Professional Documents

Culture Documents

Designing of Beams To Eurocode

Designing of Beams To Eurocode

Uploaded by

papapetroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Designing of Beams To Eurocode

Designing of Beams To Eurocode

Uploaded by

papapetroCopyright:

Available Formats

Designing to Eurocode 2

This chapter covers the analysis and design of concrete beams to Eurocode 2

1

which is essentially the same as with BS 8110

2

lowever, the |ayout and

content o lurocode 2 may appear unusua| to des|gners am|||ar w|th bS S!!0

lurocode 2 does not conta|n the der|ved ormu|ae or spec||c gu|dance on

determ|n|ng moments and shear orces h|s has ar|sen |ecause |t has

|een luropean pract|ce to g|ve pr|nc|p|es |n the codes and or the deta||ed

app||cat|on to |e presented |n other sources such as text|oo|s

Chapter !, or|g|na||y pu|||shed as /|oJac|/o |o /aocoJe h|gh||ghted the

|ey d|erences |etween lurocode 2 and bS S!!0, |nc|ud|ng term|no|ogy

lt shou|d |e noted that va|ues rom the 0l Nat|ona| Annex (NA) have |een

used throughout, |nc|ud|ng va|ues that are em|edded |n der|ved ormu|ae

(der|vat|ons can |e ound at wwweurocode2|no) A ||st o sym|o|s re|ated

to |eam des|gn |s g|ven at the end o th|s chapter

3

Design procedure

A procedure or carry|ng out the deta||ed des|gn o |eams |s shown |n a||e !

h|s assumes that the |eam d|mens|ons have prev|ous|y |een determ|ned

dur|ng conceptua| des|gn Concept des|gns prepared assum|ng deta||ed des|gn

wou|d |e to bS S!!0 may |e cont|nued through to deta||ed des|gn us|ng

lurocode 2 More deta||ed adv|ce on determ|n|ng des|gn ||e, act|ons, mater|a|

propert|es, methods o ana|ys|s, m|n|mum concrete cover or dura||||ty and

contro| o crac| w|dths can |e ound |n Chapter 2, or|g|na||y pu|||shed as

Oe||/q |a|eJ

, and in Chapter !

Fire resistance

lurocode 2, lart !2 |ac|aa/ |/e Je/q , g|ves a cho|ce o advanced,

s|mp|||ed or ta|u|ar methods or determ|n|ng the |re res|stance 0s|ng ta||es

|s the astest method or determ|n|ng the m|n|mum d|mens|ons and cover

or |eams here are, however, some restr|ct|ons and | these app|y urther

gu|dance on the advanced and s|mp|||ed methods can |e o|ta|ned rom

spec|a||st ||terature

kather than g|v|ng a m|n|mum cover, the ta|u|ar method

|s |ased on nom|na| ax|s d|stance,

a (see l|gure !) h|s |s the d|stance rom

the centre o the ma|n re|norc|ng |ar to the top or |ottom surace o the

Co|/ae oaqe ??

How to design concrete structures using Eurocode 2

4. Beams

R Moss BSc, PhD, DIC, CEng, MICE, MIStructE O Brooker BEng, CEng, MICE, MIStructE

specialist literature. Rather than giving a minimum cover, the tabular method

chapter

in

26

e c n a d i u g r e h t r u F k s a T p e t S

d r a d n a t S Chapter in this publication

! Leterm|ne des|gn ||e 2 Oe||/q |a|eJ NA to bS lN !990 a||e NA2!

2 Assess act|ons on the |eam 2 Oe||/q |a|eJ bS lN !99! (!0 parts) and Nat|ona| Annexes

3 Leterm|ne wh|ch com||nat|ons o act|ons app|y ! /|oJac|/o |o /aocoJe NA to bS lN !990 a||es NAA!! and NAA!2 (b)

4 Leterm|ne |oad|ng arrangements 2 Oe||/q |a|eJ NA to bS lN !992!!

S Assess dura||||ty requ|rements and determ|ne concrete strength 2 Oe||/q |a|eJ bS SS00 2002

6 Chec| cover requ|rements or appropr|ate |re res|stance per|od 2 Oe||/q |a|eJ and 'l|re res|stance' Approved Locument b bS lN !992!! Sect|on S

sect|on

/ Ca|cu|ate m|n cover or dura||||ty, |re and |ond requ|rements 2 Oe||/q |a|eJ bS lN !992!! C| 44!

S Ana|yse structure to o|ta|n cr|t|ca| moments and shear orces 2 Oe||/q |a|eJ and a||e 3 bS lN !992!! sect|on S

9 ! 6 n o | t c e s ! ! 2 9 9 ! N l S b n o | t c e s ' e r u x e | l ' e e S t n e m e c r o n | e r | a r u x e | n g | s e L

2 6 n o | t c e s ! ! 2 9 9 ! N l S b n o | t c e s ' r a e h s | a c | t r e V ' e e S y t | c a p a c r a e h s | c e h C 0 !

4 / n o | t c e s ! ! 2 9 9 ! N l S b n o | t c e s ' n o | t c e | e L ' e e S n o | t c e | e d | c e h C ! !

