Professional Documents

Culture Documents

Industrial Automation Tutorial: Type of Transmission Lines Unbalanced Differential Differential

Uploaded by

aloordominicOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Industrial Automation Tutorial: Type of Transmission Lines Unbalanced Differential Differential

Uploaded by

aloordominicCopyright:

Available Formats

Industrial Automation Tutorial

Introduction

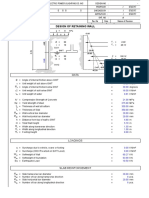

Industrial communications refers to the wide range of hardware and software products and protocols used to communicate between standard computer platforms (PC, Macintosh, or workstation) and devices used in industrial automation applications. This tutorial describes the fundamentals of serial interfaces and the simpler software protocols commonly used with industrial devices. There are communications many protocols that require sophisticated hardware and software to ensure robust, reliable, and sometimes real-time operation. These industrial networks are sometimes generically referred to as eldbus. This tutorial will introduce you to some of the many industrial networking protocols in use and under development. Type of transmission lines Maximum number of drivers Maximum number of receivers Maximum cable length meters (feet) Maximum data rate RS-232 Unbalanced 1 1 15.2 (50) 20 kb/s RS-422 Differential 1 10 1.2 (4000) 10 Mb/s RS-485 Differential 32 32 1.2 (4000) 10 Mb/s

Table 1. Features of RS-232, RS-422, and RS-485

soft-ware protocol. Table 1 summarizes the main features of these three serial interfaces as dened in their respective standards documents. RS-232 (ANSI/EIA-232 Standard) is the serial connection found on IBM-compatible PCs. It is used for many purposes, such as connecting a mouse, printer, or modem, as well as industrial instrumentation. Due to improvements in line drivers and cables, applications often increase the performance of RS-232 beyond the distance and speed listed in the standard. RS-232 is limited to point-to-point connections between PC serial ports and devices. RS-422 (EIA RS-422-A Standard) is the serial connection used on Apple Macintosh computers. RS-422 uses a differential electrical signal, as opposed to the unbalanced signals referenced to ground with RS-232. Differential transmission, which uses two lines each for transmit and receive signals, results in greater noise immunity and

longer distances as compared to RS-232. The greater noise immunity and distance are big advantages in industrial environments. RS-485 (EIA-485 Standard) is an improvement over RS-422 because it increases the number of devices from 10 to 32, and denes the electrical characteristics necessary to ensure adequate signal voltages under maximum load. With this enhanced multidrop capability, you can create networks of devices connected to a single RS-485 serial port. The noise immunity and multidrop capability make RS-485 the serial connection of choice in industrial applications requiring many distributed devices networked to a PC or other controller for data collection, MMI, and other operations.

Tutorial

Serial Interface Standards

Many devices used in industrial applications use EIA standards RS-232, RS-422, or RS-485 to connect to computers and to one another. (In this tutorial, we use the term RS-xxx to refer generically to RS-232, RS-422, and RS-485). A common misconception about these specications is that they dene specic software protocols. The ANSI/EIA RS-xxx standard species only the electrical characteristics not the

Tem

pe

ratu

re

Flo

w Con trol Pan

Pre

el

ssur

eA

larm

Con

ditio

ns

RS-485

RS-485 device

ST

OP

"#0110.000\r"

Carriage return to end message Analog output value in mA or % Hex address of device Character signifying beginning of message

Figure 1. An example of a command string sent to a 6B analog output module.

6-6 NATIONAL INSTRUMENTS PHONE: (512) 794-0100 FAX: (512) 794-8411 info@natinst.com www.natinst.com

