Professional Documents

Culture Documents

ACM and Demolition General Work Plan

ACM and Demolition General Work Plan

Uploaded by

russt2Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ACM and Demolition General Work Plan

ACM and Demolition General Work Plan

Uploaded by

russt2Copyright:

Available Formats

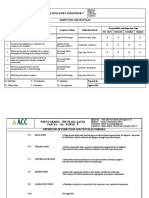

ABATEMENT AND DEMOLITION WORK PLAN

for

GENERAL ELECTRIC POWER SYSTEMS

Abatement, Demolition and Limited Soil Excavation and Site Restoration Activities 920 East Fort Avenue Baltimore, Maryland 20230

Prepared For: Mr. Edward F. Jamison, P.G. General Electric Power Systems 1 River Road, Building 43-237 Schenectady, New York 12345 (518) 339-6478 Prepared By: Cleveland Wrecking Company 85 East Market Street Buffalo, New York 14204 (716) 842-0230 October 2002

1.0 1.1

INTRODUCTION PURPOSE OF THE ABATEMENT AND DEMOLITION WORK PLAN

Cleveland Wrecking Company (CWC) has prepared this Abatement and Demolition Work Plan, hereafter referred to as the Work Plan, for the purpose of providing a detailed description of abatement (asbestos containing materials and regulated building materials), demolition, limited soil excavation, and restoration activities that CWC will be implementing during on-site activities at the General Electric Power Systems, Baltimore, Maryland Project. This Work Plan has been prepared in accordance with the Contract Specifications for the Abatement, Demolition, and Limited Soil Excavation and Site Restoration Activities at the General Electric Power Systems (GEPS) facility. The procedures described in the Work Plan comply with industry standards and Federal, State, and local governing regulations. 1.2 SITE LOCATION AND DESCRIPTION

The project site is located at 920 East Fort Street, Baltimore, Maryland 21230. The facility consists of a former industrial building owned by General Electric Power Systems and considered a GE Apparatus Service Shop. The building contains one main warehouse section and a two-story office area. The total floor space encompasses approximately 42,000 square feet. The work site is located within a residential and light manufacturing and commercial area. The facility location with respect to regional features is included in Figure 1 Site Vicinity Map.

1.3

GENERAL WORK ACTIVITY OVERVIEW

CWC shall provide all labor, equipment, supplies and services to complete the Abatement, Demolition and Limited Soil Excavation at the former GEPS site. The project will be completed in a series of stages following the Preconstruction and planning phase that includes the submittal of Work Plans, Schedules, Notifications and Certifications. Furthermore, during this phase CWC will locate, de-energize and terminate all utility connections at the site. Stage 1: Abatement Activities Project activities will involve the abatement, removal / segregation, loading, preparation and transportation of all fixtures, equipment, or materials from

the GEPS facility for disposal at a GEPS-approved disposal facility. Materials for proper handling and disposal may include: Asbestos-Containing Materials (ACM) Lead-Based Paint and Lead Hazards Polychlorinated biphenyl (PCB) Materials Mercury Containing Fixtures Batteries Halon Fire Suppressant Systems Freon Smoke Detectors and Emergency Exit Signs Animal Excrement Wood Block Flooring and Railroad Ties Stored Liquids and Solid Materials

Stage 2: Demolition Activities Project activities will involve the demolition, preparation, loading and transportation for off-site disposal of the building structure and certain site features including: Roof, Ceiling, Walls, and Partitions, etc. Above grade structures, floor slabs, foundations Basement Walls, floor slabs and foundations Pits, Sumps, separations, drain line laterals, railroad spurs, above ground storage tanks, and all pipes, pumps and mechanical equipment.

Stage 3: Limited Soil Excavation Activities Following completion of building demolition, CWC will perform the following activities: Excavate, load and transport impacted soils from specific areas on the property to GEPS-approved disposal facility. Backfill of excavations to surface grade Backfill shall be compacted and documented in accordance with commonly accepted protocol to demonstrate 95% compaction Conduct site restoration activities.

Following the completion of all site activities, CWC will prepare and submit a written summary of the work performed. CWC will also confirm that GEPS has received copies of all waste management paperwork. Included as Appendix A is a comprehensive project schedule detailing the sequencing of work and task items that will be performed concurrently, where possible.

1.4

PERSONNEL HEALTH & SAFETY

CWC considers safety and the prevention of accidents an integral part of its operation. Under Federal, State and local law, CWC is responsible to provide training and a safe working environment, to protect life, health and safety of its employees and subcontractor personnel. Although providing safe working conditions is primarily a management responsibility, safety and accident prevention can be accomplished only through coordinated efforts of all employees and subcontractor personnel. It is the policy of CWC for this project as with all of our projects, that if the task or service being undertaken cannot be done safely, that work is to be stopped until proper controls can be established. CWC has completed a Site-Specific Health & Safety Plan (SSHSP) for the completion of this project that can be reviewed at any time in the CWC Field Office. Every worker on the GEPS Project Site will be required to read and sign an acknowledgment form and follow the SSHSP for the duration of the project. In addition, CWC will hold daily tailgate meetings prior to work commencement. These meetings are designed to discuss the projected work schedule and prepare each worker for any potential hazards associated with the days work activities. A copy of the daily or weekly safety meeting logs will be maintained onsite at all times. All personnel attending the safety meeting will be required to sign the safety meeting log upon completion of the tailgate safety meeting. During the tailgate meetings, personnel will be reminded of site conditions and are encouraged to participate with health and safety concerns. CWC has designed and prepared the SSHSP to be utilized as a stand-alone reference document and is therefore not included as a part of this Work Plan. However, for reference purposes the Table of Contents for the SSHSP has been included in Appendix B. 2.0 2.1 PRECONSTRUCTION ACTIVITIES & MOBILIZATION DECONTAMINATION, SUBMITTALS DEMOLITION, AND REMEDIATION

Decontamination, demolition, and remediation of the GEPS facility will be completed under the direction of the State of Maryland Office of the Environment and the City of Baltimore Fire Department. The following information, plans, and/or programs will be required and utilized during the

completion of the proposed project. 2.1.1 Detailed Construction Schedule (Appendix A) The detailed construction schedule includes durations and milestones for all activities anticipated during decontamination, asbestos abatement; structure demolition and salvage; and environmental remediation. The schedule will be updated on a bimonthly basis to reflect scheduling changes, delays, and/or improvements. 2.1.2 Site-Specific Health and Safety Plan (Appendix of Contents only) B, Table

A site-specific Health and Safety Plan (SSHSP) has been developed for this project. CWCs Standard Operating Procedures incorporate the requirements specified by Federal, State, and local regulations, specifically CFR 29, CFR40, and CFR49. Tailgate safety meetings will be held at the beginning of every work shift; during new phases of operation; at the time new personnel are introduced to the site; and when site conditions warrant such meetings. These meetings will identify potential workplace hazards and problems so that appropriate control measures can be implemented. The SSHSP will establish procedures and address emergencies that may arise during all site activities. Emergency vehicular access evacuation procedures, and a listing of all contract personnel with phone numbers will be included in the SSHSP. The purpose of the SSHSP is the protection of personnel and the environment on-site, as well as the general public and environment in adjacent properties and neighborhoods. The site-specific SSHSP will be enforced within site boundaries at all times. Detailed, specific health and safety issues related to the former processing, storage, and material handling areas within the Facility, will be identified by a CWC Health and Safety Officer. For those employees required to be certified to participate in abatement and environmental activities, employee certifications will be kept on file in the CWC Field Office. Emergency Procedures or Contingency Supplement

