Professional Documents

Culture Documents

V1 I1 Connecting Your Trailer

Uploaded by

Turan GökdemirCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

V1 I1 Connecting Your Trailer

Uploaded by

Turan GökdemirCopyright:

Available Formats

Components that Connect Your Truck and Trailer

by Howard Katz To connect our truck to our trailer, we back our truck up to our trailer, run the trailers jack down so that the trailers coupler drops over the ball on the truck, snap the coupler closed, attach the trailers safety chains and break away system cable to the truck, and connect the trailers electrical systems to the truck by inserting the trailers electrical plug into the trucks electrical receptacle. And to disconnect our truck from our trailer, we mindlessly do the same steps, but in reverse. Normally, we do not think much about the components of the truck and trailer that connect together. However, we should pay much more attention to the connection of our truck and trailer because our safety and the safety of our horses depend upon the connection. The first thing to do before connecting your trailer to your truck is to perform a visual inspection of all components that connect your truck to your trailer. If you use your trailer infrequently, you should establish a regular periodic inspection schedule and adhere to it.

Truck Components

Bumper Pull Hitch A bumper pull hitch is mounted to the rear end of the frame of your tow vehicle. The hitch exits the rear of your tow vehicle below the bumper. The hitch has a hollow square tube into which is inserted a draw bar. There is a hole through the hollow square tube for inserting a draw bar pin. Inspect the tightness of the bolts that attach the hitch to the frame of your tow vehicle. Inspect the hitch for cracks and the condition of the welds holding the pieces of the hitch together. Inspect the hollow square tube for cracks and the hole for the draw bar pin for wear. Bumper Pull Draw Bar There are two types of draw bars: 1) dead weight; and 2) weight distributing. A dead weight draw bar is a square hollow steel tube or solid steel bar with a flat steel

plate welded to it. The hitch ball is attached to the draw bar through a hole in the flat steel plate. The draw bar pin goes through a hole in the square part of the draw bar to hold the draw bar in the hitch. Inspect the square steel and flat steel parts of the draw bar for cracks or brakes and check the condition of the weld between them. A weight distributing draw bar is a solid, lshaped, square steel bar with a spring bar assembly and ball mount attached to one end of it. The other end is inserted into the square tube of the bumper pull hitch. The draw bar pin goes through a hole in the end without the spring bar assembly to hold the weight distributing draw bar in the hitch. Inspect the l-shaped square steel bar for cracks or breaks. Inspect the spring bar assembly and ball mount for cracks, breaks, loose bolts, and the condition of its welds. Bumper Pull Draw Bar Pin The draw bar pin is a hardened steel pin with a 0.625 inch diameter. One end is bent or has a loop welded to it and the other end has a hole or slot in it for attachment of a clip. The bend or loop and the clip on opposite ends of the draw bar pin keep it in place once it is inserted through the square tube of the hitch and draw bar. Inspect the draw bar pin for wear, cracks, and the hole or slot for wear. Bumper Pull Hitch Ball A bumper pull hitch ball is the focal point of the connection between your tow vehicle and your bumper pull trailer. The ball is sized appropriately for the class of the hitch. A Class I hitch requires a 1 7/8-inch diameter hitch ball with a 3/4-inch shank. A Class II hitch requires a 2-inch diameter hitch ball with a 1-inch shank. A Class III hitch requires a 2 5/16inch diameter hitch ball with a 1-inch shank. A Class IV hitch requires a 2 5/16-inch diameter hitch ball with a 1 1/4-inch shank. Inspect the ball for wear, it should be round not elliptical, and it should not have any cracks or breaks. The nut holding the hitch ball tight to the draw bar must be tight. Ideally, it should be tightened with a torque wrench to at least 120 lb-ft of torque. Also, it is extremely important that the shank of the hitch ball is the same size as the hole in the draw bar. If the shank is smaller than the

