Professional Documents

Culture Documents

Trip Relays Operating Manual

Trip Relays Operating Manual

Uploaded by

rajaramdossdossOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trip Relays Operating Manual

Trip Relays Operating Manual

Uploaded by

rajaramdossdossCopyright:

Available Formats

VA TECH TRANSMISSION & DISTRIBUTION

VA TECH Reyrolle ACP Ltd

Tripping relays type TR - operating recommendations

DESCRIPTION

Type TR are a range of attracted armature, high speed, trip relays. A product designation number following the "TR" identifies the particular features of the model. Product designations:First digit:Specification TR1** - Low burden to ES1 48-4 EB1 TR2** - High burden to ES1 48-4 EB2 TR312 - NGC (CEGB) TDM 5/11, low burden trip relay TR431 - NGC (CEGB) P11 (1978), switching relay TR9** - Special purpose relays If damage has been sustained a claim should immediately be made against the carrier, also inform Reyrolle Protection and the nearest Reyrolle agent. When not immediately required return the relay to its carton and store in a clean, dry place.

PRELIMINARY TESTS

Check that the operating voltage (and reset voltage if a reset coil is fitted) are correct for the auxiliary voltage to be used. In some instances relays are to be used with the coil in series with a voltage dropper resistor, this is advised on our Order Acknowledgement and shown on the relay label as "+Ext R", suitable resistors are supplied with the relay, ensure that such resistors are mounted vertical, are securely fixed, wired to the correct relay, and the correct relay terminals. Isolate from the auxiliary supply(s) by removing fuses and links as necessary. Physically check the wiring to the relay terminals for security and to prove that it is wired correctly to the circuit schematic/wiring diagrams.

Second digit:- Contact reset 1 - Self reset 2 - Hand reset 3 - Electrical reset 4 - Hand and electrical reset Third digit:Operating coil cut-off 1 - Instantaneous 2 - Economy 3 - Time delay 4 - Time delay economy

INSULATION TESTS

Using a 500V insulation test set:a) Connect all relay terminals together and measure the resistance to earth. b) Connect the d.c. input terminals together and measure the resistance between these terminals and all other terminals connected together and to earth.

SAFETY

The commissioning and future maintenance of this equipment should only be carried out by skilled personnel trained in protective relay operation and capable of observing all the necessary safety precautions and regulations appropriate to this equipment and also the associated primary plant. Equipment should be isolated from auxiliary supplies and the circuit breaker trip circuit prior to commencing any work on an installed product.

c) Connect the relay output contacts together and measure the resistance between these terminals and all other terminals connected together including earth. A value of 2.5 to 3.0 megohms obtained from the above tests is considered satisfactory a value of less than 1.0 megohm is not satisfactory, and the cause of such a low reading should be determined and corrected.

UNPACKING, HANDLING & STORAGE

On receipt unpack the relay and inspect for any obvious damage. It is not normally necessary to remove the relay from its polythene bag unless some damage is suspected or if it is required for immediate use.

REYROLLE

Tripping relays type TR - operating recommendations

MECHANICAL SETTINGS

It should not be necessary to adjust settings during routine tests unless parts have been replaced or other repairs carried out. Adjustment of one setting will often influence another, therefore all settings must be checked after the final adjustment. The Table of Mechanical Settings provides the basic settings necessary before the final settings are applied to the relay to obtain the performance requirements. The mechanical settings given are generally minimum values. Contacts Contact tips are fine silver on copper and should only be burnished if any pitting has occurred. Contact pressures

CONTACT STACK ASSEMBLY

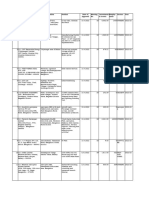

Rated Voltage V d.c. 30 48 125

EB1 Minimum Current (mA) 10 10 25

EB2 Minimum Current (mA) 20 20 50

POWER FREQUENCY TESTS

Relays should withstand: 2.0kV rms 50Hz applied for 1 minute between: a) Coil and contacts connected together and earth b) Coil to contacts and earth connected together. 1.0 kV rms 50 Hz applied for 1 minute across normally open contacts.

are set by gentle pressure with contact setting pliers near to the contact stack assembly, during this operation avoid putting any stress on the contact actuating comb. Contact pressures should be measured using an accurate gram gauge at the tip of the contact leaf.

