Professional Documents

Culture Documents

Desde Glucosa Por Enzimas

Desde Glucosa Por Enzimas

Uploaded by

Nicolás Maximiliano BerteroCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Desde Glucosa Por Enzimas

Desde Glucosa Por Enzimas

Uploaded by

Nicolás Maximiliano BerteroCopyright:

Available Formats

J. Am. Chem. Soc.

1998, 120, 10545-10546

10545

Synthesis of Vanillin from Glucose

Kai Li and J. W. Frost* Department of Chemistry Michigan State UniVersity East Lansing, Michigan 48824 ReceiVed May 21, 1998 Condensation of glyoxylic acid with benzene-derived guaiacol (Scheme 1) is currently the dominant route for vanillin manufacture.1 Natural vanillin is produced from glucovanillin (Scheme 1) when the beans of the orchid Vanilla planifolia are submitted to a multistep curing process.1a Because of the extreme care that must be exercised during vine cultivation, bean harvesting, and hand pollination of flowers, natural vanillin can supply only 2 104 kg/yr of the worlds 1.2 107 kg/yr demand for vanillin.1b This has resulted in the substitution of synthetic vanillin for natural vanilla in most flavoring applications. Limited vanilla bean supplies have also led to extensive research into the use of plant tissue culture and microbes to convert ferulic acid (Scheme 1) into vanillin suitable for labeling as a natural or nature-equivalent flavoring.2 A synthesis of vanillin from glucose (Scheme 1) has now been elaborated. Glucose is converted into vanillic acid by a recombinant Escherichia coli biocatalyst under fed-batch fermentor conditions. Reduction of vanillic acid to vanillin is catalyzed by aryl aldehyde dehydrogenase isolated from Neurospora crassa. This synthesis qualifies both as a route to natural vanillin and as a first step toward large-scale, environmentally benign manufacture of vanillin using biocatalysis. Vanillate-synthesizing E. coli KL7 biocatalysts carried a mutated aroE locus and an aroBaroZ cassette inserted into the serA locus. The lack of aroE-encoded shikimate dehydrogenase resulted in the synthesis of 3-dehydroshikimic acid which was converted into protocatechuic acid by genome-localized, aroZencoded 3-dehydroshikimate dehydratase. Plasmid-localized PtacCOMT encoded catechol-O-methyltransferase for conversion of protocatechuic acid into vanillic acid (Scheme 2). Plasmid pKL5.97A carried two PtacCOMT loci, while only a single PtacCOMT locus was present in pKL5.26A. These plasmids also carried an aroFFBR and a serA insert. The aroFFBR insert encodes a 3-deoxy-D-arabino-heptulosonic acid 7-phosphate synthase isozyme insensitive to feedback inhibition which increased carbon flow into the common pathway. Due to a mutation in the genomic serA locus required for L-serine biosynthesis, growth in minimal salts medium and plasmid maintenance followed from expression of plasmid-localized serA. The two genomic copies of aroB increased 3-dehydroquinate synthase (Scheme 2) activity to the point where this enzyme no longer impeded carbon flow.3 KL7/pKL5.26A and KL7/pKL5.97A were cultured for 48 h under fed-batch fermentor conditions at 37 C, pH 7.0, and