Industrial Automation Tutorial

Software Protocols

Note that RS-xxx protocols do not specify anything about the software used to communicate with devices. A common question asked about RS-485 devices in particular is, How do I address my RS-485 device? The answer is, It depends on the device. RS-485 species only that it is capable of connecting multiple electrical loads (devices) on a single set of wires. It does not say anything about how to address (or communicate at all with) these loads. It is the job of a particular devices software protocol to describe how to address a specic device. There are very few protocols that have widespread use by serial instrument manufacturers. The most common solution is a set of ASCII strings that constitute commands to the device. These protocols are most commonly implemented as asynchronous protocols, so-called because the transmitter and receiver do not have any tightly-coupled synchronization mechanisms. These networks are commonly master/slave, where one device (usually the computer) is the master and the devices are slaves. Normally, all devices power up in receive mode, waiting to receive messages. When the master transmits a message, all devices receive the message (on a multidrop network) and determine if the message is addressed to them. If it is, they act upon the message, writing data on the serial interface if required to do so. Figure 1 shows an example of a command string used to set the output level of an Analog Devices 6B analog output module. Similar commands are used to read data from a module. Most manufacturers of serial devices invent their own ASCII protocol for their particular device. It is a relatively straightforward task to read and write these ASCII strings using the standard serial functions built into a language such as Visual Basic. You must understand how to use the string formatting commands and serial functions in order to build and parse command strings. Instrument libraries in LabVIEW, BridgeVIEW, or LabWindows/CVI encapsulate these types of commands into high-level VIs, servers, or functions for conguring and querying serial devices. OptoMux and ModBus ASCII are examples of serial protocols that use standard serial ports and have achieved broad acceptance across many devices and suppliers. (See Table 2 for a list of devices that use the modbus protocol.) Another protocol commonly used with standard PC serial ports (using an electrical adapter for physical signal conversion) and that has found wide usage across process control instrumentation is the HART (Highway Addressable Remote Transducer) protocol. HART is a hybrid network that uses the 4-20 mA analog signal commonly found on process control instrumentation and adds to it a digital signal. The digital signal is added in such a way that it does not interfere with the standard 4-20 mA functionality. In a control system where the HART protocol is understood, the digital signals can be read from the device to read and write data. There are many protocols that are used on standard serial interfaces but use much more sophisticated data packaging schemes. These protocols use different mechanisms Device Type Gas chromatograph Power measurement DCS systems Tank level instruments Value systems Single loop controllers Flow computers/transmitters PLCs RTUs Variable speed drives Manufacturer Daniels, Applied Automation, ABB Multilin, Power Measurements, Bitronics, Sprecher+Schuh Foxboro, Honeywell, Rosemount, Westinghouse, Fisher&Porter, Fisher Controls Rosemount HTG, Gauging Systems, Enraf, Sarasota, Saab, Varec, Endress+Hauser Keystone Controls, Limitorque, Pakscan Eurotherm, Micon, Toshiba OMNI, Daniels, MicroMotion, Eliot GE, Square-D, TI, Siemens, Westinghouse, Modicon Arcom, Automation Electronics, Westronics, (almost every RTU manufactured) Allen-Bradley, Telemechanique/Square-D, Siemens, Toshiba, Magnetek, Saftronics

Figure 2. PLCs typically use vendor-specic communications protocols that require specialized hardware interfaces and software drivers.

to ensure reliable, robust communication. Most such protocols are proprietary to a specic supplier, requiring special software drivers and often special interface hardware. Examples of these protocols are those used for communicating with PLCs, for example DataHighway+ from Allen-Bradley or ModBus+ from Modicon. (Figure 2)

Tutorial

Table 2. Devices and Manufacturers that use the Modbus Protocol

NATIONAL INSTRUMENTS 6-7

PHONE: (512) 794-0100 FAX: (512) 794-8411 info@natinst.com www.natinst.com

Industrial Automation Tutorial

Industrial Networks

There is growing momentum toward more multivendor connectivity through standardized versions of the sophisticated industrial network protocols mentioned at the end of the previous section. In this tutorial, we will generally refer to these networks as industrial networks. There are some key reasons that users are looking to move to standardized industrial networks. Open Systems It is difcult and costly to integrate systems with instrumentation from several vendors because of the multitude of communication protocols. With standard protocols, devices from many suppliers can coexist on the same network and communicate with one another. Cost Reduction in Wiring Many systems are still using 4-20 mA analog instrumentation, requiring extensive point-to-point wiring. Multidrop wiring means lower installation costs. Increased Information Need In todays regulatory environment, companies are required to gather more information about their processes and the instrumentation connected to the processes. Traditional 4-20 mA instrumentation provides only one value, the process value. On a digital network, instruments can provide maintenance and diagnostics information for better tracking of instrument performance. Sensorbus CAN Seriplex ASI LONWorks Devicebus CAN DeviceNet Probus DP LONWorks FIPIO SDS Interbus-S Fieldbus IEC/SP50 Fieldbus Foundation Probus PA LONWorks WorldFIP

Table 4. Classication of Industrial Device Networks.

