Professional Documents

Culture Documents

John Deere Design, Process, and Assembly Review

Uploaded by

cucuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

John Deere Design, Process, and Assembly Review

Uploaded by

cucuCopyright:

Available Formats

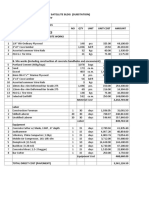

JOHN DEERE DESIGN, PROCESS, and ASSEMBLY REVIEW

Supplier

Date Supplier Name

Number:

Product

PDP/OFP Supplier Location

Group

ECN or SCR Part Number Rev. Part Description QPL Previous Part number

Number

ATTENDANCE "Review Attendees (Required “sign-off” in Bold if affected) ATTENDANCE

Required Functional Area to hold DPAR Optional Functional Area

Design Engineer Production Employee

Quality Engineer Factory Safety and Ergonomics

Supply Management Specialist Environmental Engineer

Supplier Representative Product Safety

Materials Engineer (QPL 3 & 4) PV&V Engineer

Manufacturing Engineer Other representatives

Applicable Documents:

EQP201 DPAR Procedure

F-DCO-233-01 Part Level Quality Planning form

JDS-G223 Supplier Quality Manual and Supplier Forms

Meeting Notes Template

The list of items below should be considered when conducting a DPAR. Documentation of the DPAR results should be recorded in the on-line tool.

C = Complete; O = Open; N = Not Applicable

F201.1.2 Check List do DPAR

Revisão: 1 DESCRIPTION C-O-N RESPONSIBILITY COMMENTS

Elaboração: Eduardo Correa

1 DESIGNAprovação:

REVIEW (Print or Model)

Luís Morcelli

1.1 Verify that title block information is complete and drawing is at the latest revision

and addresses all known issues identified through:

- FMEAs – system, design and process

- Design Reviews – system level

- Design Reviews - sensing systems (for any assembly utilizing a sensor)

- Functional Geometry Review

- Manufacturing Process Development

1.2 Confirm that drawing / model meets:

- GD&T requirements

- Tolerances for manufacturability

- Functional requirements

- Standards (Paint, cleanliness, appearance, etc.)

- BOM accuracy

1.3 Confirm material requirements

1.4 Review John Deere / Supplier PV&V test plan

1.5 Review Product KCs

2 SUPPLIER / INTERNAL MANUFACTURING PROCESS REVIEW

2.1 Additional processes - for checklist items related to specific processes such as

welding, casting, heat treat, painting, plating, etc., go to the "Additional Link to Additional Processes section

Processes" section.

2.2 Additonal part types - for checklist items related to specific part types such as

electrical components, axles, brakes, hydraulic components, etc., go to the Link to Additional Part Types section

"Additional Part Types" section.

2.2 Discuss process flow chart of the manufacturing process.

2.3 Determine what measuring equipment gages, test fixtures, etc. are required

2.4 Review supplier designated Process KCs and appropriate Process capability and

Gage R&R plan for Process and Product KC's.

2.5 Review PFMEA high RPNs and mitigation strategy.

2.6 Verify control plan status and plans.

566944092.xlsx Page 1 of 33 Print Date: 12/27/2021

JOHN DEERE DESIGN, PROCESS, and ASSEMBLY REVIEW

Supplier

Date Supplier Name

Number:

2.7 Verify work instruction status and plans.

2.8 Review need for assembly fixtures and tools. Also review supplier material

handling plan.

566944092.xlsx Page 2 of 33 Print Date: 12/27/2021

JOHN DEERE DESIGN, PROCESS, and ASSEMBLY REVIEW

Supplier

Date Supplier Name

Number:

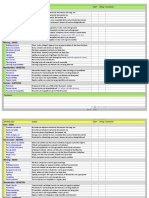

3 JOHN DEERE ASSEMBLY REVIEW

3.1 Review manufacturing process for final assembly

- Fastener and torque requirements

- Mistake proofing opportunities

3.2 Determine what measuring equipment gages, test fixtures, etc. are required

3.3 Review assembly KCs/Critical processes and appropriate process capability and

Gage R&R plan.

3.4 Discuss End of the Line and in-process test plan, monitoring and process control

methods for complex assemblies.

