Professional Documents

Culture Documents

Crane Runway Girder: Dr. Ibrahim Fahdah Damascus University

Crane Runway Girder: Dr. Ibrahim Fahdah Damascus University

Uploaded by

waleedroomyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Crane Runway Girder: Dr. Ibrahim Fahdah Damascus University

Crane Runway Girder: Dr. Ibrahim Fahdah Damascus University

Uploaded by

waleedroomyCopyright:

Available Formats

2011-2012

Crane Runway Girder

Dr. Ibrahim Fahdah Damascus University

https://sites.google.com/site/ifahdah/home/lectures

2011-2012

2011-2012

Components of Crane system

2011-2012

The Crane Runway Girder and the Structure

Issue1: Vertical Load Transformation The support method of the crane runway girder depends on the magnitude of the reactions being transmitted. Some typical arrangements ranging from the lightest to the heaviest are shown

2011-2012

The Crane Runway Girder and the Structure

Issue2: Free Rotation at the Supports Free rotation at the supports of crane runway girders is important in order to prevent bending and torsional moments in the columns.

2011-2012

The Crane Runway Girder and the Structure

Issue3: Transverse Load Transformation Figure (b) illustrates the reversible strain to which the girder web is subjected - an action leading to the result shown in Figure (c)

Dangerous details for lateral forces

2011-2012

The Crane Runway Girder and the Structure

Issue3 could easily be prevented by simply connecting the top flange directly to the column, as shown. The top flange acts as a horizontal beam delivering its reaction to the column.

2011-2012

Typical Section of Crane Girders

2011-2012

Rail Fastenings

2011-2012

Design Procedure (BS5950 Code)

2011-2012

Classification of Cranes

2011-2012

Step1: Calculate the maximum vertical Loads

The weight of the trolley (carriage) + Lifted Load (Rh) The weight of the crane bridge (Rs) The self weight of the crane girder & Rails (Rg)

Note: The load to the crane girder will be maximum when trolley wheels are closest to the girder.

2011-2012

Step1: Calculate the maximum vertical Loads (cont.)

For Warehouse or workshop F=1.3 => the load combinations below

Conservatively we can simplify the calculation , a factor of 1.3 can be applied simultaneously to both the lifted load and to the self-weight of the crane.

2011-2012

Step1: Calculate the maximum vertical Loads (cont.)

So the maximum unfactored static point load per wheel, assuming there are two wheels on each side, is: Rw=1.3*0.5*(Rs/2+Rh*(Lc-ah)/Lc)

2011-2012

Step2: Calculate the Horizontal Loads

Plan View

2011-2012

Step2: Calculate the Horizontal Loads

Inertia forces produced by the motion drives or brakes. Referred to as the surge load. (clause 3.1.5.1 of BS 2573-1:1983[4]).

Skew loads due to travelling referred to as the crabbing force. (clause 3.1.5.2, BS 2573: Part 1:1983 [4])

2011-2012

Step2: Calculate the Horizontal Loads

Transverse Surge load is taken as 10% of the combined weight of the crab and the lifted load.

Longitudinal Surge load of 5% of the static vertical reactions. (i.e. from the weight of the crab, crane bridge and lifted load).

Crabbing forces are obtained from clause 4.11.2 (BS 5950-1:2000). If the crane is class Q1 or Q2, then the crabbing forces would not need to be considered.

Note : Horizontal loads need not to be combined together.

2011-2012

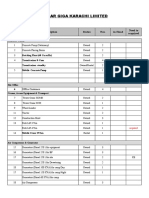

Step3: Load Combinations

Wv FR Wh1 Wheel Wh2 Rail

Load combination according to BS 5950-1:2000 (Table 2) are: LC1 =1.4 DL + 1.6 Wv LC2 =1.4 DL + 1.6 (Wh1 or Wh2 or FR) LC3 =1.4 DL + 1.4 Wv + 1.4 (Wh1 or Wh2 or FR)

2011-2012

Step4: Design Checks

1. 2. 3. 4. 5. 6. 7. 8. Major axis bending Lateral-torsional buckling Horizontal moment capacity Consider combined vertical and horizontal moments Web shear at supports Local compression under wheels Web bearing and buckling under the wheel Deflection

2011-2012

Major Axis Bending

For plastic section: Note : Sx is for the whole section

Check limit to avoid irreversible deformation under serviceability loads.

BS 5950-1-2000 4.2.5.1

BS 5950-1-2000 4.2.5

Note: for section classification of compound I- or H-sections, see BS 5950-1-2000 : 3.5.3 & Table 11. Note: Moment capacity should be reduced in case of high shear according to BS 5950-1-2000 : 4.2.5.3

2011-2012

Lateral-Torsional Buckling

Check gantry girder as an unrestrained member for vertical loads. Due to interaction between crane wheels and crane rails, crane loads need not be treated as destabilizing, assuming that the rails are not mounted on resilient pads. No account should be taken of the effect of moment gradient i.e. mLT (lateral-torsional buckling factor) should be taken as 1.0.

