Professional Documents

Culture Documents

Smaw Fillet Aws d1.1

Smaw Fillet Aws d1.1

Uploaded by

fallalovaldesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Smaw Fillet Aws d1.1

Smaw Fillet Aws d1.1

Uploaded by

fallalovaldesCopyright:

Available Formats

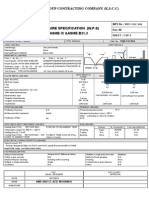

Prepared by: WPSAmerica.

com

WELDING PROCEDURE SPECIFICATION (WPS)

SMAW

Process Type

AWS A5.1: E6010

Identification #

Ref. Code

PQR No.

DEMO-SMAW

AWS D1.1

PREQUALIFIED

Company Name: www.WPSAmerica.com Address: info@WPSAmerica.com, Toll Free: 1 (877) WPS-WELD

Process Base Metals Filler Metals

Manual

Positions

Flat, Horizontal

Only Steels in Category A of Table 3.2 of AWS D1.1

Preheat/ Interpass Temp., Min

Up to 20 mm (3/4): 0 C (32 F) ; Table 3.2 of AWS D1.1 on requirements for larger thicknesses

N/A

Chip, File, Brush and/ or Grind

Interpass Temp., Max Interpass Cleaning

Current/ Polarity

DCEP

Fillet Weld

Weld Type

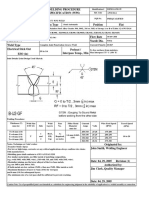

Joint Details/ Joint Design Used/ Sketch:

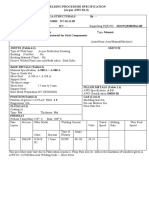

Welding Procedure:

Weld Size (S) mm (in)

Side

Weld Layers

Pass No.

Filler Diameter mm (in)

Current Amps

Alternate Filler Diameters mm (in)

2.4 mm (3/32)

4.0 mm (5/32)

4.8 mm (3/16)

Current Amps

50-85

120-170

140-215

5 mm (3/16) 1 1 6 mm (1/4) 1 1 8 mm (5/16) 1, 2 1-3 (2 Flat) 1 or 3.2 mm (1/8) 90-140 10 mm (3/8) 1, 2 1-3 (2 Flat) 2 12 mm (1/2) 1-3 1-6 (4 Flat) 16 mm (5/8) 1-4 1-8 (6 Flat) >=20 mm (3/4) 1 to 5+ 1-12 (9 Flat) Notes, Technique or Codes rules: -Larger size electrodes may be used for fill and/ or cap passes of the thicker material. -Smaller size electrodes usually applicable for root passes and/ or for thinner material.

Originated by: John Smith, Welding Engineer

Date: 04, 29, 2005 Revision (1) Authorized by: Jim Clark, Quality Manager

Date: 04, 29, 2005

Caution Note: Use of prequalified joint is not intended as a substitute for engineering judgment in the suitability of application to a welded assembly or connection.

You might also like

- Welding Procedure Specification SampleDocument2 pagesWelding Procedure Specification Sampleezdi2083% (23)

- AWS D1-1 PQR-WPS Yes Pre QualifiedDocument2 pagesAWS D1-1 PQR-WPS Yes Pre QualifiedJRodengineerNo ratings yet

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- AWS D1.1 - Example PQR & WPS DocumentsDocument4 pagesAWS D1.1 - Example PQR & WPS DocumentsPaul Cassells0% (1)

- WPS-PQR (Er309l Mo)Document4 pagesWPS-PQR (Er309l Mo)Hamza Nouman0% (1)

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocument1 pageAws D1.1 - WPS - Smaw-Fcaw PDFThe Welding Inspections CommunityNo ratings yet

- Sample Welding Procedure Specification (WPS) FormDocument1 pageSample Welding Procedure Specification (WPS) Formfallalovaldes50% (4)

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- Smaw Wps FinalDocument3 pagesSmaw Wps FinalsheikmoinNo ratings yet

- Qw-482 Welding Procedure Specification (WPS)Document4 pagesQw-482 Welding Procedure Specification (WPS)Aldeline SungahidNo ratings yet

