Professional Documents

Culture Documents

Tema Standards

Uploaded by

jose_alberto20 ratings0% found this document useful (0 votes)

443 views1 pageFor shell side nozzles there is the additional problem of high velocity fluids impinging on the tube bundle. TEMA lays down fairly strict requirements for this case. Impingement protection is always required for gases which are corrosive and / or abrasive.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFor shell side nozzles there is the additional problem of high velocity fluids impinging on the tube bundle. TEMA lays down fairly strict requirements for this case. Impingement protection is always required for gases which are corrosive and / or abrasive.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

443 views1 pageTema Standards

Uploaded by

jose_alberto2For shell side nozzles there is the additional problem of high velocity fluids impinging on the tube bundle. TEMA lays down fairly strict requirements for this case. Impingement protection is always required for gases which are corrosive and / or abrasive.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Shell&Tube Nozzles - TEM...

Page 1

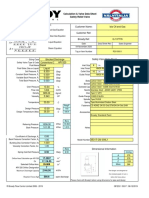

Shell&Tube Nozzles - TEMA Standards

For shell side nozzles there is the additional problem of high velocity fluids impinging on the tube bundle. TEMA, which is the usual standard adopted, lays down fairly strict requirements for this case which may be summarized as follows: Impingement protection, which would usually be in the form of a square plate, 6 mm (1/4 inch) thick, tack welded to the tube bundle (an 'impingement plate'), to be provided for nozzle rho-v2 greater than; 2230 kg/ms2 (1500 lb/ft s2) for non-corrosive, non-abrasive, single phase fluids. 740 kg/ms2 (500 lb/ft s2) for liquids which are corrosive, abrasive or at their boiling point. Impingement protection is always required for gases which are corrosive and/or abrasive. Impingement protection is always required for saturated vapors and for two phase mixtures. Shell or bundle entrance or exit flow area (whether impingement protection fitted or not) is to be such that the rho-v2 does not exceed 5950 kg/ms2 (4000 lb/ft/ s2). For tube side nozzles, TEMA standard is less restrictive, at 8928 kg/ms2 (6000 lb/ft/ s2), because there are no impingement issues. See also Nozzles - Achieving TEMA Standards

mk:@MSITStore:C:\Progra...

31/08/2011

11:58:55 a.m.

You might also like

- Typical Specification For Steam Surface Condensers Appendix ADocument5 pagesTypical Specification For Steam Surface Condensers Appendix Ahappale2002No ratings yet

- Astm F436.04 PDFDocument6 pagesAstm F436.04 PDFWelington Volpatto MoraisNo ratings yet

- IR HL Heatless DryerDocument1 pageIR HL Heatless DryerYing Kei ChanNo ratings yet

- Helium leak test procedureDocument7 pagesHelium leak test procedureChandrasekhar mishraNo ratings yet

- Ab 536 Requirements For The Integrity Management of Grade 91 Steel Used Above Currently Permitted Allowable StressesDocument17 pagesAb 536 Requirements For The Integrity Management of Grade 91 Steel Used Above Currently Permitted Allowable StressesCarlos Maldonado SalazarNo ratings yet

- Canalta Orifice Fitting Parts & Accessories: Precision Machined Accuracy Reliability PerformanceDocument90 pagesCanalta Orifice Fitting Parts & Accessories: Precision Machined Accuracy Reliability Performanceray mojicaNo ratings yet

- Asme Sec XDocument1 pageAsme Sec XSARSAN NDTNo ratings yet

- What Is An ASME Appendix 2 Flange Design PDFDocument1 pageWhat Is An ASME Appendix 2 Flange Design PDFMangesh BanaleNo ratings yet

- Asme - HeaderDocument3 pagesAsme - HeaderReadersmoNo ratings yet

- Comparison ASME KTADocument7 pagesComparison ASME KTAAndres_Pastor1987No ratings yet

- TEMA Eighth Edition - ClarificationsDocument13 pagesTEMA Eighth Edition - ClarificationsJerome100% (1)

- PED 2014-68-EU Guidelines EN v4Document235 pagesPED 2014-68-EU Guidelines EN v4Nav TalukdarNo ratings yet

- Bulk Air Eliminator R1Document1 pageBulk Air Eliminator R1hydrothermsNo ratings yet