!2 Chec| spac|ng o |ars 2 Oe||/q |a|eJ bS lN !992!! sect|on /3

Note

NA Nat|ona| Annex

Table 1

Beam design procedure

Table 2

Minimum dimensions and axis distances for beams made with reinforced concrete for fire resistance

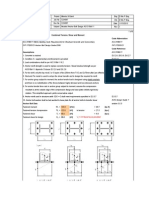

Figure 3

Simplified rectangular stress block for

concrete up to class C50/60 from Eurocode 2

d

h

x

Section

A

s2

A

s

Neutral axis

b

d

2

Strain

sc

0.8x

F

sc

f

cd

Stress block and forces

z

F

c

F

st

Figure 1

Section through structural member,

showing nominal axis distances a and a

sd

b

a

a

sd

h > b

Standard fire resistance Minimum dimensions (mm)

Possible combinations of a and b

min

where a is the average axis distance and b

min

is the width of the beam

Simply supported beams Continuous beams

A B C D E F G H

R60 b

min

= 120 160 200 300 120 200

a = 40 35 30 25 25 12

a

R90 b

min

= 150 200 300 400 150 250

a = 55 45 40 35 35 25

R120 b

min

= 200 240 300 500 200 300 450 500

a = 65 60 55 50 45 35 35 30

R240 b

min

= 280 350 500 700 280 500 650 700

a = 90 80 75 70 75 60 60 50

Notes

1 This table is taken from BS EN 199212 Tables 5.5 and 5.6.

2 The axis distance, a

sd

, from the side of the beam to the corner bar should be a +10 mm except where b

min

is greater than the values in columns C and F.

3 The table is valid only if the detailing requirements (see note 4) are observed and, in normal temperature design, redistribution of bending moments does not exceed 15%.

4 For fire resistance of R90 and above, for a distance of 0.3l

eff

from the centre line of each intermediate support, the area of top reinforcement should not be less than the following:

A

s,req

(x) = A

s,req

( 0)( 1 2.5( x/ l

eff

) )

where:

x is the distance of the section being considered from the centre line of the support.

A

s,req

( 0) is the area of reinforcement required for normal temperature design.

A

s,req

(x) is the minimum area of reinforcement required at the section being considered but not less than that required for normal temperature design.

l

eff

is the greater of the effective lengths of the two adjacent spans.

5 For fire resistances R120 R240, the width of the beam at the first intermediate support should be at least that in column F, if both the following conditions exist:

a there is no fixity at the end support; and

b the acting shear at normal temperature V

sd

> 0.67 V

Rd,max

.

Key

a Normally the requirements of BS EN 199211 will determine the cover.

26

How to design concrete structures using Eurocode 2

2006

2 0 120 2

27

Outside scope of this

publication

Carry out analysis of beam to determine

design moments (M) (see Table 3)

Obtain lever arm z from Table 5 or use

Calculate tension reinforcement

required from

Check minimum reinforcement

requirements (see Table 6)

No compression reinforcement required

Check maximum reinforcement requirements A

s, max

= 0.04 A

c

for tension or compression reinforcement outside lap locations

Determine K from Table 4 or

K = 0.60d 0.18d

2

0.21

where d 1.0

Compression reinforcement

required

Calculate lever arm z from

START

Concrete class

C50/60?

Is K K ?

Yes

Yes

No

No

Determine K from K =

M

bd

2

f

ck

Calculate compression

reinforcement required from

where

Figure 2

Procedure for determining flexural reinforcement

Table 3

Bending moment and shear coefficients for beams

member. It is a nominal (not minimum) dimension, so the designer

should ensure that:

a c

nom

+ f

link

+ f

bar

/2 and a

sd

= a + 10 mm

Table 2 gives the minimum dimensions for beams to meet the

standard fire periods.

Flexure

The design procedure for flexural design is given in Figure 2; this includes

derived formulae based on the simplified rectangular stress block from

Eurocode 2. Table 3 may be used to determine bending moments and

shear forces for beams, provided the notes to the table are observed.

Table 4

Values for K

% redistribution d (redistribution ratio) K

0 !00 020S

a

!0 090 0!S2

a

!S 0SS 0!6S

20 0S0 0!S3

30 0/0 0!20

2S 0/S 0!3/

Key

a lt |s oten recomended |n the 0l that /shou|d |e ||m|ted to 0!6S to ensure duct||e a||ure

K z/d

<00S 0 9S0

a

006 0944

00/ 0934

00S 0924

009 09!3

0!0 0902

K z/d

0!! 0S9!

0!2 0SS0

0!3 0S6S

0!4 0SS6

0!S 0S43

0!6 0S30

0!/ 0S!6

0!S 0S02

0!9 0/S/

020 0//!

Key

a l|m|t|ng to 09SJ |s not a requ|rement o lurocode 2, |ut |s cons|dered to |e good pract|ce

for singly reinforced rectangular sections

Table 6

Minimum percentage of required reinforcement

f

ck

f

ctm

Minimum percentage (0.26 f

ctm

/ f

yk

a

)

2S 26 0!3%

2S 2S 0!4%

30 29 0!S%

32 30 0!6%

3S 32 0!/%

40 3S 0!S%

4S 3S 020%

S0 4! 02!%

Key

a Assum|ng |

y|

S00 Mla

Table 5

z/d

A

s2

=

(KK) f

ck

bd

2

f

sc

(dd

2

)

Calculate tension

reinforcement required from

1 + 1 3.53K z =

2

d

[ ]

1 + 1 3.53K 0.95d z =

2

d

[ ]

A

s, min

= where f

ck

25

f

yk

0.26 f

ctm

b

t

d

A

s

=

f

yd

z

M

A

s

= + A

s2

f

yd

z

Kf

ck

bd

2

f

yd

f

sc

f

sc

= 700 f

yd

x

x d

2

[ ]

Moment Shear

Outer support 25% of span moment 0.45 (G + Q)

Near m|dd|e o end span 0090 Gl + 0.100 Ql

At first interior support 0.094 (G + Q) l 0.63 (G + Q)

a

At middle of interior spans 0.066 Gl + 0.086 Ql

At interior supports 0.075 (G + Q) l 0.50 (G + Q)

Key

a 0.55 (G + Q) may be used adjacent to the interior span.