* Author to whom correspondence should be addressed. Phone: 517-3559715, ext 115. FAX: 517-432-3873. E-mail: frostjw@argus.cem.msu.edu. (1) (a) Ranadive, A. S. In Spices, Herbs, and Edible Fungi; Charalambous, G., Ed.; Elsevier: Amsterdam, 1994; p 517. (b) Clark, G. S. Perfum. FlaVor. 1990, 15, 45. (c) Esposito, L.; Formanek, K.; Kientz, G.; Mauger, F.; Maureaux, V.; Robert, G.; Truchet, F. In Kirk-Othmer Encyclopedia of Chemical Technology, 4th ed.; Kroschwitz, J. I., Howe-Grant, M., Eds.; Wiley: New York, 1997; Vol. 24, p 812. (2) (a) Falconnier, B.; Lapierre, C.; Lesage-Meessen, L.; Yonnet, G.; Brunerie, P.; Colonna-Ceccaldi, B.; Corrieu, G.; Asther, M. J. Biotechnol. 1994, 37, 123. (b) Lesage-Meessen, L.; Delattre, M.; Haon, M.; Thibault, J.-F.; Ceccaldi, B. C.; Brunerie, P.; Asther, M. J. Biotechnol. 1996, 50, 107. (c) Lesage-Meessen, L.; Haon, M.; Delattre, M.; Thibault, J.-F.; Ceccaldi, B. C.; Asther, M. Appl. Microbiol. Biotechnol. 1997, 47, 393. (d) Labuda, I. M.; Goers, S. K.; Keon, K. A. U.S. Patent 5,279,950, 1994. (e) Westcott, R. J.; Cheetham, P. S. J.; Barraclough, A. J. Phytochemistry 1994, 35, 135. (3) Snell, K. D.; Draths, K. M.; Frost, J. W. J. Am. Chem. Soc. 1996, 118, 5605.

Scheme 1a

a Key: (a) KL7/pKL5.26A or KL7/pKL5.97A. (b) N. crassa aryl aldehyde dehydrogenase. (c) Microbial catabolism. (d) HCO3H, HCO2H. (e) Me2SO4. (f) (i) HCOCO2H, (ii) O2, (iii) H+. (g) UDP-glucose:coniferyl alcohol glucosyltransferase. (h) Unidentified enzymes. (i) -glucosidase.

Scheme 2a

a Key: (a) 3-Deoxy-D-arabino-heptulosonic acid 7-phosphate synthase (aroFFBR). (b) 3-Dehydroquinate synthase (aroB). (c) 3-Dehydroquinate dehydratase (aroD). (d) 3-Dehydroshikimate dehydratase (aroZ). (e) Catechol-O-methyltransferase (COMT). (f) Aryl aldehyde dehydrogenase. (g) D-glucose 6-phosphate dehydrogenase; D-glucose 6-phosphate; SAM, S-adenosylmethionine; SAH, S-adenosylhomocysteine.

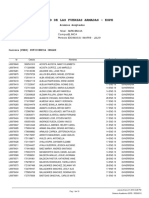

dissolved oxygen at 20% of saturation. Extracellular accumulation (Figure 1) of vanillic, isovanillic, protocatechuic, and 3-dehydroshikimic acids began in mid log phase of microbial growth. 3-Dehydroshikimic acid usually constituted 5-10 mol % of the total product mixture, indicating that the rates for its biosynthesis and dehydration were nearly equal. However, the molar dominance of protocatechuic acid (Figure 1, Table 1) relative to vanillic acid pointed to inadequate catechol-Omethyltransferase activity. Although increasing the specific activity (Table 1) of catechol-O-methyltransferase in KL7/ pKL5.97A relative to KL7/pKL5.26A had little impact on the concentrations (Table 1) of synthesized vanillic acid, supplementation with L-methionine nearly doubled the amount of vanillic acid synthesized by both biocatalysts (Table 1). The 4-fold to 6-fold molar excess of vanillic acid synthesized relative to

S0002-7863(98)01774-0 CCC: $15.00 1998 American Chemical Society Published on Web 09/25/1998

