Professional Documents

Culture Documents

Rug Osita

Rug Osita

Uploaded by

lavius_mCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rug Osita

Rug Osita

Uploaded by

lavius_mCopyright:

Available Formats

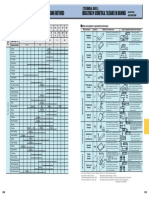

SURFACE ROUGHNESS

Categories of surface roughness

TECHNICAL DATA

Excerpt from JIS B 0601(1994)and JIS B 0031(1994)

TECHNICAL DRAWINGS

TECHNICAL DATA

METHOD OF INDICATING SURFACE TEXTURE ON DRAWINGS

Excerpt from JIS Z B 0031(1994)

Positions of respective indicating symbols relative to indicating symbol of surface

Each grain surface position is indicated as shown in Fig. 1.This includes surface roughness, cut-off value or reference length, processing method, symbol of direction of lay, surface waviness, etc.

Fig. 1 Legend a :Value of Ra b :Processing method

b f c g

Definitions and indications for surface roughness parameters for industrial products) specified. They are arithmetical mean roughness Ra) ( are ( , maximum height Ry)ten-point mean roughness Rz) mean spacing of profile irregularities Sm)mean spacing of local peaks of the profile S) ( , ( , ( , ( and profile bearing length ratio tp)Surface roughness is given as the arithmetical mean value for a randomly sampled area. [Mean center line ( . roughness Ra 75) defined in the annexes of JIS B 0031 and JIS B 0061]. ( is Typical ways for obtaining surface roughness Arithmetical mean roughness Ra) (

A section of standard length is sampled from the mean line on the roughness chart. The mean line is laid on a Cartesian coordinate system wherein the mean line runs in the direction of the x-axis and magnification is the y-axis.The value obtained with the formula on the right is expressed in micrometer (Om)when y=f(a) . Y

m

c :Cutoff value. Evaluation length c :Reference length. Evaluation length d :Symbol of direction of lay f :Parameter other than Ra With tp, parameter/cutoff level) ( g :Surface waviness according to JIS B 0610) (

Ra= r

f( x ) d x

a e d

c g e d

Ra

X r

Note: Items other than a and f are added as necessary. Reference:The location of lay of e in Fig. 1.is given as the finish allowance in ISO 1302. Symbol Meaning Parallel to the projected surface on which the direction of lay of the cutting blade is indicated. (ex) Shaped surface Figure

IExamples indicating surface texture on drawing

Indicating symbol of surface

Maximum peak Ry) (

A section of standard length is sampled from the mean line on the roughness chart. The distance between the peaks and valleys of the sampled line is measured in the y direction. The value is expressed in micrometer Om) ( .

Note:To obtain Ry, sample only the standard length. The part, where peaks and valleys are wide enough to be interpreted as scratches, should be avoided.

m

Rp Ry

Direction of lay of cutting blade

Rv

Indicating symbol of surface requiring removal press

Ry=Rp+Rv

Ten-point mean roughness Rz) (

Yp 1

m

Yp 2 Yp4 Yp 5 Yp 3

A section of standard length is sampled from the mean line on the roughness chart. The distance between the peaks and valleys of the sampled line is measured in the y direction. Then, the average peak is obtained among 5 tallest peaks Yp) as ( , is the average valley between 5 lowest valleys Yv) ( . The sum of these two values is expressed in micrometer Om) ( .

Perpendicular to the projected surface on which the direction of lay of the cutting blade is indicated. (ex) Shaped surface when viewed ( from the side)machined or cyli, ndrical ground surface. Intersection of two diagonal lines on the projected surface on which the direction of lay of the cutting blade is indicated. (ex) Honing finished surface

Indicating symbol of surface on which no removal process is permitted

Direction of lay of cutting blade

Y V1

Y V2

Y V3

Y V4

Y V5

Rz=

Yp1+Yp2+Yp3+Yp4+Yp 5 + Yv1+Yv 2+Yv 3+Yv 4+Yv 5

Examples indicating the upper limits of Ra

(a) 25 (b) 6.3 (c) 25

5

Yp1, Yp2, Yp3, Yp4, Yp5: Tallest 5 peaks within sample Yv1, Yv2, Yv3, Yv4, Yv5: Lowest 5 peaks within sample

Direction of lay of cutting blade

25 6.3 25

Reference:Relationship between arithmetical mean roughness Ra) conventional symbols ( and

Arithmetical mean roughness Ra Preferred number series 0.012 0.025 0.05 0.1 0.2 0.4 0.8 1.6 3.2 6.3 12.5 25 50 100 a a a a a a a a a a a a a a

Cut-off value c(mm)

