Professional Documents

Culture Documents

Pile-Caps-01:: Design A Pile Cap For A 9-Pile Cluster

Pile-Caps-01:: Design A Pile Cap For A 9-Pile Cluster

Uploaded by

Georges Abi SaadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pile-Caps-01:: Design A Pile Cap For A 9-Pile Cluster

Pile-Caps-01:: Design A Pile Cap For A 9-Pile Cluster

Uploaded by

Georges Abi SaadCopyright:

Available Formats

**Pile-caps01: Design a pile cap for a 9-pile cluster.

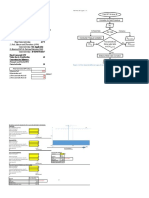

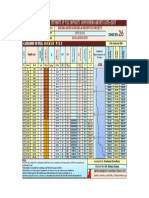

Design a pile cap footing to support an 18 square column subjected to a live load reaction of 180 kips and a dead load reaction of 160 kips at service loads. The testing laboratory recommends an ultimate pile load of 70 kips per pile, and a service pile load of 42 kips per pile. The vertical steel in the column consists of 12 No.7 bars. Use c = 3000 psi, y = 40,000 psi, and 12 diameter piles. Solution. Since the footing weight will be about 3 kips/pile, the net service load per pile is 42.0-3.0 = 39.0 kips/ pile. The number of piles required in N=W/P = 340/39 = 8.7, or 9 piles. Use a pile pattern as shown in Fig. 1. The net ultimate load is used to design the footing; thus Wu = (1.4) (160) + (1.7) (180) = 530 kips, and the load per pile is Pu = 530/9 = 58.9, say 59.0 kips/pile, which is less than the maximum ultimate load, 70 kips/ pile. Punching shear around a single pile often governs the footing depth determination, except in cases in which the loads are small. In this case, it will be shown that beam shear governs. Referring to Fig. 2, we calculate the punching shear stress. After several trials, assume d = 19.5 . The shear perimeter is bo = (12 + d) = 99.0 . The permissible shear force around the pile will be, Vc = 4 f c bod = 4 3000 (99) (19.5) / 1000 = 423 kips Since the actual shear force is the nominal pile reaction, Pn = Pu/ = 59.0/0.85 = 69.4 kips < 423 kips, the pile will not punch through the pile cap (footing).

Figure 1

Figure 2

525

Figure 3

Figure 4

Perimeter shear (punching shear) must now be checked around the column in a similar manner. In this case, all of the nominal pile reactions outside of the critical section plus any partial reactions outside of the critical section will contribute to punching shear for the column. Refer to Figure 3. Assuming No. 6 bars will be used, clearance above the pile butts will be 3 and embedment of the piles will be 6 . The total dept required will be 28.75 . For practical reasons use 29 ; this furnishes an effective depth d = 19.625 . Thus c = a + b = 18.0 + 19.625 = 37.625 and bo = 4(37.625) = 150.0 . Hence, Vou = 472 kips on 8 piles outside of the critical section as shown on Fig. 3. The permissible punching shear force (c = 18/18 < 2) is given by (6.12) as Vc = 4 3000 (150) (19.625) / 1000 = 644.9 kips The force to be resisted is Vn = Vou/ = 472/0.85 = 555.3 kips; therefore the pile cap (footing) is satisfactory for punching shear. Beam shear must now be checked. Refer to Fig. 4. Three piles exist beyond the critical section, so Vu = (3) (59.0) = 177.0 kips. Since b = B= 8 -6 = 102 , the permissible beam shear (one-way shear) force on the critical section is Vc = 2 c bd = 2 3000 (102) (19.625) / 1000 = 219.3 kips The force to be resisted is the nominal shear force, Vn = Vu / = 177/ 0.85 = 208.2 kips. Hence the footing is satisfactory for beam shear. The bending moment about the face of the column must now be investigated. Refer to Fig. 4 Mu = (177) (27/12) = 398.3 ft-kips

Ru = Mu / bd2 = 398.3 x 12,000 / (102)(19.625)2 = 121.67 psi

Table 5.2 for c = 3000 psi and y = 40,000 psi, discloses the fact that the steel ration required is less than the minimum steel ration, min = 200 / y = 0.005. Further, if the steel ration required is increased by 1/3, it will still be less than min. It would appear that 4/3 times the required steel ration would satisfy the 1983 ACI Code. However, the Code does not permit un-reinforced (plain concrete) pile caps. Since any section having less than minimum reinforcement is usually considered to be un-reinforced, the minimum are of steel will be provided. Thus,