10546 J. Am. Chem. Soc., Vol. 120, No. 40, 1998

Communications to the Editor

Use of an intact microbe to reduce vanillic acid will be essential for future large-scale vanillin synthesis. Vanillic acid synthesized by one microbe from glucose could be reduced to vanillin by a second, different microbe. Conversion of glucose into vanillin using a single vanillate-synthesizing microbe expressing aryl aldehyde dehydrogenase may also be possible. Irrespective of the strategy employed, improved protocatechuic acid methylation will be essential. The lack of significantly improved protocatechuic acid methylation with increased catechol-O-methyltransferase activity and the improvement in methylation observed with L-methionine supplementation suggest that cosubstrate S-adenosylmethionine availability and/or feedback inhibition6 may be limiting in vivo methyltransferase activity. Improving regioselectivity for protocatechuic acid meta-oxygen methylation using a different isozyme of widely distributed4 catechol-O-methyltransferase would also be advantageous. Biocatalytic synthesis of vanillin from glucose has a number of advantages relative to other biocatalytic vanillin syntheses (Scheme 1). Coniferol, formed during phenylpropanoid biosynthesis, is converted into coniferin by a glucosyltransferase in V. planifolia.1a Coniferin is then transformed into glucovanillin which is finally hydrolyzed by a -glucosidase.1a Synthesis of vanillin via 3-dehydroshikimic, protocatechuic, and vanillic acids circumvents phenylpropanoid biosynthesis and glucosylation/ deglucosylation reactions. This substantially reduces the number of enzymes required to synthesize vanillin. Ferulic acid (Scheme 1) can be microbially converted into vanillin. However, these routes produce vanillin titers below 1 g/L.2 Cultured plant tissue in medium supplemented with ferulic acid has also been used to produce vanillin although this conversion is slow and scale-up is relatively difficult.2d,e A problem with all vanillin syntheses from ferulic acid is the absence of low-cost, commercial production of this phenylpropanoid. Biocatalytic synthesis of vanillin from glucose, although a longer-term commercial prospect, also has advantages relative to synthetic vanillin manufacture1c (Scheme 1). Phenol and guaiacol are toxic and are derived from carcinogenic benzene.7 Nontoxic 3-dehydroshikimic, protocatechuic, and vanillic acids are derived from innocuous glucose. Corrosive H2O2 used for the oxidation of phenol into catechol requires special handling precautions7 while biocatalytically synthesized vanillin derives its oxygen atoms from the oxygen atoms of glucose. Dimethyl sulfate, a carcinogen,7 has historically been used to methylate catechol. Protocatechuic acid methylation employs S-adenosylmethionine generated and consumed intracellularly. Finally, synthetic vanillin manufacture is based on the use of nonrenewable petroleum, whereas glucose is derived from abundant, renewable starch. This difference in feedstock utilization is important, given projected fierce international competition as global petroleum production diminishes.8

Acknowledgment. Research was supported by the United States Department of Agriculture and the National Science Foundation. Orion Corporation provided the COMT gene. Supporting Information Available: Enzyme isolation, fermentor synthesis, and enzymatic reduction (7 pages, print/PDF). See any current masthead page for ordering information and Web access instructions.

Figure 1. Fermentor culture of KL7/pKL5.97A supplemented with L-methionine.

Table 1. Products Formed after 48 h under Fed-Batch Fermentor Conditions as a Function of Catechol-O-methyltransferase Activity and L-Methionine Supplementation KL7/pKL5.26Aa

L-methioninec

KL7/pKL5.97Ab 0.012 3.0 0.6 12.9 1.0 + 0.010 5.0 1.2 10.5 1.8

COMTd vanillic acide isovanillic acide protocatechuic acide 3-dehydroshikimic acide

0.0060 2.5 0.4 9.7 0.9

+ 0.0055 4.9 1.3 7.1 1.0

a aroFFBRP COMTserA. b aroFFBRP COMTP COMTserA. c 0.4 g/L tac tac tac added every 6 h beginning at 12 h. d Specific activity, mol/min/mg. e g/L.

isovanillic acid (Table 1) conforms to the reported selectivity of catechol-O-methyltransferase toward meta-hydroxyl group methylation.4 Aryl aldehyde dehydrogenase5 in N. crassa mycelial extract was purified from an unwanted dehydrogenase which reduced vanillin to vanillyl alcohol. Vanillic, protocatechuic, and isovanillic acids were extracted into EtOAc after acidification of the fermentor broth. A subsequent reprecipitation step increased the vanillic acid/protocatechuic acid ratio from 1:2 to 2.5:1 (mol/ mol). The resulting aromatic mixture was incubated with glucose 6-phosphate dehydrogenase (to recycle NADP+) and aryl aldehyde dehydrogenase at 30 C and pH 8.0 using 0.07 equiv of NADP+ and 2 equiv of ATP relative to vanillic acid. Reduction of vanillic acid to vanillin (Scheme 2) proceeded in 92% yield in 7 h. Reduction of protocatechuic acid was slower with a 33% yield of protocatechualdehyde obtained after 7 h. Vanillin was extracted from the enzymatic reduction with CH2Cl2, leaving protocatechualdehyde and protocatechuic acid in the aqueous phase. Isovanillin at 10 mol % remained as the only contaminant. Extraction of the fermentor broth, selective precipitation to remove excess protocatechuic acid, aryl aldehyde dehydrogenase reduction, and the final CH2Cl2 extraction led to a 66% overall yield (mol/mol) for the conversion of vanillic acid into vanillin.