FRAME FLAG

ELECTRICAL TESTS

Check that the relay operates over its operating range, it should operate smoothly and the armature go fully home. Operating Range:Operate coil, 50% to 120% of rated voltage Electrically reset relays:Reset coil, 50% to 120% of rated voltage Timing Operating time is measured at rated voltage, it is to be less than 10ms from switch on to first touch of normally open contacts. TR112 & TR212 Reset Voltage. The relay must reset when the applied voltage is reduced to not less than 5% of rated voltage. If necessary the residual screw can be adjusted to achieve the required drop-off. TR214 The operating range of the delayed reset element is 45% to 120% of rated voltage.

3 2 4 Make 1 2

SCREW & LOCK WASHER COIL

ARMATURE RESIDUAL PIP

Major component parts of a typical attracted armarture relay.

Mechanical settings, TR112, TR212 & TR214 Residual gap measured at top of core, mm Armature gap measured at residual pip, mm a) Clearance between comb and moving contact, mm 3 Break contact b) Force to separate closed contacts, gms c) Force required to lift fixed contact off its backing strip, gms d) Contact separation, minimum in mm a) Remaining armature travel, measured at the residual pip, minimum in mm b) Contact separation, minimum in mm d) Force required to lift the fixed contact off its backing strip, gms 0.15 2.2 0.1-0.2 12 min 10 min 1.8 0.4 1.8

contact c) Force required to lift moving contact off the comb, gms 10 min 16 min

Mechanical settings, TR121, TR131, TR141, TR221, TR231& TR241 1 Residual gap, these relays must have a plain armature. The armature MUST NOT have a residual pip or a tapped hole for a residual screw Latch setting, between core and armature, adjust latch screw to allow it to just engage the latch block, mm Armature gap measured at residual pip, mm a) Clearance between comb and moving contact, mm 4 Break contact b) Force to separate closed contacts, gms c) Force required to lift fixed contact off its backing strip, gms d) Contact separation, minimum in mm

zero 0.1 1.8 0.1-0.2 12 min 10 min 1.8 0.4 1.8

Reset time is to be within the limits of 1.8 to 2.6 seconds. This time is measured at rated voltage and between switch off and the re-opening of normally open contacts. Minimum Operating Current Measure the current taken immediately prior to pick up and ensure that it is greater than the values shown in the following table.

5 Make

a) Remaining armature travel, measured at the top edge of the core, minimum in mm b) Contact separation, minimum in mm d) Force required to lift the fixed contact off its backing strip, gms

contact c) Force required to lift moving contact off the comb, gms 10 min 16 min 12min 1.7

6 Series a) Force at moving contact tip to open contact, gms break contact b) Contact separation, minimum in mm

VA TECH TRANSMISSION & DISTRIBUTION

VA TECH REYROLLE ACP LTD, PO Box 8, North Farm Road, Hebburn, Tyne & Wear NE31 1TZ, England. Tel: +44 (0)191 401 1111 Fax: +44 (0)191 401 5575

You might also like

- Body Electrical SystemDocument360 pagesBody Electrical Systemsebastião SantosNo ratings yet

- FL10 - 3 - FUN - SM - AEN - 120110 CDocument137 pagesFL10 - 3 - FUN - SM - AEN - 120110 Craver1213100% (1)

- E P1 KH2 EJAZai CCVZ G1 KW1600900047Document35 pagesE P1 KH2 EJAZai CCVZ G1 KW1600900047RosNo ratings yet

- Iron Rich Foods List of Foods HiDocument6 pagesIron Rich Foods List of Foods Hikkamal600No ratings yet

