Professional Documents

Culture Documents

Elevators Types

Uploaded by

eng_waleed2008Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Elevators Types

Uploaded by

eng_waleed2008Copyright:

Available Formats

Machine-Roomless Elevators This revolutionary elevator system is based on the first major breakthrough in lifting technology in nearly 100

years. Designed for buildings between two and 30 stories, this system employs a smaller sheave than conventional geared and gearless elevators. The reduced sheave size, together with a redesigned machine, allows the machine to be mounted within the hoistway itselfeliminating the need for a bulky machine room on the roof. Just as unique are the flat polyurethane-coated steel belts, an Otis invention for the Gen2 elevator system, that replace the heavy, woven steel cables that have been the industry standard since the 1800s. The belts make the smaller sheave possible. They are only 0.1 inch (3 mm) thick, yet they are as strong as woven steel cables and far more durable, flexible and space-saving. Machine-roomless elevators are ideal for a variety of applicationsand the most unusual, such as the Christ the Redeemer monument in Rio de Janeiro.

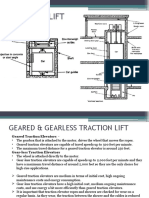

Gearless Traction Elevators In 1903, Otis introduced the design that would become the standard in the elevator industrythe gearless traction elevator. These elevators typically operate at speeds greater than 500 feet per minute (2.54 meters per second). In a gearless traction machine, woven steel cables called hoisting ropes are attached to the top of the elevator car and wrapped around the drive sheave in special grooves. The other ends of the cables are attached to a counterweight that moves up and down in the hoistway on its own guiderails. The combined weight of the elevator car and the counterweight presses the cables into the drive sheave grooves, providing the necessary traction as the sheave turns. Gearless technology makes the tallest buildings in the world possible, such as Malaysias Petronas Towers.

Geared Traction Elevators As the name implies, the electric motor in this design drives a gear-type reduction unit, which turns the hoisting sheave. While slower than a typical gearless elevator, the gear reduction offers the advantage of requiring a less powerful motor to turn the sheave. These elevators typically operate at speeds from 350 to 500 feet per minute (1.7 to 2.5 meters per second) and carry loads of up to 30,000 pounds (13,600 kgs). An electrically controlled brake between the motor and the reduction unit stops the elevator, holding the car at the desired floor level.

You might also like

- Elevators Type From OttisDocument2 pagesElevators Type From OttisWesame ShnodaNo ratings yet

- Elevators & Escalators: Compiled by Ar. B. K. PrabuDocument35 pagesElevators & Escalators: Compiled by Ar. B. K. PrabushobanaNo ratings yet

- ElevatorsDocument10 pagesElevatorsKavyaNo ratings yet

- Selection of Drives and Control Systems For LiftsDocument4 pagesSelection of Drives and Control Systems For LiftsSaikat ChakrabortyNo ratings yet

- Elevator TypesDocument4 pagesElevator TypesIranthaMuthuNo ratings yet

- Mechanical System ReportDocument9 pagesMechanical System ReportLea MaligsayNo ratings yet

- Basic Components of Elevator Elevator Types: Hydraulic ElevatorsDocument4 pagesBasic Components of Elevator Elevator Types: Hydraulic ElevatorsEstiven GierNo ratings yet

- Elevators and Shafts: Qurat-Ul-Ain 103 4th YrDocument5 pagesElevators and Shafts: Qurat-Ul-Ain 103 4th Yraini zahidNo ratings yet

- ElevatorsDocument11 pagesElevatorsDalia M-aNo ratings yet

- ElevatorsDocument27 pagesElevatorsshelmiNo ratings yet

- Elevator TypesDocument4 pagesElevator TypesAngelica SantosNo ratings yet

- Lift2 Escalator Travelators and Walkways9.1.16Document41 pagesLift2 Escalator Travelators and Walkways9.1.16Manoj JainNo ratings yet

- Elevators: 3 Century B.C.E 1743Document15 pagesElevators: 3 Century B.C.E 1743Mara Erna TagupaNo ratings yet

- LiftDocument22 pagesLiftAmit KumarNo ratings yet

- BMC - Escalator, ElevatorDocument23 pagesBMC - Escalator, ElevatorJisniNo ratings yet

- Elevators: Sahar Khan Jadoon FA11-BAR-017Document5 pagesElevators: Sahar Khan Jadoon FA11-BAR-017saharkj67No ratings yet

- Fundamentals of Elevators and Escalators in The WorkplaceDocument10 pagesFundamentals of Elevators and Escalators in The WorkplaceTin VillalbaNo ratings yet

- BU 2 Study Guide 6 1Document19 pagesBU 2 Study Guide 6 1Bautista JunNo ratings yet