(4) Guldberg, H. C.; Marsden, C. A. Pharmacol. ReV. 1975, 27, 135. (5) (a) Gross, G. G.; Bolkart, K. H.; Zenk, M. H. Biochem. Biophys. Res. Commun. 1968, 32, 173. (b) Gross, G. G.; Zenk, M. H. Eur. J. Biochem. 1969, 8, 413. (c) Gross, G. G. Eur. J. Biochem. 1972, 31, 585. (d) Zenk, M. H.; Gross, G. G. Recent AdV. Phytochem. 1972, 4, 87.

JA9817747

(6) Coward, J. K.; Slisz, E. P.; Wu, F. Y.-H. Biochemistry 1973, 12, 2291. (7) Lewis, R. J., Sr. Hazardous Chemicals Desk Reference, 3rd ed.; Van Nostrand Reinhold: New York, 1993. (8) Campbell, C. J.; Laherre ` re, J. H. Sci. Am. 1998, 278 (3), 78.

You might also like

- Food Additives and Its ClassificationDocument10 pagesFood Additives and Its ClassificationBaishaliNo ratings yet

- Paints and Coatings With Formulations Technology Book PDFDocument15 pagesPaints and Coatings With Formulations Technology Book PDFMOHAMED100% (1)

- Question Bank MCQ MouldsDocument72 pagesQuestion Bank MCQ MouldsThilak P Gowda100% (2)

- Non MetalsDocument34 pagesNon MetalsDigvijay Patil100% (2)

- 13-2 ProblemarioDocument18 pages13-2 ProblemarioGloria Stefhany Garcia GarciaNo ratings yet

- Printing ProcessesDocument8 pagesPrinting ProcessesPriyanka ChaudharyNo ratings yet

- Ashland Chemicals Guide To Fabricating Composites PDFDocument57 pagesAshland Chemicals Guide To Fabricating Composites PDFAntheaLouloudiNo ratings yet

- II. Polymers MCQs 1Document7 pagesII. Polymers MCQs 1fuckjungali100% (1)

- Supercritical FluidDocument5 pagesSupercritical FluidNuradila Athirah LockmanNo ratings yet

- Conceptos Basicos CronocoulomDocument3 pagesConceptos Basicos Cronocoulombettypaz89No ratings yet

- Air Stripping of AcetoneDocument19 pagesAir Stripping of AcetoneGabe100% (1)

- Thermodynamics of The Ionization ofDocument2 pagesThermodynamics of The Ionization ofNicolás PeñaNo ratings yet

- Functional Group TestsDocument2 pagesFunctional Group TestsSalman HusainNo ratings yet

- Chemical Kinetics of Complex Reactions - Sample Solution - Question 2Document3 pagesChemical Kinetics of Complex Reactions - Sample Solution - Question 2Trung VõNo ratings yet

- Acetaldol MsdsDocument6 pagesAcetaldol Msdsdlr1233No ratings yet

- Campus El IncaDocument10 pagesCampus El IncaEddy FernandoNo ratings yet

- Sweet Indigestion: A Directed Case Study On Carbohydrates: Part I-Of Cows and CarbsDocument3 pagesSweet Indigestion: A Directed Case Study On Carbohydrates: Part I-Of Cows and CarbsLillian MuellerNo ratings yet

- Oxidation of Benzoin To BenzilDocument4 pagesOxidation of Benzoin To BenzilJonathan Shao100% (1)