Tutorial

Intelligent Devices Device vendors are putting more intelligence into their devices to satisfy customers demands for more functionality at lower costs. The increased information available with a digital network is necessary for capitalizing on the extra capabilities made possible by intelligence in the devices. Figure 6 on page 6-12 illustrates how standard industrial networks will transform todays control system. Industrial networks are often characterized according to the type of device best suited for residence on the network. Three general classes of such networks are sensorbus, devicebus, and eldbus. Table 3 summarizes the major characteristics of each type of bus. There are many networks in use and under development today. Table 4 lists some of these networks and their bus classication(s). The reason for the many buses is that there is a very wide range industrial process and manufacturing

applications that can use digital communications. For example, simple proximity sensors on a conveyor belt can be networked together to a system that controls the movement of boxes on the belt. Another example is a control valve used to regulate the ow of crude oil within a petroleum renery. These two examples show the extremes of digital communication. The proximity sensor has a simple function transmit an on/off signal indicating if a box is near the sensor. This signal can be accommodated in a few bits of data. Diagnostic information from the sensor, if it exists at all, is probably limited to a single health indicator which again requires very little data to communicate. The control valve, on the other hand, could be expected to provide very sophisticated diagnostics, such as number of turns since last servicing, bearing friction, and ambient operating temperature. These parameters may be extremely critical in an environment such as a renery where failures can result in dangerous situations and costly downtime. The network in Fieldbus Process DCS Up to 1000 bytes Yes Yes Sophisticated 100 ms Long Smart valve with PID capability and advanced diagnostics

Primary applications Typical control system Data size Microprocessor-based Embedded intelligence Diagnostics Response time Distance Example device

Sensorbus Discrete, machine PLC Less than 1 byte No No No 5 ms or less Short Discrete proximity sensor

Devicebus Discrete, machine PLC Up to 32 bytes Yes Varies Simple 5 ms or less Short Photoelectric sensor with diagnostics

Table 3. General Characteristics of Industrial Device Networks.

6-8 NATIONAL INSTRUMENTS PHONE: (512) 794-0100 FAX: (512) 794-8411 info@natinst.com www.natinst.com

Industrial Automation Tutorial

a renery may therefore be expected to be extremely robust and able to handle large amounts of data. It stands to reason, then, that the proximity sensor and the control valve have different network requirements. Thus, the reason for such a wide variety of industrial communication networks. As mentioned previously, industrial network protocols are much more sophisticated than the simple command sets commonly used with typical serial instruments. Dedicated hardware and software drivers are required to provide robust connections between computer platforms and each of these networks. Options for using these networks today include DDE servers and DLL function libraries for the Windows environment. Though it is not clear that any one network will satisfy all industrial networking requirements, these buses will bring more standardized interconnection between computers and the devices used in industrial automation applications.

OSI Model

Fieldbus Model

User Application

User Application

Application Layer

Fieldbus Message Specification Fieldbus Access Sublayer

Presentation Layer Session Layer Transport Layer Network Layer Data Link Layer Physical Layer

6 5 4 3 2 1 Data Link Layer Physical Layer Physical Layer Communication Stack

Tutorial

Figure 3 The Fieldbus model compared to the OSI 7-layer communications model. Note that OSI does not dene a user application.

FOUNDATION Fieldbus

FOUNDATION Fieldbus is a very sophisticated industrial network specically targeted at the need for robust, distributed control in process control environments. The eldbus specications were developed by the Fieldbus Foundation, a group representing over 80% of the worlds suppliers of industrial automation systems, devices, and services. FOUNDATION Fieldbus is based upon existing standards and other proven technologies, including work from the ISA (International Society for Measurement and Control), IEC (International Electrotechnical Committee), Probus (Process Fieldbus, a German national standard), FIP (Factory Instrumentation Protocol, a French national standard), and HART (Highway Addressable Remote Transducer, a widely-used process instrumentation protocol). The FOUNDATION Fieldbus communication protocols are based on the OSI (Open Systems Interconnect) seven layer communi-

