Professional Documents

Culture Documents

Wall Thickness and MITER

Uploaded by

nirga0 ratings0% found this document useful (0 votes)

126 views1 pageCopyright

© Attribution Non-Commercial (BY-NC)

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

126 views1 pageWall Thickness and MITER

Uploaded by

nirgaCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 1

16"-CB-211096205-32

Plate SB-265 Gr. 2 / SB-862 Gr. 2

ASME B31.3 / ASTM B 862

CLASS 32

mm inch inch mm

406.40 16.00 0.098 2.50

C F inch mm

50 122 0.098 2.50

bar g PSI inch mm

12.00 174.05 0.118 3.00

Mpa PSI inch mm

115.14 16700 N.A. N.A.

C F inch mm

21 70 0.109 2.80

bar g PSI inch mm

16.00 232.06 0.110 2.80

Mpa PSI inch mm

275.79 40000 0.165 4.19

inch mm

0.144 3.67

mm inch

0.0 0.00

deg rad

11.25 0.20

mm inch

200.2 8

mm inch i. Using allowable stress at T design:

609.6 24 (a) Pm= 16.9 bar g

mm inch (b) Pm= 23.6 bar g

6 0.236 ii. Using of yield stress:

(a) Pm= 20.2 bar g

(b) Pm= 28.2 bar g

Max. allowable internal pressure for this condition:

Pmax= 16.9 bar g

Adopted Wall Thickness:

TADOPTED= 6 mm

CONCLUSION

PIPE WALL THICKNESS

R1

T

MAX. ALLOWABLE INTERNAL PRESSURE FOR MULTIPLE MITER BEND PER ASME B31.3 -para 304.2.3

DATA

r2

SELECTED THK' (T)

LINE No.

A

c

c

.

t

o

A

S

T

M

B

-

8

6

2

MIN. REQ'D THK'

(HYDROTEST)

SELECTED THK' (T)

SPEC

Pdesign

Tambient

DATA

MIN. REQ'D THK'

(DESIGN)

Tdesign

THK' INCLUDING

CORROSION

MATERIAL

CODE

CALCULATION

D0

A

c

c

.

t

o

B

3

1

.

3

Ptest

THK' INCLUDING

CORROSION

Sdesign

THK' -

MILL TOLERANCE 12.5%

E 0.85

TH'K -

MILL TOLERANCE 12.5%

Syield

0.4

CONCLUSION

C ADOPTED:

Pipe 16" made of plate SB-265 Gr. 2 thk' 3mm /

Pipe 16" sch. 5 (4.19mm) SB-862 Gr. 2

Y

C t +

min

C t +

min

( ) Y P E S

D P

+

2

0

( ) Y P E S

D P

Y

+

2

1

2

0

( )

( )

( ) ( )

|

|

.

|

\

|

+

=

c T r c T

c T

r

c T E S

Pm a

2 2

tan 643 . 0 u

( )

( )

|

|

.

|

\

|

=

2 1

2 1

2

5 . 0 r R

r R

r

c T E S

Pm b

1 of 1

You might also like

- ASME B31.3 Pipe Wall ThicknessDocument2 pagesASME B31.3 Pipe Wall ThicknessAnonymous cyKuQKNo ratings yet

- Piping Stress Handbook - by Victor Helguero - Part 2 PDFDocument121 pagesPiping Stress Handbook - by Victor Helguero - Part 2 PDFCESAR100% (2)

- Thermal Expansion Loop Sizing for Pipes and TubingDocument2 pagesThermal Expansion Loop Sizing for Pipes and Tubingzshehadeh0% (1)

- PY SEW Do P T: Pipe Wall Thickness Calculation SheetDocument1 pagePY SEW Do P T: Pipe Wall Thickness Calculation Sheetanon_714194540No ratings yet

- Mitered BendsDocument1 pageMitered BendsTsouki TsoukiNo ratings yet

- Pipe Thickness Calculation PDFDocument1 pagePipe Thickness Calculation PDFHeny Martha67% (3)