- CPP Assignment 1Document2 pagesCPP Assignment 1AmandaEdwinNo ratings yet

- Método BicinconinatoDocument8 pagesMétodo BicinconinatoCamila ContrerasNo ratings yet

- Dixon TestDocument8 pagesDixon TestVil SieNo ratings yet

- 1-Phenylethanol H-NMR PDFDocument2 pages1-Phenylethanol H-NMR PDFkobir960% (1)

- Tarea I FQ II SOLUCIÓN PDFDocument7 pagesTarea I FQ II SOLUCIÓN PDFRoberto Daniel Rivera CastroNo ratings yet

- P5&6Document28 pagesP5&6Valeria NatashaNo ratings yet

- Combustion PDFDocument7 pagesCombustion PDFdiego andré cava leandroNo ratings yet

- Problemario de Biorreactores Cap 14Document5 pagesProblemario de Biorreactores Cap 14Nycte Nava0% (1)

- Esercizi Sulla Combustione - TurnsDocument5 pagesEsercizi Sulla Combustione - TurnsMario TodiscoNo ratings yet

- Cre-Ii Lectppts Partii CatreactionsDocument325 pagesCre-Ii Lectppts Partii CatreactionsdhruvNo ratings yet

- The Acid Base Titration of A Very Weak Acid: Boric Acid: M. Celeste C. Azevedo and Ana M. V. CavaleiroDocument4 pagesThe Acid Base Titration of A Very Weak Acid: Boric Acid: M. Celeste C. Azevedo and Ana M. V. CavaleiroAitor PastorNo ratings yet

- Development of Solvay Clusters of Chemical Reactions PDFDocument11 pagesDevelopment of Solvay Clusters of Chemical Reactions PDFJordan Lopez FernandezNo ratings yet

- EJERCICIOS DISTR ContinuasDocument3 pagesEJERCICIOS DISTR ContinuasJulio IbarraNo ratings yet

- Especific HeatDocument18 pagesEspecific HeatRafaela RibeiroNo ratings yet

- Apéndice - E.SMITH VAN NESSDocument2 pagesApéndice - E.SMITH VAN NESSsaraNo ratings yet

- Organic Chemistry QuizDocument7 pagesOrganic Chemistry QuizCarlo Jay BasulNo ratings yet

- Cellic CTec3 HS Application Sheet NADocument5 pagesCellic CTec3 HS Application Sheet NADaniel RivaldiNo ratings yet

- BE184P Exercise 3.1 Voltammetry PolarographyDocument9 pagesBE184P Exercise 3.1 Voltammetry PolarographyDen CelestraNo ratings yet

- Material Balances ExercisesDocument3 pagesMaterial Balances ExercisesMigue MolinaNo ratings yet

- A Substitution or Single Displacement Reaction Is Characterized by One Element Being Displaced From A Compound by Another Element. A + BC Ac + BDocument19 pagesA Substitution or Single Displacement Reaction Is Characterized by One Element Being Displaced From A Compound by Another Element. A + BC Ac + BESPITIA GARCIA LAURA CRISTINANo ratings yet

- Reacciones Con Yoduro de PotasioDocument3 pagesReacciones Con Yoduro de PotasioFredy Hernandez100% (1)

- Ijee 1157Document5 pagesIjee 1157Mike PerkinsNo ratings yet

- Elementos de Ingeniería de Las Reacciones Químicas 3° Edición - Fogler PDFDocument1,004 pagesElementos de Ingeniería de Las Reacciones Químicas 3° Edición - Fogler PDFShamir Jose ContrerasNo ratings yet

- Significance of Brix Reading in Determination of Quality of Oral Syrup and Semisolid FormulationsDocument7 pagesSignificance of Brix Reading in Determination of Quality of Oral Syrup and Semisolid FormulationsOpal Priya WeningNo ratings yet

- Diapositiva de Recursos Humanos 1: Total Synthesis of CoprinolDocument22 pagesDiapositiva de Recursos Humanos 1: Total Synthesis of CoprinolAngelOrtegaZarcoNo ratings yet