- Marshall MG100HDFX Owners Manual PDFDocument6 pagesMarshall MG100HDFX Owners Manual PDFALNo ratings yet

- Contactor and StarterDocument106 pagesContactor and StarterththeeNo ratings yet

- Tektronix 576 Curve Tracer Operation and Service ManualDocument251 pagesTektronix 576 Curve Tracer Operation and Service Manualmunnizza64100% (3)

- Bts Code FaultDocument11 pagesBts Code FaultChejoPSNo ratings yet

- Oltc RTCCDocument6 pagesOltc RTCCSuresh Kumar VengaliNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Frame 9e Gas Turbine PlantDocument12 pagesFrame 9e Gas Turbine Plantkoohestani_afshin100% (1)

- HVAC CalculationDocument1 pageHVAC CalculationbradalbiNo ratings yet

- Omega Matrix 45 Users ManualDocument92 pagesOmega Matrix 45 Users Manualamro galibNo ratings yet

- Aut Section 0 - PMSDocument44 pagesAut Section 0 - PMShari95No ratings yet

- ABB SACE Tmax XT Series - IEC - TECHNICAL CHARACTERISTICSDocument412 pagesABB SACE Tmax XT Series - IEC - TECHNICAL CHARACTERISTICSIoannis PerperisNo ratings yet

- A PRESENTATION On Modular Mini Refinery Project PDFDocument28 pagesA PRESENTATION On Modular Mini Refinery Project PDFrashidulNo ratings yet

- OGO Dual Mode MAP-MAF Sensor EnhancerDocument5 pagesOGO Dual Mode MAP-MAF Sensor EnhancerDotunder GroundNo ratings yet

- EON15-G2: Technical ManualDocument21 pagesEON15-G2: Technical Manualr3loop100% (1)

- SolkorR RF Op RecsDocument14 pagesSolkorR RF Op Recsrashid rahmanNo ratings yet

- C.T Requirements For VATECH Prot Products Dec03Document11 pagesC.T Requirements For VATECH Prot Products Dec03gavinilaaNo ratings yet

- Harmonic Filtering ReactorsDocument6 pagesHarmonic Filtering Reactorsvicky_doshi096004No ratings yet

- AstraApr2003 PDFDocument302 pagesAstraApr2003 PDFNeodan_2008No ratings yet

- AVR-4310CI - 4310 - AVC-4310 (v.6) (SM)Document211 pagesAVR-4310CI - 4310 - AVC-4310 (v.6) (SM)Roberd MihailovNo ratings yet

- Magnat Ultra 4000Document13 pagesMagnat Ultra 4000irfz44No ratings yet

- ES Series Hardware Manual170413Document64 pagesES Series Hardware Manual170413Oscar MontañezNo ratings yet

- Phase Locked LoopDocument4 pagesPhase Locked LoopsagarduttaNo ratings yet

- Automatic Voltage Regulator Reg D E.eberleDocument28 pagesAutomatic Voltage Regulator Reg D E.eberleAnkur_soniNo ratings yet

- Basic Calculation of DOLDocument4 pagesBasic Calculation of DOLumerNo ratings yet

- Obs EURDocument4 pagesObs EURramonpardovzNo ratings yet

- Regulators: Integrated Circuits GroupDocument1 pageRegulators: Integrated Circuits GroupKSNo ratings yet

- Ups SL500Document82 pagesUps SL500semen1963No ratings yet

- PID Buck-BoostDocument8 pagesPID Buck-BoostIvan RahmanNo ratings yet

- 2m214 MagnetronDocument14 pages2m214 MagnetronecherodrigoNo ratings yet

- Modified 0-30V - 0-3A Variable Power Supply - Rev.2Document2 pagesModified 0-30V - 0-3A Variable Power Supply - Rev.2Manuel Cereijo NeiraNo ratings yet

- Samsung Plasma Pn42a450p1Document76 pagesSamsung Plasma Pn42a450p1videoson100% (3)

- Owner'S Manual TG1000i: Digital GeneratorDocument37 pagesOwner'S Manual TG1000i: Digital GeneratoraidaNo ratings yet