HorseWheels Volume 1 Issue 1 - Page 1

Page 2 - HorseWheels Volume 1 Issue 1

hole, no matter how tight you get the hitch ball, it can move in the hole and create a dangerous situation. Gooseneck Hitch A gooseneck hitch is mounted through the bed of your tow vehicle and attached to its frame by welds, bolts, or both. A gooseneck hitch has two basic parts: 1) a mount for the hitch ball; and 2) base rails which connect the ball mount to the tow vehicles frame. Inspect the ball mount and base rails for cracks or breaks, loose bolts, and the condition of its welds. If the ball mount moves, has a mechanism to fold the ball into it, or move the ball under the bed, inspect the mechanism for proper and easy operation. Gooseneck Hitch Ball A gooseneck hitch ball is the focal point of the connection between your tow vehicle and your gooseneck trailer. The ball is 2 5/16-inch in diameter with at least a 1 1/4-inch shank. Inspect the ball for wear, it should be round not elliptical, and it should not have any cracks or breaks. If the hitch ball is held to the ball mount with a nut, the nut must be tight. Ideally, it should be tightened with a torque wrench to at least 120 lb-ft of torque. If the hitch ball is tightened directly into the ball mount, it should be tightened into the ball mount with a similar amount of torque. If the ball is held in the ball mount by another type of mechanism, be sure the mechanism is functioning properly and holding the ball firmly. Electrical Receptacle A receptacle with seven pins that accepts a 7-pin plug from a trailer. The receptacle and plug contain a pin connection to link the trucks ground with the trailers ground. The other six pins connect six electrical circuits: 1) tail lights; 2) brake lights; 3) left turn signal; 4) right turn signal; 5) electric brakes; and 6) backup lights. The trucks receptacle is normally located either next to the rear license plate or under the rear bumper next to or on the hitch. Electrical Wiring The trucks electrical wiring for a trailer connection is spliced into the six circuits mentioned directly above. If the truck has anti-lock brakes, the electric brake circuit must be integrated with it and work with it.

Trailer Components

Jack Assembly The jack assembly lifts the trailers coupler off of the ball attached to the truck. Jacks are either manual or electric. Both require lubrication to work smoothly, lightly apply water pump grease or penetrating oil like WD40 on the part of the jack that extends and the mechanism that turns to extend the jack. Landing Gear There are two types of landing gear: for a gooseneck trailer and for a bumper pull trailer. Gooseneck trailer landing gear looks similar to a large steel foot. Its function is to provide a solid, flat end for the jack so that the jack does not cut into the ground with detaching the trailer. The landing gear should be a considerable distance from the ground when the trailer is in motion so that it will not come in contract with the ground and cause serious damage to the trailer. Bumper pull trailer landing gear is normally a removable wheel that slips onto the end of the jack when the trailer is being detached from the truck and is removed from the end of the jack when the trailer is attached to the truck. The wheel should not be left on the jack when the trailer is attached to the truck as it may come in contact with the ground while the trailer is in motion and may cause serious damage to the trailer. Coupler The coupler is attached to the end of the tongue of a bumper pull trailer and to the lower end of the gooseneck of a gooseneck trailer. The coupler closes around the ball on the truck to lock the trailer to the truck. The most important thing about a coupler is that it must be the same size as the ball that is being mated with it. If the ball is smaller than the coupler, the ball will move within the coupler and may come out of the coupler. If the ball is larger than the coupler, the coupler will not close properly around the ball and may come out of the coupler. Safety Chains If for some reason a trailers coupler fails, or the coupler opens and comes off the ball of the tow vehicle, safety chains maintain a connection between the trailer and the tow vehicle. Without safety chains, if a coupler failure occurred, the trailer would be

loose and be hazardous to other vehicles and to its contents. Safety chains are normally welded close to the coupler on the tongue of a bumper pull trailer or the connecting post of a gooseneck trailer. Safety chains should be sufficiently strong to hold the trailer to the tow vehicle. The welds connecting the safety chains to the trailer should be solid and free from cracks and rust. Breakaway Brake System The breakaway system is comprised of three elements: 1) the connection cable; 2) the breakaway switch; and 3) the breakaway battery. The connection cable attaches the trailers breakaway switch to the tow vehicle. The connection cable usually has a loop on one end that is placed over the ball on the tow vehicle before the trailers coupler is lowered onto it. The breakaway switch is normally attached to the tongue of a bumper pull trailer close to the coupler and on the gooseneck post on a gooseneck trailer. The breakaway battery is attached to the breakaway switch and to the trailers brake circuit. If the trailer separates from the tow vehicle, the connection cable will remain attached to the tow vehicle and will pull a pin out of the breakaway switch. When the pin is pulled out of the breakaway switch, a circuit is completed between the breakaway battery and the trailers brakes causing the brakes to be applied and stop the trailer independently of the tow vehicle. Electrical Plug The electrical plug connects all of the trailers electrical circuits to the appropriate tow vehicles electrical circuits. The electrical plug has seven pins, one for each of the trailers six circuits and a ground. Refer above to the trucks Electrical Receptacle and Electrical Wiring. Electrical Wiring The trailer normally has six circuits and a ground. Refer above to the trucks Electrical Receptacle and Electrical Wiring.