(e.g.pumps, valves, manifolds, engines, transmission, gear box, motors)

3.5 Review material handling systems.

4 PACKAGING REVIEW

4.1 Review requirements for packaging / returnable containers to include labeling of

the country of origin and location. What are standard order quantities?

4.2 Review the need for temporary sealing for the wash or paint process

4.3 Review packaging and shipping protection requirements to ensure cleanliness

requirements and possible contamination problems including rust proofing

4.4 Review part orientation and presentation in the container, including methods to

remove or reposition dunnage

4.5 Review container size and type, and part quantity (layout and material

replenishment planning).

5 MISCELLANEOUS ITEMS REVIEW

5.1 Review cost targets and opportunties for cost reduction

5.2 Verify and document service parts requirements.

(Service parts require disposable packaging, special packaging and paint)

5.3 Review to ensure the part or assembly does not contain substances in excess of

the amounts set forth on the John Deere Restricted Materials List (e.g. asbestos,

lead in paint)

5.4 Verify that the supplier can meet the drawing specification of JDM H31 –

Chemical Restrictions at the Homogeneous Material Level

5.5 Review all software requirement specifications

5.6 Review need for experimental parts

5.7 Determine if a supplier audit / visit is required and target date determined

6 REVIEW OF QUALITY PLAN DEPLOYMENT AND PPAP

6.1 Are Tier II suppliers applicable:

If yes, discuss Tier II PPAP expectations and if PVA or visit is needed

6.2 Discuss and confirm PPAP requirements as per QPL including any special

requirements. Include child part PPAP requirements. Add any special

requirements to the comments column.

TOOLING RELEASE PLAN

Part Number Revision Tooling Description Tooling Cost Release Tooling (Y/N)

566944092.xlsx Page 3 of 33 Print Date: 12/27/2021

JOHN DEERE DESIGN, PROCESS, and ASSEMBLY REVIEW

Supplier

Date Supplier Name

Number:

SCHEDULE PLAN

Item Lead time (days) Date Comments

Today's Date 12/27/2021

Prints to COMPLETE 12/27/2021

Tooling PO Release 12/27/2021

Purchase Order sent to supplier 12/27/2021

Supplier PPAP parts and paperwork submitted 12/27/2021

Production Part Approval Process (PPAP) approval 12/27/2021

First production order 12/27/2021

ACTION ITEMS TO BE ENTERED INTO NCCA:

Line NCCA number ACTION / STATUS Champion Primary investigator Verifier Target Due date

item

DPAR STATUS OPEN Completion Date

566944092.xlsx Page 4 of 33 Print Date: 12/27/2021

DESCRIPTION C-O-N

A SPECIFIC REVIEW FOR CASTING PARTS

B SPECIFIC REVIEW FOR WELDED PARTS

C SPECIFIC REVIEW FOR HEAT TREATMENT

D SPECIFIC REVIEW FOR PLATED PARTS

E SPECIFIC REVIEW FOR PART CLEANLINESS

F SPECIFIC REVIEW FOR FORGINGS

G SPECIFIC REVIEW FOR MACHINED PARTS

H SPECIFIC REVIEW FOR PAINTED PARTS

I SPECIFIC REVIEW FOR POWDER COATED METALS

J SPECIFIC REVIEW FOR PLASTIC PARTS

RESPONSIBILITY COMMENTS

DESCRIPTION C-O-N

A SPECIFIC REVIEW FOR ELECTRICAL COMPONENTS

B SPECIFIC REVIEW FOR AXLES/GEARBOXES/TRANSMISSIONS

C SPECIFIC REVIEW FOR BRAKES

D SPECIFIC REVIEW FOR CABS

E SPECIFIC REVIEW FOR ROLL-OVER PROTECTION SYSTEMS (ROPS)