526

As = (200/y) bd = (200/ 40,000) (102) (19.925) = 10.0in.2 Use seventeen No. 7 bars (As = 10.2 in.2). The 1983 ACI Code is not explicit concerning minimum steel for footings. Hence, some structural engineers use 0.002bh for minimum steel area if y 40,000 psi and 0.0018bh if y = 60,000 psi. This corresponds to temperature and shrinkage reinforcement requirements. The assumed footing weight must finally be checked. The total weight is WF = (8.5) (8.5) (29) (12.5) / 1000 = 26.2 kips And the weight per pile is 26.2/ 9 = 2.91 kips / pile. The assumed weight of 3.0 kips / pile is most satisfactory. The final details are shown in Fig. 5.

Figure 5

527

You might also like

- Laterally Loaded Rock Socket Design - A Review of The P-Y Curve Design ApproachDocument9 pagesLaterally Loaded Rock Socket Design - A Review of The P-Y Curve Design Approachmyplaxis100% (1)

- Pile NotesDocument16 pagesPile NotesSatya kaliprasad vangara100% (1)

- Wide Beam DesignDocument6 pagesWide Beam DesignNaveen RevannaNo ratings yet

- Book of Nadeem Hussain - Chapter 9 One Way Joist SlabDocument19 pagesBook of Nadeem Hussain - Chapter 9 One Way Joist SlabahmadNo ratings yet

- Chapter 9Document12 pagesChapter 9Jelianne Kyla Tanpian0% (1)

- ASCE 7-22 CH 06 - For PC - SouDocument92 pagesASCE 7-22 CH 06 - For PC - SousharethefilesNo ratings yet

- Ce 03024Document211 pagesCe 03024kimchhoungNo ratings yet

- Eigen Modes - PDF Timesaving-Torsiondesign-Ia PDFDocument32 pagesEigen Modes - PDF Timesaving-Torsiondesign-Ia PDFGeorge GeorgianNo ratings yet

- Isolated Footing Design ProblemDocument5 pagesIsolated Footing Design ProblemthabisNo ratings yet

- Structural Design II (Steel/Timber) Lab: Prepared By: Cedrick L. AngelesDocument122 pagesStructural Design II (Steel/Timber) Lab: Prepared By: Cedrick L. AngelesPascasio PascasioNo ratings yet

- AE401 - Tee Spandrel and SlabsDocument13 pagesAE401 - Tee Spandrel and SlabsThomas MartinNo ratings yet

- RCD GuidelinesDocument5 pagesRCD GuidelinesFlorenz Marc BermundoNo ratings yet

- Example 24.7-Design For Depth of Footing On Piles: × 8.5 FT × 16 inDocument6 pagesExample 24.7-Design For Depth of Footing On Piles: × 8.5 FT × 16 inSeptian BrandalzxNo ratings yet

- Forklift Truck LoadingDocument7 pagesForklift Truck LoadingJurie Sulistio KumaraNo ratings yet

- Design Example of A Double Corbel Using Strut-and-Tie Method Per ACI 318-02 Appendix ADocument5 pagesDesign Example of A Double Corbel Using Strut-and-Tie Method Per ACI 318-02 Appendix APrashant DalviNo ratings yet

- AISC ExamI1&2&3Document11 pagesAISC ExamI1&2&3Dhurai KesavanNo ratings yet

- One-Way and Two-Way SlabsDocument5 pagesOne-Way and Two-Way SlabsMark Kim BadiangNo ratings yet

- CVX7640 32Document14 pagesCVX7640 32malingauomNo ratings yet

- Examples Composite Beams CE413Document17 pagesExamples Composite Beams CE413Shayan AbagnaleNo ratings yet

- Structural Design of Pile Caps Using Strut and Tie ModelDocument4 pagesStructural Design of Pile Caps Using Strut and Tie ModelselinaNo ratings yet

- Connections 1 - Ch.2,3 Summarized Exercise Solutions (150-153)Document5 pagesConnections 1 - Ch.2,3 Summarized Exercise Solutions (150-153)travis8zimmermannNo ratings yet

- Rc2module 5 ReqDocument7 pagesRc2module 5 ReqRanie boy CabanillaNo ratings yet

- Steel Page 60Document108 pagesSteel Page 60Rawaz KanabieNo ratings yet

- Beam Ledge DesignDocument2 pagesBeam Ledge Designauatipu100% (1)