- Chromatography: The Separation Technique of The 20th CenturyDocument11 pagesChromatography: The Separation Technique of The 20th CenturyAnonymous qOxE6C7kNo ratings yet

- Octyl AcetateDocument6 pagesOctyl AcetateKristine BautistaNo ratings yet

- C01 14PDocument33 pagesC01 14PTiffany LiuNo ratings yet

- Sintesis de Metronidazol A Partir de La Etilendiamina PDFDocument3 pagesSintesis de Metronidazol A Partir de La Etilendiamina PDFAstridChoqueNo ratings yet

- SM 3500 AlDocument4 pagesSM 3500 AlNARET85No ratings yet

- Quiz Show FileDocument18 pagesQuiz Show FileLeaniel SilvaNo ratings yet

- Wittig LabDocument5 pagesWittig Labthrowaway_accountNo ratings yet

- Diels Alder ReactionDocument6 pagesDiels Alder ReactionEdward PittsNo ratings yet

- Tutorial # 1 - KineticsDocument7 pagesTutorial # 1 - KineticsbebsybiswezNo ratings yet

- SY-8100 Manual OperacionDocument36 pagesSY-8100 Manual OperacionJOse ArmentaNo ratings yet

- Thermochemistry - Heat of Neutralization and Hess - S Law (Chemistry PDFDocument13 pagesThermochemistry - Heat of Neutralization and Hess - S Law (Chemistry PDFLiyana AthirahNo ratings yet

- Azulene and NaphthaleneDocument5 pagesAzulene and NaphthaleneDanNo ratings yet

- Manual Phmetro Altronix PDFDocument22 pagesManual Phmetro Altronix PDFMatias OliveraNo ratings yet

- Water SeerDocument3 pagesWater SeerBagus SadewoNo ratings yet

- LAB5Document1 pageLAB5Tarmizi Al-AminNo ratings yet

- Cryoscopic Constants For Calculation of Freezing Point DepressionDocument1 pageCryoscopic Constants For Calculation of Freezing Point DepressionantonioNo ratings yet

- Kinetics of The Selective Hydrogenation of Phenol To Cyclohexanone Over A Pd-Alumina CatalystDocument8 pagesKinetics of The Selective Hydrogenation of Phenol To Cyclohexanone Over A Pd-Alumina CatalystTaylor PennaNo ratings yet

- OptimizationDocument2 pagesOptimizationVaidish SumariaNo ratings yet

- The Role of ATP Citrate Lyase, Malic Enzyme and Fatty Acid Synthase in The Regulation of Lipid Accumulation in Cunninghamella Sp. 2A1Document6 pagesThe Role of ATP Citrate Lyase, Malic Enzyme and Fatty Acid Synthase in The Regulation of Lipid Accumulation in Cunninghamella Sp. 2A1Bara' HammadehNo ratings yet

- Improved Chemical Syntheses of 1-And 5-Deazariboflavin: Abstract: The Cofactor Flavin Adenine Dinucleotide (FAD)Document4 pagesImproved Chemical Syntheses of 1-And 5-Deazariboflavin: Abstract: The Cofactor Flavin Adenine Dinucleotide (FAD)Hylze ChavesNo ratings yet

- Changes in Membrane Fatty Acids Composition of MicrobialDocument5 pagesChanges in Membrane Fatty Acids Composition of MicrobialDaniel JimenezNo ratings yet

- Influence of Chitosan Derivatization On PDFDocument10 pagesInfluence of Chitosan Derivatization On PDFOrlandoCialliNo ratings yet

- Pmecx 5 - Marcado TotalDocument11 pagesPmecx 5 - Marcado TotalVictor RoticivNo ratings yet

- Syntheses of The Enantiomers of 1-Deoxynojirimycin and 1-Deoxyaltronojirimycin Via Chemo-And Diastereoselective Olefinic Oxidation of Unsaturated AminesDocument14 pagesSyntheses of The Enantiomers of 1-Deoxynojirimycin and 1-Deoxyaltronojirimycin Via Chemo-And Diastereoselective Olefinic Oxidation of Unsaturated AminesDiogo DiasNo ratings yet

