology May-Aug 2007

Applications

Applications

Applications required necessary corrosion or heat- resisting

properties and for special engineering applications.

Chemical plant, heat exchanger, reaction furnace, rotary kiln,

turbine blades.

Used as alloying elements in stainless steels, and in other

elements such as copper, cobalt, chromium, etc.

Aerospace flow bodies

www.immnet.com

Turbine blades

www.msm.cam.ac.uk

Heat exchangers Reaction furnace

Rotary kiln

Tapany Udomphol

Suranaree University of Technology May-Aug 2007

Production of nickel

Production of nickel

www.mii.org

First discovery of nickel mineral by the German was

mistakenly misunderstood to be rich-copper mineral.

There are three major types of nickel deposits (sources):

1) Nickel-copper sulphide

2) Nickel silicates

3) Nickel laterites and serpentines

Nickel laterite deposits

research.eas.ualberta.ca/ egg/nilaterite.jpg

Nickeline or niccolite

Serpentine deposits

home.arcor.de

Tapany Udomphol

Extraction of nickel

Extraction of nickel

Nickel-sulphide ore

(Fe, Cu)

Crushing

Grinding

Magnetic separation

Iron sulphide

(pyrrhotite

concentrate)

Iron ore

recovery plant

Froth flotation treatment

Nickel concentrate Copper concentrate

Remaining ore

(Ni, Cu)

Copper

smelter

Roasting

Smelting (Reverberatory furnace)

Bessemer matte

(Ni and Cu sulphides)

Recrystallisation

Cooling

Crushing & grinding

Crystals of Ni and Cu

sulphides.

Ni-Cu metallic alloy

Froth flotation

Copper sulphide Nickel sulphide

Different grade

of nickel oxides

Roasting

Nickel refinery

Pure nickel and

other nickel alloy

products

Suranaree University of Technology May-Aug 2007

Tapany Udomphol

Suranaree University of Technology May-Aug 2007

Classification of nickel alloys

Classification of nickel alloys

There are different types of nickel and nickel alloys;

1) Commercially pure nickel

2) Nickel-copper alloys (Monels)

3) Nickel-chromium alloys

4) Nickel-base superalloys

5) Nickel-iron superalloys

Tapany Udomphol

Suranaree University of Technology May-Aug 2007

Commercially pure nickel

Commercially pure nickel

High purity nickel contains 99.99% Ni.

Commercially pure nickel contains

99.5% Ni (+Co).

Microstructure consists of solid solution

phase in annealed condition.

Cold drawn Nickel 200 annealed

at 829

o

C

Properties

Good mechanical properties

and retains its strength at

elevated temperature.

Excellent resistance to most

corrosive environment.

Applications

Food processing equipment

Electrical & electronic parts

Caustic handling equipment.

100 x

Tapany Udomphol

Suranaree University of Technology May-Aug 2007

Nickel

Nickel

-

-

copper alloys (

copper alloys (

Monels

Monels

)

)

Ni and Cu form complete solid solution.

Most important Ni-Cu alloy contains

67%Ni and 33%Cu, called Monels.

Properties

Applications

High strength and toughness over

a range of temperature.

Good weldability

Excellent corrosion resistance

Microstructure of

cold drawn Monel

R405 and

annealed at 829

o

C,

showing solid

solution phase of

Ni-Cu with

sulphide stringers

(black)

Values, pumps, marine fixtures

and fasteners.

Chemical processing equipment.

Oil-well drill collars and

instruments.

Ni-Cu phase diagram

250 x

Tapany Udomphol

Suranaree University of Technology May-Aug 2007

Nickel

Nickel

-

-

chromium alloys

chromium alloys

Cr forms solid solution with Ni up to~30%

at RT. High corrosion resistance is due to

high Cr addition.

Inconel 600 (15.5%Cr, 8%Fe) is a

standard engineering alloy. Other Ni-Cr

alloys are Inconel 601 and 625 with

improved properties.

Ni-Cr phase diagram

Properties

Applications

High corrosion resistance at

high temperature.

High strength and workability.

Heat exchanger tubing

Chemical and food

processing equipment.

Furnace muffle.

Inconel 600, solution

heat-treated at

1200

o

C/1h+870

o

C/4h,

showing solid solution

phase with chromium

carbide precipitates at

GBs and some titanium

carbides and nitrides

within the grains

1500 x

Tapany Udomphol

Suranaree University of Technology May-Aug 2007

Nickel

Nickel

-

-

base

base

superalloys

superalloys

High temperature heat-resistance alloys, which can retain

high strengths at elevated temperatures.