Within the SSHSP, CWC describes emergency operating and evacuation procedures to be implemented at the Baltimore facility. The Emergency Procedures Program, outlined in Section 2.2 of the SSHSP at a minimum describes an emergency situation, specific emergency horn signals, emergency radio communications protocol (all work crews will have radio contact with the field office and site safety officer), proper procedure for workers to follow in an emergency situation, evacuation routes and meeting places. These items will be reiterated in the daily or weekly tailgate safety meeting mandated by the SSHSP. Lead Compliance Plan Included within the SSHSP is a Lead Compliance Plan that is meant to provide a detailed description of lead-based paint abatement activities that CWC will implement for this project, if required. CWC shall be responsible for mitigation of potential environmental and construction hazards resultant from the presence of lead dust or fumes. The activities that have a potential to emit lead dust or fumes include torch cutting and burning, and the welding process. Specific task related engineering controls and personal protection measures will be implemented to reduce the potential for lead exposure during the construction and demolition activities. Refer to the SSHSP Attachment E for a copy of the Lead Compliance Plan. 2.1.3 Asbestos Containing Materials (Appendix C BMW Information) Abatement Supplement

This Asbestos Supplement has been prepared in accordance with State regulations and industry standards for complete demolition projects. CWC has included in Section 3.0 of this Work Plan, a detailed description of asbestos abatement activities that CWC with the services of BMW Construction Specialists (BMW) will be implementing for this project. The following means and methods described in Section 3.0 comply with local, State and Federal regulations and address only those items to be removed as part of the dismantling project. Subcontractor licenses, insurance certificates, certifications, ACM Standard Operating Procedures, MSDS Sheets, and employee certifications and medical information are included in Appendix C. 2.1.4 Quality Assurance Project Plan (Appendix D)

CWC will utilize a Quality Assurance Project Plan that includes key issues relating to task and data management on this project. The purpose of this plan is to describe the procedures to be followed in managing the project tasks and the resultant data that is generated during the course of the project. It will also provide measures to ensure the validity and accuracy of each project task and the generated data.

2.1.5 Storm Water Pollution Prevention and Erosion Control Plan (Appendix E) CWC will utilize a Storm Water Prevention and Erosion Control Plan (SWPP/ECP) that includes the requirements and prevention procedures to be utilized and enforced during all work activities to control storm and wash water and prevent sediment erosion. The Plan will demonstrate compliance with the current GEPS - National Pollutant Discharge Elimination System (NPDES) Permit. 2.1.6 Construction Dust Control Plan (Appendix F) CWC has included a nuisance Dust Control Plan that will discuss the procedures and requirements necessary to control fugitive dust emissions during the course of on-site activities. These procedures and requirements will include, at a minimum, the following measures: Monitoring to ensure dust is not leaving the site; Suppressing dust with water using minimal amounts of water; Minimizing vehicular traffic; and enforcing designated traffic routes. (Appendix G)

2.1.7 Odor Control Plan

CWC has included an Odor Control Plan that will discuss the procedures and requirements necessary to control odiferous emissions during the excavation of petroleum impacted soils. These procedures include, but are not limited to the following: Monitoring of soils with an organic vapor analyzer or equivalent

Suppressing odors as outlined in local AQMD requirements Covering stockpiles with visqueen sheeting or odor suppressing liquids

2.1.8 Noise Control Plan (Appendix H) CWC has included a Noise Control Plan to identify and protect employees and subcontractors, site employees and the general public from hazardous and nuisance noise exposures and to prevent hearing loss.

2.1.9 Communication Plan

(Appendix I)

The purpose of the Communication Plan is to identify Project personnel, define their roles in the Project, and develop a clear plan for communications (including verbal and written information, review and distribution, and project meetings) among all Project personnel. The objective is to ensure efficient communication among project personnel and to avoid potential problems associated with insufficient or ineffective communication. 2.1.10 Contract Closeout

CWC will outline the protocol to be utilized for contract closeout or Final Deliverables in accordance with the guidelines noted in the contract documents. After completion of work, CWC will submit a written certification to GEPS acknowledging that the contract documents have been reviewed, the work has been inspected, and that the work is complete with respect to the contract. CWC and GEPS will then perform an inspection to ensure that the work has been completed in accordance with the contract. CWC will provide GEPS with the required documentation for all activities conducted during the completion of the abatement, decommissioning and demolition activities in an Interim Post Closure Report. This includes providing confirmation of the tasks completed, associated disposal and analytical records and a certification that all proposed activities were conducted in accordance with the RFP, and/or

State regulations. Information to be submitted will include, but not be limited to: 2.2 Copies of all job related permits and agency sign-off records Ongoing Compilation of Weekly Summaries Interim and Final Survey Analysis Reports Health & Safety and Environmental Monitoring Logs Asbestos Abatement Final Clearances Fugitive Nuisance Dust Monitoring Logs and Data Utility Disconnects and Utility Cap Locations and Lock Out/Tag Out information Generated Analytical Data Copies of all shipping manifests and waste profiles Certified compaction testing and reporting Photo Documentation As-built and Record Drawings

GENERAL PERMITTING AND NOTIFICATION

Prior to mobilization on-site, CWC will contact the regulatory agencies having jurisdiction over the work activities and acquire all necessary permits and make the necessary notifications for the performance of the work. Copies of permits will be maintained in the filed office trailer and will be included in the Closeout Project Report. 2.3 MOBILIZATION

Following the preconstruction activities, CWC will make preparations for and begin mobilizing to the GEPS facility. One of the first items to be accomplished will be to establish work areas and the CWC field office. Equipment and materials necessary to complete the project will be moved to the facility and staged at predetermined locations within the facility. In addition to the field office, the following work areas will be established: ACM/Chemical Personnel Decontamination Areas; ACM/Chemical Equipment Decontamination Areas; Hazardous and Non-Hazardous Waste Staging/Storage Areas; Product and Decon Water (rinseate) Tank/Drum Storage Areas; Temporary Conveyance Systems for Rinseate and Surface Water;

Equipment and Supplies Laydown Areas; and Demolition Salvage Staging and Loading Areas.

The work areas listed above, as well as other tasks that will be conducted during the mobilization phase of this project, are described in the following sections. 2.3.1 Personnel Decontamination Areas Personnel decontamination areas will be established for work activities that may expose workers to unique safety hazards and/or hazardous levels of chemicals and waste materials. These requirements will be used to determine appropriate personnel protective equipment (PPE) that will be used in each of the separate facility areas during each phase of work. Required PPE, decontamination procedures and personnel decontamination equipment will be identified in the Health & Safety Plan. 2.3.2 Equipment Decontamination Areas Equipment decontamination areas will also be established at predetermined locations. Chemical decontamination will occur in different areas to prevent commingling of waste streams. These areas will only be used for the cleaning of light and heavy equipment (cranes, tracked construction equipment, vehicles, etc.) used during decontamination activities. All decontamination equipment will be cleaned in these areas before leaving the facility. 2.3.3 Rinseate Storage Areas (as required) CWC will utilize drums and or Baker style storage tanks for the storage of decon water and/or rinseate generated as part of decontamination activities. Waste streams will be segregated as necessary depending of generation process. Waste streams will be analyzed and profiled as necessary. CWC assumes that decon/rinseate which meets active NPDES permit requirements can be discharge onsite at a GEPS designated location. Storage of these liquids will be located in agreed locations and the necessary stormwater controls and Best Management Practices (BMP) will be implemented. Existing tanks and lines will be cleaned and used for the temporary storage of

rinseate, but only as a last resort. Staging and laydown areas will be identified throughout the facility which best compliment the completion of the decontamination activities. 2.3.4 Temporary Conveyance Systems for Surface Water (as required) Existing collection trenches and sumps may be used to collect surface water during inclement weather. The locations of these trenches and sumps will be confirmed and identified by CWC during the premobilization activities as well as throughout the completion of on-site work activities. During collection of surface water, this material will be transferred to respective holding tanks with portable pumps, hoses, or vacuum trucks. 2.3.5 Pipe and Equipment Draining Areas (as required) Locations where structures, equipment, and pipes can be placed following initial in-place cleaning will be established. In-place cleaning may include rinsing and/or dry, gross cleaning. The purpose of the areas will be to provide a contained environment where cleaned equipment/material can be placed and residual rinseate allowed to drain, or where further cleaning can be conducted. Specially constructed areas or existing, bermed areas that have been cleared of all equipment and structures will be designated for this purpose. Drains and sumps, already located within these areas, will be used to contain potential rinseate runoff. If additional berms are necessary, a double row of sandbags will be placed in required areas to form a barrier. Plastic sheeting or silt fencing may be used to prevent rinseate from flowing through sandbags berms. 2.3.6 Demolition Salvage Staging and Loading Areas Several demolition salvage, staging and loading areas will be established for cleaned material and equipment. These areas will be accessible to expedite loading and transport activities. Surface cover in these areas will be durable enough to withstand storage and movement of heavy scrap material without breaking apart and creating difficulties when loading the material or impacting the areas.