HorseWheels Volume 1 Issue 1 - Page 3

You might also like

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Adjustable Tow Bar Instructions: Read, Understand, Follow and Save These InstructionsDocument22 pagesAdjustable Tow Bar Instructions: Read, Understand, Follow and Save These InstructionsWilliam BarriosNo ratings yet

- Aotema Motor Kit Installation Instructions Rev2.3Document7 pagesAotema Motor Kit Installation Instructions Rev2.3Dennis KrizanNo ratings yet

- Chevelle Performance Projects: 1964-1972From EverandChevelle Performance Projects: 1964-1972Rating: 4.5 out of 5 stars4.5/5 (2)

- Articulated Boom Truck Student ManualDocument35 pagesArticulated Boom Truck Student ManualErc Nunez VNo ratings yet

- CDL Study Guide: Commercial driver's license manual, vehicle inspection and exam preparationFrom EverandCDL Study Guide: Commercial driver's license manual, vehicle inspection and exam preparationNo ratings yet

- S Master: Towing and Suspension SolutionsDocument24 pagesS Master: Towing and Suspension SolutionsjteegNo ratings yet

- Holding Down BoltsDocument4 pagesHolding Down BoltsLakshan KarunarathneNo ratings yet

- Roughter Crane ManualDocument33 pagesRoughter Crane ManualAbdul Majid Zulkarnain56% (9)

- 601 Car Frame Installations R1Document16 pages601 Car Frame Installations R1bhupiisterNo ratings yet

- Brushless Exciter Alignment GuideDocument3 pagesBrushless Exciter Alignment GuideanilscoobNo ratings yet

- Owners Manual Judy 2000Document6 pagesOwners Manual Judy 2000groening1993No ratings yet

- Haynes Pump 6500 ManualDocument8 pagesHaynes Pump 6500 Manualhiram avilaNo ratings yet

- Tensioner Training PresentationDocument29 pagesTensioner Training Presentationaravindan476No ratings yet

- Prestolite Starter MMDocument155 pagesPrestolite Starter MMleather_nun100% (2)

- Maintenance Troubleshooting GuideDocument28 pagesMaintenance Troubleshooting Guidenordsmendoza100% (1)

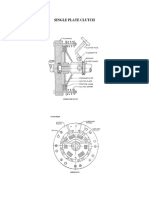

- Single Plate ClutchDocument4 pagesSingle Plate Clutchsaffrin0% (2)

- Drum Brake Installation: TIE DOWN ENGINEERING - 255 Villanova Drive SW - Atlanta, GA 30336Document4 pagesDrum Brake Installation: TIE DOWN ENGINEERING - 255 Villanova Drive SW - Atlanta, GA 30336asterdiscNo ratings yet

- Swagman 64095 2-Bike Ball Mount Bike RackDocument2 pagesSwagman 64095 2-Bike Ball Mount Bike RackSrijish SridharanNo ratings yet

- Motorcycle clutch system: functions, parts, assembly, disassembly, problemsDocument15 pagesMotorcycle clutch system: functions, parts, assembly, disassembly, problemsSelazinap LptNo ratings yet

- Shimano AlivioDocument1 pageShimano AlivioBrent MitchellNo ratings yet

- Tool List: Please Read Completely Before BeginningDocument5 pagesTool List: Please Read Completely Before BeginningDavíð Örn SvavarssonNo ratings yet

- 01 Rock Shox Judy Owners ManualDocument7 pages01 Rock Shox Judy Owners ManualakjasonNo ratings yet

- Martin Maintenance Anf Troubleshooting GuideDocument28 pagesMartin Maintenance Anf Troubleshooting GuidesuperalitosNo ratings yet

- Belt & Bucket Elevator: Installation, Maintenance & Spare Parts ManualDocument13 pagesBelt & Bucket Elevator: Installation, Maintenance & Spare Parts ManualratheeshNo ratings yet