cations model. FOUNDATION Fieldbus has optimized the OSI architecture for process control by removing the middle layers that are generally associated with non-time critical applications such as le transfer. FOUNDATION Fieldbus technology consists of a) the Physical Layer, b) the Communication Stack, and c) the User Application. Figure 3 shows these components modeled using the OSI layered communication model. The physical layer (electrical, wiring, and so on) is based upon standards created by ISA/IEC (ISA S50.02-1992, IEC 1158-2). These physical layer standards specify data communication rates of 31.25 kb/s, 1 Mb/s, and 2.5 Mb/s. Devices operating at 31.25 kb/s can draw their power directly from the network. This Physical Layer also species the capability for intrinsically safe operation. The layers above the Physical Layer together are often referred to as the stack for eldbus. Detailed discussion of the stack is beyond the scope of this tutorial. Several characteristics and functions in the Data Link Layer, however, are key to the distributed, real-time control capabilities of FOUNDATION Fieldbus:

1. The Data Link Layer is based on a token passing protocol. 2. The Link Active Scheduler (LAS) is a centralized device that acts as the arbitrator of the bus. 3. The LAS executes a schedule that makes possible deterministic communication. 4. The LAS distributes time to the network to permit all devices to share the same sense of time. A key 8th layer of FOUNDATION Fieldbus is the User Application, or User Layer. The User Layer denes blocks that represent the functions and data available in a device. Rather than interface to a device through a set of commands as commonly used with communication protocols, a FOUNDATION Fieldbus user interacts with devices through a set of blocks that dene device capabilities in a standardized way. In this tutorial, well describe the most important block type Function Blocks. Function Blocks are the core components with which a user species the behavior of a control system. FOUNDATION Fieldbus denes standard sets of Function Blocks.

NATIONAL INSTRUMENTS 6-9

PHONE: (512) 794-0100 FAX: (512) 794-8411 info@natinst.com www.natinst.com

Industrial Automation Tutorial

Function Block Name Analog Input Analog Output Bias Control Selector Discrete Input Discrete Output Manual Loader Proportional/Derivative Proportional/Integral/Derivative Ratio Symbol AI AO B CS DI DO ML PD PID RA other functions. Note that the DD is a mechanism for describing the functions in a device. This is the key to eldbus interoperability. This can be contrasted to a more simplistic and common approach to the problem of compatibility and interchangeability, namely by specifying that only a given set of functions can be used in a device to ensure that a given system can always talk to a new device. This would severely restrict the ability of a device manufacturer to innovate by adding new device features, and there would be never-ending contention about the right set of functions upon which to standardize. With the DD, developers can add new features and be condent that host systems can learn about and take advantage of these features in standard way.

Table 5 The 10 basic standard function blocks dened by FOUNDATION Fieldbus.

AI

PID

AO

Tutorial

Figure 4 A Basic Control Loop Using AI, PID, and AO Function Blocks.

Controller Area Network (CAN)

The Controller Area Network is a serial bus growing in popularity as a devicelevel network. CAN was developed by Bosch to address the needs of in-vehicle automotive communications. Automobiles have a variety of control devices in them, for such functions as engine timing, carburetor throttle control, and antilock brake systems. With increasing demands placed upon these systems for safety, performance, and customer needs, CAN was developed to provide a digital serial bus system to connect controllers. CAN has been standardized internationally (ISO DIS 11898 and ISO DIS 11519-2) and is already available in a number of silicon implementations. The CAN protocol meets real-time requirements encountered in many automotive applications. The network protocol can detect and correct transmission errors caused by electromagnetic interference. Also, the network itself is relatively easy to congure and offers the ability to perform centralized diagnostics. Comparison of automotive and industrial network requirements show that a number of characteristics of CAN also make it suitable for industrial applica-

There is a set of 10 basic control and I/O functions (see Table 5). The inputs and outputs of individual functions blocks can be connected to specify communication of data on the bus. Even more importantly, the execution of a function block can be precisely scheduled. This is a very key capability of FOUNDATION Fieldbus because it allows execution of control loops directly over the network. The Function Blocks themselves reside in individual devices but the overall scheduling of execution is specied and executed across the network. Figure 4 shows a simple control loop with three Function Blocks AI, PID, AO. The function blocks shown in Figure 4 could be implemented on the eldbus in several different ways. The AI, PID, and AO could each reside in separate devices, such as a transmitter, loop controller, and valve. Alternatively, the PID itself could reside in the control valve. In the second case, there is no explicit controller device. In either system, the users view is the same a series of connected function blocks and an execution schedule. The

