Professional Documents

Culture Documents

Butadiene Pipe Insulation Scope

Butadiene Pipe Insulation Scope

Uploaded by

Subhashis ChatterjeeOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Butadiene Pipe Insulation Scope

Butadiene Pipe Insulation Scope

Uploaded by

Subhashis ChatterjeeCopyright:

Available Formats

BUTADIENE PIPE INSULATION SCOPE (FOR OSBL ONLY) APPLICATION SPECIFICATION:

The job shall be carried out as per the following procedure: 1] Fix required thickness of polyurethane foam pipe sections (for 6 NB Pipe PUFF thickness 50 mm) with the help of hot bitumen 85/25. Secure the same with the help of 24 swg G.I. wire at 300 mm centre to centre distance. 2] Apply vapour barrier with open waive glass cloth sandwiched between two coats of specialty fire retardant mastic MAS-130. Pl. refer to the specification below 3] The final finish shall be sand cement plastering (12.5MM thick) with Tar-felt Type II, Grade I, in two layers with proper overlap & fixed with Bitumen. The finish must be whitish in appearance (Vendor may suggest specific plastering) 4] For Valve & flange insulation should be attached with valve & flange (not removable type for outside Plant premise). INSULATION MATERIAL: POLYURETHANE FOAM: The insulation material shall be rigid performed cellular urethane foam of self extinguishing type in accordance with ASTM C 591, type II, Grade 2. The foam shall be formulated in such a way that it shall be of a self extinguishing quality which under no circumstances shall cause fire to spread. COMPOSITION: The insulation material shall be produced by reacting poly-iso-cyanates with poly-hydroxy compounds and expanded with a fluorocarbon blowing agent. The finished foam in the form of slabs or half sections shall be of uniform closed cell structure, free from unreacted materials, shrinkage and distortion. DENSITY: The density of finished foam shall be within 36.0 kg/m3 to 39.9 kg/m3 and shall be determined in accordance with ASTM C-302 and IS:12436. At pipe support locations use insulated high density Supertherm Polyurethane pipe support of 200 Kg/M3 density. VAPOUR BARRIER WITH MAS 130: 1] 3.0 mm thick MAS 130 on cold insulation (Puff) 2] Supply and application of glass cloth of 1.6 mm thick. 3] Supply and application of 3.0 mm thick MAS 130 over the glass cloth.

You might also like

- BOQ For Waterproofing Works: Modern IT Solutions, NoidaDocument4 pagesBOQ For Waterproofing Works: Modern IT Solutions, NoidaAbhinav Saini100% (1)

- Butene Pipe Insulation Scope - OsblDocument1 pageButene Pipe Insulation Scope - OsblSubhashis ChatterjeeNo ratings yet

- Mark III LNG TanksDocument3 pagesMark III LNG TanksEdutamNo ratings yet

- Isohemp - Specificationes XDDocument2 pagesIsohemp - Specificationes XDjosepNo ratings yet

- SECTION 15082 Equipment Insulation Part 1 - General 1.1 GeneralDocument5 pagesSECTION 15082 Equipment Insulation Part 1 - General 1.1 GeneralfatREVITNo ratings yet

- Epoxy Bonded Reinforcement To Concrete Decks and BeamsDocument2 pagesEpoxy Bonded Reinforcement To Concrete Decks and BeamsFrancisco Javier Martinez BurgoNo ratings yet

- 711 BSP 02waterproofingDocument4 pages711 BSP 02waterproofinghery siregarNo ratings yet

- GTT Mark III PlaquetteDocument4 pagesGTT Mark III PlaquetteAlexandros HatzisNo ratings yet

- UP PWD WP SpecDocument9 pagesUP PWD WP Specsanjay kumarNo ratings yet

- Chapter 26 PDFDocument10 pagesChapter 26 PDFruel delacruzNo ratings yet

- Polyethylene InsulationDocument2 pagesPolyethylene InsulationJeghi100% (1)

- Waterproofing For Sub-StructureDocument2 pagesWaterproofing For Sub-StructureAtif RizviNo ratings yet

- Fosroc - UG Water Tank SpecsDocument1 pageFosroc - UG Water Tank SpecsShakil AkhterNo ratings yet