- Zoombicycles Bicycle Engine Installation GuideDocument37 pagesZoombicycles Bicycle Engine Installation GuideOlin Stej100% (1)

- 2009 UTILITY Trailer Manual V3.0Document92 pages2009 UTILITY Trailer Manual V3.0CR CNo ratings yet

- DIY - Replacing Timing BeltsDocument3 pagesDIY - Replacing Timing Beltstron68bizz100% (2)

- Home Built CNCDocument110 pagesHome Built CNCBobby Chipping100% (4)

- Tsubaki Large Pitch Roller Conveyor ChainDocument139 pagesTsubaki Large Pitch Roller Conveyor Chaincakhokhe100% (1)

- rd-m592 2Document1 pagerd-m592 2faizgpNo ratings yet

- Bucket Elevator Chain InstallationDocument27 pagesBucket Elevator Chain Installationm s sankar raoNo ratings yet

- Maintaining Square PlansiftersDocument16 pagesMaintaining Square PlansiftersEdwar André PgalNo ratings yet

- Chain Pulley Block Safety GuideDocument7 pagesChain Pulley Block Safety GuideRajanbabu100% (3)

- OWI 1000 DrawworksDocument54 pagesOWI 1000 DrawworksÖnder Büyükişcan100% (1)

- 80-96 F150 2 1/2" Lift Kit InstructionsDocument4 pages80-96 F150 2 1/2" Lift Kit Instructionsisaacllugo1No ratings yet

- 2210 Industrial Crane Safety PresentationDocument3 pages2210 Industrial Crane Safety PresentationbangladragosNo ratings yet

- Troubleshooting Rub Marks in A Centrifugal PumpDocument4 pagesTroubleshooting Rub Marks in A Centrifugal Pumpابو المعالي الهمامNo ratings yet

- Proclimb Procross Torsional Conversion KitDocument8 pagesProclimb Procross Torsional Conversion KitcpcracingNo ratings yet

- Bottom Bracket Installation ProcedureDocument1 pageBottom Bracket Installation ProcedureaufcheNo ratings yet

- Diesel Engine Bedplate ComponentsDocument117 pagesDiesel Engine Bedplate ComponentsNandakishore Pradeep100% (1)

- Derailleur AdjustmentDocument19 pagesDerailleur AdjustmentpitbullNo ratings yet

- Tie Bolts or Tie RodsDocument8 pagesTie Bolts or Tie RodsAayush AgrawalNo ratings yet

- Modelo de Carreta EnroladorDocument15 pagesModelo de Carreta EnroladorthiagoNo ratings yet

- Lycoming Starter AdapterDocument11 pagesLycoming Starter AdapterakNo ratings yet

- Golden Eagle Rake Manual 2016 COMPLETEDocument20 pagesGolden Eagle Rake Manual 2016 COMPLETEИванов ИвановNo ratings yet

- Clock Escapement Drop LockDocument5 pagesClock Escapement Drop Lockapi-10966495No ratings yet

- Ahvf GRGNHGDocument1 pageAhvf GRGNHGRafaell DalpraNo ratings yet

- 001-Component-Build: Build The Following Contraptor Components Before AssemblyDocument50 pages001-Component-Build: Build The Following Contraptor Components Before AssemblyTashi BestNo ratings yet

- BC BRONCO Rear Disk Brakes: B.C. BRONCOS Tech LibraryDocument11 pagesBC BRONCO Rear Disk Brakes: B.C. BRONCOS Tech LibrarycarlvpNo ratings yet

- General Clutch InstructionsDocument4 pagesGeneral Clutch InstructionstonythetigerNo ratings yet

- Oral TipsDocument147 pagesOral TipsRaj MalikNo ratings yet

- Diy Kart Plans - Electric CarDocument8 pagesDiy Kart Plans - Electric CarzaoioazNo ratings yet

- Chapter Thirty-Five: ClutchesDocument24 pagesChapter Thirty-Five: ClutchesKkbhuvan KkNo ratings yet

- Basic Guide to Europe Dinghy Rigging EssentialsDocument9 pagesBasic Guide to Europe Dinghy Rigging Essentialsmoha19841No ratings yet

- Rolling InstallnstructionsDocument8 pagesRolling InstallnstructionsANDINo ratings yet