- Lecture 12Document37 pagesLecture 12esttifNo ratings yet

- Design and Detailing of Steel in Combined FootingsDocument34 pagesDesign and Detailing of Steel in Combined FootingsgundulpNo ratings yet

- Fa D F B: Example 1Document19 pagesFa D F B: Example 1Sevet Gnow DrachirNo ratings yet

- Full Beam Design Example: GivenDocument17 pagesFull Beam Design Example: Giventap ramosNo ratings yet

- Unit 5Document31 pagesUnit 5Nirina ArimananaNo ratings yet

- 20 M SpanDocument20 pages20 M SpanEr KanwarPal SinghNo ratings yet

- Shear DesignDocument17 pagesShear DesignAyez Sassin100% (1)

- Singly Design 2Document3 pagesSingly Design 2kolbeh423No ratings yet

- Compression-Tension-Bending&biaxel Bending: Sharif Haji RasulDocument19 pagesCompression-Tension-Bending&biaxel Bending: Sharif Haji RasulRekan DahoNo ratings yet

- Example 3.2 - Continuous Beam-Updated 010812Document15 pagesExample 3.2 - Continuous Beam-Updated 010812Muhammad Farhan Gul100% (3)

- Design of RCC Corbel As Per Aci 318 95Document3 pagesDesign of RCC Corbel As Per Aci 318 95Maad Ahmed Al-Maroof50% (2)

- Design of Anchorage Length EC2Document4 pagesDesign of Anchorage Length EC2ECC100% (2)

- Lecture 29 Strut Tie Modeling Example FW 18octDocument40 pagesLecture 29 Strut Tie Modeling Example FW 18octMitchell Mulvey100% (1)

- Design of Pile CapDocument6 pagesDesign of Pile CapJasy DasNo ratings yet

- Example 3.9 - Design of Short Column Subjected To Uniaxial BendingDocument3 pagesExample 3.9 - Design of Short Column Subjected To Uniaxial BendingMuhammad Farhan Gul100% (1)

- 13UJ BeamsDocument82 pages13UJ BeamsthembalethuNo ratings yet

- Homework 5Document9 pagesHomework 5Omar Calisaya RamosNo ratings yet

- CES522 A 04 - Topic 2b - 2. RC Beam Design - Examples234 PDFDocument38 pagesCES522 A 04 - Topic 2b - 2. RC Beam Design - Examples234 PDFAizuddinNo ratings yet

- Electrical Machine DesignDocument8 pagesElectrical Machine DesignArvin TorrenteNo ratings yet

- SEAOC Seismic Design Manual - Volume II PDFDocument12 pagesSEAOC Seismic Design Manual - Volume II PDFMIKHA2014No ratings yet

- A. Design of Flanged Beam SectionDocument7 pagesA. Design of Flanged Beam SectionWilson PatyalNo ratings yet

- Flexural Design Examples - (C)Document7 pagesFlexural Design Examples - (C)Zohaib AhmadNo ratings yet

- CE305 Reinforced Concrete Design: Topics: Examples On T Beam Design WEEK: 11 Level: 6 Prerequisites: NoneDocument22 pagesCE305 Reinforced Concrete Design: Topics: Examples On T Beam Design WEEK: 11 Level: 6 Prerequisites: NoneAsadullah Khan GhalibNo ratings yet

- Results and Discussion:: Figure 1 (Steel Reinforced Concrete Beam Strain and Stress Diagram)Document6 pagesResults and Discussion:: Figure 1 (Steel Reinforced Concrete Beam Strain and Stress Diagram)sikandar abbasNo ratings yet

- Electrical and Electronic Principles 3 Checkbook: The Checkbook SeriesFrom EverandElectrical and Electronic Principles 3 Checkbook: The Checkbook SeriesNo ratings yet

- O level Physics Questions And Answer Practice Papers 3From EverandO level Physics Questions And Answer Practice Papers 3Rating: 3 out of 5 stars3/5 (1)

- O level Physics Questions And Answer Practice Papers 2From EverandO level Physics Questions And Answer Practice Papers 2Rating: 5 out of 5 stars5/5 (1)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- Stress in ASME Pressure Vessels, Boilers, and Nuclear ComponentsFrom EverandStress in ASME Pressure Vessels, Boilers, and Nuclear ComponentsNo ratings yet

- Bearing Capacity Spunpile Based On Luciano Decourt MethodDocument43 pagesBearing Capacity Spunpile Based On Luciano Decourt MethodGary AbdullahNo ratings yet