- BS 5500 Appendix K and DDocument14 pagesBS 5500 Appendix K and DCRISTIAN SILVIU IANUCNo ratings yet

- ASME Pressure VesselsDocument41 pagesASME Pressure VesselsJawed Akhter100% (1)

- ASCE 7-05 Table 15-4-2Document1 pageASCE 7-05 Table 15-4-2barouniamineNo ratings yet

- Oil Gas Construction Factory L.L.CDocument2 pagesOil Gas Construction Factory L.L.CRenny DevassyNo ratings yet

- FDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Document15 pagesFDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Gisela ViskaNo ratings yet

- Valvula Mariposa Danais 150Document15 pagesValvula Mariposa Danais 150Oscar CherroNo ratings yet

- Pressure Points: Ask The EngineerDocument5 pagesPressure Points: Ask The EngineerMario MolinaNo ratings yet

- En 13121-3:2008+a1:2010 (E)Document1 pageEn 13121-3:2008+a1:2010 (E)TIME STAR COMPOSITENo ratings yet

- U1a - 735834Document2 pagesU1a - 735834Alex SimonNo ratings yet

- Anodes in Cooling Water Exchangers PDFDocument12 pagesAnodes in Cooling Water Exchangers PDFcbrittaivNo ratings yet

- ABO Ball ValveDocument6 pagesABO Ball ValveSunil BajpaiNo ratings yet

- WHRB-265!08!00 Front and Rear Mirrors, Shell CalculationDocument2 pagesWHRB-265!08!00 Front and Rear Mirrors, Shell CalculationmehmacarNo ratings yet

- Snamprogetti fluid list piping classDocument3 pagesSnamprogetti fluid list piping classadesloopNo ratings yet

- Tubesheet As Per ASME Sec. VIII-Div.1 UHXDocument1 pageTubesheet As Per ASME Sec. VIII-Div.1 UHXruponline1No ratings yet

- Is 210Document16 pagesIs 210Debopriyo GhoshNo ratings yet

- Low Temperature and Cryogenic Ball ValvesDocument4 pagesLow Temperature and Cryogenic Ball Valves윤병택100% (1)

- Hoja de Datos Sistema Aire Comprimido ReferencialDocument18 pagesHoja de Datos Sistema Aire Comprimido ReferencialchepeluchounNo ratings yet

- ASTM F1545 Plastic Lined Pipe 0803Document6 pagesASTM F1545 Plastic Lined Pipe 0803JabranYounasNo ratings yet

- Welding Neck Flanges 1Document3 pagesWelding Neck Flanges 1bikkelbobNo ratings yet

- Ansi b36.10 Seamless Pipe SizesDocument2 pagesAnsi b36.10 Seamless Pipe SizesmohitNo ratings yet

- Sodium Leak Through Pin HolesDocument9 pagesSodium Leak Through Pin HolesAvinash ChittellaNo ratings yet

- 10inch Inlet DiffuserDocument1 page10inch Inlet DiffuserJulian Vega DiazNo ratings yet

- Checklist For Above Ground Tanks-QueenslandDocument2 pagesChecklist For Above Ground Tanks-QueenslandmohanumaNo ratings yet

- Design partition plate for refinery distillation columnDocument5 pagesDesign partition plate for refinery distillation columnpippo2378793No ratings yet

- b2020-Tdc-Fas-004 Fasteners r3Document2 pagesb2020-Tdc-Fas-004 Fasteners r3Ramalingam PrabhakaranNo ratings yet

- Afnor 28 CDV 5-08 SteelDocument1 pageAfnor 28 CDV 5-08 SteelMagoroku D. YudhoNo ratings yet

- 2019 ASME Section VIII Division 1 SynopsisDocument58 pages2019 ASME Section VIII Division 1 SynopsisCristian Xavier Avendaño BelloNo ratings yet

- SP-2069 Specification For Pressure VesselsDocument68 pagesSP-2069 Specification For Pressure Vesselsarjunprasannan7No ratings yet

- E1 Technical Data Sheet - ShortDocument2 pagesE1 Technical Data Sheet - ShortOmaiyio M. SaginiNo ratings yet