2.4

UTILITY SYSTEMS IDENTIFICATION AND LOCK-OUT

Prior to the initiation of any field work, existing facility utilities and process piping systems will be identified. These procedures will be conducted with CWC crews and with the assistance of the designated GEPS operations person. It will be necessary to lock-out most of the utilities and process piping in all areas of the plant prior to cleaning and dismantling. CWC crews will determine what systems need to remain active to facilitate the removal of residual products, asbestos containing materials and cleaning and demolition activities in each of the facility areas. A detailed description of utility systems lock-out protocol is included in the SSHSP. Lock-out procedures will generally include the following objectives: Lock-out (close, disconnect, plug, and/or blank) and tagging valves; Lock-out and tagging, or disconnection of electrical systems;

2.5

Capping/plugging of sewer and storm water lines as necessary to complete clearing, or cleaning and, Documentation of utility caps on facility maps. SITE SECURITY

CWC understands that the facility is currently surrounded by security fencing that will prevent unauthorized individuals access to the site. CWC will control access to work areas during operating hours through the monitoring of a single ingress/egress location with mandatory sign-in procedures for all personnel. During off-hours, sensitive work areas will be cordoned off with temporary barricades, delineators and caution tape. 2.6 TEMPORARY FACILITIES AND CONSTRUCTION CONTROL

CWC will establish temporary facilities and construction control procedures to be implemented at the project site. CWC will maintain suitable temporary office space outside work areas to coordinate field construction activities. Adequate sanitary facilities, fences, barricades and scaffolding will be provided as needed. Storage for tools, light equipment and appropriate signs will also be provided. Temporary services will be coordinated with the GEPS representative for existing and future construction activities, demolition activities, and site traffic. 2.6.1 Traffic Control Given the contaminant and volume (i.e., approximately 1,300 tons) of soil that will be removed, the impacted soil will be loaded directly from the excavation areas into awaiting transportation vehicles. It is anticipated that approximately 56 transport truckloads will be needed to haul the impacted soil from the facility. This estimate is based on each truckload weighing 23 tons. The following routes will be followed depending upon the disposal facility to receive the waste material. King George Landfill, Virginia: Exit the site and travel east on East Fort Street Turn right on Lawrence Street, Turn right o Key Highway, Turn right on East McCommas Street, to 95 South to Forestville F, Travel to MD-337 south, to Md-5 south, to US-301 south, Va-205 west to Va-3

west. CWMI, Model City, New York: Exit the site and travel east on East Fort Street Turn right on Lawrence Street, Turn right on Light Street, turns into East Pratt Street; Left on President and follow to Rt. I-83 North, Travel to PA-230 West, to US-22 West, to US 11-North. To PA-I47 North, to I-180 West, to US-15 North, into New York to I-86 West, to I-390 North, to NY-36 North, to NY-63 West, to NY 98 North to I-90 West to I290 West to I-190 North, to Local 190 West, to NY 104 East to Model City. In the event that an alternate route is identified, the contractor will verify the new truck route with GEPS personnel prior to initiating field activities. Onsite traffic control will be the responsibility of the CWC onsite project manager. The coordination of the transportation of impacted soils will be facilitated on a daily basis and arrangements for transport vehicles will be schedule as needed. The average on-site time for the loading of impacted soils will be 30-45 minutes. This will involve, manifesting, loading, tarping, and removal of dust or dirt which may have accumulated on the vehicles. This cleaning activity will be conducted on those trucks leaving the facility with impacted soils. In the event that trucks require staging, a location will be utilized outside of the neighborhood. 2.7 PRECONSTRUCTION MEETING

Once CWC has established temporary support and project controls at the GEPS project site, CWC Project Management will coordinate a site preconstruction meeting to detail the proposed work activities and project scheduling. This meeting will be considered Meeting Number One (1) and will be referenced as such in the meeting minutes deliverables to provided on a weekly basis. Weekly meetings will be designated in numeric succession and logged as such. As discussed in the following Section 2.8, documentation will be submitted 48 hours prior to the following weekly operations meeting. 2.8 INTERIM DELIVERABLES

Once CWC has established operations at the GEPS facility, CWC Project Management will provide for ongoing documentation of daily activities during an organized weekly meeting between CWC Project Management, supporting

subcontractors and GEPS personnel and/or representatives. information to be discussed includes: 3.0 Daily Work Activities 2-week Look Ahead Schedule New Business/Old Business

Weekly

Documentation of Tool-Box Safety Meetings (i.e. hazards, issues, man power) Project Logs Waste Disposal Documentation

ASBESTOS CONTAINING MATERIALS

CWC has subcontracted with BMW Construction Specialists (BWM) to provide the removal of asbestos containing materials from the GEPS, Baltimore, Maryland facility. BWM is considered an integral part of the CWC Team and will be referenced as part of this team. The following details CWCs approach for asbestos abatement. Please note that all asbestos abatement activities will be performed in accordance with the State of Maryland Regulations and OHSA standards. 3.1 GENERAL

3.1.1 Pre-Abatement Inspection CWCs policy, prior to beginning any work area preparation, is to coordinate a thorough walk-through of the intended work areas with GEPS to identify existing conditions of the work areas. During the inspection, any structural or finished surface defects will be documented as a means of determining whether the abatement activity had a negative impact on the building after it has been completed. 3.1.2 Contingency Plans In the event of any emergency such as fire, earthquake, worker injury, etc., a Contingency Plan will be followed to ensure the rapid communication of an emergency situation to project members to affect a swift and safe evacuation of the work area until the emergency has subsided.

CWC will take all necessary precautions to avoid accidents within the work place by anticipating their causes. To prevent the possibility of fire, our team utilizes temporary lighting with protective lens cages, strategic placement of fire extinguishers, Ground Fault Circuit Interruption and worker training. In the event of a fire outside of the work area, an air horn will be sounded by the abatement employee until all employees have vacated the work area. If there is ample time, workers will attempt decontamination through misting or wetting procedures before exiting the work area. In the event of an earthquake, no matter how intense, workers are instructed to exit the work area due to the possibility of power outages, contamination of the shower water source by ruptured sewage lines and possible structural damage. If possible, before leaving, the entrance to the decontamination facility will be taped shut to prevent fiber migration if power to the negative air units is lost. Once it has been confirmed that the structure is safe to re-enter, the workers will do so and resume abatement work. Should a worker be injured inside containment, CWC will take the appropriate course of action depending upon the type of injury involved. For example, if a worker suffers a fall, the team will determine whether the employee can exit the containment under his/her own power. If not, a stretcher or equivalent device will be employed to remove the worker. Decontamination of the worker will be attempted through wetting and misting until emergency personnel arrive. If a worker is stricken with heat stress, the worker will be removed from the work area and given adequate fluids until his/her body temperature has returned to normal. Whenever possible, first aid will be administered from the OSHA approved kit maintained on-site. In order to obtain swift emergency service assistance from the police, fire department or local hospital, a list of emergency telephone numbers will be posted in strategic areas in and around the facility with directions to the nearest telephone. 3.2 ABATEMENT DOCUMENTATION