- YZ 250-02-10 Flywheel Weight Installation InstructionsDocument2 pagesYZ 250-02-10 Flywheel Weight Installation InstructionsJoe ScaliaNo ratings yet

- Vessel Pedestal Crane Student ManualDocument19 pagesVessel Pedestal Crane Student Manualfafejaya1350% (2)

- BrakesDocument27 pagesBrakesNiño Jhim AndrewNo ratings yet

- Fall2011 MENG470 Homework1Document1 pageFall2011 MENG470 Homework1Turan GökdemirNo ratings yet

- V1 I1 Connecting Your TrailerDocument3 pagesV1 I1 Connecting Your TrailerTuran GökdemirNo ratings yet

- V1 I1 Connecting Your TrailerDocument3 pagesV1 I1 Connecting Your TrailerTuran GökdemirNo ratings yet

- V1 I1 Connecting Your TrailerDocument3 pagesV1 I1 Connecting Your TrailerTuran GökdemirNo ratings yet

- V1 I1 Connecting Your TrailerDocument3 pagesV1 I1 Connecting Your TrailerTuran GökdemirNo ratings yet

- Fall2011 MENG470 Homework1Document1 pageFall2011 MENG470 Homework1Turan GökdemirNo ratings yet

- MENG470 Spring2011 Vibration of Two DOFSDocument66 pagesMENG470 Spring2011 Vibration of Two DOFSTuran GökdemirNo ratings yet

- Fall2011 MENG2011 Review Problems 2Document3 pagesFall2011 MENG2011 Review Problems 2Turan GökdemirNo ratings yet

- Fall2011 MENG470 Homework1Document1 pageFall2011 MENG470 Homework1Turan GökdemirNo ratings yet

- Fall2011 MENG2011 Review Problems 2Document3 pagesFall2011 MENG2011 Review Problems 2Turan GökdemirNo ratings yet

- Fall2011 MENG2011 Review Problems 2Document3 pagesFall2011 MENG2011 Review Problems 2Turan GökdemirNo ratings yet

- Fall2011 MENG2011 Review Problems 2Document3 pagesFall2011 MENG2011 Review Problems 2Turan GökdemirNo ratings yet

- Fall2011 MENG2011 Review Problems 2Document3 pagesFall2011 MENG2011 Review Problems 2Turan GökdemirNo ratings yet

- Fall2011 MENG2011 Review Problems 2Document3 pagesFall2011 MENG2011 Review Problems 2Turan GökdemirNo ratings yet

- Fall2011 MENG2011 Review Problems 2Document3 pagesFall2011 MENG2011 Review Problems 2Turan GökdemirNo ratings yet

- Fall2011 MENG2011 Review Problems 2Document3 pagesFall2011 MENG2011 Review Problems 2Turan GökdemirNo ratings yet

- Fall2011 MENG470 Homework1Document1 pageFall2011 MENG470 Homework1Turan GökdemirNo ratings yet

- MENG470 Homework3 Team1Document9 pagesMENG470 Homework3 Team1Turan GökdemirNo ratings yet

- Fall2011 MENG2011 Review Problems 2Document3 pagesFall2011 MENG2011 Review Problems 2Turan GökdemirNo ratings yet

- Fhwa AbsDocument49 pagesFhwa Absgnoble30No ratings yet

- Fhwa AbsDocument49 pagesFhwa Absgnoble30No ratings yet

- Fall2011 MENG470 Homework1Document1 pageFall2011 MENG470 Homework1Turan GökdemirNo ratings yet

- MENG470 Homework3 Team4Document13 pagesMENG470 Homework3 Team4Turan GökdemirNo ratings yet

- Fhwa AbsDocument49 pagesFhwa Absgnoble30No ratings yet

- MENG470 Homework3 Team1Document9 pagesMENG470 Homework3 Team1Turan GökdemirNo ratings yet

- Grandma Gatewood's Walk: The Inspiring Story of the Woman Who Saved the Appalachian TrailFrom EverandGrandma Gatewood's Walk: The Inspiring Story of the Woman Who Saved the Appalachian TrailRating: 4.5 out of 5 stars4.5/5 (308)

