Professional Documents

Culture Documents

Torque Estimating Chart

Uploaded by

Satish ShewaleCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Torque Estimating Chart

Uploaded by

Satish ShewaleCopyright:

Available Formats

_

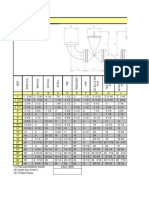

Torque Estimating Chart

ASTM A193, GRADE B7 STUDS

LUBRICANT: MOLY PASTE

NUT FACTORS (K): 0.14, 0.18, OR 0.20

TORQUE VALUES CALCULATED USING MECHANICAL ENGINEERING SHORT FORMULA

T = K (Nut Factor) X Clamp Load

STUD

DIAMETER

(inches)

1/2

5/8

3/4

7/8

1

1-1/8

1-1/4

1-3/8

1-1/2

1-5/8

1-3/4

1-7/8

2

2-1/4

2-1/2

2-3/4

3

3-1/4

3-1/2

3-3/4

4

NUT

SIZE

(AFT)

7/8

1-1/16

1-1/14

1-7/16

1-5/8

1-13/16

2

2-3/16

2-3/8

2-9/16

2-3/4

2-15/16

3-1/8

3-1/2

3-7/8

4-1/4

4-5/8

5

5-3/8

5-3/4

6-1/8

40% YIELD

K= .14 K= .18

35

45

69

89

123

158

198

255

297

382

435

560

613

788

831

1,068

1,097

1,410

1,417

1,822

1,784

2,293

2,214

2,847

2,715

3,490

3,925

5,046

4,921

6,327

6,620

8,512

8,658

11,132

11,080 14,246

13,903 17,875

17,190 22,102

20,943 26,927

K= .20

50

99

175

283

424

622

875

1,187

1,567

2,025

2,548

3,163

3,878

5,607

7,030

9,457

12,369

15,829

19,864

24,558

29,919

X D [Bolt Diameter (Inches)]

12

TORQUE VALUES (FT - LBS)

50% YIELD

K= .14 K= .18 K= .20

43

56

62

87

111

124

153

197

249

248

318

354

371

477

530

544

700

778

766

984

1,094

1,038

1,335

1,483

1,371

1,762

1,958

1,772

2,278

2,531

2,230

2,867

3,185

2,768

3,559

3,954

3,393

4,990

4,848

4,906

6,308

7,009

6,151

7,909

8,788

8,275

10,639 11,822

10,823 13,916 15,461

13,850 17,807 19,786

17,379 22,344 24,827

21,488 27,627 30,697

26,179 33,659 37,398

60% YIELD

K= .14 K= .18

52

67

104

134

184

237

297

382

445

573

653

840

919

1,181

1,245

1,602

1,645

2,115

2,126

2,733

2,675

3,440

3,321

4,270

4,072

5,235

5,887

7,569

7,382

9,491

9,930

12,767

12,987 16,698

16,620 21,369

20,854 26,813

25,785 33,153

31,415 40,396

MATERIAL YIELD STRENGTH

NUMBER OF THREADS

1/2 2-1/4 DIAMETER STUDS: 105,000 PSI

2-1/2 4 DIAMETER STUDS: 95,000 PSI

1/2 DIAMETER STUDS: 13 TPI

5/8 DIAMETER STUDS: 11 TPI

3/4 DIAMETER STUDS: 10 TPI

7/8 DIAMETER STUDS: 9 TPI

1 - 4 DIAMETER STUDS: 8 TPI

The K Factor is an experimentally determined constant that relates the torque applied to the load induced in the fastener. This

factor is affected by the condition of the fastener, the lubricant used and the condition of the flange. For example, the 0.18 K

Factor listed above is based on the following conditions:

1.

2.

3.

New condition of flanges, studs and nuts

Thorough application of lubricant on all mating surfaces of flange, nut and stud.

Use of hardened steel washers

Pipeline Supply and Service Co., Inc.