- Aluminium WPSDocument2 pagesAluminium WPSAnonymous yCpjZF1rF100% (1)

- Wps A53 Gtaw R00Document2 pagesWps A53 Gtaw R00Richard PeriyanayagamNo ratings yet

- Aws d1.5 PQRDocument2 pagesAws d1.5 PQRjacquesmayolNo ratings yet

- P-WPS 135 - MAG (GR 316)Document9 pagesP-WPS 135 - MAG (GR 316)Tarun PatelNo ratings yet

- Sample Wps Multi ProcessDocument1 pageSample Wps Multi ProcessMohammed Elmodathir Ali100% (1)

- Aws D1.6 - SS316 WPSDocument1 pageAws D1.6 - SS316 WPSBoby Thomas0% (1)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Welding Procedure Specification (WPS) of The ManufacturerDocument9 pagesWelding Procedure Specification (WPS) of The ManufacturerfallalovaldesNo ratings yet

- Welding Procedure Specification Review and Approval ProcessDocument4 pagesWelding Procedure Specification Review and Approval ProcessfallalovaldesNo ratings yet

- Gmaw Complete Aws d1.6Document1 pageGmaw Complete Aws d1.6Silvia CardenasNo ratings yet

- Wps 7018 SmawDocument1 pageWps 7018 SmawErick VazquezNo ratings yet

- Welding Procedure Specification: Neo StructoDocument2 pagesWelding Procedure Specification: Neo Structohareesh13hNo ratings yet

- SS WPSDocument1 pageSS WPSMOHAMEDABBASNo ratings yet

- PQR Sample PrintoutDocument2 pagesPQR Sample PrintoutDhewo Rachmad Yansyah100% (3)

- Aws d1.1 WPS, PQR & WQTDocument4 pagesAws d1.1 WPS, PQR & WQTWeld Bro SandeepNo ratings yet

- WPQ Sample PrintoutDocument1 pageWPQ Sample PrintoutKannan VelNo ratings yet

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaNo ratings yet

- Poposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015Document12 pagesPoposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015MulPXNo ratings yet

- Weld Test Checklist: Welder (S) DetailsDocument2 pagesWeld Test Checklist: Welder (S) DetailsScott Trainor100% (1)

- WPS Format For AWS D1.1 - WPS - FCAWDocument1 pageWPS Format For AWS D1.1 - WPS - FCAWThe Welding Inspections CommunityNo ratings yet

- QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQW-301, Section IX, ASME Boiler and Pressure Vessel Code)rajuNo ratings yet

- QW - 483 Procedure Qualification Record: Wps No. Welding Process (Es) Type (Manual, Automatic, Semi-Auto)Document3 pagesQW - 483 Procedure Qualification Record: Wps No. Welding Process (Es) Type (Manual, Automatic, Semi-Auto)Alesol EquipmentNo ratings yet

- WPS 2014-002 006 - 6G PipeDocument3 pagesWPS 2014-002 006 - 6G PipejeswinNo ratings yet

- WPS Dissimilar UpdatedDocument3 pagesWPS Dissimilar UpdatedVimin Prakash100% (1)

- Wps PQR Aws d11 FormDocument2 pagesWps PQR Aws d11 Formflakosisas100% (1)

- Welding Procedure Specification (W.P.S) According To ASME IX &ASME B31.3Document2 pagesWelding Procedure Specification (W.P.S) According To ASME IX &ASME B31.3Erick HoganNo ratings yet

- Welding Qualification As Per AWS D1.1Document19 pagesWelding Qualification As Per AWS D1.1Ouni AchrefNo ratings yet

- I-963 Welder Certificate Smaw-Gtaw-1Document1 pageI-963 Welder Certificate Smaw-Gtaw-1nivedithdigitals onlineservices100% (1)

- 03 WPS PQR For FCAWDocument3 pages03 WPS PQR For FCAWBrijesh Yadav100% (1)

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- WPS - 024Document4 pagesWPS - 024MAT-LIONNo ratings yet