6-10 NATIONAL INSTRUMENTS

second system, however, shows the true potential of FOUNDATION Fieldbus distributed control, where the control functionality exists out in the eld rather than concentrated in larger controllers. A second important feature of the FOUNDATION Fieldbus User Layer is Device Descriptions. A key objective for FOUNDATION Fieldbus is interoperability the ability to build systems comprised of devices from a variety of manufacturers and take full advantage of both the standard and unique capabilities of every device. Function Blocks go a long way to ensuring a consistent model of a control system. From a system point-of-view, however, a mechanism is needed to document in a standard way the types of functions available in any given device. To achieve this end, FOUNDATION Fieldbus denes the Device Description (DD), is a standardized description of the functions available in a device. Using the DD, the host in a control system, for example a Windows NT-based MMI, can obtain the information necessary to create the human interface for interacting with the device to congure parameters, perform calibration and diagnostics, and

PHONE: (512) 794-0100 FAX: (512) 794-8411 info@natinst.com www.natinst.com

Industrial Automation Tutorial

tions. These characteristics include low cost, suitability for harsh electrical environments, good real-time capabilities, and ease of conguration. There are now many examples of CAN being the basis for networks used in industrial manufacturing applications. CAN is particularly well-suited to networking smart I/O devices, as well as sensors and actuators, either in a single machine or in a plant. Several industrial devicebus systems have been built upon CAN. Allen-Bradley developed DeviceNet, a CAN-based protocol now maintained by the Open DeviceNet Vendors Association. Other such industrial networks include CANopen, developed by CAN in Automation (CiA) and the Smart Distributed System (SDS), developed by Honeywell Microswitch. CAN is a communications protocol specication that denes parts of the OSI Physical and Data Link Layers. CAN does not specify the entire Physical Layer or the Medium upon which it resides, or the Application Layer protcol used to move data. (See Figure 5). As with the other network protocols previously mentioned, detailed technical description of CAN and CAN-based protocols is beyond the scope of this tutorial. Listed below are some key technical aspects of CAN. 1. Typical data rates are 125 k/s to 1 M/s, dependent upon the distance over which the network is operating. The allowable distance ranges from 40 m at 1 Mb/s to 500 m at 125 kb/s. 2. CAN communications are performed in a unit called a frame.CAN frames can be up to 8 bytes in length. 3. CAN provides extensive error correction, including bit monitoring (comparing transmitted bits to received), bit stufng, CRC checksum, acknowledgment by all receivers, frame check (verify length), automatic retry, and fault connement (defective devices automatically shut off).

Application Layer Logical Link Control (LLC) Data Link (Layer 2) Medica Access Control (MAC) CAN Protocol Specification Physical (Layer 1) Physical Layer Signaling (FLS) Medium Attachment Unit (MAU) Media (Layer 0) Transmission Media

Tutorial

Figure 5 CAN denes parts of the Physical and Data Link Layers of the OSI 7 layer com model .

4. Access to the CAN network is performed using a method called nondestructive bitwise arbitration. In this system, when a CAN node wants to send a frame, it waits for the bus to become idle, then starts its frame with an arbitration identier (ID). Because of the underlying physical layer, a dominant bit (0) always overrides any recessive bit (1). As a node is writing its bits to the bus, it also reads the bus to determine if the bit on the bus is different than the bit written by the node. If the bits are different, the node stops its write because some other node has higher priority to the bus. Thus, the arbitration ID determines the priority of messages on the bus, with lower IDs having higher priority. The industrial protocols built upon CAN add further specications in such areas as wiring types, connectors, diagnostics indicators, conguration switches, and hot-swapping capability. Of great importance with such networks is the denition of objects for organizing data within devices as well as for dening classes of devices, such as switches, motor starters, and I/O systems. These higher-level software denitions add the ease of use and standardization to

enable CANs widespread use in industrial automation applications.