Max. height Ry

Ten-point mean roughness Rz

Indication of surface texture on drawings

Preferred number series 0.05 0.1 0.2 0.4 0.8 s s s s s 0.05 0.1 0.2 0.4 0.8 z z z z z

Standard length of RyCRz r (mm) 0.08 0.25

Triangular indication

0.08 0.25 0.012 ~ 0.2

Multidirectional intersection or nondirectional point on the projected surface on which the direction of lay of the cutting blade is indicated. (ex) Rapping finished surface, super finished surface, face milled or end milled surface in surfacing feed direction Concentric circles roughly centered on the same on the surface on which the direction of lay of the cutting blade is indicated. (ex) Facing surface

Examples indicating direction of lay

Examples indicating the upper limit and lower limit of Ra

(a) 6.3 1.6 6.3 1.6 (b)

0.8

0.4 3.2 12.5 50

~ ~ ~ ~

1.6 6.3 25 100

1.6 s 3.2 s 6.3 s 12.5 s 25 s

1.6 z 3.2 z 6.3 z 12.5 z 25 z 50 100 200 400 z z z z

0.8

0.25 8

0.25 8 ~

50 100

200 400

s s s s

Radiating shape roughly centered on the same point on the surface on which the direction of lay of the cutting blade is indicated.

Examples indicating processing method

(a) Front milled 3.2 3.2 (b) M

GThe interdependence for 3 classes is not strictly enforced. GThe evaluation length of Ra, Ry and Rz:Five times the cut-off value standard length respectively.

1167

1168

You might also like

- Force UsersDocument64 pagesForce UsersLuftWulf100% (7)

- John Deere Design, Process, and Assembly ReviewDocument33 pagesJohn Deere Design, Process, and Assembly ReviewcucuNo ratings yet

- General Tolerances To DIN ISO 2768 T1 and T2Document2 pagesGeneral Tolerances To DIN ISO 2768 T1 and T2manageieNo ratings yet

- Iso 15330 en PDFDocument6 pagesIso 15330 en PDFScube engineersNo ratings yet

- Gauge BlockDocument32 pagesGauge Blocksava88100% (1)

- Taoism and Chinese Religion (PDFDrive)Document620 pagesTaoism and Chinese Religion (PDFDrive)Daniel Lions100% (1)

- MSS-SP-112 (1999)Document9 pagesMSS-SP-112 (1999)mubs997100% (1)

- Foreword: ISO 7044:2012 (En) Prevailing Torque Type All-Metal Hexagon Nuts With Flange, Style 2 - Product Grades A and BDocument4 pagesForeword: ISO 7044:2012 (En) Prevailing Torque Type All-Metal Hexagon Nuts With Flange, Style 2 - Product Grades A and BMarcelo KleinNo ratings yet

- Surface Texture SymbolDocument1 pageSurface Texture SymbolSrinivas RaoNo ratings yet

- Engineering Material Specification: Printed Copies Are UncontrolledDocument6 pagesEngineering Material Specification: Printed Copies Are UncontrolledRicardo VitorianoNo ratings yet

- DIN13 ISO Metric Threads enDocument1 pageDIN13 ISO Metric Threads enwagner jr100% (1)

- Beat Sheet For FilmDocument7 pagesBeat Sheet For Filmphileasfogg760No ratings yet

- DinDocument1 pageDinMelissa SmithNo ratings yet

- DIN ISO Equivalent FastenersDocument12 pagesDIN ISO Equivalent FastenersGunnie PandherNo ratings yet

- Mws Che Ode TXT Runge4th ExamplesDocument6 pagesMws Che Ode TXT Runge4th ExamplesDheiver SantosNo ratings yet

- Ford Worldwide Fastener Standard: Printed Copies Are UncontrolledDocument7 pagesFord Worldwide Fastener Standard: Printed Copies Are Uncontrolledferhat aydoganNo ratings yet

- ISO-10664Document10 pagesISO-10664Daniel Quijada LucarioNo ratings yet

- Welding Machine Validation Check ListDocument4 pagesWelding Machine Validation Check ListAnilkumar G NairNo ratings yet

- ISO 1302 DIN 4768 Comparison of Surface Roughness Values - Stainless Steel T PDFDocument2 pagesISO 1302 DIN 4768 Comparison of Surface Roughness Values - Stainless Steel T PDFgalvaosilva33% (3)

- SAE J1926, MS 16142 - CuttersDocument11 pagesSAE J1926, MS 16142 - CutterspbsurfNo ratings yet

- Standard Machining Tolerance JIS B 0405Document6 pagesStandard Machining Tolerance JIS B 0405fsijestNo ratings yet

- Metric Tolerance ChartDocument6 pagesMetric Tolerance ChartVinoth Sang100% (1)