BS 5950-2000 4.11.3

BS 5950-2000 4.11.3 BS 5950-2000 4.3.6.3 ,4.3.6.2, and 4.3.6.4

Pb is the bending strength and is dependent on the design strength py and the equivalent slenderness LT.

BS 5950-2000 4.3.6.7(a)

For compound section (Rolled section + plate ), use I and H with unequal flanges to calculate LT.

2011-2012

Horizontal Moment Capacity

Horizontal loads are assumed to be carried by the top flange plate only.

Moment capacity of the top flange plate, Mc,plate is equal to the lesser of 1.2py Zplate and py*Splate.

BS 5950-1-2000 4.2.5

2011-2012

Consider Combined Vertical and Horizontal Moments 1-Section Capacity:

BS 5950-1-2000 4.8.3.2

2-Buckling Capacity: simplified method

BS 5950-1-2000 4.8.3.3.1

For simplicity take maximum M x and M y (rather than coexistent M x and M y) and assume that the minor axis loads are carried by the plate only. M LT is the maximum major axis moment in the segment. Note : mx, my factors can be taken as 1.0 for simplicity.

2011-2012

Web Shear at Supports

BS 5950-1-2000 4.8.3

Note: It is ok to assume that the sear is resisted by the UB section => Av = tD (for rolled I-sections, load parallel to web)

BS 5950-1-2000 4.8.3 (a)

2011-2012

Local Compression under Wheels

The local compressive stress in the web due to a crane wheel load may be obtained by distributing it over a length xR given by:

BS 5950-1-2000 4.11.1

45

HR Tplate Tflange

2(HR+T) The stress (fw) obtained by dispersing the wheel load over the length xR should not be greater than py for the web.

2011-2012

Web bearing and buckling under the wheel/supports

BS 5950-1-2000 4.5.2.1

Bearing capacity of web for unstiffened web

Buckling resistance of the unstiffened web

BS 5950-1-2000 4.5.31.

2011-2012

Deflections

Vertical deflection due to static vertical wheel loads from overhead travelling cranes

BS 5950-1-2000 2.5.2 Table 8(c)

Horizontal deflection (calculated on the top flange properties alone) due to horizontal crane loads

Note : The deflection of crane beams can be important and the exact calculations can be complex with a system of rolling loads. However, For two equal loads, a useful assumption is that the maximum deflection occurs at the centre of the span when the loads are positioned equidistant about the centre.

You might also like

- Cranes-Design Principles For Loads and Load CombinationsDocument10 pagesCranes-Design Principles For Loads and Load CombinationsEnrique Santiago BenavidesNo ratings yet

- 762X267X197Crane Gantry Girder Design (BS5950)Document5 pages762X267X197Crane Gantry Girder Design (BS5950)Ravindu Jayalath100% (1)

- CraneDocument27 pagesCranemsk7182No ratings yet

- Crane Gantry DesignDocument1 pageCrane Gantry DesignAnonymous RXXdbl36ANo ratings yet

- Design of BeamsDocument28 pagesDesign of BeamsNayan Fatania100% (2)

- Design of Crane Runway Beam (10 Tons)Document5 pagesDesign of Crane Runway Beam (10 Tons)maris_sasec100% (1)

- Design of Gantry GirderDocument28 pagesDesign of Gantry Girders_bharathkumar75% (12)

- Lifting Analysis GuideDocument3 pagesLifting Analysis GuideNwosu Augustine100% (1)

- Manual Crane CalculationDocument98 pagesManual Crane CalculationLarry Bea67% (15)

- Crane Girder Design Sheet - ASD 2005Document36 pagesCrane Girder Design Sheet - ASD 2005Panha Menh100% (3)

- Gantry GirderDocument5 pagesGantry GirderDas TadankiNo ratings yet

- Crane Girder DesignDocument31 pagesCrane Girder Designgvlanusha100% (1)

- Crane Runway Beam Design - Crane Load Calculation-1Document5 pagesCrane Runway Beam Design - Crane Load Calculation-1sergiooiNo ratings yet

- Crane LoadingsDocument2 pagesCrane Loadingsmoseslugtu632470% (10)

- Crane Buffer ForcesDocument243 pagesCrane Buffer ForcesFourHorsemenNo ratings yet

- Crane Gantry Girder (BS5950 - Part1 - 2000)Document6 pagesCrane Gantry Girder (BS5950 - Part1 - 2000)sayed100% (1)