- Viewer 2 EngDocument35 pagesViewer 2 EngChamara JanithNo ratings yet

- Px-777p Service ManualDocument30 pagesPx-777p Service ManualLennertNo ratings yet

- Sony XM-D400P5 Car Power Amplifier SMDocument22 pagesSony XM-D400P5 Car Power Amplifier SMRoger Martínez Bermúdez100% (1)

- Amp Kicker 350x4Document28 pagesAmp Kicker 350x4Luis AyalaNo ratings yet

- Eng Silovie TransformatoriDocument28 pagesEng Silovie TransformatoriSameh Rashad AhmedNo ratings yet

- Sony KDL 42W800A42W801A42W807A47W800A47W801A47W807A55W800A55W801A55W807A L3Document34 pagesSony KDL 42W800A42W801A42W807A47W800A47W801A47W807A55W800A55W801A55W807A L3pasantito100% (1)

- L9235F - Car Alternator Voltage RegulatorDocument11 pagesL9235F - Car Alternator Voltage Regulatorlongtrandang5867No ratings yet

- REF7541a SMDocument29 pagesREF7541a SMslickwhb707No ratings yet

- Car BaseDocument44 pagesCar BaseLaimis KarnyzasNo ratings yet

- Alçalma Kartları JeppDocument1,289 pagesAlçalma Kartları JeppferkutNo ratings yet

- LG 32LG80FR PDFDocument32 pagesLG 32LG80FR PDFboroda241067% (3)

- DSO 138 Oscilloscope UserManual 138 New SDocument4 pagesDSO 138 Oscilloscope UserManual 138 New SSinghPKNo ratings yet

- SM PromigEvolution V1.0ENDocument32 pagesSM PromigEvolution V1.0ENValiBardaNo ratings yet

- 29fu1rg ZK CW 91aDocument20 pages29fu1rg ZK CW 91aNina PankovskaNo ratings yet

- Philips+PL13 16 PDFDocument106 pagesPhilips+PL13 16 PDFFernando SotoNo ratings yet

- 42LS3450, 345S, 345TDocument53 pages42LS3450, 345S, 345TAndres Fermin OchoaNo ratings yet

- IP5305 Datasheet v1.0 - enDocument13 pagesIP5305 Datasheet v1.0 - enKevin Yang YangNo ratings yet

- Jbl-GTO504 CarampDocument27 pagesJbl-GTO504 CarampAndrea FaddaNo ratings yet

- EPRC ST10 ControllerDocument5 pagesEPRC ST10 ControllerZait IepurasNo ratings yet

- 7PG15 - TR: Answers For EnergyDocument4 pages7PG15 - TR: Answers For Energyahmedmaged88No ratings yet

- 96dcs - Siemens Xr152 - 7pg17Document8 pages96dcs - Siemens Xr152 - 7pg17Mohd Ghazali Mohd NorNo ratings yet

- 1-1 Safety PrecautionsDocument2 pages1-1 Safety PrecautionsRaymundo Moran LopezNo ratings yet

- 1-1 Safety PrecautionsDocument2 pages1-1 Safety Precautionsvladimir FamiliyNo ratings yet

- SyncMaster 150TDocument41 pagesSyncMaster 150TSilviu AnghelacheNo ratings yet

- Gh17ls Es LCD Monitor SMDocument36 pagesGh17ls Es LCD Monitor SMmimelendezaNo ratings yet

- Service: ManualDocument58 pagesService: ManualCaptain444No ratings yet

- Samsung 151s (GH15LS)Document25 pagesSamsung 151s (GH15LS)aaaaannnnn100% (2)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Factorization Method PDFDocument12 pagesFactorization Method PDFArifsalimNo ratings yet

- Cable Serial - USB MicomDocument18 pagesCable Serial - USB Micomrofer_2005No ratings yet

