Professional Documents

Culture Documents

Analysis of A Centrifugal Pump: Pumping Head Curves: CM3215 Fundamentals of Chemical Engineering Laboratory

Analysis of A Centrifugal Pump: Pumping Head Curves: CM3215 Fundamentals of Chemical Engineering Laboratory

Uploaded by

JackSparrow86Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Analysis of A Centrifugal Pump: Pumping Head Curves: CM3215 Fundamentals of Chemical Engineering Laboratory

Analysis of A Centrifugal Pump: Pumping Head Curves: CM3215 Fundamentals of Chemical Engineering Laboratory

Uploaded by

JackSparrow86Copyright:

Available Formats

1

CM3215

Fundamentals of Chemical Engineering Laboratory

Professor Faith Morrison

Department of Chemical Engineering

Michigan Technological University

Analysis of a

Centrifugal Pump:

Pumping Head Curves

Faith A. Morrison, Michigan Tech U.

Centrifugal Pumps

Faith A. Morrison, Michigan Tech U.

Centrifugal force is used to

fling fluid from the suction

side to the discharge

Centrifugal pumps put out

neither constant flow rate

nor constant pressure

We must use the

mechanical energy balance

to figure out how a

centrifugal pump will perform

in a given situation

suction

discharge

CM3215 Fundamentals of Chemical Engineering Laboratory

2

Faith A. Morrison, Michigan Tech U.

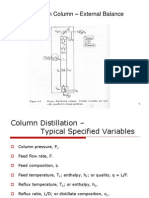

Pumping Head Characteristic Curves are provided by

the manufacturer (plots of what a pump can do)

The manufacturer determines pump characteristic

curve by measuring AP on the suction/discharge system

(we do this now for the CM3215 Lossy pump)

How do you choose a centrifugal pump for a given system?

CM3215 Fundamentals of Chemical Engineering Laboratory

System Curve Assignment (week 8)

Pumping Head Lab (this week)

Calculate the flow-rate-dependent demands of a system

= system head curve (previous assignment)

Compare the system-head curve (demands) to the

available pumping-head curve (supply), and choose

Faith A. Morrison, Michigan Tech U.

T

O

T

A

L

H

E

A

D

(

f

t

)

US GALLONS PER MINUTE

Krum Pump Company

Kalamazoo, MI

Model: Peerless pump

Type: PE50B

Performance Curve No: 4848278

RPM: 3450

3

To analyze the performance of a centrifugal pump, we

apply the Mechanical Energy Balance around the pump

( )

m

W

F z g

v P

on s

friction

,

2

2

= + A +

A

+

A

o

z

s

v

s

P

s

z

d

v

d

P

d

suction

discharge

Faith A. Morrison, Michigan Tech U.

CM3215 Fundamentals of Chemical Engineering Laboratory

2 2

, ,

,

2 2

, ,

,

( )

2

( )

2

s on ds

d s d s

d s d s

s on ds

d s d s

d s d s

v v W

P P

g z z F

m

v v W

P P

g z z F

m

+ + + =

+ + =

Centrifugal Pumps - MEB written on suction/discharge system

m

W

pump by s

,

q

brake horsepower

pump efficiency

Faith A. Morrison, Michigan Tech U.

CM3215 Fundamentals of Chemical Engineering Laboratory

z

s

v

s

P

s

z

d

v

d

P

d

suction

discharge

Losses

inside

pump only

4

F

a

i

t

h

A

.

M

o

r

r

i

s

o

n

,

M

i

c

h

i

g

a

n

T

e

c

h

U

.

Calculating the Pumping Head curve:

Write the MEB on the suction-discharge system

Measure pressures, velocities, elevations at (d) and (s)

Pump friction is subtracted from the work to give usable

head, H

p

; therefore we need not measure pump friction

2 2

, ,

( )

2

s on d s d s d s

d s p

v v W F P P

z z H

g g mg g

| |

+ + =

|

\ .

2 2

( )

2

d s d s

p d s

v v

P P

H z z

g g

+ +

Total

head

energy

weight

| |

=

|

\ .

CM3215 Fundamentals of Chemical Engineering Laboratory

The resulting expression is a

function of flow rate (through

the average velocity).