- Guide For EOT Crane SelectionDocument15 pagesGuide For EOT Crane SelectionMaulik Patel100% (1)

- SWP PLW HandbookDocument59 pagesSWP PLW HandbookVan Sot100% (1)

- Vehicles ClipartDocument22 pagesVehicles ClipartSteve Harmon100% (12)

- Crane Beam DesignDocument4 pagesCrane Beam DesignPat Baker100% (1)

- 4 IFlex Operator Manual - ATF 80-4Document60 pages4 IFlex Operator Manual - ATF 80-4Thein Htoon lwin100% (1)

- Crane Girder Design ProcedureDocument18 pagesCrane Girder Design ProcedureBhadresh Shah0% (1)

- Gantry Beam DesignDocument5 pagesGantry Beam DesignSanjeev Kumar Pillai100% (9)

- Crane Girder DesignDocument6 pagesCrane Girder DesignAya Montes100% (3)

- Crane Beam DesignDocument23 pagesCrane Beam DesignVignesh RamalingamNo ratings yet

- Crane BeamDocument8 pagesCrane BeamastorNo ratings yet

- Lifting Operations Management StandardDocument14 pagesLifting Operations Management StandardJalal Albadri100% (1)

- Runway Crane GirdersDocument15 pagesRunway Crane GirdersFabio OkamotoNo ratings yet

- Design of Gentry GirderDocument21 pagesDesign of Gentry GirderDebarshi SahooNo ratings yet

- 1984Document46 pages1984Praveen Kumar85% (13)

- FEM9.311 EnglDocument6 pagesFEM9.311 EnglPınar SunNo ratings yet

- Crane GirdersDocument15 pagesCrane GirdersRaduku RaduNo ratings yet

- Bridge Chapt. 4Document19 pagesBridge Chapt. 4Shita AlemieNo ratings yet

- Civilbay Crane Runway Beam DesignDocument3 pagesCivilbay Crane Runway Beam Designwudongxiao3953No ratings yet

- Crane Design and CalculationDocument28 pagesCrane Design and Calculationodim7371% (24)

- Aashto - DIN Standard (In Germany) - BS 5400 (British Standard) - Indian Roads Congress (IRC) Bridge CodeDocument45 pagesAashto - DIN Standard (In Germany) - BS 5400 (British Standard) - Indian Roads Congress (IRC) Bridge CodeTeshu NigusieNo ratings yet

- Design of Crane BeamsDocument4 pagesDesign of Crane BeamsUzor Emmanuel Chukwuma0% (1)

- Runway Beam Esdep Lecture Note (Wg14)Document19 pagesRunway Beam Esdep Lecture Note (Wg14)kayakeras3335No ratings yet

- CraneBeam v1 1Document44 pagesCraneBeam v1 1harry_1981No ratings yet

- Gantry GirderDocument2 pagesGantry GirderSivaAgathamudiNo ratings yet

- Bridge Analysis & Design ProcedureDocument6 pagesBridge Analysis & Design ProcedurePrakash Singh Rawal80% (5)

- Structure Design Guide For Crane GirderDocument61 pagesStructure Design Guide For Crane Girderalbertoxina100% (2)

- Design of Crane Runway Beam With ChannelDocument9 pagesDesign of Crane Runway Beam With Channellatyrniang100% (3)

- Gantry Girder UnprotectedDocument95 pagesGantry Girder Unprotectedjignesh14283% (12)

- Crane DesignDocument18 pagesCrane DesignSina Enteshari100% (4)

- Design-Loads Eot CraneDocument11 pagesDesign-Loads Eot CranesteelageNo ratings yet

- National Crane 800D PDFDocument16 pagesNational Crane 800D PDFSantiago Hernadez Rodriguez100% (1)

- GRP Pipe Lamination ProcedureDocument27 pagesGRP Pipe Lamination Procedurer. kubendranNo ratings yet

- Bridge CH 4Document113 pagesBridge CH 4Zerihun mulugetaNo ratings yet

- TOTAL Angola Block 17 Pazflor Fields Development ProjectDocument26 pagesTOTAL Angola Block 17 Pazflor Fields Development ProjectYangNo ratings yet

- Multi DeckDocument83 pagesMulti Deckdion2110No ratings yet

- AISC Crane Runway TipsDocument25 pagesAISC Crane Runway Tipstpaterno77100% (10)

- Chapter 3-0Document45 pagesChapter 3-0chaltu TerefeNo ratings yet

- Is Modularization Right For Your Project?Document6 pagesIs Modularization Right For Your Project?ttplan800No ratings yet

- Detail Design of Crane Runway Girders - bk105 PDFDocument6 pagesDetail Design of Crane Runway Girders - bk105 PDFTiago CastelaniNo ratings yet