Houston, TX 77054

Phone 713-747-0090 Fax 713-747-0855

http://www.pipelinesupply.com/

K= .20

75

148

263

424

696

933

1,313

1,780

2,350

3,037

3,822

4,745

5,817

8,411

10,545

14,186

18,554

23,743

29,792

36,836

44,876

You might also like

- International Body &chassis Wiring Diagrams and InfoDocument105 pagesInternational Body &chassis Wiring Diagrams and InfoClifton Jamison72% (81)

- Guides For Shoes CalculationDocument16 pagesGuides For Shoes CalculationgopaltryNo ratings yet

- VibrationControl CATALOGO SOPORTES PDFDocument12 pagesVibrationControl CATALOGO SOPORTES PDFMilena Lemus FonsecaNo ratings yet

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- Torque Chart For ASTM A193 Grade B7 StudsDocument3 pagesTorque Chart For ASTM A193 Grade B7 Studssarip83100% (4)

- Prompting Science and Engineering Students in Practical TrigonometryFrom EverandPrompting Science and Engineering Students in Practical TrigonometryNo ratings yet

- Prying ActionDocument8 pagesPrying ActionjoseherreramogollonNo ratings yet

- HensleyAftermarketBladeManual 2009Document520 pagesHensleyAftermarketBladeManual 2009Elmer Lagua Malpaso100% (1)

- PRYING9 - AISC 9th ED. PRYING ACTION ANALYSIS PROGRAMDocument5 pagesPRYING9 - AISC 9th ED. PRYING ACTION ANALYSIS PROGRAMCarlos Valverde PortillaNo ratings yet

- XTD ForceDocument7 pagesXTD ForceZULFIKAR AZANNo ratings yet

- Line Stop Welded To Shoe CalculationDocument16 pagesLine Stop Welded To Shoe CalculationmohdnazirNo ratings yet

- Calibracion Doble ResorteDocument60 pagesCalibracion Doble ResorteHector Jamaica100% (6)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- MAST CalculationDocument4 pagesMAST Calculationaniket100% (3)

- Introduction and Customer Information: T149498 - UN-01FEB02Document563 pagesIntroduction and Customer Information: T149498 - UN-01FEB02Alfredo Zablah100% (1)

- Piping Design DataDocument148 pagesPiping Design Datarerezhassan100% (1)

- 2 SP NHDocument63 pages2 SP NHJhonny VasquezNo ratings yet

- Grupuri ConiceDocument12 pagesGrupuri ConiceAnonymous l99acagNcLNo ratings yet

- Flange SeriesSKRDocument6 pagesFlange SeriesSKRHendra JurbonNo ratings yet

- DIMENSIONS (Inches) : Rebar Size US (Metric) Coupler Outside Diameter (In.)Document2 pagesDIMENSIONS (Inches) : Rebar Size US (Metric) Coupler Outside Diameter (In.)Marco Antonio Quispe BerrocalNo ratings yet

- API Bit Connection ChartDocument1 pageAPI Bit Connection ChartriobmNo ratings yet

- 180 23-RP4Document16 pages180 23-RP4ghilesNo ratings yet

- Rexroth Cylinder Accessories: Part No. CB CD CE CH CW F L A KK ERDocument1 pageRexroth Cylinder Accessories: Part No. CB CD CE CH CW F L A KK ERdinobrncicNo ratings yet

- C-900-1320-001 - 4A - 0001 (Calculation Sheet For Standard Anchor Bolts)Document9 pagesC-900-1320-001 - 4A - 0001 (Calculation Sheet For Standard Anchor Bolts)DavidPrasojoNo ratings yet

- Lasco Fittings - Tech80Document14 pagesLasco Fittings - Tech80cario_mak_ainsworthNo ratings yet

- 8 Stressing PDFDocument14 pages8 Stressing PDFKaushal K SharmaNo ratings yet

- Forged Steel Clevis: Caution: Never Exceed The Working Load LimitDocument1 pageForged Steel Clevis: Caution: Never Exceed The Working Load LimitrajedmaglinteNo ratings yet

- TI Manual Safety Clamp OM008 CDocument22 pagesTI Manual Safety Clamp OM008 Cedinson piñerosNo ratings yet

- DC Make-Up TorqueDocument5 pagesDC Make-Up TorquepatelsujanNo ratings yet

- Bolt Loads RevisedDocument1 pageBolt Loads RevisedhecalsieNo ratings yet

- 3071173Document11 pages3071173zulkarnain hamzahNo ratings yet

- Tolerancing GuidelinesDocument14 pagesTolerancing GuidelinesDhatchina Moorthy100% (1)

