Professional Documents

Culture Documents

Online Viscosity Systems Temperature Vs. Kinematic Viscosity ASTM D341

Uploaded by

Agustin C. MontalvoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Online Viscosity Systems Temperature Vs. Kinematic Viscosity ASTM D341

Uploaded by

Agustin C. MontalvoCopyright:

Available Formats

1

Online Viscosity Systems

Multi-curve Referral

Temperature Vs. Kinematic Viscosity: ASTM D341

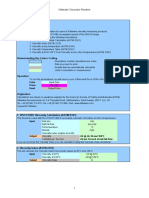

400.00 350.00 300.00 250.00 200.00 150.00 100.00 50.00 0.00 50 60 70 80 90 100 110 120 130 140 150

Kinematic Viscosity cst

log.log (v + 0.7) = A-BlogT v = kinematic viscosity; cst T = temperature deg Kelvin

Temperature deg C

using ASTM D341 log.log (v + 0.7) = A-BlogT

two process variables

kinematic viscosity (cst) temperature (OK)

two constants A & B therefore with two sets of calibration data.... A&B can be found

Calculations

log.log (v + 0.7) = A-BlogT........(i)

let v = 128.58cst at 40 OC log.log (129.28) = A-Blog(313).............(ii) let v = 15.00 cst at 100 OC log.log (15.70) = A-Blog(373)...............(iii) (ii) - (iii) and solve for B: B=3.24 substitute B in (ii) and solve for A log.log (15.70) = A-3.24log(373).............(iv)

calculating base viscosity

now substitute A and B in (i) log.log (v + 0.7) = 8.41-3.24logT........(v) and now: enter the temperature of interest in T, e.g. 50 OC, the base temperature find v log.log (v + 0.7) = 8.41-3.24log(323) v = 80.0cst at 50 OC

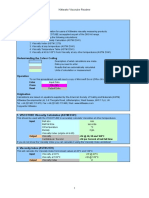

the multi-curve method

for products where quality changes dramatically for multiple products combines ASTM equation with ratio technique for bunker monitoring and blending control

Heavy Fuel Oils

1000 900

Calibration Curves

800 700

Product Curve

Viscosity

600

500

400

300

200

100

0 40 50 60 70 80 90 100 110 120 130 140

Temperature

determining base viscosity

1000

Logarithmic scale

The viscosity at the base Find the calibration curve temperature viscosities at the base a Find the Ratio of calibration Viscosity measured temperature and then apply at curve viscosities at the temperature b the ratios process to find the process temperature to the viscosity for the process measured value curve

100

a b

10 40 50 60 70 80 90 100 110 120 130 140

You might also like

- Practice Problems For Instrumentation and MeasurementDocument13 pagesPractice Problems For Instrumentation and MeasurementMark lord bongatNo ratings yet

- MMI Training Viscosity Referrel ASTM D341Document12 pagesMMI Training Viscosity Referrel ASTM D341gabo mangoNo ratings yet

- Viscotube r2Document15 pagesViscotube r2Chemical EngNo ratings yet

- CSTR Saponification ReactionDocument7 pagesCSTR Saponification ReactionKelly Sheine SisonNo ratings yet

- MLE1101 Tutorial 4 - Suggested Solutions AnalysisDocument7 pagesMLE1101 Tutorial 4 - Suggested Solutions AnalysisYin HauNo ratings yet

- Report InstrumentDocument8 pagesReport Instrumentmuhamad syafaizNo ratings yet

- 4.C Saybolt Universal Viscosity and Viscosity INDEX (ASTM D 88-94 D 2161-93 D 2270-93)Document12 pages4.C Saybolt Universal Viscosity and Viscosity INDEX (ASTM D 88-94 D 2161-93 D 2270-93)Rafid JawadNo ratings yet

- Creep Analysis With SolidworksDocument3 pagesCreep Analysis With Solidworksanjal22No ratings yet