PHONE: (512) 794-0100 FAX: (512) 794-8411 info@natinst.com www.natinst.com

NATIONAL INSTRUMENTS

6-11

Industrial Automation Tutorial

Te

mp

era

tur

Flo

w Co ntr ol Pa

Pres

ne

sure

Ala

rm

Co

nd

itio

ns

ST

OP

Controller I/O

Proprietary digital or custom interfaces PLC

Tutorial

4-20 mA

4-20 mA plus digital or proprietary digital

Analyzer

Traditional analog and discrete instruments Hybrid instruments Hybrid instruments or intelligent instruments with custom interfaces

Figure 6a. Todays control systems use a combination of point-to-point analog connections and hybrid or proprietary digital communications networks.

Te

mp

era

tur

Flo

w Co ntr ol Pa

Pre

ne

ssu

re

Ala

rm

Co

nd

itio

ns

ST

OP

Higher speed fieldbus

Controller I/O PLC

Device or sensorbus

Lower speed fieldbus

Analyzer

Figure 6b. Using industrial device networks, system architecture is simplied because devices share common protocols.

6-12 NATIONAL INSTRUMENTS PHONE: (512) 794-0100 FAX: (512) 794-8411 info@natinst.com www.natinst.com

You might also like

- Siemens Building ManagementDocument266 pagesSiemens Building ManagementGirish Jha100% (2)

- Aa094.101.05 - Conveyor Belt With Brush DC Motor Dunker Drive CanDocument8 pagesAa094.101.05 - Conveyor Belt With Brush DC Motor Dunker Drive CanplacintaruNo ratings yet

- Industrial AutomationDocument28 pagesIndustrial Automation4happy12383% (6)

- PLC Training Tutor0001 PDFDocument158 pagesPLC Training Tutor0001 PDFengineeraina100% (1)

- Nordson EFD E Series Operating ManualDocument132 pagesNordson EFD E Series Operating ManualTreborNo ratings yet

- Horticulture of Taj Mahal 2010Document5 pagesHorticulture of Taj Mahal 2010Rm GoldNo ratings yet

- Manual Conectare ErpDocument82 pagesManual Conectare Erpe-noreplyNo ratings yet

- Industrial AutomationDocument16 pagesIndustrial AutomationSooraj Sureshkumar0% (1)

- Industrial Automation Using PLCDocument29 pagesIndustrial Automation Using PLCAditya JagannathanNo ratings yet

- Industrial Automation WiringDocument14 pagesIndustrial Automation Wiringtjahyo02No ratings yet

- Industrial AutomationDocument21 pagesIndustrial Automationsanju245100% (1)

- SimulatedTrain Energy Consumption STECDocument20 pagesSimulatedTrain Energy Consumption STECCarlos Redondo BenitezNo ratings yet

- Programmable Logic Controller (PLC) - Industrial Wiki - ODESIE® by Technology TransferDocument41 pagesProgrammable Logic Controller (PLC) - Industrial Wiki - ODESIE® by Technology TransferAbhishek SinghNo ratings yet

- Industrial Sensors and Control PDFDocument62 pagesIndustrial Sensors and Control PDFSurendra SainiNo ratings yet

- PLCs and Pneumatic SystemsDocument5 pagesPLCs and Pneumatic SystemsKazi Mehdi0% (2)

- Condition Monitoring TataDocument24 pagesCondition Monitoring TataNicolas Pérez MoralesNo ratings yet

- Industrial AutomationDocument30 pagesIndustrial Automationsony0123100% (1)

- Servo Motor and Servo MechanismDocument11 pagesServo Motor and Servo MechanismkloirywbdNo ratings yet

- PLC For Electrical EngineersDocument113 pagesPLC For Electrical EngineersBilal Shahid100% (3)

- Automation Studio ProDocument24 pagesAutomation Studio PronelsonNo ratings yet

- What Is Industrial AutomationDocument72 pagesWhat Is Industrial AutomationSanket AcharyaNo ratings yet

- AI 310 Field Bus PrinciplesDocument18 pagesAI 310 Field Bus Principlessarvesh2705No ratings yet

- About MESDocument5 pagesAbout MESSAINTJOENo ratings yet

- Final PresentationDocument103 pagesFinal PresentationQasir NawazNo ratings yet

- SR-D100 User's Manual - E PDFDocument138 pagesSR-D100 User's Manual - E PDFRLome RicardoNo ratings yet

- Serial BusDocument42 pagesSerial BuskL10111No ratings yet

- Logic Design Seminar - Programmable Logic ControllersDocument35 pagesLogic Design Seminar - Programmable Logic Controllersabhisingh28No ratings yet