3.2.1 Daily Entry Logs From the moment the work areas are declared "under containment,"

all workers and authorized visitors are required to sign an entry log upon entering and exiting the containment or work area. Copies of these logs will be provided to the Health & Safety Manager at the end of each shift. 3.2.2 Daily Employee Exposure Monitoring Each day one personal air monitoring sample will be taken for each separate work space and procedure. 3.2.3 Event Reports Any incident involving aberrant behavior on the behalf of project personnel will be considered an event to be documented and investigated until resolved. CWC will document worker behavior (e.g. insubordination) for internal purposes and similar information can be presented to GEPS upon request. 3.2.4 Accident Reports

CWC will thoroughly document all accidents regardless of the degree of injuries sustained for Worker Compensation and internal record keeping purposes. All information leading up to the cause and description of each accident will be documented and will be presented to the Health & Safety Manager. 3.2.5 Discovered Condition Reports If, in the course of abatement activity, a condition is uncovered which significantly affects the scope of work, a report will be completed by the supervisor documenting the extent of the condition, materials involved and any related information. All information recorded will be presented to GEPS for verification. 3.2.6 Site Visitors All visitors will be requested to sign an entry log upon entering and exiting the containment. Visitors will be required to provide written documentation verifying all medical examinations, awareness, medical training and respiratory fit tests have been performed.

3.3

CODES, REGULATIONS AND STANDARDS

3.3.1 Federal, State, and Local Regulations Affecting Work CWC will comply with all applicable local, State, and Federal regulations governing asbestos removal including but not limited to: Environmental Protection Agency (EPA) Regulations for Asbestos (CFR Title 40, part 61) Guidance for Controlling Friable AsbestosContaining Materials in Buildings. Occupational Safety and Health Administration (OSHA) Asbestos Regulations (CFR Title 29, Part 1910.134 Section 1910.1001 and Section 1926.58) National Institute for Occupational Safety and Health (NIOSH) Respiratory Protection... A Guide for the Employee. American National Specification for Air. Standards Institute (ANSI): Commodity

Maryland Department of the Environment Regulating Asbestos in Complete Demolition. Licenses and Registrations

3.3.2

CWCs subcontractor, BMW Construction Specialists, is a licensed asbestos abatement contracting firm in the State of Maryland, Asbestos License No. M21-00-319HA and Maryland Contractor's License number 555788. Copies of BMWs license and registration are included in Appendix C of this Work Plan. 3.3.3 Notifications and Forms All notifications to applicable regulatory agencies will be submitted 10 days prior to the commencement of abatement activities. These notifications include: MDE and EPA Establish disposal site interfacing for waste disposal (friable and

non-friable). 3.3.4 Warning Signs, Labels, and Posters CWC will install OSHA-specified warning signs in English and Spanish around the work space and at every point of potential entry from the outside including the entrance to the Decontamination Facilitys Clean Room. The signs will conform to OSHA requirements with the words Danger, Asbestos Hazard, Do Not Enter. The warning signs will be a bright color so that they will be easily noticeable. The size of the sign and its lettering will be no less than OSHA requirements. CWC will also provide OSHA and DOT-required labels for all plastic bags utilized to transport contaminated material from the work areas to the on-site storage facility. Any other required signs, labels, warnings, and posted instructions that are necessary to protect, inform, and warn workers and visitors of the hazard from asbestos exposure will be provided. Our project team will post in a prominent and convenient place for workers use, a copy of the latest applicable regulations of OSHA, EPA, and NIOSH; and a copy of these specifications and the applicable drawings. 3.4 DETAILED ABATEMENT PROCEDURES

The following abatement activities describe the projected general approach that shall be followed at the various GEPS structures on this project. 3.4.1 General 3.4.1.1 Description of Work

Abatement personnel will furnish labor, materials, facilities, equipment, services, employee training and medical testing, permits, and agreements necessary to perform the work required for asbestos removal in accordance with MDE regulations for asbestos abatement in complete demolition conditions. CWC will perform the work and provide the services listed below: Perform removal of specified asbestos-containing materials (ACM) from designated areas of the project

Remove Thermal System Insulation, friable hazardous ACM waste, using full containment procedures or glovebag removal methods or whole component removal as specified herein. Thoroughly clean the work areas and obtain receipts of final approval from the Asbestos Contractor. Emergency Precautions CWC will notify only parties that are required by law to be notified. CWC will be prepared to administer appropriate first aid to injured personnel at the site after decontamination. Seriously injured personnel will be treated immediately in the work area or evacuated without performing decontamination. When an injury occurs, team members will stop work and implement fiber reduction techniques (e.g., water spraying) until the injured person has been removed from the work area. CWC will post a site safety plan, specific to the facilities on the property, which will include provisions for emergency evacuation from regulated work areas. (See also Contingency Plans.) Asbestos Waste Disposal Procedures

3.4.1.2

3.4.1.3

It will be the responsibility of CWC to dispose of all asbestos waste generated from the abatement activities at the site. CWC will handle the removal of waste from the site, as well as disposal, and manifesting of all waste. CWC will be responsible for handling, packaging, and labeling all waste bags or containers in compliance with the MDE regulations. Only a licensed hazardous waste hauler and designated landfill site will be utilized, conforming to 40 CFR 61.156.

CWC will coordinate the placement of containers to facilitate removal of waste from the facility. Abatement personnel will be responsible for lining each container with six-mil poly sheeting on floor and walls prior to waste loading. Waste Packaging: All waste material will be promptly placed in 6-mil polyethylene bags as it is generated. A sufficient number of waste bags will be located in the immediate work area, and in the equipment room. Packaged waste will be moved from the work area and placed directly in properly prepared waste dumpsters. Waste Labeling: Warning labels, having waterproof print and permanent adhesive, in compliance with OSHA, EPA and DOT requirements, will be affixed to or printed on the sides of all waste bags or transfer containers. Wetting of Waste: A fine water spray will be used to keep waste in containers thoroughly wet at all times. When a waste bag is full, it will be securely sealed with tape or other secure fastener. Waste Container Decontamination and Removal Procedures: The following minimum procedures will be followed whenever containers or equipment are removed from the work area through the Waste Decontamination Facility. The clean room will be considered a holding area only during the period of active waste transfer for the purpose of the loading of carts or drums. Waste removal will not occur during worker shift changes or when workers are showering or changing. Care will be taken to prevent short circuiting and cycling of air outward through the shower and clean room when used for waste removal. Workers will be stationed in each room of the waste decontamination facility to transfer the containers and equipment to or from adjacent sections. These workers will not cross the air locks into the adjacent rooms until the waste or equipment transfer is finished for that period and the workers have gone through decontamination. The workers in the clean room or holding area will enter from uncontaminated areas with appropriate personal

protective equipment; or prior to the start of waste transfer, these workers will exit the work area, fully decontaminated, and subsequently don clean personal protective equipment. External surfaces of contaminated containers and equipment will be cleaned by wet cleaning and/or HEPA-vacuuming in the work area before moving such items into the decontamination facility airlock. Workers will not enter the airlock during this procedure. The containers of waste and the equipment will be removed from the airlock by workers stationed in the washroom during waste removal operations. The cleaned containers of waste and equipment will be placed in uncontaminated leak-tight plastic bags (or 6-mil sheeting if physical characteristics necessitate and permit). Air volumes will be minimized, and the bags or sheeting will be sealed. Items that may puncture or tear the plastic bags or sheeting will be placed in a hard wall container such as a drum, and then be sealed. The clean re-containerized items will be moved into the airlock for subsequent transfer to the holding area. The decontamination room workers will not enter this airlock or the work area until waste removal is finished for the period. Re-containerized items and cleaned equipment will be removed from the airlock to the holding area by workers who have entered from uncontaminated areas with appropriate personal protective equipment. The re-containerized items of waste and cleaned, bagged equipment will be placed in open top, watertight plastic carts. These carts will be held in the holding area pending removal. The carts will be HEPA-vacuumed and wet-cleaned following the removal of the containers of waste from them. Waste Transportation and Disposal: CWC will comply with the current waste handling regulations applicable to each work site. 3.4.2 Products

3.4.2.1 Materials, Tools, and Equipment All materials, tools, and equipment will comply, with relevant federal, state, and local codes. HEPA-Filtered Exhausts: Air inside each asbestos removal work area, requiring containment, will be exhausted to the atmosphere (building exterior) through a High Efficiency Particulate Air (HEPA) filter. One or more HEPA-filtered portable exhaust units will be provided for each work area. Flexible hoses (ducts) of sufficient length will be provided to allow the units to discharge outside of the buildings. Plastic Sheeting and Bags: Will be polyethylene or equivalent with a thickness of at least 6 mil for all applications. Both transparent and opaque plastic will be required, as directed by the Resident Hygienist. Waste disposal bags will be of a 6-mil thickness with appropriate warning labels.