Properties

Applications

Heat resistant and high strength at high

temperature (760-980

o

C).

Good corrosion resistance.

Good oxidation resistance.

There are three types of Ni-base superalloys; nickel base, nickel-

iron base and cobalt base. The alloys contain high Cr with Ti, Al to

from precipitates and additions of Mo, Co, Nb, Zr, B, Fe.

Microstructures are complex.

Aircrafts, space vehicles, rocket engines

Industrial gas turbines, high temp applications.

Nuclear reactors, submarines.

Steam power plants, petrochemical equipment.

www.stratcor.com

Tapany Udomphol

Suranaree University of Technology May-Aug 2007

Microstructure of nickel base

Microstructure of nickel base

superalloys

superalloys

The major phases present in the nickel-base superalloys:

1) 1) 1) 1) (gamma) phase the continuous matrix of FCC austenite.

2) 2) 2) 2) (gamma prime) phase the major precipitate phase

(more cubic shape).

3) Carbides various types, mainly M

23

C

6

and MC. M = metal.

Complex microstructure of astroloy

forging after heat treatments

10,000 x

Carbides

at GB

Note: GB carbides affect high-temp strength, ductility, creep.

Tapany Udomphol

Suranaree University of Technology May-Aug 2007

Nickel

Nickel

-

-

iron

iron

superalloys

superalloys

Fe is added to replace some of Ni as it has lower cost.lowering

the properties as compared with nickel base superalloy.

therefore it is used at lower temperatures.

Ni-Fe superalloys contains 25-45%Ni and 15-60%Fe.

Higher Ni content increases operating temp (upto 815

o

C), due to

improved stability but more costly.

Ex: Inconel 707, 718, 901.

Microstructure consists of

austenistic FCC matrix and can

be strengthened by solid solution

strengthening (Mo, Cr), and

precipitation hardening (Ti, Nb, Al)

by forming intermetallic phases.

15,000 x

Optical micrograph of

Inconel 901 after

precipitation hardening

SEM micrograph of Inconel 718

after exposure at 705

o

C/6,048

h, 37 ksi

Tapany Udomphol

Suranaree University of Technology May-Aug 2007

Single

Single

-

-

crystal castings of

crystal castings of

nickel

nickel

-

-

base

base

superalloys

superalloys

A major increase in strength and temperature capability of

superalloy casting has been much improve with the introduction of

columnar-grained and single crystal casting.

Diagram of setup

for single crystal

casting

www.nap.edu

Simulation of

evolution of grain

structure in a single

crystal casting.

Turbines blades are

cast using a spiral

starter

Competitive

grain

www.msm.cam.ac.uk

Tapany Udomphol

Suranaree University of Technology May-Aug 2007

Applications of single

Applications of single

-

-

crystal castings of

crystal castings of

nickel

nickel

-

-

base

base

superalloys

superalloys

Used in production of aerofoils, gas turbine engines,

which allow the operating temperature range ~ 50

o

C higher

than normal materials.

Single crystal casting

of superalloy

www.grc.nasa.gov

Property

comparison

between

polycrystal,

columnar

crystal and

single crystal

(a) Polycrystal

(b) Columnar

crystal

(c) Single

crystal

Tapany Udomphol

Suranaree University of Technology May-Aug 2007

References

References

. a.a. +..+..+ . :-. u.uu+..a..a+a. ISBN

974-582-155-1.

Smith, W.F., Structure and properties of engineering

alloys, second edition, 1993, McGraw-Hill, ISB 0-07-59172-5.

www.cda.org.uk.

Heuner, U., Nickel alloys, 1998, Marcel Dekker, Inc., ISBN

0-8247-0440-1.