- Kilian Tablet Press Replacement Parts CatalogDocument40 pagesKilian Tablet Press Replacement Parts CatalogIndependent TradingNo ratings yet

- Festo Troubleshooting and Maintenance in PneumaticsDocument2 pagesFesto Troubleshooting and Maintenance in PneumaticsYousef AlkabbaniNo ratings yet

- Micro800 PLC SystemsDocument16 pagesMicro800 PLC SystemsNicolás A. SelvaggioNo ratings yet

- Manual Cutler HammerDocument114 pagesManual Cutler HammerMarcelo Palacios SantanaNo ratings yet

- PLCDocument36 pagesPLCsonhack96No ratings yet

- Tutorial On PLCDocument33 pagesTutorial On PLCmanojnancyNo ratings yet

- PLCDocument30 pagesPLCAnkit ShuklaNo ratings yet

- Automation Chapter 2Document11 pagesAutomation Chapter 2Owais GharaibehNo ratings yet

- Molded Parts DefectsDocument9 pagesMolded Parts DefectsPadmanava DasguptaNo ratings yet

- 112 Distribution Trainee RelC PDFDocument170 pages112 Distribution Trainee RelC PDFFerney BecerraNo ratings yet

- Smart Factory For Future Industry DevelopmentDocument5 pagesSmart Factory For Future Industry DevelopmentIAES International Journal of Robotics and AutomationNo ratings yet

- Implementation of Condition Based Maintenance For MediumDocument4 pagesImplementation of Condition Based Maintenance For Medium__kami__No ratings yet

- CKD-Components For Industrial AutomationDocument112 pagesCKD-Components For Industrial AutomationJohansen ChandraNo ratings yet

- Industrial Automation and RoboticsDocument24 pagesIndustrial Automation and RoboticsRoHan ShaRmaNo ratings yet

- Energy Consumption OptimizationDocument23 pagesEnergy Consumption OptimizationAmare KassawNo ratings yet

- PLC QuestionsDocument2 pagesPLC QuestionsSreejithRaveendran100% (1)

- Programmable Logic Controller PLCDocument53 pagesProgrammable Logic Controller PLCokk chuNo ratings yet

- PLC AutomationDocument18 pagesPLC AutomationRavi JoshiNo ratings yet

- Flexible Manufacturing SystemDocument36 pagesFlexible Manufacturing Systemamit_aryaanNo ratings yet

- MpsDocument8 pagesMpsVictor AlNo ratings yet

- Catalog PDFDocument448 pagesCatalog PDFykuscuNo ratings yet

- Panasonic FPWIN ManualDocument317 pagesPanasonic FPWIN Manualelkin mezaNo ratings yet

- Roles of Models in Production ManagementDocument3 pagesRoles of Models in Production ManagementArnold AcquayeNo ratings yet

- Air Compressor Control Using PLCDocument2 pagesAir Compressor Control Using PLCsagar4pranith4t100% (1)

- Chapter2-Automation System in IndustryDocument31 pagesChapter2-Automation System in IndustryAbdul Razzi0% (1)

- HmiDocument12 pagesHmiEr. Piush JindalNo ratings yet

- Industrial Automation: PLC & ScadaDocument35 pagesIndustrial Automation: PLC & ScadaRahulGunde100% (1)

- Rockwell Allen Bradley PLC - Controller Quick ReferenceDocument4 pagesRockwell Allen Bradley PLC - Controller Quick ReferenceGary8100% (4)

- Production Planning and ControlDocument36 pagesProduction Planning and ControlPadmavathi Putra LokeshNo ratings yet

- Mces clm2Document3 pagesMces clm2RAKSHITHA R REDDYNo ratings yet

- Description Digital Interface RSXXXDocument2 pagesDescription Digital Interface RSXXXAhsan SNNo ratings yet

- 398644875238424558571001109498an740 0Document8 pages398644875238424558571001109498an740 0api-27535945No ratings yet

- What's The Difference Between The RS-232 and RS-485 Serial Interfaces?Document7 pagesWhat's The Difference Between The RS-232 and RS-485 Serial Interfaces?Pranjali patil100% (1)

- 3 Types of Industrial Serial CommunicationDocument2 pages3 Types of Industrial Serial CommunicationAbdelkaderBenbadaNo ratings yet