F SPECIFIC REVIEW FOR ENGINES

G SPECIFIC REVIEW FOR HYDRAULIC COMPONENTS

H SPECIFIC REVIEW FOR LABELS

I SPECIFIC REVIEW FOR SEATS

J SPECIFIC REVIEW FOR SHEET METAL PARTS

K SPECIFIC REVIEW FOR CLUTCHES

RESPONSIBILITY COMMENTS

Date

Notes

TITLE ORIGINATOR_USERID ISSUE_CREATE_DATE D0_DATE UNIT_CODE

12/27/21

12/27/21

12/27/21

12/27/21

Future enhancemen

12/27/21

12/27/21

12/27/21

12/27/21

available 15 Novem

12/27/21

12/27/21

12/27/21

12/27/21

12/27/21

12/27/21

12/27/21

12/27/21

12/27/21

This will allow DPAR action i

spreadsheet to be imported to

create ISSUES

DATASOURCE RESPONSIBLE_BUSINESS_MODULE SOURCE

Z_AUTO_CREATED_ISSUE

Z_AUTO_CREATED_ISSUE

Z_AUTO_CREATED_ISSUE

Z_AUTO_CREATED_ISSUE

ncement to NCCA

Z_AUTO_CREATED_ISSUE

Z_AUTO_CREATED_ISSUE

Z_AUTO_CREATED_ISSUE

Z_AUTO_CREATED_ISSUE

5 November 2016

Z_AUTO_CREATED_ISSUE

Z_AUTO_CREATED_ISSUE

Z_AUTO_CREATED_ISSUE

Z_AUTO_CREATED_ISSUE

Z_AUTO_CREATED_ISSUE

Z_AUTO_CREATED_ISSUE

Z_AUTO_CREATED_ISSUE

Z_AUTO_CREATED_ISSUE

Z_AUTO_CREATED_ISSUE

DPAR action items from this

e imported to NCCA to

SOURCE_IDENTIFIER PROJECT KEY_PART_NUMBER IS_SUPPLIER_RELATED_ISSUE SUPPLIER_NUMBER

DEPARTMENT_RESPONSIBLE SEVERITY_RATING LT_IMPLEMENTATION_TARGET_DATE

VERIFIER_USERID CHAMPION_USERID PRIMARY_INVESTIGATOR_USERID

SECONDARY_INVESTIGATOR_USERID PROBLEM_SOURCE UNIT_CODE_PRODUCT_ID_MODEL_ID

ISSUE_IDENTIFICATION Additional Issue Identification/Short Term Action

Change History

JOHN DEERE DESIGN, PROCESS, and ASS

CHANGE HISTORY

Date Division Who Made Changes Criteria Owner(s)

1-Jul-16 Enterprise Daniel Falkenstein Enterprise Strategic Quality

566944092.xlsx Page 32 of 33 Print Date: 12/27/2021

Change History

N, PROCESS, and ASSEMBLY REVIEW

CHANGE HISTORY

Reason for Change

New - substantially revised from the previous version

566944092.xlsx Page 33 of 33 Print Date: 12/27/2021

You might also like

- Design & Process ReviewDocument33 pagesDesign & Process ReviewFarm AgrobotNo ratings yet

- Foreword: ISO 7044:2012 (En) Prevailing Torque Type All-Metal Hexagon Nuts With Flange, Style 2 - Product Grades A and BDocument4 pagesForeword: ISO 7044:2012 (En) Prevailing Torque Type All-Metal Hexagon Nuts With Flange, Style 2 - Product Grades A and BMarcelo KleinNo ratings yet

- Simha Lagna: First House Ruled by The Planet Sun (LEO) : The 1st House Known As The Ascendant orDocument3 pagesSimha Lagna: First House Ruled by The Planet Sun (LEO) : The 1st House Known As The Ascendant orRahulshah1984No ratings yet

- Catalan NumbersDocument17 pagesCatalan NumbersVishal GuptaNo ratings yet

- MIL Aa 58092Document6 pagesMIL Aa 58092sanjay_aranakeNo ratings yet

- Wilsons LTD Nickel Alloy AMS 5662 Alloy 718 450Document3 pagesWilsons LTD Nickel Alloy AMS 5662 Alloy 718 450Ray Mark De TorresNo ratings yet

- VW 011 03Document22 pagesVW 011 03Alexandre UrquizaNo ratings yet

- Next Generation Mobile Network PosterDocument1 pageNext Generation Mobile Network PosterTarik Kazaz100% (2)

- Material Specification: Specification: Revision Date: Revision LevelDocument2 pagesMaterial Specification: Specification: Revision Date: Revision LevelReginaldo Santos100% (1)

- PROPOSED ARFF BUILDINGDocument27 pagesPROPOSED ARFF BUILDINGDale Bryan S DalmacioNo ratings yet