Pumping Head - pump

characteristic curve

Faith A. Morrison, Michigan Tech U.

CM3215 Fundamentals of Chemical Engineering Laboratory

H (ft)

Q (gal/min)

increasing RPM

5

Faith A. Morrison, Michigan Tech U.

Pumping Head Characteristic Curves are usually supplied by the

manufacturer

In this lab we measure the pumping head characteristic curve for a

custom pump, the CM3215 Lossy pump

Once we measure the pump characteristic curve for our Lossy

pump, we use this to predict operating points as if we were

designing a new system

Finally, we check these predicted operating points against the

actual operating points we measure in the lab. This gives us a feel

for how accurate these types of design predictions are.

CM3215 Fundamentals of Chemical Engineering Laboratory

H (ft)

Q (gal/min)

system curves

(Assignment 5)

Measured lossy

pumping curve

operating point predictions

Faith A. Morrison, Michigan Tech U.

CM3215 Fundamentals of Chemical Engineering Laboratory

We can use the methods of Assignment 3 to predict the operation of the

Lossy pump against the laboratory system

In Assignment 3 we calculated three curves for our lab system with different

settings of WV5: 0.5 turn, 1.0 turn, and 1.5 turns open.

We now need to operate under those conditions (set WV5: 0.5 turn, 1.0 turn,

and 1.5 turns open).

With the theoretical system curves, we can predict operating points for the

settings of the valve above and compare to actual.

System curve for

WV5 set one turn

open

6

CM3215 Fundamentals of Chemical Engineering Laboratory

Lab 6: Analysis of a Centrifugal Pump

Measure pressure changes over suction/discharge system

for the Lossy pump over a wide range of flow rates

Operate the Lossy pump against the system you modeled

in Assignment 3 System Head Curves

Acquire the appropriate replicates on all data

Report measured pumping head curve (fit to a curve)

Using the system-head calculations from Assmt 3 to predict

operating points

Compare the predictions with the actual.

Faith A. Morrison, Michigan Tech U.

CM3215 Fundamentals of Chemical Engineering Laboratory

F

a

i

t

h

A

.

M

o

r

r

i

s

o

n

,

M

i

c

h

i

g

a

n

T

e

c

h

U

.

The CM3215 Lossy Pump

Extends from the pump suction to the exit of the orifice meter.

Lossy

pump

Pressure tap at exit of orifice meter (discharge of lossy pump)

Pressure tap at Krumppump suction (suction of lossy pump)

(has a great deal

of internal losses,

including the

orifice meter and

the rotameter)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 36 PneumaticDocument65 pages36 PneumaticTarik Benzineb83% (6)

- PRP - Added 04 Practicals (30th Oct 2013)Document6 pagesPRP - Added 04 Practicals (30th Oct 2013)idyllic20No ratings yet

- Name: Shariq Saleem Address: R-69 Aramish Banglows Gulistan-E-Johar, Karachi CONTACT #: 03428079122 Email Address: &Document2 pagesName: Shariq Saleem Address: R-69 Aramish Banglows Gulistan-E-Johar, Karachi CONTACT #: 03428079122 Email Address: &idyllic20No ratings yet

- Graduate Directory Form For Final Year StudentsDocument1 pageGraduate Directory Form For Final Year Studentsidyllic20No ratings yet

- Lab Report FinalDocument13 pagesLab Report Finalidyllic20No ratings yet

- 0625 s13 QP 11Document20 pages0625 s13 QP 11idyllic20No ratings yet

- 9702 s13 QP 31Document12 pages9702 s13 QP 31idyllic20No ratings yet

- Work Book: Chemical Process Optimization (CH-404)Document4 pagesWork Book: Chemical Process Optimization (CH-404)idyllic20No ratings yet

- Distillation ColumnDocument20 pagesDistillation ColumnNeeshä RagnathNo ratings yet

- Process Simulation in Chemical EngineeringDocument10 pagesProcess Simulation in Chemical Engineeringidyllic20No ratings yet

- Airframes Question BankDocument22 pagesAirframes Question Bankgaurav aryaNo ratings yet