- 2MARKDocument19 pages2MARKkkamal600No ratings yet

- Iron Rich FoodDocument12 pagesIron Rich Foodkkamal600No ratings yet

- Current Transformer Requirements Fro VA Tech RelaysDocument7 pagesCurrent Transformer Requirements Fro VA Tech Relayskkamal600No ratings yet

- Trip Relay ManualDocument2 pagesTrip Relay Manualkkamal600No ratings yet

- Charger M HDocument4 pagesCharger M HgeorgeNo ratings yet

- Half Wave RactifierDocument3 pagesHalf Wave RactifierGAMMA GAMINGNo ratings yet

- 3 - Electrode Boilers Introduction - IAPWS Workshop 2022 - AddisonDocument26 pages3 - Electrode Boilers Introduction - IAPWS Workshop 2022 - AddisonAnnelize Schoeman TrollipNo ratings yet

- Grade 8 Science - Table of ContentsDocument3 pagesGrade 8 Science - Table of ContentsClarence VilbarNo ratings yet

- Guide To EPA Tier 4 Emissions Limits LEXE0152 01Document4 pagesGuide To EPA Tier 4 Emissions Limits LEXE0152 01Sixto Guarniz AnticonaNo ratings yet

- E12686-1601-YC21-11-04 Low Voltage Distribution Overview PDFDocument1 pageE12686-1601-YC21-11-04 Low Voltage Distribution Overview PDFthanhNo ratings yet

- Babcock EICDocument2 pagesBabcock EICsl73No ratings yet

- Windmilling: by Vignesh BhatDocument8 pagesWindmilling: by Vignesh BhatVignesh MaratheNo ratings yet

- Power System Statistics 41st Edition PDFDocument83 pagesPower System Statistics 41st Edition PDFYahya DarNo ratings yet

- Ass. # 4 ACDCDocument10 pagesAss. # 4 ACDCmjbicaldoNo ratings yet

- 7UG Monitoring RelaysDocument10 pages7UG Monitoring RelaysRoy VNo ratings yet

- Low Voltage Fixed and Automatic Power Factor Correction SystemsDocument6 pagesLow Voltage Fixed and Automatic Power Factor Correction Systemszabiruddin786No ratings yet

- Thomas Ackermann, Ph.D. - Selected PublicationsDocument3 pagesThomas Ackermann, Ph.D. - Selected PublicationshmitlarNo ratings yet

- 057 2015 en GL ThermalPower WEBDocument16 pages057 2015 en GL ThermalPower WEBmisthahNo ratings yet

- Report Transient Analysis2Document4 pagesReport Transient Analysis2Diego F RodríguezNo ratings yet

- Data in BriefDocument16 pagesData in BriefJuan QuispeNo ratings yet

- How To Start Preparing For IIT JEE From Class 10 - 2 Year Study PlanDocument10 pagesHow To Start Preparing For IIT JEE From Class 10 - 2 Year Study PlanMurali Karthik VNo ratings yet

- Bushing SensorsDocument2 pagesBushing SensorsAgus AchoNo ratings yet

- MSEDCL - Final Order Case No 19 of 2012Document352 pagesMSEDCL - Final Order Case No 19 of 2012hardeep08No ratings yet

- GenEd 7Document22 pagesGenEd 7Leih Anne Quezon AnonuevoNo ratings yet

- Ece Lab Manual - MiteDocument44 pagesEce Lab Manual - MiteSubuddhi DamodarNo ratings yet

- SHLCCapprovedprojectssince 58 TH SHLCCmeetingDocument7 pagesSHLCCapprovedprojectssince 58 TH SHLCCmeetingfelixfperiaNo ratings yet

- Neraca Massa Dan Energi n0.18 Hal 446Document9 pagesNeraca Massa Dan Energi n0.18 Hal 446GalangsetyoNo ratings yet

- A Synchronous Motor From A Hammond OrganDocument8 pagesA Synchronous Motor From A Hammond Organsiva prakashNo ratings yet

- Fiksna Kompenzacija TransformatorDocument3 pagesFiksna Kompenzacija Transformatorts45306No ratings yet