Tapany Udomphol

You might also like

- NickelDocument12 pagesNickelsadia Sultana100% (1)

- Stainless Steel AOD Operation and Slag OptimisationDocument41 pagesStainless Steel AOD Operation and Slag OptimisationRamiz Shaikh100% (1)

- Basic Information About Metals and AlloysDocument7 pagesBasic Information About Metals and AlloysMahesh JingarwarNo ratings yet

- Effect of Elements in SteelDocument3 pagesEffect of Elements in SteelJayakrishnan Radhakrishnan100% (1)

- Lecture 04-CCT and TemperingDocument17 pagesLecture 04-CCT and TemperingRudy Dwi PrasetyoNo ratings yet

- A Model For The Graphite Formation in Ductile Cast Iron Part I Inoculation MechanismsDocument25 pagesA Model For The Graphite Formation in Ductile Cast Iron Part I Inoculation MechanismsAdams GodoyNo ratings yet

- Solidification and Crystalline Imperfection Part 1Document25 pagesSolidification and Crystalline Imperfection Part 1Aiman MutallidNo ratings yet

- Extrusion and Its ApplicationDocument28 pagesExtrusion and Its ApplicationLakhan GuptaNo ratings yet

- Nickle Based SuperalloyDocument25 pagesNickle Based SuperalloyLavesh Kumar100% (1)

- Physical Metallurgy of SteelDocument174 pagesPhysical Metallurgy of SteelMarisa RobertsNo ratings yet

- Aluminium and Its Alloys: EF420 Lecture 11 John TaylorDocument48 pagesAluminium and Its Alloys: EF420 Lecture 11 John TaylorzorazhrNo ratings yet

- Aluminium: Designation of Aluminium AlloyDocument20 pagesAluminium: Designation of Aluminium Alloymuhammed sabry tahaNo ratings yet

- Extraction of ZN FinalDocument20 pagesExtraction of ZN FinalYashodeep Ravindra HireNo ratings yet

- Electrometallurgy 1Document24 pagesElectrometallurgy 1KALESMI A/P AMARALATHAN STUDENT100% (1)

- Nickel Base Alloys: Topics To Discuss .Document15 pagesNickel Base Alloys: Topics To Discuss .Muhammad Zam-zamNo ratings yet

- Materials For Engineering 12 - Ferritic Stainless SteelDocument14 pagesMaterials For Engineering 12 - Ferritic Stainless SteelKris WilochNo ratings yet

- The Iron-Carbon Phase Diagram: Prof. H. K. Khaira Professor in MSME Deptt. MANIT, BhopalDocument38 pagesThe Iron-Carbon Phase Diagram: Prof. H. K. Khaira Professor in MSME Deptt. MANIT, BhopalYogesh KumbharNo ratings yet

- Brazing and SolderingDocument15 pagesBrazing and SolderingAjij MujawarNo ratings yet

- Chapter 7 - Dislocations and Strengethening MechanismsDocument50 pagesChapter 7 - Dislocations and Strengethening MechanismsmikeengineeringNo ratings yet

- A Brief Study On Nickel Based SuperalloysDocument22 pagesA Brief Study On Nickel Based SuperalloysVIMAL JOSHYNo ratings yet

- AlloysDocument91 pagesAlloysNiccoloNo ratings yet

- Ferrous Metals ClassificationDocument7 pagesFerrous Metals ClassificationaadhithyarajasekaranNo ratings yet

- CH 6-Cooling and Solidification of CastingDocument33 pagesCH 6-Cooling and Solidification of CastingGosaye Desalegn100% (1)

- Application Note Powder MetallurgyDocument6 pagesApplication Note Powder MetallurgyVictoria TechiNo ratings yet

- Extractive MetallurgyDocument52 pagesExtractive MetallurgyMohamed TreXxNo ratings yet

- 9 Engineering AlloysDocument17 pages9 Engineering AlloysdavidtomyNo ratings yet

- EBSD Overview NowellDocument86 pagesEBSD Overview NowellRolando Nuñez MonrroyNo ratings yet

- Lecture 3 Titanium and Its AlloysDocument13 pagesLecture 3 Titanium and Its AlloysMarisa RobertsNo ratings yet

- Cupola Furnace eDocument5 pagesCupola Furnace eAshok PradhanNo ratings yet

- Lecture - Magnesium Alloys - Hue'sDocument29 pagesLecture - Magnesium Alloys - Hue'sMurali ManuNo ratings yet

- 07 - Zinc and Its AlloysDocument22 pages07 - Zinc and Its AlloysessnelsonNo ratings yet

- Electric Arc Furnace With Oxygen ReactionpdfDocument9 pagesElectric Arc Furnace With Oxygen ReactionpdfMarisa RobertsNo ratings yet