- SECTION 07 12 00 Built-Up Bituminous WaterproofingDocument6 pagesSECTION 07 12 00 Built-Up Bituminous WaterproofingMorris AlcantaraNo ratings yet

- Boscoseal Torch OnDocument3 pagesBoscoseal Torch OnjbonvierNo ratings yet

- 03 en PSI Kebu Anti Corrosion TapesDocument13 pages03 en PSI Kebu Anti Corrosion Tapesmechanical_engineer11No ratings yet

- Pittsburgh Corning Foamglass Cold Process Piping Installation GuidelineDocument7 pagesPittsburgh Corning Foamglass Cold Process Piping Installation Guidelinenaseema1No ratings yet

- ITCC in Riyadh Residential Complex J10-13300 07200-1 Building InsulationDocument5 pagesITCC in Riyadh Residential Complex J10-13300 07200-1 Building InsulationuddinnadeemNo ratings yet

- Detailed Specification PE Casing Jacket With Standard UIP System 1) GeneralDocument3 pagesDetailed Specification PE Casing Jacket With Standard UIP System 1) GeneralMina MagdyNo ratings yet

- TDS Bostik BoscoSeal PU XDocument5 pagesTDS Bostik BoscoSeal PU XJosip MedvedNo ratings yet

- Building Analysis RoofDocument2 pagesBuilding Analysis RoofEvelyne BujoreanNo ratings yet

- WSDDDocument3 pagesWSDDThankappan Ramesan AcharyNo ratings yet

- Baumit Facade Insulating Board EPS-F: ProductDocument6 pagesBaumit Facade Insulating Board EPS-F: ProductIbrahim SahinNo ratings yet

- Piping and Equipment InsulationDocument4 pagesPiping and Equipment InsulationttshareefNo ratings yet

- International Fire Code.: PlasticDocument1 pageInternational Fire Code.: Plastickeerthivasan_mrvNo ratings yet

- Suspended Ceilings Construction GuideDocument4 pagesSuspended Ceilings Construction GuideHassan RahilNo ratings yet

- Dm-dsi-SPEC09 - Corrosion PR & Odor CNTRLDocument13 pagesDm-dsi-SPEC09 - Corrosion PR & Odor CNTRLhardikNo ratings yet

- Duct Work Method StatementDocument5 pagesDuct Work Method StatementAla Makram Sunna0% (1)

- Duct Work Method StatementDocument5 pagesDuct Work Method StatementHai LeNo ratings yet

- SECTION 15081: Duct Insulation 15081Document5 pagesSECTION 15081: Duct Insulation 15081fatREVITNo ratings yet

- 07545-Foam RoofingDocument4 pages07545-Foam RoofingEfz EfzNo ratings yet

- Bih Ceresit cp30 Silikonski Hidroizolacioni Premaz Tds BihDocument2 pagesBih Ceresit cp30 Silikonski Hidroizolacioni Premaz Tds BihPuppala Laxmana PrasadNo ratings yet

- AHU CasingDocument3 pagesAHU Casingmirali74No ratings yet

- Bostik Paneltack HM Dekton Tds en 2020Document5 pagesBostik Paneltack HM Dekton Tds en 2020Miguel ZuzaNo ratings yet

- Section 15250 - Mechanical InsulationDocument8 pagesSection 15250 - Mechanical Insulationrizviabbas2012No ratings yet

- Classification: Internal UseDocument6 pagesClassification: Internal UseSiva SankarNo ratings yet

- Water Proof SpecDocument2 pagesWater Proof SpecdjgiumixNo ratings yet

- Specification GlassFiberDocument6 pagesSpecification GlassFiberMukesh MaharjanNo ratings yet

- Rates For TilesDocument5 pagesRates For TilesLamichhane SauravNo ratings yet

- 2.3. External Waterproofing SystemsDocument2 pages2.3. External Waterproofing SystemsKrishna SankarNo ratings yet

- Water Proofing WorksDocument8 pagesWater Proofing Worksukali_csNo ratings yet

- TMP 1674627247 PDFDocument14 pagesTMP 1674627247 PDFvivekNo ratings yet

- Duct InsulationDocument9 pagesDuct Insulationphyolwin ooNo ratings yet

- Enquiry - Passive Fire Protection SystemDocument6 pagesEnquiry - Passive Fire Protection Systemrkpatel40No ratings yet