- 18 Feb 03Document47 pages18 Feb 03Patrick Bernard BanzemwaboNo ratings yet

- Laboratory A: Steady State Heat Conduction in A CylinderDocument14 pagesLaboratory A: Steady State Heat Conduction in A CylindercfellowNo ratings yet

- Group 1_ALEJANO_DEZOLLER_GRATIS_BATCH REACTORDocument8 pagesGroup 1_ALEJANO_DEZOLLER_GRATIS_BATCH REACTORJohn Frix AlejanoNo ratings yet

- Tabla 310.15 (B) (2) (A) - Corrección Por Temperatura 30C PDFDocument1 pageTabla 310.15 (B) (2) (A) - Corrección Por Temperatura 30C PDFDettagli GuateNo ratings yet

- Excel charts and equationsDocument5 pagesExcel charts and equationsSourav SutradharNo ratings yet

- Screenshot 2023-04-19 at 9.14.13 AMDocument34 pagesScreenshot 2023-04-19 at 9.14.13 AMJojo NyameNo ratings yet

- Measurement of Viscosity and DensityDocument6 pagesMeasurement of Viscosity and DensityMr ChuNo ratings yet

- VDM 300 ThermoDocument4 pagesVDM 300 ThermoAmr KonswaNo ratings yet

- Viscosity Vs Temperature CalculatorDocument7 pagesViscosity Vs Temperature Calculatormoh_ichwanuddinNo ratings yet

- API and Daubarts Methods - SlidesDocument10 pagesAPI and Daubarts Methods - SlidesStiles stilinskiNo ratings yet

- Introduction to Pinch Technology Network DesignDocument46 pagesIntroduction to Pinch Technology Network DesignM Scott GreenNo ratings yet

- (379315304) 151221525-Deber-2Document19 pages(379315304) 151221525-Deber-2Daniel Armas100% (3)

- G4 Chem BoilingDocument5 pagesG4 Chem BoilingNashwaAlinsangaoNo ratings yet

- Technical Paper Life Cycle of CableDocument4 pagesTechnical Paper Life Cycle of CableVIRENDRA MISHRANo ratings yet

- Tutorial 2Document3 pagesTutorial 2danielruthers2No ratings yet

- Calorimetry Lab: Calculate Enthalpy of NeutralizationDocument4 pagesCalorimetry Lab: Calculate Enthalpy of Neutralizationzaid armoushNo ratings yet

- Chapter 15 Heat Exchanger NetworksDocument29 pagesChapter 15 Heat Exchanger NetworksRina Hapsarininggar0% (1)

- SaponificationDocument35 pagesSaponificationsemanasemana80% (5)

- PhysicsDocument4 pagesPhysicsDexter the DoubledmintNo ratings yet

- Dynamic Modeling of A Batch Bioreactor For Trans-Esterification of Waste Vegetable OilDocument40 pagesDynamic Modeling of A Batch Bioreactor For Trans-Esterification of Waste Vegetable Oilaremunabeel5895No ratings yet

- Wassce Questions On SS1 TopicsDocument2 pagesWassce Questions On SS1 TopicsAlvan Mmaduwuba100% (2)

- Process Control Tutorial Introduction InstrumentsDocument6 pagesProcess Control Tutorial Introduction InstrumentsEstherNo ratings yet

- Kalibrasi Termometer 1: B o D o B o D oDocument10 pagesKalibrasi Termometer 1: B o D o B o D oIqbal Chadels BerryNo ratings yet

- Temperature: By: S K MondalDocument4 pagesTemperature: By: S K Mondalhirenpatel_universalNo ratings yet

- MCB Breaking & Making Capacity PDFDocument43 pagesMCB Breaking & Making Capacity PDFWai Yan Soe ThwinNo ratings yet

- Lab 3 - Heat ExchangerDocument8 pagesLab 3 - Heat ExchangerNeel NadparaNo ratings yet