- RS 485Document6 pagesRS 485luinks100% (1)

- Oracle® Fail Safe: Tutorial Release 4.1 For Microsoft WindowsDocument46 pagesOracle® Fail Safe: Tutorial Release 4.1 For Microsoft WindowsPaxa TrumanNo ratings yet

- 6ES71384DF110AB0 Datasheet enDocument3 pages6ES71384DF110AB0 Datasheet enkphcmNo ratings yet

- Get Unlimited Downloads With A 30 Day Free Trial: Download Alexe, Dan - Dacopatia Si Alte Rataciri Romanesti OcrDocument3 pagesGet Unlimited Downloads With A 30 Day Free Trial: Download Alexe, Dan - Dacopatia Si Alte Rataciri Romanesti OcrDragosusNo ratings yet

- Optane Memory Brief 1100902Document4 pagesOptane Memory Brief 1100902Subhra Misra100% (1)

- Discover Britain Feb-March 2019Document92 pagesDiscover Britain Feb-March 2019netvelopxNo ratings yet

- Rate Analysis For Vault Roof Shuttering-12.05.2008Document4 pagesRate Analysis For Vault Roof Shuttering-12.05.2008Chanchal SarkarNo ratings yet

- Final - Yachts Script (1) - 1Document3 pagesFinal - Yachts Script (1) - 1Poloroid RoNo ratings yet

- Ccie Routing SwitchingDocument20 pagesCcie Routing SwitchingMusaib SyedNo ratings yet

- CAE PLM Solution and Integration With CAEDocument31 pagesCAE PLM Solution and Integration With CAEIgor OrtizNo ratings yet

- Central Station Air Handlers: Cs SeriesDocument32 pagesCentral Station Air Handlers: Cs SeriesTanjim FakirNo ratings yet

- LG R410 Quanta QL6 Rev 4A SCHDocument39 pagesLG R410 Quanta QL6 Rev 4A SCHleethax0No ratings yet

- LM - 2 14rp5 15Document16 pagesLM - 2 14rp5 15Rohan KulkarniNo ratings yet

- Information Architecture: What and Why?Document31 pagesInformation Architecture: What and Why?gelvanNo ratings yet

- Tablon Retaining Wall Ht. - Clark - With WindDocument27 pagesTablon Retaining Wall Ht. - Clark - With WindclarkgaguiNo ratings yet

- Programming AVR Micro Controllers in CDocument50 pagesProgramming AVR Micro Controllers in CDhishan AmaranathNo ratings yet

- Java J2EE Java Interview QuestionsDocument357 pagesJava J2EE Java Interview QuestionsJitsNavinNo ratings yet

- LECTURE 2 Pre-Stressed ConcreteDocument13 pagesLECTURE 2 Pre-Stressed ConcretepatriciaNo ratings yet

- California Citrus State Historic Park BrochureDocument6 pagesCalifornia Citrus State Historic Park BrochureCalifornia State ParksNo ratings yet

- ISSUE Tracking DocumentDocument64 pagesISSUE Tracking DocumentAishwarya SairamNo ratings yet

- How To Trust Another CAS ServerDocument7 pagesHow To Trust Another CAS ServerNguyễn Văn Thành - TLMCNo ratings yet

- House There Be Picture Dictionaries 56906Document4 pagesHouse There Be Picture Dictionaries 56906Azeneth SantosNo ratings yet

- Virtual Private LAN Service (VPLS) Using Label Distribution Protocol (LDP) SignalingDocument31 pagesVirtual Private LAN Service (VPLS) Using Label Distribution Protocol (LDP) Signalingredmouse10No ratings yet

- NJKKMLMLKDocument43 pagesNJKKMLMLKMohammad ZubairNo ratings yet

- Calculation For Service Platform & Pump Shelter StructureDocument36 pagesCalculation For Service Platform & Pump Shelter Structuretrian33100% (1)

- MaPDArch ETSAVDocument2 pagesMaPDArch ETSAVNermin ŠabaniNo ratings yet

- IHI0062D B System Mmu Architecture SpecificationDocument368 pagesIHI0062D B System Mmu Architecture SpecificationStefania RossiNo ratings yet

- Thomas Heatherwick VesselDocument32 pagesThomas Heatherwick VesselAlina VoNo ratings yet