Encapsulants: (see also Encapsulating of ACM) Encapsulating agents will be penetrating or bridging sealants, and will meet the following criteria: They will withstand most impact or abrasion and protect the encapsulant surface. They will have high flame retardant characteristics, and a low toxic fume and smoke emission rating. They will not be noxious or toxic to application workers, or subsequent users of the building. They will have some permeability to water vapor to prevent condensation accumulation, and resists solution by common cleaning agents. They will have acceptable weathering and aging characteristics.

Wetting Agent or Surfactant: Will be 50% polyoxyethylene ester and 50% polyoxyethylene ether, or equivalent, mixed in the proportion of one ounce surfactant per five gallons of water. The material will be odorless, non-flammable, nontoxic, non-irritating, and noncarcinogenic. It will be applied as a mist using a low-pressure airless sprayer recommended by the surfactant manufacturer. Tape and Glue: Will be capable of sealing plastic joints, and attaching plastic to finished surfaces. The bonding strength and resulting seal integrity will not be affected by mist or water, encapsulating agent, or any other materials to be used in the work area. Warning Signs and Labels: Shall comply with 29 CFR 1926.58(K), and all other federal, state, or local codes and regulations. Waste Containers and Transportation: Will be bags, drums or other closed containers, suitable for loading, temporary storage, transit, and unloading of contaminated waste without rupture, or otherwise causing spillage or exposure to persons or emissions to the atmosphere. All containers will be labeled in accordance with OSHA Regulation 29 CFR 1926.58K(2) and 49 CFR Parts 171 and 172, Hazardous Substances:

Final Rule. Respiratory Protection Devices: Will be NIOSH and MSHA-approved, and will comply with all provisions of 29 CFR 1926.58. Fit testing procedures will comply with 29 CFR 1926.58. Provide documentation of fit testing procedure. Electrical Equipment: Will be Underwriters Laboratory listed and approved, and will have ground fault circuit interrupt protection which has been installed by a licensed electrician. Ladders or Scaffolds: Will be OSHA-approved, and be of sufficient dimensions and quantities so that all work surfaces can be easily and safely accessed by workers, and other inspectors. Scaffold joints and ends will be sealed with tape to prevent incursion of asbestos fibers. Brushes: All brushes shall have nylon bristles. Lumber/Plywood: All lumber and plywood supplied by and used by the D&M Group will be fire retardant. 3.4.3 Pre-Asbestos Abatement Preparations for Removal of Friable Asbestos-Containing Building Materials CWC will prepare the work area as described in this section. Preparation work will be performed according to the following general sequence of steps and procedures to ensure that proper containment and protection systems are installed prior to any work that could generate airborne asbestos fibers. The following procedures apply to preparation of structures where friable asbestos containing materials are to be abated. Remove and relocate any non-fixed items. Isolate, clean by HEPA-vacuuming and washing, and seal airtight with plastic. Carefully clean all surfaces in the work area that may be contaminated with any dust or debris by using wet methods and a vacuum equipped with a HEPA-filter.

Cover any windows or other openings with poly sheeting. Erect any required barriers, coverings, or access platforms; post access restriction signs, seal all openings into the work area; install any temporary access openings; poly all floors and walls; protect and cover all fixed items. Install Decontamination Facility and HEPA-exhaust system as described herein. Isolate all electrical systems and provide temporary power and lighting as required for the work area and affected non-work areas.

3.4.4 Isolation of Electrical Systems and Installation of Temporary Power and Lighting The scope of the required electrical isolation and protection work includes isolation and protection of electrical equipment that is in the area from which asbestos must be removed, and could therefore possibly become a hazard through contact or water spray shortcircuiting. Shutdown of electrical circuits will include providing labor to monitor, inspect, and service temporary power circuits, lighting, and equipment as required by local codes and regulations. CWC will provide a Lock Out system on all electrical panels or equipment that will be shutoff during the removal process. Temporary lighting and power systems will meet all OSHA, State and local regulations; temporary lighting levels will meet OSHA requirements and provide surface lighting for nighttime work (if required). Portable tools and appliances protected by an approved system of double insulation need not be grounded. All light and power circuits in the asbestos removal area will be ground fault protected. Extension cords will be the 3-wire type; will be protected from damage; and will not be fastened with staples, hung from nails, or suspended from wires. Splices will have soldered wire connection with insulation equal to the cable. Worn or frayed cords will not be used. Receptacles for attachment plugs will be approved, concealed contact type. Where different voltages, frequencies, or types of current are supplied, receptacles will be of such design that attachment plugs are not interchangeable. Each disconnecting means for motors and appliances and each service feeder or branch circuit at the point where it originates will be legibly marked to indicate its purpose.

3.4.5 Isolation of Work Areas and Installation of Decontamination Facilities

CWC will isolate the work area for the duration of work by completely closing and sealing all openings and doorways into the work area including, but not limited to, heating and ventilation ducts, doorways, windows, floors and ceiling penetrations, and lighting. Isolation/sealing will be accomplished by using two (2) layers of 6-mil plastic sheeting taped securely in place. The work area will be protected and sealed airtight to the extent possible. Emergency and fire exits will be clearly marked and maintained. Isolation Partitions and Barriers - Open doorways, cased openings, windows, and other openings as mandated by project conditions will be sealed airtight with temporary partitions as follows: Openings will be covered with a double layer of plastic sheeting with joints staggered and sealed with tape (black plastic will be used to shield the work area from the public view). Heating, cooling, and ventilating air systems will be isolated to prevent decontamination and fiber dispersal. Dust or debris will be cleaned from all fixed objects, floors, radiators, or other equipment within the work area using HEPAvacuuming equipment and/or wet wiping. Team members will install work area HEPA-filtered exhaust systems as previously specified. Warning signs in English and Spanish will be posted meeting the requirements of OSHA 29 CFR 1926.58(k)(1) and (k)(2)(ii) at the outside doorway to the Decontamination Facility. Warning signs will be readily visible to any person attempting to enter the work area.

3.4.6 Asbestos Removal Under General Containment Procedures: This section covers the removal of asbestos-containing thermal system

insulation. Amended water (wetting agent), mixed and carefully applied using an airless sprayer as specified by the manufacturer, will continuously be used to control the release of asbestos fibers from the friable material prior to and during removal. The amended water will be applied in sufficient quantity to fully penetrate and saturate the friable material prior to its removal. Control procedures will be implemented as previously described. Removal Methods (when applicable): Abatement personnel will wear respirators and protective clothing as previously described throughout all removal, cleanup, and waste handling operations. After large areas of the asbestos material have been fully wetted and tested, the asbestos will be carefully removed in small sections by hand using scrapers or other suitable tools. As the material is removed, it will be promptly wetted and packed into impermeable, labeled 6-mil polyethylene disposal bags. When each bag is full, the packaged material will be sprayed with amended water, sealed and transported to a temporary storage area inside of the work area. The friable material will be repeatedly sprayed to prevent it from drying out. Once the majority of the asbestos is removed, the substrate surface will be scrubbed with a nylon brush or equivalent, and a water spray, and then thoroughly wash it to remove all remaining material. After obtaining approval of the cleaning, abatement personnel will seal all substrate surfaces from which asbestos material was removed with at least one (1) coat of an approved penetrating encapsulant.