- Analysis and Design of Power House StructureDocument13 pagesAnalysis and Design of Power House StructureMesfin Derbew100% (1)

- Lifting 2012Document12 pagesLifting 2012Luffy11No ratings yet

- Cranerunwaybeams 4ed bk180Document13 pagesCranerunwaybeams 4ed bk180Antonio Perez Garcia50% (2)

- Bridge ConstructionDocument34 pagesBridge ConstructionGolam Mostofa67% (3)

- Lecture-8 (Laterally Unsupported Beams-Crane Girders)Document30 pagesLecture-8 (Laterally Unsupported Beams-Crane Girders)SeifeldinNo ratings yet

- Crane Loads-Design ManualDocument207 pagesCrane Loads-Design ManualvasanthNo ratings yet

- Bridge LoadingDocument42 pagesBridge LoadingMahesh KalyanshettiNo ratings yet

- CMAA 70 2000 Structure DesignDocument19 pagesCMAA 70 2000 Structure DesignmishikhanNo ratings yet

- Axle ShaftsDocument13 pagesAxle ShaftsankitsarvaiyaNo ratings yet

- Design of Electric Overhead Traveling (EOT) Crane - Sameer MeshramDocument17 pagesDesign of Electric Overhead Traveling (EOT) Crane - Sameer Meshrampradeep shindeNo ratings yet

- Static & Dynamic LoadingDocument9 pagesStatic & Dynamic LoadingAnkush ThakurNo ratings yet

- WCE2010 pp1913-1916Document4 pagesWCE2010 pp1913-1916Katherine FoxNo ratings yet

- 15.rolling Bearings in Bulk ConveyorsDocument17 pages15.rolling Bearings in Bulk ConveyorsPrashant DinkarNo ratings yet

- ESDEP LECTURE NOTE (WG14) CraneDocument22 pagesESDEP LECTURE NOTE (WG14) Cranefloi dNo ratings yet

- Hoisting FacilitiesDocument22 pagesHoisting FacilitiesArmie May RicoNo ratings yet

- CE-461 Coning of Wheels Train Resistances Hauling CapacityDocument43 pagesCE-461 Coning of Wheels Train Resistances Hauling CapacityManjul PratapNo ratings yet

- Lecture 15A.3: Loads (II) - Other LoadsDocument8 pagesLecture 15A.3: Loads (II) - Other LoadsnormaszuhailahNo ratings yet

- Structural Modeling and Analysis - 36Document1 pageStructural Modeling and Analysis - 36dunglxNo ratings yet

- Installation Manual FPIDocument60 pagesInstallation Manual FPIMohamed Reda HusseinNo ratings yet

- Dimensi MesinDocument28 pagesDimensi MesinSyahrir QoimNo ratings yet

- A Part of Normet CorporationDocument58 pagesA Part of Normet CorporationRodrigo MendizabalNo ratings yet

- PRO40 - Data SheetDocument4 pagesPRO40 - Data Sheetmario gultomNo ratings yet

- Quick Box Barge Metric Rev ADocument8 pagesQuick Box Barge Metric Rev ARuben Bartolome GarciaNo ratings yet

- M21Z - M25Z - M30Z - M45 - Bro - May 2022Document4 pagesM21Z - M25Z - M30Z - M45 - Bro - May 2022palok7246No ratings yet

- PERIDocument9 pagesPERIkrmcharigdc100% (1)

- Design and Construction of A Tower Crane: June 2009Document6 pagesDesign and Construction of A Tower Crane: June 2009Beza GetachewNo ratings yet

- Equipment Deployment EmaarDocument8 pagesEquipment Deployment Emaaraliengineer953No ratings yet

- Lifting Equipment StandartDocument6 pagesLifting Equipment StandartRezaYulisnaPNNo ratings yet

- Minimum Design Loads For Buildings and Other Structures ASCE SEI 07 - Chap24Document9 pagesMinimum Design Loads For Buildings and Other Structures ASCE SEI 07 - Chap24ADRIAN EMMANUEL CLEMENTENo ratings yet

- Câmeras MOTECDocument29 pagesCâmeras MOTECsuedcozerNo ratings yet

- FP - EHSP-02-F1 KTS Risk Assessment Form REV D 21102020Document85 pagesFP - EHSP-02-F1 KTS Risk Assessment Form REV D 21102020Arjel SagadNo ratings yet

- Industrial Hall May 2015Document4 pagesIndustrial Hall May 2015Paweł BaranNo ratings yet

- Catalogo CLT Egoin - EngDocument50 pagesCatalogo CLT Egoin - EngVisky AgostonNo ratings yet

- Petroleum Development Oman LLCDocument48 pagesPetroleum Development Oman LLCxu zhaoNo ratings yet

- Car CraneDocument12 pagesCar Cranedema_diasNo ratings yet