- Reinforcement CheckDocument2 pagesReinforcement Checkviv0102No ratings yet

- Taller1 Hanger Sizing in CaesarDocument37 pagesTaller1 Hanger Sizing in CaesarAnkithNo ratings yet

- Points To Be Considered During Stress AnalysisDocument24 pagesPoints To Be Considered During Stress AnalysismishtinilNo ratings yet

- Calculation of PipeReinforcement ASMEB31 1Document4 pagesCalculation of PipeReinforcement ASMEB31 1threedlabsNo ratings yet

- 8 AS4041 ASME B31 3 Pipe Wall ThicknessDocument8 pages8 AS4041 ASME B31 3 Pipe Wall ThicknessĐinh Thiện SỹNo ratings yet

- Pipe Wall Thickness Calculation Methods ASME B31.1 vs B31.3Document8 pagesPipe Wall Thickness Calculation Methods ASME B31.1 vs B31.3Ton PhichitNo ratings yet

- Hydrostatic Test Pressure Calculation: Pipe DataDocument2 pagesHydrostatic Test Pressure Calculation: Pipe DataAkram AlhaddadNo ratings yet

- Above Ground Piping Wall Thickness CalculationsDocument7 pagesAbove Ground Piping Wall Thickness Calculationslutfi awn100% (1)

- NozzlePRO PDFDocument185 pagesNozzlePRO PDFIan CarrNo ratings yet

- Pipe cap thickness and coupling rating calculationsDocument2 pagesPipe cap thickness and coupling rating calculationsmasaminathanNo ratings yet

- Pipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)Document1 pagePipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)farhadNo ratings yet

- Modeling of Internal Pressure and Thrust Load On Nozzles Using WRC 368Document5 pagesModeling of Internal Pressure and Thrust Load On Nozzles Using WRC 368m5416No ratings yet

- Selection Criteria For Lines Subject To Comprehensive Stress AnalysisDocument10 pagesSelection Criteria For Lines Subject To Comprehensive Stress AnalysisNithin Zs100% (1)

- Stress Sample Calculation On Base EllDocument1 pageStress Sample Calculation On Base EllLionel TorradoNo ratings yet

- Petroleum Development Oman LLC: Appendix-2: Pipe Stress Analysis Checklist-Input/OutputDocument5 pagesPetroleum Development Oman LLC: Appendix-2: Pipe Stress Analysis Checklist-Input/OutputAbhijeetNo ratings yet

- Astm D2517 (2000)Document5 pagesAstm D2517 (2000)SANKARAN.KNo ratings yet

- Easyflex Flexible Hose DatasheetDocument2 pagesEasyflex Flexible Hose DatasheetzassssNo ratings yet

- Pipeline Calculations - ASAB Gas Lift LinesDocument11 pagesPipeline Calculations - ASAB Gas Lift LinesSaqib LaeeqNo ratings yet

- Finite Element Analysis of Stress Factors in Pipe BendsDocument7 pagesFinite Element Analysis of Stress Factors in Pipe BendsSteve IpNo ratings yet

- SIF CalculatorDocument4 pagesSIF CalculatorKannaphat WattanaphanNo ratings yet

- Reinforcement Pad CalculationDocument4 pagesReinforcement Pad CalculationMohammad AbdullahNo ratings yet

- Air Release Vacuum Breaker ValveDocument16 pagesAir Release Vacuum Breaker ValveLao Zhu100% (1)

- Calc Hoop StressDocument11 pagesCalc Hoop StressApril TrevinoNo ratings yet

- Harmonic Analysis REV. 1Document7 pagesHarmonic Analysis REV. 1Amro SalahNo ratings yet

- Calculation of PipeReinforcement ASMEB31.1Document3 pagesCalculation of PipeReinforcement ASMEB31.1jayaarnav100% (1)

- Calculation of RC PAD2Document1 pageCalculation of RC PAD2m 418No ratings yet

- PSV Reaction Forces and DirectionDocument29 pagesPSV Reaction Forces and Directionpvmsson100% (1)

- Stress Itensification FactorsDocument51 pagesStress Itensification FactorsSyed AhsanNo ratings yet