Notes

1 Redistribution of support moments by 15% has been included.

2 Applicable to 3 or more spans only and where Q

k

G

k

.

3 Minimum span 0.85 longest span.

4 l is the span, G is the total of the ULS permanent actions, Q is the total

of the ULS variable actions.

27

4. Beams

0.45 (G

d

+ Q

d

)

0.075 (G

d

+ Q

d

)l 0.50 (G

d

+ Q

d

)

0.55 (G

d

+ Q

d

) may be used adjacent to the interior span

l is the span, G

d

is the design value of permanent actions (at ULS) and Q

d

is the design

value of variable actions (at ULS).

0.066 G

d

l + 0.086 Q

d

l

0.094 (G

d

+ Q

d

)l

0.090 G

d

l + 0.100 Q

d

l

0.63 (G

d

+ Q

d

)

a

It is often recommended in the UK that K should be limited to 0.168 to ensure ductile failure.

28 4

Figure 5

Procedure for determining vertical shear reinforcement

Determine v

Ed

where

v

Ed

= design shear stress v

Ed

= V

Ed

/(b

w

z) = V

Ed

/(0 . 9 b

w

d)] [

Yes (cot y = 2.5)

No No

START

Determine the concrete strut capacity v

Rd, max cot y = 2.5

from Table 7

Redesign

section

Determine y from:

Calculate area of shear reinforcement:

Check maximum spacing for vertical shear reinforcement:

s

l, max

= 0.75 d

=

s

A

sw

y = 0.5 sin

-1

0.20 f

ck

(1 f

ck

/250)

v

Ed

| |

f

ywd

cot y

v

Ed

b

w

Is

v

Ed

< v

Rd, max coty = 2.5

?

Is

v

Ed

< v

Rd, max cot y = 1.0

?

(see Table 7)

Yes

Table 7

Minimum and maximum concrete strut capacity in terms of stress

f

ck

v

Rd,max cot y = 2.5

v

Rd,max cot y = 1.0

20 2.54 3.68

25 3.10 4.50

28 3.43 4.97

30 3.64 5.28

32 3.84 5.58

35 4.15 6.02

40 4.63 6.72

45 5.08 7.38

50 5.51 8.00

Figure 4

Strut inclination method

Longitudinal

reinforcement in tension

Vertical shear

reinforcement

Concrete strut in compression

y

Eurocode 2 offers various methods for determining the stress-strain

relationship of concrete. For simplicity and familiarity the method

presented here is the simplified rectangular stress block, which is

similar to that found in BS 8110 (see Figure 3).

Eurocode 2 gives recommendations for the design of concrete up to

class C90/105. However, for concrete greater than class C50/60, the

stress block is modified. It is important to note that concrete strength

is based on the cylinder strength and not the cube strength (i.e. for

class C30/37 the cylinder strength ( f

ck

) is 30 MPa, whereas the cube

strength is 37 MPa).

Vertical shear

Eurocode 2 introduces the strut inclination method for shear capacity

checks. In this method the shear is resisted by concrete struts acting in

compression and shear reinforcement acting in tension.

The angle of the concrete strut varies, depending on the shear force

applied (see Figure 4). The procedure for determining the shear capacity

of a section is shown in Figure 5 (which includes UK NA values) and is

in terms of shear stress in the vertical plane rather than a vertical force

as given in Eurocode 2. Where shear reinforcement is required, then

the angle of the concrete strut should be calculated. For many typical

beams the minimum angle of strut will apply (when cot y = 2.5 or y =

21.8) i.e. for class C30/37 concrete the strut angle exceeds 21.8 only

when the shear stress is greater than 3.27 N/mm

2

(refer to Table 7).

As with BS 8110, there is a maximum permitted shear capacity, v

Rd,max

,

(when cot y =1.0 or y = 45), but this is not restricted to 5 MPa as in

BS 8110.

Deflection

lurocode 2 has two a|ternat|ve methods or chec||ng de|ect|on,

e|ther a ||m|t|ng span-to-depth rat|o may |e used or the theoret|ca|

de|ect|on can |e assessed us|ng the express|ons g|ven |n the Code

he |atter |s dea|t w|th |n deta|| |n Chapter S, or|g|na||y pu|||shed as

/e|/ec|/o ca/ca/a|/o7

he span-to-depth rat|os shou|d ensure that de|ect|on |s ||m|ted to

span/2S0 and th|s |s the procedure presented |n l|gure 6

Flanged beams

l|anged |eams can |e treated |n much the same way as |n bS S!!0

he ma|n d|erences compared w|th bS S!!0 are that the assessment

o the |ange w|dth |s more soph|st|cated (see l|gures 9 and !0) and

that lurocode 2 conta|ns a chec| to con|rm that the shear stress at

Co|/ae oaqe 3'

28

How to design concrete structures using Eurocode 2

.

6

3.64

29

12

14

16

18

20

22

24

26

28

30

32

34

36

S

p

a

n

t

o

d

e

p

t

h

r

a

t

i

o

(

Percentage of tension reinforcement (A

s,reqd

/bd)

l

/

d

)

0.40% 0.60% 0.80% 1.00% 1.20% 1.40% 1.60% 1.80% 2.00%

f

ck

ck

ck

ck

ck

ck

ck

ck

ck

= 50

f = 45

f = 40

f = 35

f = 32

f = 30

f = 28

f = 25

f = 20

f

ck

ck

ck

ck

ck

ck

ck

ck

ck

= 50

f = 45

f = 40

f = 35

f = 32

f = 30

f = 28

f = 25

f = 20

Figure 7

Basic span-to-effective-depth ratios

Notes

1 This graph assumes simply supported span condition

(K = 1.0).