- Exhibit B-30 InsulationDocument7 pagesExhibit B-30 Insulationsethu1091No ratings yet

- DocumentDocument3 pagesDocumentPronay DhakNo ratings yet

- MP HALL - Speci-DDocument3 pagesMP HALL - Speci-DAbdul RahumanNo ratings yet

- 2790 - Mechanical InsulationDocument2 pages2790 - Mechanical InsulationMohammedIrfanNo ratings yet

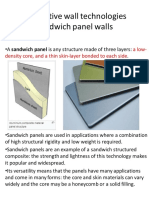

- Alternative Wall Technologies-Sandwitch PanelsDocument14 pagesAlternative Wall Technologies-Sandwitch PanelsDiya MakanurNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 07100-1 WaterproofingDocument5 pagesITCC in Riyadh Residential Complex J10-13300 07100-1 WaterproofinguddinnadeemNo ratings yet

- SBI Direction 189 External Walls Edition OCWDocument18 pagesSBI Direction 189 External Walls Edition OCWAlexandra TotoianuNo ratings yet

- External Pipe CoatingsDocument15 pagesExternal Pipe Coatingsupesddn2010100% (3)

- Group 6 Rule 16 18Document30 pagesGroup 6 Rule 16 18Melvin AlarillaNo ratings yet

- Plastic Felt:-: Product GuideDocument8 pagesPlastic Felt:-: Product GuideKVRamananNo ratings yet

- Defence Standard 02-801Document2 pagesDefence Standard 02-801zubimehNo ratings yet

- M2 - Manual PDFDocument0 pagesM2 - Manual PDFFlorinHanu100% (1)

- Kimmco InsulationDocument7 pagesKimmco InsulationMujjo SahbNo ratings yet

- Rockwool Intumescent PillowsDocument3 pagesRockwool Intumescent PillowsBobana AdamovicNo ratings yet

- Different Sides.: Material Downloaded From - 1 / 6Document6 pagesDifferent Sides.: Material Downloaded From - 1 / 6Subhashis ChatterjeeNo ratings yet

- Npcil Plis SchemeDocument9 pagesNpcil Plis SchemeSubhashis Chatterjee0% (1)

- GLOBE - LATITUDE AND LONGITUDE (Key Notes)Document2 pagesGLOBE - LATITUDE AND LONGITUDE (Key Notes)Subhashis ChatterjeeNo ratings yet

- Kendriya Vidylaya Chenani Worksheet English (August) Class I Name: . Competency: Reading Roll No. . and WritingDocument2 pagesKendriya Vidylaya Chenani Worksheet English (August) Class I Name: . Competency: Reading Roll No. . and WritingSubhashis ChatterjeeNo ratings yet

- Best of Bikaner Recommended by Indian Travellers: Created Date: 29 November 2015Document10 pagesBest of Bikaner Recommended by Indian Travellers: Created Date: 29 November 2015Subhashis ChatterjeeNo ratings yet

- NPS Lite - The Low Cost Model For "Groups"Document19 pagesNPS Lite - The Low Cost Model For "Groups"Subhashis ChatterjeeNo ratings yet

- Document Check ListDocument1 pageDocument Check ListSubhashis ChatterjeeNo ratings yet

- Ayodhya Pahar, PuruliaDocument16 pagesAyodhya Pahar, PuruliaSubhashis ChatterjeeNo ratings yet

- Sbi Guidelines Checkoff ListDocument5 pagesSbi Guidelines Checkoff ListSubhashis ChatterjeeNo ratings yet

- ANSI B16.9 ElbowDocument3 pagesANSI B16.9 ElbowLuna LukaNo ratings yet

- Change The Positions of The Frogs On Right and Left. Usually It Can Be Done in 3 Minutes If Your IQ Is Not Under 50Document3 pagesChange The Positions of The Frogs On Right and Left. Usually It Can Be Done in 3 Minutes If Your IQ Is Not Under 50Subhashis ChatterjeeNo ratings yet

- Valve Moc TypesDocument2 pagesValve Moc TypesSubhashis ChatterjeeNo ratings yet