- Process Industry Basket StrainersDocument27 pagesProcess Industry Basket StrainersmartinnovelNo ratings yet

- Flange Asmeviii Div.1 App.2 Rev0Document10 pagesFlange Asmeviii Div.1 App.2 Rev0lk700615100% (1)

- Stress Analysis Guidelines for Liquid Pipelines per ASME B31.4Document4 pagesStress Analysis Guidelines for Liquid Pipelines per ASME B31.4Nilesh GohelNo ratings yet

- Piping Stress Analysis Is The Most Important Activity in Piping DesignDocument10 pagesPiping Stress Analysis Is The Most Important Activity in Piping DesignShreesanth SreenivasanNo ratings yet

- CAESARII Output WebinarDocument43 pagesCAESARII Output WebinarAnkithNo ratings yet

- Increase Allowable Stress CodeDocument9 pagesIncrease Allowable Stress Codewenny_tpdNo ratings yet

- Modeling Procedure of Rigid Strut in Caesar IIDocument5 pagesModeling Procedure of Rigid Strut in Caesar IIHmd MokhtariNo ratings yet

- Virtual Anchors For Dummies - M Blackman Jan 09: Modelling in CAESAR IIDocument4 pagesVirtual Anchors For Dummies - M Blackman Jan 09: Modelling in CAESAR IImartin_blackmanNo ratings yet

- Piping Support Design ManualDocument4 pagesPiping Support Design ManualxkokarcaxNo ratings yet

- PDIL-Stress Analysis Design Basis PDFDocument13 pagesPDIL-Stress Analysis Design Basis PDFDarshan Panchal100% (1)

- Document Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking PlantDocument49 pagesDocument Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking Plantsusa2536No ratings yet

- Pipe wall thickness calculation sheet for high pressure natural gas lineDocument1 pagePipe wall thickness calculation sheet for high pressure natural gas lineAris KancilNo ratings yet

- Tank design calculations sheet analysisDocument5 pagesTank design calculations sheet analysisapminshull88% (8)

- UEPL THICKNESS CALCULATION FOR SBA AND SAC VESSELS ROSA TPPDocument8 pagesUEPL THICKNESS CALCULATION FOR SBA AND SAC VESSELS ROSA TPPmkchy12100% (1)

- Hydrotest Pressure CalculationDocument26 pagesHydrotest Pressure CalculationChetan B Kapadia100% (13)

- Steam Drum, Water Wall & Evaporator - VWHA054Document36 pagesSteam Drum, Water Wall & Evaporator - VWHA054Mani SunNo ratings yet

- Hydrostatic Test Pressure Formula GuideDocument26 pagesHydrostatic Test Pressure Formula Guiderudrakr0% (1)

- Design Calculations For V2703 Rev 0Document9 pagesDesign Calculations For V2703 Rev 0Dilip KatekarNo ratings yet

- Internal CoilDocument2 pagesInternal CoilwhngomjNo ratings yet

- ASME 31 - 8mDocument1 pageASME 31 - 8mMarcoAlbaNo ratings yet

- Rectangular TankDocument38 pagesRectangular TankSam LowNo ratings yet

- Wall THK Calculation Asme b31.4Document5 pagesWall THK Calculation Asme b31.4Dwi Hermawan100% (2)

- RCC Slab Design and Reinforcement DetailsDocument79 pagesRCC Slab Design and Reinforcement Detailssurendra_panga100% (2)

- Calculo de Recipientes A PresionDocument2 pagesCalculo de Recipientes A PresionCesar Augusto Castellar OrtegaNo ratings yet

- RCC Design SheetsDocument40 pagesRCC Design Sheetsashuswara84% (25)

- Weld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersDocument30 pagesWeld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersmishtinilNo ratings yet

- When Trying To Import PCFDocument2 pagesWhen Trying To Import PCFnirgaNo ratings yet

- How To Highlight A Row in Excel Using Conditional FormattingDocument5 pagesHow To Highlight A Row in Excel Using Conditional FormattingnirgaNo ratings yet