K = 1.5 for interior span condition

K = 1.3 for end span condition

K = 0.4 for cantilevers.

2 Compression reinforcement, r, has been taken as 0.

3 Curves based on the following expressions:

where r r

0

and

where r > r

0

.

11+ + 3.2 1 = K

r

f

ck

r

0

1.5

d

l

f

ck

r

r

0

[ ( ) ]

11+ + = K

(

r r

)

f

ck

r

0

1.5

d

l

12

f

ck

r

0

r

[ ]

1.5

5

Figure 6

Procedure for assessing deflection

Determine Factor 2 (F2)

Where the beam span exceeds 7 m and it supports

brittle partitions, F2 = 7/l

eff

1.0

Otherwise F2 = 1.0

Is basic l/d x K x F1 x F2 x F3 Actual l/d ?

Increase

A

s,prov

Determine basic l/d and K from Figure 7

Check complete

Determine Factor 1 (F1)

For ribbed or waffle slabs

F1 = 1 0.1 ((b

f

/b

w

) 1) 0.8

(b

f

is flange breadth and b

w

is rib breadth)

Otherwise F1 = 1.0

No

Yes

START

The Eurocode is ambiguous regarding linear interpolation. It is understood that

it was the intention of the drafting committee that linear interpolation be used

and this is in line with current UK practice.

Figure 8

Determination of steel stress

To determine stress in the reinforcement (s

s

), calculate the ratio

G

k

/Q

k

, read up the graph to the appropriate curve and read across

to determine s

su

.

s

s

can be calculated from the expression: s

s

= s

su

A

s,req

A

s,prov

1

d

( ( ) )

Ratio G

k

/Q

k

U

n

m

o

d

i

f

i

e

d

s

t

e

e

l

s

t

r

e

s

s

,

s

s

u

180

200

220

240

260

280

300

320

1.0 2.0 3.0 4.0

c

2

= 0.8, g

G

= 1.35

c

2

= 0.6, g

G

= 1.35

c

2

= 0.3, g

G

= 1.35

c

2

= 0.2, g

G

= 1.35

c

2

= 0.6, g

G

= 1.25

c

2

= 0.3, g

G

= 1.25

c

2

= 0.2, g

G

= 1.25

Determine Factor 3 (F3)

F3 = A

s,prov

/A

s,reqd

1.5 or 310/s

s

1.5 (UK NA)

where s

s

is the stress in the reinforcement calculated

under the characteristic combination of SLS loads.

29

4. Beams

For anged sections

To determine stress in the provided reinforcement (s

s

), calculate the ratio

Percentage of tension reinforcement (A

s,req

/bd)

A

p

p

r

o

x

i

m

a

t

e

s

t

e

e

l

s

t

r

e

s

s

a

t

S

L

S

f

o

r

A

s

,

r

e

q

,

s

s

u

G

k

/Q

k

, read up the graph to the appropriate curve and read across

to determine s

su

ss .

s

s

ss can be calculated from the expression: s

s

ss = s

su

ss

A

,p

( ( ) )

A

s,req

A

s,prov

1

d

( )

Ratio G

k

/Q

k

180

200

220

240

260

280

300

320

1.0 2.0 3.0 4.0

c

2

= 0.8, g

G

gg = 1.35

c

2

= 0.6, g

G

gg = 1.35

c

2

= 0.3, g

G

gg = 1.35

c

2

= 0.2, g

G

gg = 1.35

c

2

= 0.6, g

G

gg = 1.25

c

2

= 0.3, g

G

gg = 1.25

c

2

= 0.2, g

G

gg = 1.25

( To determine stress in the provided reinforcement (s

s

ss )), calculate the ratio

A

p

p

r

o

x

i

m

a

t

e

s

t

e

e

l

s

t

r

e

s

s

a

t

S

L

S

f

o

r

A

s

,

r

e

q

,

s

u

s

u

ss

Figure 8 - no longer used

Determination of quasi-permanent steel stress

30

Figure 11

Procedure for determining flexural capacity of flanged beams

Figure 9

Definition of l

o

, for calculation of effective flange width

Figure 10

Effective flange width parameters

l

0

= 0.85 l

1

l

0

= 0.15 (l

1

+ l

2

)

l

1

l

3

l

2

l

0

= 0.7 l

2

l

0

= 0.15 l

2

+ l

3

b

1

b

1

b

2

b

2

b

w

b

eff

b

eff,2

b

b

eff,1

START

Is x 1.25h

f

?

Is K

f

K ?

Carry out analysis of beam to determine design

moments, M (see Table 3)

Neutral axis in

flange. Design

as rectangular

section (Figure 2)

and then check

longitudinal shear

(Figure 14)

Redesign section

Determine l

0

(see Figure 9) and b

eff

from:

b

eff

= (b

w

+ b

eff1

+ b

eff2

) where

b

eff1

= (0.2b

1

+ 0.1 l

0

) 0.2 l

0

b

1

b

eff2

= (0.2b

2

+ 0.1 l

0

) 0.2 l

0

b

2

Note: The flange width at the support will be

different from that at mid-span.