- Time May Not Exist - Tim Folger in DiscoverDocument3 pagesTime May Not Exist - Tim Folger in DiscoverTrevor Allen100% (5)

- Apqp Stages AIAG-1Document49 pagesApqp Stages AIAG-1Jose Antonio Santoyo RayaNo ratings yet

- BS 970-3 1991 PDFDocument38 pagesBS 970-3 1991 PDFNav TalukdarNo ratings yet

- Involute Spline and Serration Gages and Gaging: SupersededDocument21 pagesInvolute Spline and Serration Gages and Gaging: Supersededvijay pawarNo ratings yet

- Green Building by Superadobe TechnologyDocument22 pagesGreen Building by Superadobe TechnologySivaramakrishnaNalluri67% (3)

- Title: Cover-Fr Under No. 75892 NDS01Document7 pagesTitle: Cover-Fr Under No. 75892 NDS01Diego Camargo100% (1)

- Cathodic Electrocoating of Body Skin Parts Made From Aluminum Semi-Finished ProductsDocument5 pagesCathodic Electrocoating of Body Skin Parts Made From Aluminum Semi-Finished ProductsMaryana c100% (1)

- Esbm5a-B 1n261-s Aa RSWDocument37 pagesEsbm5a-B 1n261-s Aa RSWChandrajeet Shelke50% (2)

- Din 6930 Octobre 2011Document18 pagesDin 6930 Octobre 2011Franck Savignard100% (1)

- BMS 0000147Document15 pagesBMS 0000147方綵樺No ratings yet

- Geomet 500 PDFDocument2 pagesGeomet 500 PDFKaran Chadha100% (1)

- Ford-WSS-M1A365-A11A23 - (2017-09) - (Steel-CR-HR-Low Carbon) 9pgDocument9 pagesFord-WSS-M1A365-A11A23 - (2017-09) - (Steel-CR-HR-Low Carbon) 9pgdpfloresNo ratings yet

- The World's Choice For Corrosion Protection The World's Choice For Corrosion ProtectionDocument2 pagesThe World's Choice For Corrosion Protection The World's Choice For Corrosion ProtectionSquidwardNo ratings yet

- External GDiMPS Training 1804c and New Portal - V18.5 (Effective 14OCT2019)Document91 pagesExternal GDiMPS Training 1804c and New Portal - V18.5 (Effective 14OCT2019)Karina Valenzuela100% (1)

- JSG 0116-1996Document158 pagesJSG 0116-1996Loknath MathnikarNo ratings yet

- 2430 & TB2448 ComarisionDocument6 pages2430 & TB2448 ComarisionpiyushNo ratings yet

- Hes B008-03 Hexagon NutsDocument5 pagesHes B008-03 Hexagon NutsPreetam KumarNo ratings yet

- MM15M3Document40 pagesMM15M3StoneAge1No ratings yet

- Accuracy of Frame Side Member TolerancesDocument8 pagesAccuracy of Frame Side Member TolerancesAkmal NizametdinovNo ratings yet

- VW 50019 PDFDocument4 pagesVW 50019 PDFSujay Nahalde100% (1)

- 8400-A - External Painting & Protective CoatingsDocument19 pages8400-A - External Painting & Protective Coatingsamalhaj2013No ratings yet

- Acrylonitrile Butadiene Styrene - UV Stabilized and General Purpose, Heat StabilizedDocument7 pagesAcrylonitrile Butadiene Styrene - UV Stabilized and General Purpose, Heat StabilizedJefferson CruzNo ratings yet

- Code Wizard Workshop NotesDocument29 pagesCode Wizard Workshop NotesRenato SimõesNo ratings yet

- ESJU5A-1N261-AB - 2020-03-31 (Kaynak Speği) TRDocument37 pagesESJU5A-1N261-AB - 2020-03-31 (Kaynak Speği) TRMuhammet AşıkNo ratings yet

- Hollow Steel Sections Testing SchemeDocument6 pagesHollow Steel Sections Testing SchemeTARUNKUMARNo ratings yet

- Bs 443Document20 pagesBs 443abhijit1602No ratings yet

- DIN EN 10243-2-2000 钢热模锻件.尺寸公差.第2部分在水平锻造机器上的顶锻Document35 pagesDIN EN 10243-2-2000 钢热模锻件.尺寸公差.第2部分在水平锻造机器上的顶锻williansakuma0% (1)