- Calculating Stud Bolt length formulaDocument2 pagesCalculating Stud Bolt length formulanirga100% (1)

- ASME B16.5 DimensionsDocument26 pagesASME B16.5 DimensionsnirgaNo ratings yet

- Autocad ShortcutsDocument2 pagesAutocad ShortcutsnirgaNo ratings yet

- Autocad ShortcutsDocument2 pagesAutocad ShortcutsnirgaNo ratings yet

- How To Create A Reinforcing Pad in Branch Table PDFDocument1 pageHow To Create A Reinforcing Pad in Branch Table PDFnirgaNo ratings yet

- Model Distance From OriginDocument2 pagesModel Distance From OriginnirgaNo ratings yet

- Pipe Size Conversion Chart: DN to NPSDocument1 pagePipe Size Conversion Chart: DN to NPSnirga100% (1)

- Solved - Lug Butterfly Valve Issues - Autodesk Community - AutoCAD Plant 3DDocument2 pagesSolved - Lug Butterfly Valve Issues - Autodesk Community - AutoCAD Plant 3DnirgaNo ratings yet

- Excel Shortcuts 2014 PDFDocument7 pagesExcel Shortcuts 2014 PDFKaranam Attur VenkateshNo ratings yet

- Solved - Importing Isometric Configuration Settings - Autodesk Community - AutoCAD Plant 3DDocument3 pagesSolved - Importing Isometric Configuration Settings - Autodesk Community - AutoCAD Plant 3DnirgaNo ratings yet

- G Dimensions CalculationDocument15 pagesG Dimensions CalculationnirgaNo ratings yet

- Bolt Lengths and @@@ - Autodesk Community - AutoCAD Plant 3DDocument6 pagesBolt Lengths and @@@ - Autodesk Community - AutoCAD Plant 3DnirgaNo ratings yet

- PV Elite WebinarsDocument3 pagesPV Elite WebinarsnirgaNo ratings yet

- Symbol Editor For C-II IsogenDocument6 pagesSymbol Editor For C-II IsogennirgaNo ratings yet

- AFT Evaluating Pipe Dynamic Loads Caused by WaterhammerDocument24 pagesAFT Evaluating Pipe Dynamic Loads Caused by WaterhammerroyalcomNo ratings yet

- How To Find Max Absolute Value in ExcelDocument1 pageHow To Find Max Absolute Value in ExcelnirgaNo ratings yet

- How to troubleshoot a failed CAESAR II Dynamics job and send relevant filesDocument1 pageHow to troubleshoot a failed CAESAR II Dynamics job and send relevant filesnirgaNo ratings yet

- Buckling in ColumnsDocument8 pagesBuckling in ColumnsnirgaNo ratings yet

- Application of WRC Bulletins 107, 297, 368Document3 pagesApplication of WRC Bulletins 107, 297, 368shivabtowin3301100% (3)

- Trunnion Calculation SheetDocument2 pagesTrunnion Calculation Sheetnirga100% (1)

- Determination of Maximum Span Between Pipe Support Using Bending Stress TheoryDocument4 pagesDetermination of Maximum Span Between Pipe Support Using Bending Stress TheoryMannattil Krishna KumarNo ratings yet

- Connection DesignDocument33 pagesConnection DesignihpeterNo ratings yet

- App. 7 - Spring From TowerDocument5 pagesApp. 7 - Spring From TowernirgaNo ratings yet

- Application of WRC Bulletins 107, 297, 368Document3 pagesApplication of WRC Bulletins 107, 297, 368shivabtowin3301100% (3)

- Good Computer PostureDocument1 pageGood Computer PosturenirgaNo ratings yet

- GSH Pipe Supports CatalogDocument173 pagesGSH Pipe Supports Catalognirga100% (1)

- Allowable Nozzle LoadsDocument3 pagesAllowable Nozzle Loadsnirga100% (6)

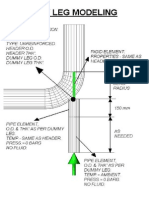

- App. 6 - Dummy Leg ModelingDocument1 pageApp. 6 - Dummy Leg Modelingnirga100% (1)