For symbols refer to Figures 9 and 10

Determine K from Table 4 or

K = 0.60d 0.18d

2

0.21 where d 1.0

Calculate depth to neutral axis x from:

x = 2.5 (d z)

Calculate lever arm z from

Neutral axis in web

Calculate moment capacity of flange from:

M

R,f

= 0.57 f

ck

(b

eff

b

w

) h

f

(d 0.5h

f

)

Calculate area of reinforcement required from Check longitudinal

shear

(see Figure 14)

Yes

No

Yes

No

Determine K from K =

where b = b

w

at support

b = b

eff

in span

1 + 1 3.53K 0.95d z =

2

d

[ ]

bd

2

f

ck

M

A

s

= +

f

ywd

(d 0.5 h

f

)

M

R,f

f

ywd

M M

R,f

K

f

= and

f

ck

b

w

d

2

M M

R,f

Figure 12

Placing of tension reinforcement in flanged cross section

Figure 13

Notations for the connection between flange and web

A

A

F

d

F

d

S

f

b

eff

A

sf

h

f

F

d

+ F

d

D

F

d

+ F

d

D

Dx

b

w

y

f

Longitudinal bar

anchored beyond

this projected point

Compressive struts

b

eff

b

eff1

b

eff2

A

s

b

w

h

f

30

How to design concrete structures using Eurocode 2

f

yd

(d 0.5 h

f

) f

ydz

z

31

Figure 14

Procedure for determining longitudinal shear capacity of flanged beams

Yes

No No

No

Calculate the longitudinal shear stress

from: v

Ed

= DF

d

/(h

f

Dx)

(see Figure 13)

Determine the concrete strut capacity

fromTable 8 or from:

v

Rd

= 0.160 f

ck

(1 f

ck

/250)

Calculate area of transverse reinforcement from:

Yes (cot y

f

= 2.0) Yes (cot y

f

= 1.25)

Is v

RD

> v

Ed

? Is v

RD

> v

Ed

?

Is length of

flange under consideration

in tension?

Determine y

f

from:

Determine the concrete

strut capacity fromTable 8

or from:

v

Rd

= 0.195 f

ck

(1 f

ck

/250)

=

s

A

sf

y

f

=0.5sin

-1

0.2f

ck

(1 f

ck

/250)

v

Ed

| |

f

yd

cot y

f

v

Ed

h

f

Table 8

Concrete strut capacity for longitudinal shear in flanged beams

f

ck

v

Rd,max

Flange in compression Flange in tension

9 S 3 4 9 2 0 2

9 3 4 0 6 3 S 2

S S 4 S 9 3 S 2

S ! S 2 2 4 0 3

4 4 S 6 4 4 2 3

/ S S 2 S 4 S 3

S S 6 S 3 S 0 4

0 2 / 0 9 S S 4

0 S / 0 4 6 0 S

Minimum area of shear reinforcement

he m|n|mum area o shear re|norcement |n |eams, /sw,m|n shou|d

|e ca|cu|ated rom

where

r

w,m|n

can |e o|ta|ned rom a||e 9

/

sw

/

w

4 r

w,m|n

the |nterace o the |ange and we| can |e res|sted |y the transverse

re|norcement |n the |ange he pos|t|on o the neutra| ax|s shou|d

|e determ|ned, and then the area o re|norcement can |e ca|cu|ated

depend|ng whether |t ||es |n the |ange or we| (see l|gure !!)

At supports the tens|on re|norcement to res|st hogg|ng moments

shou|d |e d|str||uted across the u|| w|dth o the eect|ve |ange as

shown |n l|gure !2 he span-to-depth de|ect|on chec|s us|ng rat|o o

tens|on re|norcement shou|d |e |ased on area o concrete a|ove

centre o tens|on stee|

Longitudinal shear

he shear stress |n the vert|ca| p|ane |etween the |ange and we| shou|d

|e assessed accord|ng to sect|on 624 and l|gure 6/ o the lurocode

(reproduced here as l|gure !3) he change |n orce |n the |ange can

|e assessed rom the moment and |ever arm at a part|cu|ar |ocat|on

he lurocode states that the max|mum |ength that can |e cons|dered

or the change |n orce |s ha| the d|stance |etween the max|mum

moment and the po|nt where the moment |s .ero C|ear|y, the max|mum

|ong|tud|na| orce w||| occur where the change |n moment, and

thereore orce, |s the greatest, or a un|orm|y d|str||uted |oad on a

cont|nuous |eam th|s w||| |e the |ength o |eam c|osest to the support

l|gure !4 shows a |ow chart or assess|ng the |ong|tud|na| shear

capac|ty, |n many cases the transverse re|norcement |n the s|a| w||| |e

su|c|ent to res|st the shear orce h|s chec| |s |nc|uded to ensure that

where part|cu|ar|y th|n |anges are used there |s adequate re|norcement

he |ong|tud|na| shear capac|ty |s |ased on the var|a||e strut |nc||nat|on

method, wh|ch was descr||ed |n the sect|on on vert|ca| shear

Rules for spacing and

quantity of reinforcement

Minimum area of longitudinal reinforcement

he m|n|mum area o re|norcement |s /

s, m|n

026 |

c tm

/

t

J/|

y |

|ut

not |ess than 000!3/

t

J, where /

t

|s the mean w|dth o the tens|on

.one (see a||e 6) lor a -|eam w|th the |ange |n compress|on, on|y

the w|dth o the we| |s ta|en |nto account |n ca|cu|at|ng the va|ue o /

Maximum area of longitudinal reinforcement

he max|mum area o tens|on or compress|on re|norcement, outs|de

|ap |ocat|ons shou|d not exceed /

s, max

004 /

c

Minimum spacing of reinforcement

he m|n|mum c|ear d|stance |etween |ars shou|d |e the greater o

bar d|ameter

Aggregate s|.e p|us S mm

20 mm

Table 9

Values for r

w,min

f

ck 20 25 28 30 32 35 40 45 50

r

w,m|n

x !0

-3

0/2 0S0 0SS 0SS 09! 09S !0! !0/ !!3

31

4. Beams

32

References

1 bkllSl SANLAkLS lNSl0lON bS lN !992!!, lurocode 2 /e/q o| coce|e |ac|ae - /a| '-' Oeea/ a/e aJ a/e |o