- General Tolerances - DIN - ISO - 2768 PDFDocument2 pagesGeneral Tolerances - DIN - ISO - 2768 PDFHenrique MarquesNo ratings yet

- EN10034 Beams Rolling TolerancesDocument2 pagesEN10034 Beams Rolling Tolerancesrameshdatta100% (1)

- JIS B0419-1991 (Dung Sai Kich Thuoc)Document1 pageJIS B0419-1991 (Dung Sai Kich Thuoc)Giang Nguyễn BáNo ratings yet

- Loreal StrategyDocument13 pagesLoreal StrategyManpreet ChadhaNo ratings yet

- Domex Welding PDFDocument16 pagesDomex Welding PDFAgourame Abderrahmane100% (1)

- Asme 46.1 2001Document25 pagesAsme 46.1 2001jr_satish6965No ratings yet

- DIN 6930-2 Stamped Steel Parts Part 2 General TolerancesDocument17 pagesDIN 6930-2 Stamped Steel Parts Part 2 General TolerancespopoNo ratings yet

- En 10051 PDFDocument2 pagesEn 10051 PDFSrikanth Reddy0% (1)

- Iso Tolerances Din Iso 2768 - 1, Din Iso 2768 - 2Document3 pagesIso Tolerances Din Iso 2768 - 1, Din Iso 2768 - 2mameeran100% (2)

- Iso 4200 en PDFDocument6 pagesIso 4200 en PDFJorge Miguel GonçalvesNo ratings yet

- EN 10025: 2004 Is The New European Standard For Structural Steel.Document6 pagesEN 10025: 2004 Is The New European Standard For Structural Steel.Alin DavidNo ratings yet

- Locking Fasteners HandbookDocument48 pagesLocking Fasteners HandbookMomchil YordanovNo ratings yet

- Technical Handbook Stainless Steel WeldingDocument92 pagesTechnical Handbook Stainless Steel WeldingRamesh sivanNo ratings yet

- Sankashtahara Ganapathi Vratham - EnglishDocument4 pagesSankashtahara Ganapathi Vratham - EnglishGopinath Akundy100% (1)

- Measuring Surface Roughness: Drawing Symbols (DIN EN ISO 1302:2002)Document1 pageMeasuring Surface Roughness: Drawing Symbols (DIN EN ISO 1302:2002)SudhagarNo ratings yet

- Iso 10511 Nut Dimensions - RefDocument2 pagesIso 10511 Nut Dimensions - Refkumarkk1969No ratings yet

- Din 6930 Octobre 2011Document18 pagesDin 6930 Octobre 2011Franck Savignard100% (1)

- Surface RoughnessDocument1 pageSurface Roughnessapi-3848892100% (2)

- Din en Iso 1302Document51 pagesDin en Iso 1302vijayanth gNo ratings yet

- Mechanical Properties - Bolt, Nut, FastenersDocument4 pagesMechanical Properties - Bolt, Nut, FastenersmegatornadoNo ratings yet

- Tolerance of Position (TOP) - 1Document34 pagesTolerance of Position (TOP) - 1maddy_scribdNo ratings yet

- Ilnas-En Iso 19598:2016Document8 pagesIlnas-En Iso 19598:2016Victor ParvanNo ratings yet

- Aisi 1018Document1 pageAisi 10188085roNo ratings yet

- Mechanical Properties: Steel NutsDocument1 pageMechanical Properties: Steel NutsJoseph BookerNo ratings yet

- Vdocuments - MX Din 405 Universo For Knuckle Thread Din 405Document7 pagesVdocuments - MX Din 405 Universo For Knuckle Thread Din 405wauwio1906No ratings yet

- Iso Metric 32Document2 pagesIso Metric 32rahul caddNo ratings yet

- General Tolerances For Linear and Angular Dimnsions (Din Iso 2768 t1)Document1 pageGeneral Tolerances For Linear and Angular Dimnsions (Din Iso 2768 t1)VIVEK UPADHYAYNo ratings yet

- Din en 10139 1997 PDFDocument28 pagesDin en 10139 1997 PDFYogesh AnapNo ratings yet

- Fastener PDFDocument12 pagesFastener PDFdiegomilitojNo ratings yet

- ISO - TR - 20173 - 2009 - EN - PDF For Material GroupingDocument11 pagesISO - TR - 20173 - 2009 - EN - PDF For Material GroupingS.K.AGRAWALNo ratings yet