- TSB1503G 9 P 1Document18 pagesTSB1503G 9 P 1kk_pammu_915176926No ratings yet

- Bosch Norm 4 497 037 031 - N67F - CM-ZN-2Document18 pagesBosch Norm 4 497 037 031 - N67F - CM-ZN-2davi mooreNo ratings yet

- LINER JIG BUSHES AND DRILL BUSHES SPECIFICATIONSDocument2 pagesLINER JIG BUSHES AND DRILL BUSHES SPECIFICATIONSVinod GuptaNo ratings yet

- Sae J82-2013Document6 pagesSae J82-2013Marcos RosenbergNo ratings yet

- International Standard: Stainless Steels For Springs - WireDocument8 pagesInternational Standard: Stainless Steels For Springs - WireAfzal ImamNo ratings yet

- Mil STD 810h HumidityDocument22 pagesMil STD 810h Humiditymariela baigorriaNo ratings yet

- Iso 05002-2013Document20 pagesIso 05002-2013mystar_bkc100% (1)

- VW01155 en 2005-02-01Document8 pagesVW01155 en 2005-02-01koalaboi0% (1)

- Jdma17 2Document8 pagesJdma17 2qualidadesider0% (1)

- Measuring The Force-Displacement of A Membrane Switch: Standard Test Method ForDocument5 pagesMeasuring The Force-Displacement of A Membrane Switch: Standard Test Method Formasoud132No ratings yet

- Posmac: Posco Magnesium Aluminium Alloy Coating ProductDocument48 pagesPosmac: Posco Magnesium Aluminium Alloy Coating ProductCatherine DussnNo ratings yet

- 2370 Ed1 ENDocument5 pages2370 Ed1 ENanhthoNo ratings yet

- Iso228-1 00Document12 pagesIso228-1 00Jorge AldasNo ratings yet

- Iso 4162Document2 pagesIso 4162Guillermo TorresNo ratings yet

- Engineering Standards: Material Specification Metals GM6435MDocument6 pagesEngineering Standards: Material Specification Metals GM6435MAkmal NizametdinovNo ratings yet

- Cast Alloy Steel Spec Ensures WeldabilityDocument6 pagesCast Alloy Steel Spec Ensures WeldabilityarunrathikaNo ratings yet

- Ford Wa 960-2004Document1 pageFord Wa 960-2004DanielMa0% (1)

- AdvancesDocument20 pagesAdvancesZeeshan MohamedNo ratings yet

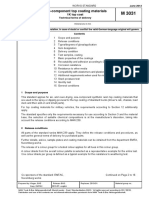

- M 3031 (2013-06)Document16 pagesM 3031 (2013-06)Hatada FelipeNo ratings yet

- Jis G 3466 - 2006 (JP)Document11 pagesJis G 3466 - 2006 (JP)HongHaiDuongNo ratings yet

- Jis D0205 1987 PDFDocument52 pagesJis D0205 1987 PDFsabaris ksNo ratings yet

- 9.55460-2009 - Needle Punched and Nonwoven Fabrics For Interior Vehicle LiningsDocument14 pages9.55460-2009 - Needle Punched and Nonwoven Fabrics For Interior Vehicle Liningsclaudio5475No ratings yet

- En 10139Document2 pagesEn 10139releone11No ratings yet

- Case-Hardening Steels RM16-RM16Pb Technical Data SheetDocument2 pagesCase-Hardening Steels RM16-RM16Pb Technical Data SheetJerzy RistujczinNo ratings yet

- Iso 7452 2013 en PDFDocument8 pagesIso 7452 2013 en PDFfahmi aballiNo ratings yet

- Is Iso 16160 2005Document11 pagesIs Iso 16160 2005Amber HudsonNo ratings yet

- Ejot - Delta PTDocument2 pagesEjot - Delta PTLucas VeronaNo ratings yet

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987From EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonNo ratings yet

- Online Instruction Page: Dependent Drop Down ListsDocument5 pagesOnline Instruction Page: Dependent Drop Down ListscucuNo ratings yet

- Online Instruction Page: Dependent ListsDocument10 pagesOnline Instruction Page: Dependent ListscucuNo ratings yet