/a//J/q bSl, 2004

2 bkllSl SANLAkLS lNSl0lON bS S!!0! I/e |ac|aa/ ae o| coce|e - /a| ' CoJe o| oac|/ce |o Je/q aJ co|ac|/o bSl, !99/

3 NAkAANAN, k S 8 bkOOllk, O /ou |o Je/q coce|e |ac|ae a/q /aocoJe ? /|oJac|/o |o /aocoJe he Concrete Centre, 200S

4 bkOOllk, O /ou |o Je/q coce|e |ac|ae a/q /aocoJe ? Oe||/q |a|eJ he Concrete Centre, 200S

5 bkllSl SANLAkLS lNSl0lON bS lN !992!2, lurocode 2 /e/q o| coce|e |ac|ae Oeea/ a/e - |ac|aa/ |/e Je/q bSl, 2004

7 vlbSlk, k 8 bkOOllk, O /ou |o Je/q coce|e |ac|ae a/q /aocoJe ? /e|/ec|/o ca/ca/a|/o he Concrete Centre, 2006

6 LllAkMlN Ol COMM0NlllS ANL lOCAl COVlkNMlN /aJ/oo/ |o //-'99?-'-? LClC, due 2006

s

/

to res|st the moment due to the des|gn

|oads (or at support or cant||evers)

r' kequ|red compress|on re|norcement at /

s2

//J

m|d-span to res|st the moment due to the

des|gn |oads (or at support or cant||evers)

(rom a||e 3!, lurocode 2)

/

l|ange th|c|ness

/ lactor to ta|e account o the d|erent See ta||e NA4 |n

x e n n A | a n o | t a N l 0 s m e t s y s | a r u t c u r t s

/

e

lect|ve span o mem|er See Sect|on S322 (!)

/

o

L|stance |etween po|nts o .ero moment

//J Span-to-depth rat|o

/ Les|gn moment at the 0lS

\ ( s | x a | a r t u e n o t h t p e L J-)/04

\

max

l|m|t|ng va|ue or depth to neutra| ax|s (d 04)J where d <!0

lever arm

a

cc

Coe|c|ent ta||ng account o |ong term 0SS or |exure and

eects on compress|ve strength and o ax|a| |oads

unavoura||e eects resu|t|ng rom the !0 or other phenomena

wa ) x e n n A | a n o | t a N l 0 m o r l ( d e | | p p a s | d a o | y

d kat|o o the red|str||uted moment to the

e|ast|c |end|ng moment

g

m

lart|a| actor or mater|a| propert|es !!S or re|norcement (g

s

)

!S or concrete (g

c

)

r

0

keerence re|norcement rat|o R|

c|

/!000

r kequ|red tens|on re|norcement at m|d-span / /J (or rectangu|ar |eams)

/

c

Cross sect|ona| area o concrete

/

s

Area o tens|on stee|

/

s2

Area o compress|on stee|

/

s, prov

Area o tens|on stee| prov|ded

/

s, req'd

Area o tens|on stee| requ|red

/

e

lect|ve |ange w|dth

/

t

Mean w|dth o the tens|on .one

/

m|n

v|dth o |eam or r||

/

w

v|dth o sect|on, or w|dth o we| on |anged |eams

J lect|ve depth

J

2

lect|ve depth to compress|on re|norcement

|

cd

Les|gn va|ue o concrete compress|ve strength a

cc

|

c|

/g

c

or |

c|

< CS0/60

|

c|

Character|st|c cy||nder strength o concrete

|

ctm

Mean va|ue o ax|a| tens||e strength 030 |

c|

(2/3)

or |

c|

< CS0/60

S e u l a V n o i t i n i f e D l o b m y Sy e u l a V n o i t i n i f e D l o b m

Selected symbols

32

4. Beams

6 WEBSTER, R & BROOKER, O. How to design concrete structures using Eurocode 2: Deection calculations. The Concrete Centre, 2006.

You might also like

- How To Design Concrete Structures Using Eurocode 2Document8 pagesHow To Design Concrete Structures Using Eurocode 2nahzemNo ratings yet

- Footfall Vibration and Finite Element AnalysisDocument4 pagesFootfall Vibration and Finite Element AnalysisthaibinhkxNo ratings yet

- 07 Sx007a en Eu BeamDocument11 pages07 Sx007a en Eu BeamMic PaulaNo ratings yet

- Punching Shear ExampleDocument3 pagesPunching Shear Exampleikanyu7950% (2)

- Canadian Seismic Design of Steel Structures An Organized OverviewDocument25 pagesCanadian Seismic Design of Steel Structures An Organized OverviewJamal Muhammad BahajajNo ratings yet

- Ec3 VerificcariDocument7 pagesEc3 VerificcariNeamtu NeamtuNo ratings yet

- Wind Actions On Signboards According To Eurocode 1 Part 4Document2 pagesWind Actions On Signboards According To Eurocode 1 Part 4mkaynak76No ratings yet

- EC2 Creep and Shrinkage LossesDocument9 pagesEC2 Creep and Shrinkage LossesSorin SavescuNo ratings yet

- Direct Analysis MethodDocument31 pagesDirect Analysis MethodgayalamNo ratings yet

- European Standards For Reinforced ConcreteDocument29 pagesEuropean Standards For Reinforced ConcretenejcllNo ratings yet

- Wind Load On Concrete and Steel Structures Using Sap2000 & Etab Programs As Per Aisc7-05, Aisc7-10, & Sbc301 CodeDocument23 pagesWind Load On Concrete and Steel Structures Using Sap2000 & Etab Programs As Per Aisc7-05, Aisc7-10, & Sbc301 CodeRamy ShahinNo ratings yet