Contamination of the work area floor, the exterior of disposal containers, and all other surfaces within the work area will be minimized. At the end of each shift, all surfaces will be cleaned of all materials and then HEPA-vacuumed or wet mopped. The decontamination facility will be wet cleaned using wet cleaning methods upon completion of any waste removal. The decontamination facility will be wet cleaned and HEPAvacuumed, as appropriate, after each shift change.

3.4.7 Asbestos Removal of Class I, Thermal System Insulation as a Whole (Primary Procedure) This section covers the removal of asbestos-containing thermal system joint or pipe insulation as a whole, where full containment procedures are not feasible. Amended water (wetting agent), mixed and carefully applied using an airless sprayer as specified by the manufacturer, will continuously be used to control the release of asbestos fibers from the friable material prior to and during removal. The amended water will be applied in sufficient quantity to fully penetrate and saturate the friable material before it is removed. Wetting will commence prior to removal work to ensure effective saturation. Worker protection will be one-half face negative pressure respirators with dual HEPA-cartridges, and a full body tyvek coveralls for preparation, removal, and final cleaning. Removal Methods: Removal workers will wear respirators and protective clothing as previously described throughout all removal, clean up, and waste handling operations. Place a large 6-mil drop cloth beneath the pipe which will be removed. Utilizing the glove bag procedures, abate the thermal system

insulation from the ends of a manageable section of an insulated pipe to be removed intact. Double wrap the pipe and thermal system insulation with 6-mil plastic and seal seams with duct tape and spray glue. Carefully cut the pipe and lower to the ground. Seal the ends with duct tape and spray glue and label the pipe.

3.4.8 Asbestos Removal Using Glove-Bag Technique (Secondary Procedure) This section covers the removal of asbestos-containing thermal system joint or pipe insulation from above ceiling level or in Hi-Bay areas, using glove bag removal technique, where full containment procedures are not feasible. Amended water mixed and carefully applied using an airless sprayer as specified by the manufacturer, will continuously be used to control the release of asbestos fibers from the friable material prior to and during removal. The amended water will be applied in sufficient quantity to fully penetrate and saturate the friable material before it is removed. Wetting will commence prior to removal work to ensure sufficient saturation. Worker protection will be one-half face negative pressure respirators with dual HEPA-cartridges, and full body tyvek coveralls for preparation, removal, and final cleaning. Removal Method for Thermal System Insulation: Install glove-bag at each removal location. Ensure that glovebag is sealed 6" on either side of asbestos containing joint or pipe insulation. Insert HEPA-vacuum into glovebag port to create negative pressure containment inside the bag. Wet the material inside the bag using amended water. After the material has been thoroughly wetted, carefully slice the

insulation lengthwise, parallel to the pipe. Remove insulation and allow to fall to the bottom of the bag. All contaminated pipe insulation inside the glovebag removal area must be removed. Apply adequate amended water to ensure the waste remains wet at all times. Thoroughly scrub pipe to completely remove all insulation. Continue misting the pipe and inside of the glove-bag during detail cleaning work. Clean inside of glove-bag by misting and wiping sides of bag and moving all debris to bottom of bag. Mist exposed pipe sections or joints with encapsulant. Remove the bag from the cleaned pipe as follows: remove air from the bag using a HEPA vacuum inserted into a side port; gather bag in the center just under the pipe; twist bag and seal around twisted neck portion; hold clean waste container under bag and cut through sealed neck dropping bag directly into clean waste container; remove top portion of bag from pipe; and seal waste container. Thoroughly clean removal area by HEPA vacuuming and wet wiping. Dispose of poly sheeting covering adjacent surfaces. All waste will be double-bagged and placed in properly labeled asbestos waste bags. Workers will dispose of protective clothing after HEPA-vacuuming tyvek suits.

3.4.9 Final Inspection and Testing Following the satisfactory completion of abatement activities, work area isolation barriers will be disassembled and will be properly disposed of as contaminated waste.

3.5 WORKER PROTECTION

The health and safety of abatement personnel is of extreme importance. Therefore, all workers assigned to the abatement crew will be trained and AHERA certified.

3.5.1

Hazardous Waste Workers General site workers (such as equipment operators, laborers and supervisory personnel) have received 40 hours of instruction under the direct supervision of a trained experience supervisor. Other workers on site (unlikely to be exposed to permissible limits) have received 32 hours of instruction. Management and supervisors have received eight hours of specialized training (at the time of job assignment) on topics related to the safety and health program (employee training, personal protective equipment, spill containment, health hazard monitoring). Annually, general site workers and managers/supervisors must receive eight hours of refresher training on respective subjects.

3.5.2 Report of Medical Examinations All asbestos workers will have had a current medical examination on file. The report includes pulmonary function tests and chest x-rays (if applicable). 3.5.3 Personnel Air Sample Results CWC will utilize a certified laboratory to conduct OSHA personnel sample analysis of samples collected within each work area. 3.5.4 Protective Clothing CWC both provides and requires the use of protective clothing, such as coveralls or similar whole-body clothing, head covering, gloves, and foot coverings for any employee exposed to airborne concentrations of asbestos, tremolite, anthophyllite, actinolite or a combination of these minerals that exceed the permissible exposure limit. Protective clothing is disposable. Hard hats and safety shoes as required by safety regulations will be provided. Protective clothing for removal, demolition, and renovation operations is issued prior to entering the work area. Employees are encouraged to strengthen "problem areas" of disposable coveralls at the beginning of each shift. The competent person periodically examines work suits

worn by employees for rips or tears that occur during performances of work. When rips or tears are detected while an employee is working within a negative-pressure enclosure, rips and tears are immediately mended, or the work suit immediately replaced. Reusable footwear, hard hats, and eye protection devices will be left in the Contaminated Equipment Room until the end of the asbestos abatement work, at which time they will be disposed of as ACM waste or transferred to another work area. All disposable protective clothing will be discarded and disposed of as asbestos waste every time the wearer exits from the work space to the outside through decontamination facilities. 3.5.5 Enclosures, Facilities) Showers and Toilets (Decontamination

Decontamination facilities will be located within the area to be abated. The Decontamination Enclosure System for workers and visitors will consist of three adjoining rooms. Clean Room at entrance followed by a Shower Room followed by an Equipment Room leading to the Work Area. The facility will be installed prior to erecting protective coverings and before disturbing any ACM. The Decontamination Facility will be constructed using PVC framing and one layer of 6-mil poly sheeting attached to the ceiling framing. The interior surfaces of the walls, floor, and roof will then be covered with an additional layer of 6-mil poly sheeting sealed water and airtight with duct tape at all overlapping seams. All joints are to be seamless. The entire floor will be covered with two (2) layers of 6-mil poly sheeting turned up 12-16" on the wall layers. An Air Lock is a system permitting ingress and egress without permitting air movement. It consists of two curtained doorways at least eight feet apart where space permits. Each curtained doorway