- Water SoftenersDocument11 pagesWater Softenersadel rihanaNo ratings yet

- ML 1015998765Document42 pagesML 1015998765ডঃ শুভম চ্যাটার্জীNo ratings yet

- Sizing CalcDocument1 pageSizing CalcHilary AbaratuNo ratings yet

- ASME UM Audit Preparation ListDocument2 pagesASME UM Audit Preparation ListMd Anamul Hoque100% (1)

- Coating Materials For Metal-Seated Ball Valves: Ensuring Tight Shut-Off and Extreme Reliability in ServiceDocument6 pagesCoating Materials For Metal-Seated Ball Valves: Ensuring Tight Shut-Off and Extreme Reliability in Serviceharish mohammedNo ratings yet

- En 12451 1999Document24 pagesEn 12451 1999victoraghiNo ratings yet

- CalcvesselDocument11 pagesCalcvesselHami Keserci100% (1)

- Pressure Vessel Inspection and Test Plan Sample: WWW - Inspection-For-Industry.c OmDocument4 pagesPressure Vessel Inspection and Test Plan Sample: WWW - Inspection-For-Industry.c OmMuh FarhanNo ratings yet

- FVCDocument0 pagesFVCsmileya_vpNo ratings yet

- Sa-516 70 TDCDocument2 pagesSa-516 70 TDCshazan100% (1)

- A 1 KDocument5 pagesA 1 KSumantrra ChattopadhyayNo ratings yet

- Nozzle flange pressure calculationDocument2 pagesNozzle flange pressure calculationsudokuNo ratings yet

- Eqn Reference ASME BPVC r1sDocument5 pagesEqn Reference ASME BPVC r1sagarcia654127No ratings yet

- Rtaa SB 20Document5 pagesRtaa SB 20kulilin1100% (1)

- Pipeclad-Product-Brochure-Sherwin-Williams-EnglishDocument12 pagesPipeclad-Product-Brochure-Sherwin-Williams-EnglishCésarNo ratings yet

- Polyguard 600 CoatingsDocument2 pagesPolyguard 600 CoatingstechdocuNo ratings yet

- How To Survive The Fourth Industrial Revolution: A 15-Minute Guide To Digital Manufacturing For SME Decision MakersDocument36 pagesHow To Survive The Fourth Industrial Revolution: A 15-Minute Guide To Digital Manufacturing For SME Decision Makersjose_alberto2No ratings yet

- Areyoureadyforindustry4 170621090030Document10 pagesAreyoureadyforindustry4 170621090030jose_alberto2No ratings yet

- 3BUR000570R401B - en Advant Controller 460 User S GuideDocument334 pages3BUR000570R401B - en Advant Controller 460 User S Guidejose_alberto2No ratings yet

- Advabuild: Configurable Control Functions (CCF) User GuideDocument678 pagesAdvabuild: Configurable Control Functions (CCF) User Guidejose_alberto2No ratings yet

- 3BUR001977R3701revA AdvaBld AdminDocument198 pages3BUR001977R3701revA AdvaBld Adminjose_alberto2No ratings yet

- Tacos Paco'sDocument1 pageTacos Paco'sjose_alberto2No ratings yet

- FideDocument1 pageFidejose_alberto2No ratings yet

- Check Valve S1Document8 pagesCheck Valve S1jose_alberto2No ratings yet

- Density of acetic acid solutionsDocument1 pageDensity of acetic acid solutionsjose_alberto2No ratings yet

- Perry S Chemical Engineers HandbookDocument1 pagePerry S Chemical Engineers HandbookdatinjacabNo ratings yet

- HitmanKeyboardLayout NumpadDocument1 pageHitmanKeyboardLayout Numpadjose_alberto2No ratings yet

- User's Handbook On Solar Water HeatersDocument36 pagesUser's Handbook On Solar Water Heatersjose_alberto2No ratings yet

- CPVCDocument9 pagesCPVCgrasimlook50% (2)

- Winkawaks145 FaqDocument9 pagesWinkawaks145 Faqapi-3836418100% (1)

- Perry S Chemical Engineers HandbookDocument1 pagePerry S Chemical Engineers HandbookdatinjacabNo ratings yet

- CPVCDocument9 pagesCPVCgrasimlook50% (2)

- Antoine Coefficient TableDocument14 pagesAntoine Coefficient Tablenafaluck0% (1)

- K FactorsDocument7 pagesK Factorsjose_alberto2No ratings yet