- Welcome to the Goddamn Ice Cube: Chasing Fear and Finding Home in the Great White NorthFrom EverandWelcome to the Goddamn Ice Cube: Chasing Fear and Finding Home in the Great White NorthRating: 4 out of 5 stars4/5 (59)

- Merle's Door: Lessons from a Freethinking DogFrom EverandMerle's Door: Lessons from a Freethinking DogRating: 4 out of 5 stars4/5 (326)

- Crazy for the Storm: A Memoir of SurvivalFrom EverandCrazy for the Storm: A Memoir of SurvivalRating: 3.5 out of 5 stars3.5/5 (217)

- 127 Hours Movie Tie- In: Between a Rock and a Hard PlaceFrom Everand127 Hours Movie Tie- In: Between a Rock and a Hard PlaceRating: 4 out of 5 stars4/5 (46)

- The Optimist: A Case for the Fly Fishing LifeFrom EverandThe Optimist: A Case for the Fly Fishing LifeRating: 4.5 out of 5 stars4.5/5 (17)

- Last Child in the Woods: Saving Our Children From Nature-Deficit DisorderFrom EverandLast Child in the Woods: Saving Our Children From Nature-Deficit DisorderRating: 4 out of 5 stars4/5 (283)

- The Mountain of My Fear and Deborah: Two Mountaineering ClassicsFrom EverandThe Mountain of My Fear and Deborah: Two Mountaineering ClassicsRating: 4.5 out of 5 stars4.5/5 (20)

- The Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsFrom EverandThe Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsNo ratings yet

- The Last of His Kind: The Life and Adventures of Bradford Washburn, America's Boldest MountaineerFrom EverandThe Last of His Kind: The Life and Adventures of Bradford Washburn, America's Boldest MountaineerRating: 4 out of 5 stars4/5 (23)

- Divided: A Walk on the Continental Divide TrailFrom EverandDivided: A Walk on the Continental Divide TrailRating: 4 out of 5 stars4/5 (17)

- Sailing a Serious Ocean: Sailboats, Storms, Stories and Lessons Learned from 30 Years at SeaFrom EverandSailing a Serious Ocean: Sailboats, Storms, Stories and Lessons Learned from 30 Years at SeaRating: 4.5 out of 5 stars4.5/5 (43)

- Hiking Through: One Man's Journey to Peace and Freedom on the Appalachian TrailFrom EverandHiking Through: One Man's Journey to Peace and Freedom on the Appalachian TrailRating: 4 out of 5 stars4/5 (99)

- Alta California: From San Diego to San Francisco, A Journey on Foot to Rediscover the Golden StateFrom EverandAlta California: From San Diego to San Francisco, A Journey on Foot to Rediscover the Golden StateRating: 5 out of 5 stars5/5 (1)

- Lost in the Wild: Danger and Survival in the North WoodsFrom EverandLost in the Wild: Danger and Survival in the North WoodsRating: 4.5 out of 5 stars4.5/5 (107)

- One Man's Climb: A Journey of Trauma, Tragedy and Triumph on K2From EverandOne Man's Climb: A Journey of Trauma, Tragedy and Triumph on K2Rating: 4.5 out of 5 stars4.5/5 (15)

- True Spirit: The True Story of a 16-Year-Old Australian Who Sailed Solo, Nonstop, and Unassisted Around the WorldFrom EverandTrue Spirit: The True Story of a 16-Year-Old Australian Who Sailed Solo, Nonstop, and Unassisted Around the WorldRating: 5 out of 5 stars5/5 (6)

- The Art of Resilience: Strategies for an Unbreakable Mind and BodyFrom EverandThe Art of Resilience: Strategies for an Unbreakable Mind and BodyRating: 4.5 out of 5 stars4.5/5 (12)

- Survival Hacks: Over 200 Ways to Use Everyday Items for Wilderness SurvivalFrom EverandSurvival Hacks: Over 200 Ways to Use Everyday Items for Wilderness SurvivalRating: 4.5 out of 5 stars4.5/5 (11)

- Dark Summit: The True Story of Everest's Most Controversial SeasonFrom EverandDark Summit: The True Story of Everest's Most Controversial SeasonRating: 4 out of 5 stars4/5 (154)

- The Lost Explorer: Finding Mallory on Mount EverestFrom EverandThe Lost Explorer: Finding Mallory on Mount EverestRating: 4.5 out of 5 stars4.5/5 (31)