- Pre-Load For BoltDocument6 pagesPre-Load For BoltJ.GuerhardNo ratings yet

- GD & TDocument63 pagesGD & THemanth KumarNo ratings yet

- Is 15582 2005Document17 pagesIs 15582 2005sarath6725No ratings yet

- Harmonized "Cluster" Document: Fasteners Property Classes of Special ServiceDocument7 pagesHarmonized "Cluster" Document: Fasteners Property Classes of Special ServiceIBRNo ratings yet

- Ford 970Document4 pagesFord 970amanNo ratings yet

- Surface Roughness Drawing Indications of Surface TextureDocument1 pageSurface Roughness Drawing Indications of Surface TextureSIVA 1010No ratings yet

- Surface RoughnessDocument1 pageSurface RoughnesswholenumberNo ratings yet

- Surface Roughness JIS B 0601 (1994)Document1 pageSurface Roughness JIS B 0601 (1994)Tú Nguyễn MinhNo ratings yet

- pr1169 1170 PDFDocument1 pagepr1169 1170 PDFrahulmuleNo ratings yet

- Scrap Retention DiesDocument1 pageScrap Retention DiesPeter NomikosNo ratings yet

- T BEAM Rectangular Beam 3sections FinalDocument24 pagesT BEAM Rectangular Beam 3sections FinalDipanjan MitraNo ratings yet

- Project Doc. No. Prepared Date Title Design of Rectangular Beams Revision Checked DateDocument1 pageProject Doc. No. Prepared Date Title Design of Rectangular Beams Revision Checked DateGovendan GopalakrishnanNo ratings yet

- T2265 PDFDocument0 pagesT2265 PDFMerlin PokamNo ratings yet

- Jonaxx Trading Corporation 1ST PageDocument1 pageJonaxx Trading Corporation 1ST PageRona Karylle Pamaran DeCastroNo ratings yet

- 2014 Organizational Behavior 7th Edition Test BankDocument24 pages2014 Organizational Behavior 7th Edition Test BankAndrewFoleydegk100% (34)

- Welch DryDocument6 pagesWelch DryRyanRRNo ratings yet

- A Digital Synchronous Sequential Circuit Is Shown in Figure Q1.1Document5 pagesA Digital Synchronous Sequential Circuit Is Shown in Figure Q1.1Orim AzizNo ratings yet

- Sup-Ec8.0 Ec Controller User ManualDocument24 pagesSup-Ec8.0 Ec Controller User Manualjaime hernandezNo ratings yet

- Honeywell GLAC01A4J DatasheetDocument52 pagesHoneywell GLAC01A4J DatasheetFranco MaderaNo ratings yet

- 1 s2.0 S1198743X17305268 MainDocument14 pages1 s2.0 S1198743X17305268 MainAizaz HassanNo ratings yet

- Concrete Tech and Design.1-10Document10 pagesConcrete Tech and Design.1-10Debendra Dev KhanalNo ratings yet

- RevolutionDocument8 pagesRevolutionpedram vakiliNo ratings yet

- 1.1 - Length and Time Igcse - Cie - PhysicsDocument12 pages1.1 - Length and Time Igcse - Cie - Physicszeinazad00No ratings yet

- Delhi, India: A Case Study of Refugees in TownsDocument15 pagesDelhi, India: A Case Study of Refugees in TownsGait CorporationNo ratings yet

- 04 Make or Buy AnalysisDocument9 pages04 Make or Buy AnalysisMnM -No ratings yet

- Expression of Offering Help: Dinda Lana Estetika 2201417023Document8 pagesExpression of Offering Help: Dinda Lana Estetika 2201417023Dinda LanaNo ratings yet

- 3 HR Frame WorksheetDocument3 pages3 HR Frame Worksheetapi-538591755No ratings yet

- A Nietzsche Reader Paperback FriedrichDocument2 pagesA Nietzsche Reader Paperback FriedrichEvan SandhoefnerNo ratings yet

- A Study On Employee Empowerment: February 2022Document9 pagesA Study On Employee Empowerment: February 2022venkatNo ratings yet

- ReligionDocument42 pagesReligionRica ChavezNo ratings yet

- Total Tube Length Reduced: Clamp CylinderDocument25 pagesTotal Tube Length Reduced: Clamp CylinderHoàng ThếNo ratings yet

- Emah Shae Food GuideDocument1 pageEmah Shae Food Guidesharonross100% (2)

- MS 500 QuestionsDocument7 pagesMS 500 QuestionsSubramanian ParthibanNo ratings yet

- Metric Units and Prefixes and Their RelationshipDocument4 pagesMetric Units and Prefixes and Their RelationshipKristineFayeSegadorCajetasNo ratings yet

- Chat GPTDocument2 pagesChat GPTGerardoMadrizNo ratings yet

- DLL 27Document14 pagesDLL 27CLARISSA TAGUBANo ratings yet