- Construction Equipment in DewateringDocument48 pagesConstruction Equipment in DewateringKAYENo ratings yet

- Structural Design Report Pile Sheeting Structural Design Report Pile Sheeting - Sai Pro., MumbaiDocument4 pagesStructural Design Report Pile Sheeting Structural Design Report Pile Sheeting - Sai Pro., Mumbaisivananda reddyNo ratings yet

- Tall Building PresentationDocument44 pagesTall Building PresentationMuhammad Azuan TukiarNo ratings yet

- Negative Skin Friction by Chow YKDocument19 pagesNegative Skin Friction by Chow YKasdas100% (1)

- Legal Supplement: The Construction Industry Development Board (Amendment) ActDocument14 pagesLegal Supplement: The Construction Industry Development Board (Amendment) ActVishwajeet UjhoodhaNo ratings yet

- Method Statement For ScaffoldingDocument3 pagesMethod Statement For Scaffoldingamg007100% (6)

- Kioko, Chrorpher Kimali MSc. Civil Engineering-.2015Document138 pagesKioko, Chrorpher Kimali MSc. Civil Engineering-.2015shivaniNo ratings yet

- Estimate RW 16-01-2024Document7 pagesEstimate RW 16-01-2024PROLOY MAJUMDERNo ratings yet

- Different Types of PileDocument16 pagesDifferent Types of PileBayu Suprayogi100% (1)

- Hong Kong BankDocument17 pagesHong Kong BankPriya Peggy Romal100% (1)

- Civil Construction ProcedureDocument6 pagesCivil Construction Procedureคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Typical Pile - Pile Cap Detail: Pile Cut Off Within Pile Cap 1 Typical Pile - Pile Cap Detail: Pile Cut-Off Below Pile Cap 2Document1 pageTypical Pile - Pile Cap Detail: Pile Cut Off Within Pile Cap 1 Typical Pile - Pile Cap Detail: Pile Cut-Off Below Pile Cap 2Bao Gia LuongNo ratings yet

- Civil Engineering Project ReportDocument82 pagesCivil Engineering Project ReportInayat AliNo ratings yet

- Waste Management at Construction SiteDocument5 pagesWaste Management at Construction SiteAmbalal DhongadiNo ratings yet

- Heavy Equipment in Construction: Group 1 Abing, Cherry Jean D. Bulatao, Jessa Mae Gadiano, Arienne F. Gracilla, R-JayDocument44 pagesHeavy Equipment in Construction: Group 1 Abing, Cherry Jean D. Bulatao, Jessa Mae Gadiano, Arienne F. Gracilla, R-JayArienne Zhel Fontillas GadianoNo ratings yet

- Correction For Overburden: Bearing Capacity Based On Standard Penetration TestDocument41 pagesCorrection For Overburden: Bearing Capacity Based On Standard Penetration TestHimal KafleNo ratings yet

- 5 - DeepEX - Verification ReportDocument14 pages5 - DeepEX - Verification ReportGeorge HaileNo ratings yet

- PR05 - Grid 2-BDocument123 pagesPR05 - Grid 2-BJustinNo ratings yet

- Hydraulic Structure Failure Questions and AnswersDocument7 pagesHydraulic Structure Failure Questions and AnswersAliyyi JamaalNo ratings yet

- Ajay Kumar Garg Engineering College, Ghaziabad Department of Civil EngineeringDocument2 pagesAjay Kumar Garg Engineering College, Ghaziabad Department of Civil EngineeringSatyam ojhaNo ratings yet

- Epc CPF Phase 2 at Badra Oilfield, IraqDocument611 pagesEpc CPF Phase 2 at Badra Oilfield, Iraqtanujaayer100% (2)

- New Jersey Department of Transportation Design Manual For Bridges and Structures PDFDocument459 pagesNew Jersey Department of Transportation Design Manual For Bridges and Structures PDFChin Thau WuiNo ratings yet

- RCD Bihar Sor 2021 Volume IIDocument614 pagesRCD Bihar Sor 2021 Volume IILalitesh KumarNo ratings yet

- Bridge Design Section OrganizationDocument10 pagesBridge Design Section OrganizationniloshaNo ratings yet

- Semiemperical Estimate of Pile Capacity Conforming Aashto Lrfd-2007Document1 pageSemiemperical Estimate of Pile Capacity Conforming Aashto Lrfd-2007civixxNo ratings yet

- SRBDocument43 pagesSRBsandeepNo ratings yet