- Types of ElevatorsDocument6 pagesTypes of Elevatorsnirvaang100% (1)

- Special Type of ElevatorDocument24 pagesSpecial Type of Elevatordeepankumar jeganathanNo ratings yet

- Building ServicesDocument57 pagesBuilding Servicessofiya0% (1)

- Functional Requirements of 8 Transportation Systems in A Building.Document40 pagesFunctional Requirements of 8 Transportation Systems in A Building.Umar Faruq AfokeNo ratings yet

- What Is Elevator / Lift?: How Does A Lift Work?Document8 pagesWhat Is Elevator / Lift?: How Does A Lift Work?ankitaNo ratings yet

- Lifts & EscalatorsDocument37 pagesLifts & EscalatorsNikita SalunkheNo ratings yet

- Term Paper 2 MENGR 3100Document5 pagesTerm Paper 2 MENGR 3100caytonericazoeNo ratings yet

- Lifts and SkyscrapersDocument9 pagesLifts and SkyscrapersSa ReddiNo ratings yet

- Design ELEVDocument30 pagesDesign ELEVShiella Barroga LorenzoNo ratings yet

- Lifting and Handling EquipmentsDocument54 pagesLifting and Handling Equipmentsalvin100% (1)

- Verticalcirculationandservices 170429050933 PDFDocument105 pagesVerticalcirculationandservices 170429050933 PDFFaisal NasimNo ratings yet

- Mech AssignmentDocument3 pagesMech AssignmentJuvy May Dedicatoria SabangNo ratings yet

- VerticalDocument26 pagesVerticalArt IjbNo ratings yet

- 10 Week NotesDocument39 pages10 Week Notescharusri74No ratings yet

- Elevators: Types of ElevatorDocument17 pagesElevators: Types of ElevatorAngelica Marie LopezNo ratings yet

- Tugas Bahasa Inggris: New Designs Going Up-Working Knowledge On ElevatorsDocument4 pagesTugas Bahasa Inggris: New Designs Going Up-Working Knowledge On ElevatorsDodiNo ratings yet

- Vertical Circulation: Team 1Document41 pagesVertical Circulation: Team 1hanya HaythamNo ratings yet

- MRL ElevatorsDocument85 pagesMRL ElevatorsAkshay PaiNo ratings yet

- Vertical Transportation in BuildingsDocument104 pagesVertical Transportation in Buildingsiqbal s.jeelaniNo ratings yet

- ECM 216 BUILDING SERVICES Bab 2.5 Lift and ElevatorDocument5 pagesECM 216 BUILDING SERVICES Bab 2.5 Lift and ElevatorAZUAN BIN AHMAD FAUZINo ratings yet

- Tumanon - Research No. 1 - SKYSCRAPERDocument15 pagesTumanon - Research No. 1 - SKYSCRAPERZiggy TumanonNo ratings yet

- So How Do Elevators or Lifts WorkDocument12 pagesSo How Do Elevators or Lifts WorkAyesha MAhmoodNo ratings yet

- Tugas Terjemahan B.Inggris (Jordi Arif Gultom) 5203321007Document3 pagesTugas Terjemahan B.Inggris (Jordi Arif Gultom) 5203321007DodiNo ratings yet

- Carunungan, Marie Util-313Document38 pagesCarunungan, Marie Util-313Marie Holgado CarununganNo ratings yet

- EscalatorDocument18 pagesEscalatorbhargav_eedeNo ratings yet

- Addis Ababa Bole Internationa Airport InterpriseDocument21 pagesAddis Ababa Bole Internationa Airport Interprisegari100% (1)

- Lenchico RSW2Document22 pagesLenchico RSW2Chanty LenchicoNo ratings yet

- Unit 1Document30 pagesUnit 1Navya chowdaryNo ratings yet

- Lift 1Document27 pagesLift 1shelmi100% (1)

- Gtu 11Document31 pagesGtu 11Suchitra dhrubcharan hotaNo ratings yet

- Mechanism of Passenger LiftsDocument11 pagesMechanism of Passenger LiftsrutujaNo ratings yet

- Dodi Sevent Situmorang - TR B.inggrisDocument5 pagesDodi Sevent Situmorang - TR B.inggrisLasro Banjar nahorNo ratings yet

- Elevators and Escalators Case StudyDocument14 pagesElevators and Escalators Case Studyakshay salvi0% (1)

- Types of Elevators - Home Elevators - Residential Elevators - 1626693900854Document9 pagesTypes of Elevators - Home Elevators - Residential Elevators - 1626693900854Aluko Damilare MosesNo ratings yet

- Transportation in Buildings: 1. Vertical 2. Inclined 3. HorizontalDocument104 pagesTransportation in Buildings: 1. Vertical 2. Inclined 3. HorizontalManoj JainNo ratings yet