- Theory of Non-Ferrous Metals and Alloys ProcessingDocument83 pagesTheory of Non-Ferrous Metals and Alloys ProcessingHimanshuDeepNo ratings yet

- Weld Metal Solidification-1 - Grain StructureDocument51 pagesWeld Metal Solidification-1 - Grain StructureChelekara Subramanian Abhilash Iyer100% (3)

- Agglomeration of Iron OreDocument22 pagesAgglomeration of Iron OreDevansh MankarNo ratings yet

- Nmd-Atm-2018r-00405 - Arghya Majumder - RinlDocument18 pagesNmd-Atm-2018r-00405 - Arghya Majumder - RinlArghya MajumderNo ratings yet

- Casting: "Net Shape" or "Near-Net Shape" Process AdvantagesDocument27 pagesCasting: "Net Shape" or "Near-Net Shape" Process AdvantagesnsbaruaoleNo ratings yet

- 2011 Steelmaking Ch12Document56 pages2011 Steelmaking Ch12Thapelo LesameNo ratings yet

- Engineering Alloys (Non Ferrous)Document52 pagesEngineering Alloys (Non Ferrous)Sukhwinder Singh GillNo ratings yet

- Analysis of AlloysDocument14 pagesAnalysis of AlloysRupendra Talekar60% (10)

- Metals From Ores: 2. Scope of Extractive MetallurgyDocument48 pagesMetals From Ores: 2. Scope of Extractive MetallurgyAdetiyo Burhanudin HakimNo ratings yet

- p3 New - 02 - Aluminium-And-Aluminium-AlloyDocument74 pagesp3 New - 02 - Aluminium-And-Aluminium-AlloyAladdin AdelNo ratings yet

- Casting Technology 04Document11 pagesCasting Technology 04Sreekumar RajendrababuNo ratings yet

- Powerpoint Presentation On Magnesium SuperplasticityDocument23 pagesPowerpoint Presentation On Magnesium SuperplasticityashvaniNo ratings yet

- TEM Lecture CrystallineDocument30 pagesTEM Lecture CrystallineSyed Abdul AhadNo ratings yet

- MetallurgyDocument17 pagesMetallurgyirajfarji2481No ratings yet

- ME 292 - Metallic Materials SessionalDocument39 pagesME 292 - Metallic Materials SessionalMuhammedNayeemNo ratings yet

- Recovery Recrystallization Grain GrowthDocument15 pagesRecovery Recrystallization Grain Growthteju1996coolNo ratings yet

- Kovar PDFDocument2 pagesKovar PDFkhers_zalNo ratings yet

- Phase Transformation of Fe-Fe3CDocument77 pagesPhase Transformation of Fe-Fe3CAhmat Safa'at100% (2)

- Failure Analysis at Deep Drawing of Low Carbon SteelsDocument7 pagesFailure Analysis at Deep Drawing of Low Carbon SteelsPaul RosiahNo ratings yet

- Solidification of MaterialDocument28 pagesSolidification of MaterialNaman DaveNo ratings yet

- Solidification of CastingDocument16 pagesSolidification of CastingSurya RaghavendarNo ratings yet

- 11 Introduction To Engineering MaterialsDocument20 pages11 Introduction To Engineering MaterialsomkardashetwarNo ratings yet

- Casting PresentationDocument14 pagesCasting PresentationSudeepNo ratings yet

- Friction Stir WeldingDocument22 pagesFriction Stir Weldingkarthik100% (4)

- NickelDocument46 pagesNickelEfy NagNo ratings yet

- Non-Ferrous Metal: Nickel & Ni Alloys: Presented By:-Deepam GoyalDocument22 pagesNon-Ferrous Metal: Nickel & Ni Alloys: Presented By:-Deepam GoyalIsrar AhmedNo ratings yet

- Welding of Ni Alloy-IraqDocument17 pagesWelding of Ni Alloy-Iraqkhairy2013No ratings yet

- Technical Update Welding of Nickel Nikel AlloysDocument15 pagesTechnical Update Welding of Nickel Nikel AlloysrezaNo ratings yet

- Nickel Is A StrongDocument5 pagesNickel Is A StrongasimrehmanurNo ratings yet

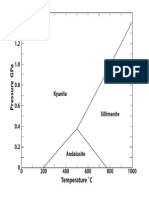

- DIAGRAMA AluminosilicatesDocument1 pageDIAGRAMA AluminosilicatesMarisa RobertsNo ratings yet