- Excel Dependent Drop Down ComboBox XelPlusDocument5 pagesExcel Dependent Drop Down ComboBox XelPluskiryukazNo ratings yet

- 5s Audit ChecklistDocument2 pages5s Audit ChecklistcucuNo ratings yet

- DuPont - Design Check ChartDocument6 pagesDuPont - Design Check ChartserenetaNo ratings yet

- CDD AssignmentDocument4 pagesCDD AssignmentHamza HebNo ratings yet

- The Future of Power Systems: Challenges, Trends, and Upcoming ParadigmsDocument16 pagesThe Future of Power Systems: Challenges, Trends, and Upcoming ParadigmsAndres ZuñigaNo ratings yet

- Guardian Brand Book - 042019Document15 pagesGuardian Brand Book - 042019FTU.CS2 Nguyễn Việt HưngNo ratings yet

- Unit 3 Digital Documentation: Multiple Choice QuestionsDocument7 pagesUnit 3 Digital Documentation: Multiple Choice Questions07tp27652% (21)

- Duobias M 200 TM Section02 Performance SpecificationDocument12 pagesDuobias M 200 TM Section02 Performance SpecificationtonytomsonNo ratings yet

- Lesson Plan Nº1Document7 pagesLesson Plan Nº1Veronica OrpiNo ratings yet

- Latihan Soal ADS Bab 14-16Document1 pageLatihan Soal ADS Bab 14-16nadea06_20679973No ratings yet

- Nasya - Paralellism - New Dengan Tambahan Dari LongmanDocument28 pagesNasya - Paralellism - New Dengan Tambahan Dari LongmannasyaayuNo ratings yet

- The Tower Undergraduate Research Journal Volume VI, Issue IDocument92 pagesThe Tower Undergraduate Research Journal Volume VI, Issue IThe Tower Undergraduate Research JournalNo ratings yet

- Lesson 4: Mean and Variance of Discrete Random Variable: Grade 11 - Statistics & ProbabilityDocument26 pagesLesson 4: Mean and Variance of Discrete Random Variable: Grade 11 - Statistics & Probabilitynicole MenesNo ratings yet

- D 4 Development of Beam Equations: M X V XDocument1 pageD 4 Development of Beam Equations: M X V XAHMED SHAKERNo ratings yet

- Liquefaction of Soil in KathmanduDocument9 pagesLiquefaction of Soil in Kathmanduajay shresthaNo ratings yet

- AGWA Guide GlazingDocument96 pagesAGWA Guide GlazingMoren AlfonsoNo ratings yet

- PR1 Module 2Document12 pagesPR1 Module 2Ervin GonzalesNo ratings yet

- Schmitt Trigger FinalDocument4 pagesSchmitt Trigger Finalsidd14feb92No ratings yet

- Combination Meter: D1 (A), D2 (B)Document10 pagesCombination Meter: D1 (A), D2 (B)PeterNo ratings yet

- Professor Barry T Hart - BiographyDocument1 pageProfessor Barry T Hart - BiographyadelNo ratings yet

- Worksheet Mendel's LawsDocument3 pagesWorksheet Mendel's LawsAkito NikamuraNo ratings yet

- Using Sunspots To Measure Solar Rotation: Astronomy 104 Observing Laboratory Spring 2009Document6 pagesUsing Sunspots To Measure Solar Rotation: Astronomy 104 Observing Laboratory Spring 2009Jeko Betguen PalangiNo ratings yet

- Economical Operation of Nuclear PlantsDocument10 pagesEconomical Operation of Nuclear PlantsArun PatilNo ratings yet

- Articulo SDocument11 pagesArticulo SGABRIELANo ratings yet

- Our Products: Powercore Grain Oriented Electrical SteelDocument20 pagesOur Products: Powercore Grain Oriented Electrical SteelkoalaboiNo ratings yet

- Quality OrientationDocument2 pagesQuality OrientationResearcherNo ratings yet

- API Training & ASNT NDT Level III Examination Preparatories From INDTT, Mumbia INDIADocument7 pagesAPI Training & ASNT NDT Level III Examination Preparatories From INDTT, Mumbia INDIAtraining6156No ratings yet

- Os8 - XCVR 8.7r3 RevaDocument85 pagesOs8 - XCVR 8.7r3 RevaDouglas SantosNo ratings yet