will be constructed by placing three overlapping sheets of plastic over a framed doorway, securing each along the top of the doorway. The middle sheet will be secured on the other side of the doorway. There are no swinging/closing doors between airlocks. The doors (curtains) will be approximately three (3) feet wide. CWC will provide uncontaminated disposable protective clothing and equipment in sufficient quantities for all workers and visitors. This room will be used by workers and visitors to change from street clothes to disposable protective clothing and gear prior to entering into the contaminated area, and to dress into street clothing after they have showered and dried in the shower room as they exit from the contaminated area. CWC will provide in shower room showering facilities with running water to arranged as to provide complete showering of workers and visitors as they exit from the contaminated area. Connect the shower water drains to a leak-proof pump and commercially manufactured filtering system consisting of at least three (3) filters in series, including a one (1) micron final filter, and an adequately-sized pump. Discharge from this system will be to a location coordinated with the Project Manager. The Equipment Room will be equipped for storage of contaminated clothing and equipment. In this room, workers and visitors will dispose of their disposable protective clothing (except respirators) as they prepare to enter the shower room. Adequate quantities of clean, protected waste bags, filters for the HEPA vacuums and exhaust units, and other tools and equipment necessary for the work will be stored in this room. The Waste Decontamination Facility will be constructed similar to the Decontamination Facility and used solely for decontamination of waste containers, supplies, and equipment. The Waste Decontamination Facility will consist of a serial arrangement of Clean Room, Wash Room and Equipment Room. Smoking, drinking, or eating will not be permitted in the work area, Shower Room or Equipment Room. CWC will post or have available, the following items in the clean room

of the Worker Decontamination Facility or on file in the site trailer/office. A copy of the U.S. Environmental Protection Agency Regulations for Asbestos, 40 CFR 61 Subparts A and M; and a copy of OSHA Asbestos Regulations, 20 CFR 1926.58. A list of telephone numbers for local hospital, location of hospital and/or emergency squad, and local fire department and the name of the designated Building Management staff members. A copy of the asbestos abatement specifications and drawings, if applicable. Name of competent person [as defined in 20 CFR 1926.58(b)] and list of names of Contractors employees conforming to requirements of who will be authorized to enter regulated area. Contractors name, list of Contractors organization chain of command at the construction site, and phone number of responsible representative who may be reached 24 hours a day. A list of telephone numbers and addresses for local hospital and/or emergency squad and local fire department.

Barriers and plastic linings will be effectively sealed and taped at all times and repair damaged barriers, and remedy defects immediately upon discovery. Team members will visually inspect the facility at the beginning of each work period. Emergency and fire exits from the work area and alternative exits satisfactory to local fire officials will be maintained. Exits will be checked daily for exterior blockages or impediments to exiting. 3.5.6 Decontamination Area Except for small scale, short duration operations, CWC will establish a decontamination area that is adjacent and connected to the regulated areas for the decontamination of employees contaminated with asbestos, tremolite, anthophyllite, or actinolite. The decontamination area consists of an equipment room, shower area, and clean room in series. Abatement personnel will ensure that employees enter and exit the regulated area through the decontamination area. 3.5.7 Shower Facilities Where applicable, shower facilities are provided which comply with 29CFR 1910.14(d)(3). The showers will be contiguous both to the equipment room and the clean change room, unless this location is demonstrably infeasible. In such situations, CWC will ensure that employees: Remove asbestos, tremolite, anthophyllite, or actinolite contamination from their work suits using HEPA vacuum before proceeding to the shower that is not contiguous to the work area; or Remove contaminated work suits, don clean work suits, and proceed to a shower that is not contiguous to the work area. The equipment room is supplied with impermeable, labeled bags and containers for the containment and disposal of contaminate protective clothing and equipment.

3.5.8

Clean Rooms CWC will provide a clean change area for employees required to work

in regulated areas or required to wear protective clothing. Change areas are equipped with separate storage facilities for protective clothing and street clothing.

3.6 DECONTAMINATION UNIT(S) 3.6.1 Personnel Decontamination Unit(s) A three-stage personnel decontamination facility will be constructed. The frame of the decontamination facility will be constructed of PVC tubing and wrapped in 6-mil polyethylene sheeting. The individual chambers will be separated by "airlocks" comprised of overlapping plastic sheeting. An asbestos warning sign will be placed at the entrance to the clean room as well as a sign-in roster. 3.6.2 Equipment Decontamination Unit The equipment room or "dirty room" will be equipped with a catch basin (in larger projects) to capture contaminated water run-off while decontaminating equipment with an airless sprayer. This room will also have storage space for hand tools, rubber boots, hard hats, etc. which each worker will bring with him/her when beginning decontamination procedures.

3.7 DECONTAMINATION ENTRY AND EXIT PROCEDURES 3.7.1 Decontamination Entry Procedures

CWC ensures that employees: Enter the decontamination area through the clean room; Remove and deposit street clothing within a locker provided for their use; and Put on protective clothing and respiratory protection before leaving the clean room. Before entering the enclosure, the employees pass through the equipment room.

3.7.2

Decontamination Exit Procedures

CWC ensures that employees: Before leaving the regulated area, employees must remove all gross contamination and debris from their protective clothing. Remove their protective clothing in the equipment room and deposit the clothing in labeled impermeable bags or containers. Employees do not remove their respirators in the equipment room. Employees completely decontaminate and shower prior to entering the clean room. After entering the shower, the employees will shampoo thoroughly while still wearing the respirator, wet their whole body, remove the respirator, shampoo the face and respirator, placing the used filters in a labeled contaminated waste bag, clean the face, entire body and respirator prior to leaving the shower area. After showering, employees enter the clean room and dry off before changing into street clothes.

3.8 CLOSE OUT DOCUMENTATION CWC will provide GEPS with the documentation for all activities conducted during the completion of the asbestos abatement activities. This includes providing confirmation of the tasks completed, air monitoring logs and personnel logs, associated transportation and disposal shipping documents. Information to be submitted will include, but not be limited to: Copies of all job related permits Asbestos monitoring and personnel logs Copies of all shipping manifests

4.0 DECONTAMINATION ACTIVITIES Presented in this section are the Decontamination Means and Methods for handling those items specified in the Project Specifications. The purpose of

this section is to provide a detailed description of the handling of regulated building materials (RBM) and other regulated waste materials (i.e. PCB, AST, impacted debris) to be implemented for this project. CWC has subcontracted with Rose Industrial, an environmental contracting firm to provide all decontamination activities for the removal of RBM and PCB regulated waste materials from the GEPS, Baltimore, Maryland project site. A copy of Rose Industrials appropriate certificates, insurances, and medical documentation for those individuals assigned to this project are included in Appendix J.

4.1 UTILITIES 4.1.1 Domestic Water

The piping run(s) to be drained and removed will be located and marked to facilitate pipe decommissioning. The specific piping unit will be severed and drained utilizing safety and standard removal procedures. CWC will utilize a State of Maryland licensed plumber to cap the water lines near the completion of the demolition phase. Utilizing existing utility drawings, the water valve which will render a particular area of concern non-operational will be located and identified. The valve will be shut by physically closing the gate valve, however; if that is not feasible, an alternative method is to install a fire plug into the line and bolt it to the line in a manner that effectively caps the subject line. Upon completion of draining and capping operations, lines will be left in place for removal during the general demolition. The piping will be staged and disposed of as demolition debris at the King George Landfill. 4.1.2 Natural Gas

Natural gas piping to be evacuated and removed will be located and marked. Disconnection of the isolated piping will proceed utilizing all safety and standard removal procedures for the piping. As scheduled by the Project Manager, the disconnection of the natural gas supply will be completed within the general work area of demolition. The Project Manager will coordinate with the local Gas Company regarding gas meter location, main supply line evacuation, and Gas Company protocol of evacuating lines. CWC personnel will evaluate each system to determine if the piping will be recycled or salvaged. Salvageable items will be removed following general demolition. Recycled piping will be staged in designated areas for eventual sizing and scrap recycling. 4.1.3 Sewer Lines

The existing sewer drain line will be excavated by CWC for off-site disposal. Fluids will be pumped or otherwise placed into 55-gallon drums for waste characterization. The line will be capped by a State of

Maryland licensed plumber.