- Group 18 ElementsDocument19 pagesGroup 18 ElementsPeki_EnglishNo ratings yet

- Chapter 7Document34 pagesChapter 7ShahrizatSmailKassimNo ratings yet

- PDP Lecture 1 4Document13 pagesPDP Lecture 1 4VIVEK MANI TRIPATHINo ratings yet

- Chn628 Especificaciones Eng 29052018Document2 pagesChn628 Especificaciones Eng 29052018Juan Carlos LopezNo ratings yet

- m10h Bio LNGDocument11 pagesm10h Bio LNGnazzq123No ratings yet

- Jet Fuel Pipelines and Storage PDFDocument2 pagesJet Fuel Pipelines and Storage PDFVrbank KrabNo ratings yet

- Turbo Flo Stallion t15 Metal EomDocument28 pagesTurbo Flo Stallion t15 Metal Eomvladimir robalinoNo ratings yet

- SpiraxSarco The Steam and Condensate Loop Block 1 14Document498 pagesSpiraxSarco The Steam and Condensate Loop Block 1 14mirceablaga86100% (1)

- Correlation Guide For Users of White: Fluid Mechanics, 5/eDocument4 pagesCorrelation Guide For Users of White: Fluid Mechanics, 5/eNg Swee Loong StevenNo ratings yet

- Sample of Nfpa Hydraulic CalculationDocument14 pagesSample of Nfpa Hydraulic Calculationzasza100% (1)

- Hydraulic Accumulator Circuits P1Document39 pagesHydraulic Accumulator Circuits P1Ruben Dario Mata Romero67% (3)

- Measurement For Determining PerformanceDocument21 pagesMeasurement For Determining Performanceroy rockNo ratings yet

- Leak Test ProcedureDocument13 pagesLeak Test ProcedureCipta AdikaryaNo ratings yet

- Reducer: Sweat Reducer Hydraulic Concentric Eccentric ReducersDocument1 pageReducer: Sweat Reducer Hydraulic Concentric Eccentric ReducersMayur MandrekarNo ratings yet

- 11 - Macroscopic Balances For Non-Isothermal Systems Part 1Document6 pages11 - Macroscopic Balances For Non-Isothermal Systems Part 1Monica TuwaidanNo ratings yet

- OCE551-Air Pollution and Control EngineeringDocument13 pagesOCE551-Air Pollution and Control EngineeringpranavmiteshNo ratings yet

- Lesson 3 Temperature Ranges and Refrigeration CycleDocument67 pagesLesson 3 Temperature Ranges and Refrigeration CycleEddie AbugNo ratings yet

- Review On Hydrogen Safety IssuesDocument23 pagesReview On Hydrogen Safety IssuesEvans Azka FNo ratings yet

- Co2 BrochureDocument2 pagesCo2 BrochureNabil HassanNo ratings yet

- Lab H1: IMPORTANT NOTE To Respective GroupsDocument70 pagesLab H1: IMPORTANT NOTE To Respective GroupsHritik LalNo ratings yet

- Indian Geography: Energy ResourcesDocument60 pagesIndian Geography: Energy ResourcesArdh0072No ratings yet

- Example 5.4 What Is The Gauge Pressure in (A) Kilopascals and (B) Newtons Per SquareDocument4 pagesExample 5.4 What Is The Gauge Pressure in (A) Kilopascals and (B) Newtons Per SquarelimaduaNo ratings yet

- KoL Mekflu - 9Document104 pagesKoL Mekflu - 9Maha D NugrohoNo ratings yet

- Crop Maintenance Machinery and Equipment Operations: SprayerDocument10 pagesCrop Maintenance Machinery and Equipment Operations: SprayerKelly EstilongNo ratings yet

- Nodal Analysis - TAMUDocument53 pagesNodal Analysis - TAMUAhmad FaizilNo ratings yet

- Fluid Machnique - Theory PDFDocument11 pagesFluid Machnique - Theory PDFhumayun khalidNo ratings yet

- Vol 10 No 1 - 2014 PlatformDocument60 pagesVol 10 No 1 - 2014 PlatformJulendra AriatedjaNo ratings yet

- Sick Well Analysis & Remedial MeasuresDocument34 pagesSick Well Analysis & Remedial MeasuresSumanth Reddy0% (1)