- Inventory 29.february 2016Document8 pagesInventory 29.february 2016Long An ĐỗNo ratings yet

- List of Quality Control Orders Notified in Gazette of India To Make The Standards Mandatory - Ministry of Chemicals and FertilizersDocument14 pagesList of Quality Control Orders Notified in Gazette of India To Make The Standards Mandatory - Ministry of Chemicals and FertilizersELP LawNo ratings yet

- Marapur PU Screen Printing Ink: Simple Print, Fabric 100-40 (T)Document4 pagesMarapur PU Screen Printing Ink: Simple Print, Fabric 100-40 (T)m_malhanNo ratings yet

- Electrode Identification: AWS A5.1-69 and A5.5-69 Designations For Manual ElectrodesDocument3 pagesElectrode Identification: AWS A5.1-69 and A5.5-69 Designations For Manual ElectrodesSi Tole Biker'sNo ratings yet

- Celazole PBI U 60 Typical PropertiesDocument4 pagesCelazole PBI U 60 Typical PropertiesnomeNo ratings yet

- Hot-Melt Extrusion in The Pharmaceutical Industry: Toward Filing A New Drug ApplicationDocument20 pagesHot-Melt Extrusion in The Pharmaceutical Industry: Toward Filing A New Drug ApplicationKamran AlamNo ratings yet

- Chemtrol Thermoplastic Piping Technical Manual PDFDocument44 pagesChemtrol Thermoplastic Piping Technical Manual PDFyanlayNo ratings yet

- The Research and Development of Thermoplastic ElastomersDocument13 pagesThe Research and Development of Thermoplastic ElastomersScienceVolksNo ratings yet

- Heteroaromatics PDFDocument27 pagesHeteroaromatics PDFkrishna prasad ghantaNo ratings yet

- 9606-Article Text PDF-22911-3-10-20170313Document6 pages9606-Article Text PDF-22911-3-10-20170313kalaiNo ratings yet

- BIO NEET BOOK-2 - (ENG) - Ch-6-J-Done-1Document64 pagesBIO NEET BOOK-2 - (ENG) - Ch-6-J-Done-1Prajapati HarishNo ratings yet

- EEE-Speaker3 - Engr. CLEMENTE - Full Paper-2022 PICE MNCTC PDFDocument6 pagesEEE-Speaker3 - Engr. CLEMENTE - Full Paper-2022 PICE MNCTC PDFShy AbuizaNo ratings yet

- ReportDocument45 pagesReportabhijith msNo ratings yet

- IPS Empress Direct OpaqueDocument2 pagesIPS Empress Direct OpaqueSunita TipmontaNo ratings yet

- Impact of Cotton Parameters On Yarn QualityDocument4 pagesImpact of Cotton Parameters On Yarn Qualityغلام جیلانی100% (6)

- Taghizadeh 2018Document11 pagesTaghizadeh 2018José BarrosNo ratings yet

- Elastic Vitrimers BeyondDocument32 pagesElastic Vitrimers BeyondMostafa AhmadiNo ratings yet

- The O' Ring: What Is It?Document28 pagesThe O' Ring: What Is It?JF ZadaNo ratings yet

- Pharchem2 Drug AlbumDocument40 pagesPharchem2 Drug AlbumLA BriguelaNo ratings yet

- O RigDocument9 pagesO Rigavabhyankar9393No ratings yet

- Kendor CDN Price List - March 2016 NEWDocument5 pagesKendor CDN Price List - March 2016 NEWerdeneNo ratings yet

- A Project/Seminar Report On Enhancement in Properties of Waterborne Acrylic ResinDocument34 pagesA Project/Seminar Report On Enhancement in Properties of Waterborne Acrylic ResinDevesh jichkarNo ratings yet

- Fiber Testing Fabric Testing Fabric Testing Jan Pegram BallardDocument24 pagesFiber Testing Fabric Testing Fabric Testing Jan Pegram Ballardirc.indusNo ratings yet