- Steel Design To Eurocode 3 University of Sheffield Structural Engineering MastersDocument55 pagesSteel Design To Eurocode 3 University of Sheffield Structural Engineering MastersephremNo ratings yet

- SCI PUBLICATION P387 Steel Building Desi PDFDocument106 pagesSCI PUBLICATION P387 Steel Building Desi PDFSabarishwaran SabariNo ratings yet

- Design Formula For EC2Document35 pagesDesign Formula For EC2Azim MuizNo ratings yet

- Advanced Concept Training Steel 15.3Document153 pagesAdvanced Concept Training Steel 15.3margitorsiNo ratings yet

- RC Design - ACIDocument41 pagesRC Design - ACIAbebe WoldeNo ratings yet

- Comprehensive Step by Step Calculations For Retaining Wall Analysis Are Provided BelowDocument15 pagesComprehensive Step by Step Calculations For Retaining Wall Analysis Are Provided BelowLakshmiWijayasiriNo ratings yet

- Eurocode Yük KombinasyonlarıDocument12 pagesEurocode Yük KombinasyonlarıVefa OkumuşNo ratings yet

- Free Standing StairsDocument16 pagesFree Standing StairsJunaid Tylor100% (1)

- Design of Transfer Slabs Using Strut and Tie Model PDFDocument181 pagesDesign of Transfer Slabs Using Strut and Tie Model PDFAbdullrhman AhmedNo ratings yet

- Seismic Design EC8Document15 pagesSeismic Design EC8Wendirad Beshada100% (1)

- Case-1 (Actual Load+tension With Anchor Bar)Document16 pagesCase-1 (Actual Load+tension With Anchor Bar)userhieNo ratings yet

- Shear KeyDocument14 pagesShear KeyMbalekelwa MpembeNo ratings yet

- Encased Composite Column in Axial CompressionDocument6 pagesEncased Composite Column in Axial Compressionboone37No ratings yet

- 1 3 6 Overview of Eq Design UK NA For EN1998 2 PD 6698Document9 pages1 3 6 Overview of Eq Design UK NA For EN1998 2 PD 6698Chirianu MarianNo ratings yet

- ETABSDocument11 pagesETABSOmar Najm100% (1)

- Stiffness of Concrete SlabsDocument61 pagesStiffness of Concrete Slabsfaumijk100% (1)

- App7 EC3 Design PDFDocument45 pagesApp7 EC3 Design PDFAndreea Vaduva100% (1)

- Direct Analysis and Its Implentation in StaadDocument10 pagesDirect Analysis and Its Implentation in StaadlavyNo ratings yet

- Eurocode Examples PDF RarDocument2 pagesEurocode Examples PDF RarHaijing0% (1)

- EC8 Seismic Design of Buildings-Worked ExamplesDocument6 pagesEC8 Seismic Design of Buildings-Worked ExamplescristinelbNo ratings yet

- Long Term Deflection in Concrete BeamsDocument6 pagesLong Term Deflection in Concrete BeamsRenganayagi BalajiNo ratings yet

- Readme v4B PDFDocument4 pagesReadme v4B PDFlucianduNo ratings yet

- Design Guide For Steel Trusses (Part 1)Document4 pagesDesign Guide For Steel Trusses (Part 1)Baguma Grace GariyoNo ratings yet

- Practical Design To Eurocode 2: Outline - Week 4Document46 pagesPractical Design To Eurocode 2: Outline - Week 4maminu1No ratings yet

- ECCS EC3-1!1!2013 LSS Compendiumv4 KopiaDocument310 pagesECCS EC3-1!1!2013 LSS Compendiumv4 KopiaManuel ValenteNo ratings yet

- Design of Diaphragm Walls According To Eurocode 7Document6 pagesDesign of Diaphragm Walls According To Eurocode 7정진교No ratings yet

- Huong Dan MegafloorDocument11 pagesHuong Dan Megafloortrung1983No ratings yet

- Reinforced Concrete Column by Zinab EC2Document15 pagesReinforced Concrete Column by Zinab EC2berto2008No ratings yet

- Deltabeam EngDocument20 pagesDeltabeam EngAmir OmeraševićNo ratings yet

- How To Design Concrete Structures Using Eurocode 2 - (3) SlabsDocument8 pagesHow To Design Concrete Structures Using Eurocode 2 - (3) Slabsbobbytirona566100% (1)

- Strut and Tie ModelDocument7 pagesStrut and Tie ModelChaudharyShubhamSachanNo ratings yet

- The Role of Cracked Stiffness in Analysis and Design - Structural Engineering General Discussion - Eng-TipsDocument3 pagesThe Role of Cracked Stiffness in Analysis and Design - Structural Engineering General Discussion - Eng-TipsIhab SorourNo ratings yet

- Extracts From Ec3 For Students 2012Document6 pagesExtracts From Ec3 For Students 2012Alexandru MarincuNo ratings yet

- Shear Wall Frame ACECOMS AIT ThailandDocument150 pagesShear Wall Frame ACECOMS AIT ThailandFernando Sernaqué CalleNo ratings yet

- Software Verification: EXAMPLE Eurocode 2-04 PT-SL-001Document7 pagesSoftware Verification: EXAMPLE Eurocode 2-04 PT-SL-001võ hoàng thái100% (1)

- Design For WindDocument8 pagesDesign For WindRamadanNo ratings yet

- Strenghening of OpeningsDocument170 pagesStrenghening of OpeningsJustina RodriguezNo ratings yet

- IBC 2012 Sample From ICCDocument5 pagesIBC 2012 Sample From ICCMIKHA2014No ratings yet