- Tightener Idler Catalog (Powerdrive - Com)Document8 pagesTightener Idler Catalog (Powerdrive - Com)PowerDriveNo ratings yet

- Control Valves 81000Document12 pagesControl Valves 81000rajanNo ratings yet

- Steel Pipe Vessel1Document279 pagesSteel Pipe Vessel1mdishong27No ratings yet

- Job Sheet 5 PDFDocument2 pagesJob Sheet 5 PDFChristian AlvarezNo ratings yet

- Raccordi A Inserto Forgiato PDFDocument3 pagesRaccordi A Inserto Forgiato PDFpeppino di capriNo ratings yet

- Footer ValveDocument200 pagesFooter Valveali96161No ratings yet

- SW ELBOW WT PDFDocument1 pageSW ELBOW WT PDFBárbara MontealegreNo ratings yet

- 5a JS T4 Air DrillDocument48 pages5a JS T4 Air DrillFredy SierraNo ratings yet

- GVSTDocument1 pageGVSTduncmcleodNo ratings yet

- Piping Valve Flange DimensionsDocument270 pagesPiping Valve Flange DimensionschadNo ratings yet

- Technical Drawings and Lists: Mazidaği Fertilizer Complex Project Doc - No: ETBMFCP-CTS-PI-ITP-0001 Rev.A Sheet 1 / 3Document3 pagesTechnical Drawings and Lists: Mazidaği Fertilizer Complex Project Doc - No: ETBMFCP-CTS-PI-ITP-0001 Rev.A Sheet 1 / 3HAKANNo ratings yet

- Annals of Oradea Manduka AbazDocument10 pagesAnnals of Oradea Manduka Abazshiny2701No ratings yet

- Appendix C' Continuous Welding Rail Thermal Expansion: The City of Winnipeg Bid Opportunity No. 712-2013Document2 pagesAppendix C' Continuous Welding Rail Thermal Expansion: The City of Winnipeg Bid Opportunity No. 712-2013didbeauNo ratings yet

- Calculations Implemented in The Online: ID Label SC MVA X/R Description Parent IDDocument4 pagesCalculations Implemented in The Online: ID Label SC MVA X/R Description Parent IDmartinbraNo ratings yet

- Investigating The Effect of Machining Parameters On Surface RoughnessDocument7 pagesInvestigating The Effect of Machining Parameters On Surface RoughnessIAEME PublicationNo ratings yet

- Asvk Specified Except Asotherwwa Specif Ledwas CaltiedDocument1 pageAsvk Specified Except Asotherwwa Specif Ledwas CaltiedandyjennNo ratings yet

- Fittings Tables1Document1 pageFittings Tables1Paúl ÁlvarezNo ratings yet

- F,') Er R: Maor+Lne DestqnDocument3 pagesF,') Er R: Maor+Lne DestqnMostafaNo ratings yet

- TasareDocument4 pagesTasareEliza BulimarNo ratings yet

- 500L - MIXING TANK - N4-SMT-03 (MP1), N4-SMT-04 (MP2) - Ellipsoidal DishDocument8 pages500L - MIXING TANK - N4-SMT-03 (MP1), N4-SMT-04 (MP2) - Ellipsoidal Dishprakash KaleNo ratings yet

- Variable Spring Support PT&P CatalogDocument1 pageVariable Spring Support PT&P CataloghgscanavinoNo ratings yet

- Figptp1def Variablespring PDFDocument1 pageFigptp1def Variablespring PDFIan CarrNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- 2022-23 School SuppliesDocument1 page2022-23 School SuppliesSatish ShewaleNo ratings yet

- Electricity Facts Label - V1.04Document2 pagesElectricity Facts Label - V1.04Satish ShewaleNo ratings yet

- Fugitive Emission Standards: ISO 15848 Iso 15848 Tightness ClassesDocument1 pageFugitive Emission Standards: ISO 15848 Iso 15848 Tightness ClassesSatish ShewaleNo ratings yet

- jvm1420 jvm1425 jvm1430 jvm1431 jvm1440Document41 pagesjvm1420 jvm1425 jvm1430 jvm1431 jvm1440Satish ShewaleNo ratings yet

- Bro Pocket GuideDocument72 pagesBro Pocket GuideSatish ShewaleNo ratings yet