- ASME IX Sample WPS GTAW SMAWDocument1 pageASME IX Sample WPS GTAW SMAWDeepak ShrivastavNo ratings yet

- WPS BhelDocument2 pagesWPS BhelpradhankruhsnaNo ratings yet

- WPS - PQR (Sa516 GR.70)Document4 pagesWPS - PQR (Sa516 GR.70)miltonangulomorrisNo ratings yet

- WPS Format For AWS D1.1 - WPS - SAWDocument1 pageWPS Format For AWS D1.1 - WPS - SAWThe Welding Inspections CommunityNo ratings yet

- PQRDocument3 pagesPQRnazirulhakimNo ratings yet

- Procedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaDocument2 pagesProcedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaMulPXNo ratings yet

- WPS D1.6 Annex m1 PDFDocument1 pageWPS D1.6 Annex m1 PDFbollascribdNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document2 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmackNo ratings yet

- A 36 WPSDocument2 pagesA 36 WPSNaqqash Sajid100% (1)

- Welding Procedure Specification SampleDocument5 pagesWelding Procedure Specification SampleAdiNo ratings yet

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Document2 pagesWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajNo ratings yet

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (3)

- Welder Continuation Log: Welder Name: Welder ID: Date of Initial QualificationDocument1 pageWelder Continuation Log: Welder Name: Welder ID: Date of Initial QualificationPerminder Singh100% (1)

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingMohammed MusaNo ratings yet

- Welder'S Qualification Test Certificate: (As Per Asme Sec Ix)Document2 pagesWelder'S Qualification Test Certificate: (As Per Asme Sec Ix)vijay100% (1)

- Piping WpsDocument37 pagesPiping WpsZulfokar FahdawiNo ratings yet

- WPS MatrixDocument4 pagesWPS MatrixHarshaVeeragandham50% (2)

- Weldspec ASME PQRDocument2 pagesWeldspec ASME PQRSunil KumarNo ratings yet

- Welding Procedure Specification Sample - New EditionDocument2 pagesWelding Procedure Specification Sample - New EditiondanteNo ratings yet

- Welding Procedure Specification (WPS) : Demo-SmawDocument1 pageWelding Procedure Specification (WPS) : Demo-SmawakranganNo ratings yet

- Welding Procedure Specification (As Per AWS D1.3) : With Preheat & PWHT (Auto/Semi-Auto/Manual/Machine) SketchDocument1 pageWelding Procedure Specification (As Per AWS D1.3) : With Preheat & PWHT (Auto/Semi-Auto/Manual/Machine) Sketchoomoom0% (1)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Testing and Inspection of WeldsDocument20 pagesTesting and Inspection of Welds7harma V1swaNo ratings yet

- Penetrant TestingDocument43 pagesPenetrant TestingVineet JeswaniNo ratings yet

- XA00048720 Stainless HandbookDocument92 pagesXA00048720 Stainless HandbookThanis SurapapwongNo ratings yet

- Welding Procedure SpecificationDocument1 pageWelding Procedure Specificationfallalovaldes100% (1)

- Welding ProcedureDocument2 pagesWelding ProcedurefallalovaldesNo ratings yet

- Study of The Factors Affecting The Sensitivity of Liquid PenetrantDocument59 pagesStudy of The Factors Affecting The Sensitivity of Liquid PenetrantfallalovaldesNo ratings yet

- Visual Inspection of WeldDocument1 pageVisual Inspection of Weldfallalovaldes100% (1)

- Welding Procedure 2Document1 pageWelding Procedure 2lovaldes62No ratings yet

- RED Dye PenetrantDocument3 pagesRED Dye Penetrantlovaldes62No ratings yet

- CBIP Examination Paper - Liquid Penetrant Inspection Level 2 GeneralDocument4 pagesCBIP Examination Paper - Liquid Penetrant Inspection Level 2 GeneralfallalovaldesNo ratings yet

- Catalogo MagnafluxDocument78 pagesCatalogo MagnafluxfallalovaldesNo ratings yet