- PDC TR-06-02 Rev 1 SBEDS Users Guide DistribADocument95 pagesPDC TR-06-02 Rev 1 SBEDS Users Guide DistribAmirko huaranccaNo ratings yet

- Lecture 1 10.05.2022 Eecq 5152 Lecture NotesDocument25 pagesLecture 1 10.05.2022 Eecq 5152 Lecture NotesGriffithsNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- The World's Largest Independent Mobile Ad NetworkDocument9 pagesThe World's Largest Independent Mobile Ad NetworkTechCrunch100% (1)

- Lester YoungDocument15 pagesLester YoungmartoNo ratings yet

- Worked Example To Eurocode 2 Vol 1Document228 pagesWorked Example To Eurocode 2 Vol 1Mohd RafiqNo ratings yet

- Reducing Sodium IntakeDocument2 pagesReducing Sodium IntakeVikas Saini, MDNo ratings yet

- Preventing Heart DiseaseDocument1 pagePreventing Heart DiseaseVikas Saini, MDNo ratings yet

- Trans FatsDocument1 pageTrans FatsVikas Saini, MDNo ratings yet

- 9004310134Document404 pages9004310134vladimir rosas ayalaNo ratings yet

- CA IPCC RTP May 2019 PDFDocument343 pagesCA IPCC RTP May 2019 PDFVeer LalanNo ratings yet

- Ineffective Institutional Investors LawDocument19 pagesIneffective Institutional Investors LawJustin HalimNo ratings yet

- Hi Mom!: I Feel Very Sad For Everything They Say To Me. I Feel Very Alone!Document3 pagesHi Mom!: I Feel Very Sad For Everything They Say To Me. I Feel Very Alone!Carol CalixtoNo ratings yet

- Uitm Kampus Seremban 3: Budget 2018 PresentationDocument6 pagesUitm Kampus Seremban 3: Budget 2018 PresentationAddin 114No ratings yet

- 04 Understanding Business Cycles-1Document14 pages04 Understanding Business Cycles-1ajay sahuNo ratings yet

- Personal Selling ProcessDocument5 pagesPersonal Selling ProcessOOOJJJAAASSSNo ratings yet

- Alr SecuritiesDocument168 pagesAlr SecuritiesParamita PrananingtyasNo ratings yet

- Coconuts in The Mekong DeltaDocument99 pagesCoconuts in The Mekong DeltaSkyle VoNo ratings yet

- Persons 2Document15 pagesPersons 2Rodney UlyateNo ratings yet

- Gender Representation in The Media Lesson PlanDocument2 pagesGender Representation in The Media Lesson Planapi-250065413No ratings yet

- EaPaaS Fit-Gap Assessment and Evaluation v2Document76 pagesEaPaaS Fit-Gap Assessment and Evaluation v2geovijayNo ratings yet

- Moses and Akhenaten One and The Same Person by Ahmed OsmanDocument12 pagesMoses and Akhenaten One and The Same Person by Ahmed OsmanMike AlexNo ratings yet

- Aashto M 17Document1 pageAashto M 17israrNo ratings yet

- FLIPPED 5 UNIT 7B Vocabulary Verbs and Prepositions Quantifiers.Document7 pagesFLIPPED 5 UNIT 7B Vocabulary Verbs and Prepositions Quantifiers.Denisse BenitezNo ratings yet

- Mutual Fund Trail CalculationDocument20 pagesMutual Fund Trail CalculationyuvirocksNo ratings yet

- Yoruba Religion and Medicine in Ibadan PDFDocument237 pagesYoruba Religion and Medicine in Ibadan PDFEnriqueHernandez100% (2)

- 2 Answer KeyDocument43 pages2 Answer Keyปาริฉัตร หล่องคำNo ratings yet

- Phòng GD-ĐT Đại Lộc ĐỀ ĐỀ NGHỊ HỌC KÌ II-Năm học 2013-2014 Trường THCS Kim Đồng Môn: Anh Văn 8 Người ra đề: Nguyễn Thị Nở Ma trậnDocument4 pagesPhòng GD-ĐT Đại Lộc ĐỀ ĐỀ NGHỊ HỌC KÌ II-Năm học 2013-2014 Trường THCS Kim Đồng Môn: Anh Văn 8 Người ra đề: Nguyễn Thị Nở Ma trậnminhtri0073No ratings yet

- The Tata WayDocument6 pagesThe Tata WayNiloy SadhuNo ratings yet

- Lloyd AviryDocument2 pagesLloyd AviryJ'mhaeGamboaNo ratings yet

- Philippine Socioeconomic Development in The 21st Century 1Document107 pagesPhilippine Socioeconomic Development in The 21st Century 1Keira FrostNo ratings yet

- Case Study 2Document4 pagesCase Study 2muzzamilNo ratings yet

- Caia Fundamentals Flyer 1-19 PDFDocument2 pagesCaia Fundamentals Flyer 1-19 PDFNasim AkhtarNo ratings yet

- MalinasDocument1 pageMalinasFábio ParenteNo ratings yet

- Cma Course Going GlobalDocument8 pagesCma Course Going GlobalMTStg InFiNiTy TauqeerNo ratings yet

- Unlawful Detainer PDFDocument2 pagesUnlawful Detainer PDFBIGBOYNo ratings yet

- HMS Bulwark (L15)Document5 pagesHMS Bulwark (L15)rbnaoNo ratings yet

- GEPC Module 3 Varieties and Registers of Language 1Document7 pagesGEPC Module 3 Varieties and Registers of Language 1Kurt Russell BalaniNo ratings yet

- Emirates Ticket 1Document2 pagesEmirates Ticket 1Bella PoarchNo ratings yet