- R7322304 Instrumentation & Bioprocess ControlDocument1 pageR7322304 Instrumentation & Bioprocess ControlsivabharathamurthyNo ratings yet

- Calibration Curve: 1. A Hygrometer, Which Measures The Amount of Moisture in A Gas Stream, Is To Be CalibratedDocument35 pagesCalibration Curve: 1. A Hygrometer, Which Measures The Amount of Moisture in A Gas Stream, Is To Be Calibratedmichsantos0% (1)

- Experiment NO. 5 KINEMATIC VISCOSITY OF ASPHALT PDFDocument6 pagesExperiment NO. 5 KINEMATIC VISCOSITY OF ASPHALT PDFsaifNo ratings yet

- Understanding The Colour Coding: Kittiwake Viscotube ReadmeDocument15 pagesUnderstanding The Colour Coding: Kittiwake Viscotube ReadmemusaveerNo ratings yet

- Viscotube r2Document15 pagesViscotube r2wisnu prabowo muktiNo ratings yet

- ENCH 405 Quiz SolutionsDocument5 pagesENCH 405 Quiz SolutionsVihan MaddumageNo ratings yet

- Laporan Makmal InstrumentasiDocument8 pagesLaporan Makmal InstrumentasiZainal PiutNo ratings yet

- SPEC-2700K June2014Document4 pagesSPEC-2700K June2014termmmNo ratings yet

- Lampiran C MTTDocument15 pagesLampiran C MTTErsa AmpingNo ratings yet

- Tech Brief 101 Cannon Fenske ViscosimetersDocument5 pagesTech Brief 101 Cannon Fenske ViscosimetersHektor EktroposNo ratings yet

- Arrhenius Plot: KT E A PDocument5 pagesArrhenius Plot: KT E A PJuan AlvarezNo ratings yet

- R07 Set No. 2Document8 pagesR07 Set No. 2Samiullah MohammedNo ratings yet

- Topic 11 Heat IntegrationDocument32 pagesTopic 11 Heat IntegrationFitria Nur LailyNo ratings yet

- Application Note: Accuracy of Vapor Dosing With The AutochemDocument3 pagesApplication Note: Accuracy of Vapor Dosing With The AutochemIngIrvingFCervantesNo ratings yet

- University of Santo Tomas CHE 514L: Chemical Engineering Laboratory IIDocument5 pagesUniversity of Santo Tomas CHE 514L: Chemical Engineering Laboratory IIKelly Sheine SisonNo ratings yet

- Agilent Digital-Multimeters TES-34401A DatasheetDocument4 pagesAgilent Digital-Multimeters TES-34401A DatasheetTeq ShoNo ratings yet

- Viscosity Vs Temperature CalculatorDocument7 pagesViscosity Vs Temperature CalculatorRafael PerraciniNo ratings yet

- r05221003 Sensors and Signal ConditioningDocument8 pagesr05221003 Sensors and Signal ConditioninghaaibudgieNo ratings yet

- Sample For Solution Manual Introduction To Chemical Engineering Thermodynamics 9th International Edition by Smith and Van Ness and AbbottDocument34 pagesSample For Solution Manual Introduction To Chemical Engineering Thermodynamics 9th International Edition by Smith and Van Ness and AbbottEnoch AffulNo ratings yet

- لاب قياسات تجربة 3Document4 pagesلاب قياسات تجربة 3akwan.proNo ratings yet

- Soft Computing in the Design and Manufacturing of Composite Materials: Applications to Brake Friction and Thermoset Matrix CompositesFrom EverandSoft Computing in the Design and Manufacturing of Composite Materials: Applications to Brake Friction and Thermoset Matrix CompositesNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetRating: 2 out of 5 stars2/5 (1)

- Some Power Electronics Case Studies Using Matlab Simpowersystem BlocksetFrom EverandSome Power Electronics Case Studies Using Matlab Simpowersystem BlocksetNo ratings yet