4.1.4

Overhead Electrical Lines

Existing on the facility is the electrical distribution by overhead electrical lines. Once the utilities have been disconnected, CWC will coordinate the severance of the power at the point of facility entrance with the Baltimore Gas and Electric, the local electrical company. Temporary service will be established for CWC utilization for support of on-site temporary facilities. Once the power has been disconnected, CWC will proceed with the removal of the supporting electrical poles and electrical wiring. The wires and wooden poles will be sent offsite for disposal at the King George landfill. 4.2 REGULATED BUILDING MATERIALS 4.2.1 Mercury Containing Items

Disconnection of the isolated item will proceed utilizing all safety and standard removal procedures for the mercury-containing item. Personnel will proceed to carefully remove mercury-containing equipment such as thermostats, thermometers or light switches. The item will be isolated and the wires clipped or housing dismantled and the removed glass ampoules will be placed in 2-gallon spill proof plastic container containing several inches of absorbent media. This media will cushion the ampoules during facility transportation. Upon completion of the days activities, the 2-gallon spill proof plastic container will then be taken to the temporary waste storage area for proper packaging. When personnel have removed all mercury items from the facility, the remaining void space in the container will be filled with absorbent. The lid will then be secured and the drum labeled with the generator information and proper shipping name. The mercury waste stream will be staged for eventual transportation and disposal to a GEPS approved disposal/recycling facility. Mercury spill kit will be made available to all site personnel involved in the removal of mercury containing items. Mercury waste will be labeled with the standard HAZARDOUS WASTE label, with the description of Mercury Contained in Manufactured Articles, 8, UN2809, P.G.III, (Mercury). This labeling and manifest

description will be required for any shipment of drummed Mercury waste. 4.2.2 Freon (CFC) Removal

The specific item containing chlorofluorocarbons (CFC) (i.e. air conditioning units and chillers) will be located and accessed for recovery. The CFC containing equipment will be disconnected utilizing the proper safety and standard removal procedures. Air conditioners and chillers will be

disconnected from their power sources. This severance of utility lines includes, but is not limited to, electrical, sewer, water and gas (if applicable). The access service valve(s) will be located for mating with the CFC evacuation system unit. CWC will provide certified refrigerant recovery personnel to facilitate evacuation and recovery of the refrigerant. The removal of the CFC will be performed by accessing the HVAC system. The CFC refrigerant is then removed under vacuum, separated and condensed into a liquid, which is then pumped into the certified cylinder tank. The tank is protected against overfilling by a float switch, which is located within the condenser unit. Compressor oil, if any, which is accumulated during CFC removal will be containerized in 5-gallon plastic spill-proof containers labeled HVAC compressor oil and at the end of each work day the accumulated oil will be consolidated in a DOT approved 55-gallon 17H steel drum for off-site recycling. Personnel removing CFCs from units located on roofs, or aboveground, will utilize scaffolding or motorized lifts to assist in handling the recovery operations as well as the handling of empty and/or full cylinders. During handling of these tanks with motorized lifts, tanks will be chained to the lift basket and secured to prevent tanks from becoming dislodged and impaired. Fall protection procedures will be utilized pursuant to the project. During temporary storage, cylinders will be secured by lock and chain to eliminate the chance for cylinder damage. Prior to shipment of any refrigerant cylinders, a sample label will be submitted to GEPS for review. After being labeled, the tank will be transported to the temporary waste storage until shipment is arranged. CWC personnel will document on an internal waste removal log, the quantity in pounds of CFCs recovered from the various units. Once the unit is cleared, the unit will be tagged with an agreed upon colored tag indicating CFCs Removed. If said equipment can be sold as a packaged unit, any operating fluids included with the machinery will not be removed prior to sell. The CWC will utilize purchase agreements with provisions to include these items, if approved by GEPS. 4.2.3 Smoke Detector Removal

The smoke detectors to be removed will be located, identified, and

cleared of all obstructions. Disconnection of the isolated smoke detector will proceed utilizing all safety and standard removal procedures. This will include disconnecting the electrical feed to the section of the building where the removals are taking place. The electrical wires feeding the isolated smoke detector will be clipped, and the unit removed. No attempt will be made to open the sealed canister containing the radioactive component. The removed smoke detectors will be placed into manufacture provided boxes suitable for the shipping of the smoke detector devices. Drums will not be used for shipment of smoke detectors. The box will contain 35 to 40 devices with each device being placed into a sealable plastic bag as recommended by the manufacturer. Boxes will be labeled Smoke Detectors and secured in the temporary waste storage area. CWC will notify the GEPS representative as to the quantity of containers. Shipment will be in compliance with DOT regulations and manufacturers recommendations. Personnel will be instructed on the type and style of radioactive smoke detectors. If other detectors are discovered, this will be brought to the attention of the CWC Project Manager. Personnel performing other site work will be made aware of detectors of concern during tailgate meetings by discussion and pictures. If detectors are encountered during subsequent site work, the units will be removed as outlined above. Shipments of these devices will involve the acquisition of a Return Material Authorization (RMA) number provided by the manufacturers. This RMA number will be considered the acceptance and tracking number by the manufacture. Shipment will be conducted as directed by the device manufacturer. 4.2.4 Self Luminous Exit Signs (if encountered)

The self-luminous exit signs to be removed will be located, identified, and cleared of all obstructions. Disconnection of the signs will proceed utilizing all safety and standard removal procedures. This will include disconnecting the electrical feed to the section of the building where the removals are taking place. The unit will be unbolted from the wall. No attempt will be made to open the body of the exit sign and precautions will be taken by personnel to ensure that the sign is not dropped.

Removed exit signs will be placed into manufacture provided boxes suitable for the shipping of the devices. The boxes will contain 10 devices with each device being placed into a sealable plastic bag as recommended by the manufacturer. Boxes will be labeled Exit Signs and secured in the temporary waste storage area. CWC will notify the GEPS representative as to the quantity of containers. Shipment will be in compliance with DOT regulations and manufacturers recommendations. Workers will be instructed on the type and style of radioactive exit signs. If other signs are discovered, this will be brought to the attention of the CWC Project Manager. Personnel performing other site work will be made aware of the exit signs during tailgate meetings by discussion and pictures. If signs are encountered during subsequent site work, the units will be removed as outlined above. Shipments of these devices will involve the acquisition of a Return Material Authorization (RMA) number provided by the manufacturers. This RMA number will be considered the acceptance and tracking number by the manufacture. Shipment will be conducted as directed by the device manufacturer.

4.2.5

Lead Acid Batteries

The battery to be removed will be located and the metal housing cover opened for access. Disconnection of the battery will proceed utilizing all safety and standard removal procedures and is to include cutting electrical lines to the battery and removing the isolated battery. As removal of batteries proceeds in an individual building, the removed batteries will be staged at the temporary waste storage area for segregation and packaging. Packaging will consist of placement of the undamaged batteries onto wooden pallets. If a battery is found to be cracked, leaking, or if the integrity of the battery is potentially impaired, it will be containerized in designated poly drums or 5-gallon containers at the temporary waste storage area, for eventual consolidation for shipment off-site. All drums will be packaged and labeled according to State or Federal requirements. All personnel handling lead acid batteries will be outfitted with appropriate safety gear including chemical resistant Polyvinyl Chloride (PVC) knee boots, PVC on polyester Acid Suits, PVC gloves, and hard hats with goggles and face shield or as required by the SSHSP. Any spills will be neutralized with baking soda and water. 4.2.6 Fluorescent Bulbs and HID Lamps

Disconnection of the lights will proceed utilizing all safety and standard removal procedures, including disconnection of electrical feed to system and removal of electrical breakers for lighting systems. After the electrical system has been de-energized, the plastic cover for the light fixture, if present, will be removed and placed on the floor, at which time the exposed fluorescent light tubes will be removed by hand and placed in a rubber/plastic container for temporary storage during removal. CWC personnel will utilize rolling scaffolding or ladders to support workers on single story floors. For ceilings of greater height, a motorized lift will be utilized to assist in retrieving light tubes and other lighting fixtures. Health and safety issues related to overhead work will be addressed in the SSHSP. As temporary containers become full, they will be transferred to a central location within the building. The tubes will then be placed