- Bu 1Document120 pagesBu 1Chi De LeonNo ratings yet

- Pedal Operated ForkliftDocument56 pagesPedal Operated Forkliftfahamith ahamed100% (1)

- Escalators: Vivek Kamlesh KareliaDocument25 pagesEscalators: Vivek Kamlesh KareliaShubhamSachdevaNo ratings yet

- 3 Wheel Forklift For Industrial PurposesDocument33 pages3 Wheel Forklift For Industrial PurposesRamakrishna KatkamNo ratings yet

- Lecture 7 - Mechanical Transportation - Module 3 - ElevatorsDocument21 pagesLecture 7 - Mechanical Transportation - Module 3 - ElevatorsShubhaNo ratings yet

- 4 - Unit 4Document99 pages4 - Unit 4Saran T SNo ratings yet

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- Line Items: Optimistic Averagepessimistic WebsiteDocument8 pagesLine Items: Optimistic Averagepessimistic Websiteeng_waleed2008No ratings yet

- Estimating & TenderingDocument13 pagesEstimating & TenderingRoshan de Silva80% (5)

- ClimaSys CV NSYCVF850M115PF PDFDocument1 pageClimaSys CV NSYCVF850M115PF PDFeng_waleed2008No ratings yet

- Section 3 Flange Out Ladder 2015Document8 pagesSection 3 Flange Out Ladder 2015eng_waleed2008No ratings yet

- Project CharterDocument2 pagesProject Chartereng_waleed2008No ratings yet

- Voltage Drop Calculator For Both AWG and MetricDocument4 pagesVoltage Drop Calculator For Both AWG and Metricahmadgce04No ratings yet

- Elkana Job Offer Letter Online Work at Your Home: Last Date Is: 07 December 2016Document2 pagesElkana Job Offer Letter Online Work at Your Home: Last Date Is: 07 December 2016eng_waleed2008No ratings yet

- Spacial SM Nsysm12830Document2 pagesSpacial SM Nsysm12830eng_waleed2008No ratings yet

- Enclosure IP54 SketchDocument1 pageEnclosure IP54 Sketcheng_waleed2008No ratings yet

- ClimaSys CV NSYCVF300M230PF PDFDocument1 pageClimaSys CV NSYCVF300M230PF PDFeng_waleed2008No ratings yet

- Climasys CV Nsycvf850m115pfDocument1 pageClimasys CV Nsycvf850m115pfeng_waleed2008No ratings yet

- Understandingconstraintsandrelationshipsinprimaverap68 130728114356 Phpapp01Document11 pagesUnderstandingconstraintsandrelationshipsinprimaverap68 130728114356 Phpapp01asnovaNo ratings yet

- ClimaSys CV NSYCVF85M230PF PDFDocument1 pageClimaSys CV NSYCVF85M230PF PDFeng_waleed2008No ratings yet

- Climasys CV Nsycvf85m230pfDocument1 pageClimasys CV Nsycvf85m230pfeng_waleed2008No ratings yet

- Climasys CV Nsycvf300m230pfDocument1 pageClimasys CV Nsycvf300m230pfeng_waleed2008No ratings yet

- Climasys CV Nsycvf165m230pfDocument1 pageClimasys CV Nsycvf165m230pfeng_waleed2008No ratings yet

- Visa Application FormDocument5 pagesVisa Application Formjast5No ratings yet

- 05 Equivalent CircuitsDocument32 pages05 Equivalent CircuitsSristick100% (1)

- Basic Access ControlDocument20 pagesBasic Access Controleng_waleed2008No ratings yet

- Building Management System PDFDocument24 pagesBuilding Management System PDFeng_waleed2008100% (3)

- VD CalculatorDocument4 pagesVD CalculatorArnabNo ratings yet

- 07-Busbar Protection Busbar Protection RFDocument63 pages07-Busbar Protection Busbar Protection RFRajesh Pillai100% (2)

- BMS SpecificationDocument10 pagesBMS SpecificationsharafanyNo ratings yet

- JKR Road Layout Design Blueprint For IskandarDocument36 pagesJKR Road Layout Design Blueprint For Iskandarchernl2004No ratings yet

- Hse Company ProfileDocument4 pagesHse Company Profileeng_waleed200850% (2)

- Eiema Guide IPCodes PDFDocument20 pagesEiema Guide IPCodes PDFsabirnaseerNo ratings yet

- 02 - Non-Dir Over CurrentDocument58 pages02 - Non-Dir Over Currenteng_waleed2008No ratings yet

- Protection FundamentalsDocument12 pagesProtection FundamentalsGeorge AsuncionNo ratings yet

- Brochure Lightblade LedDocument8 pagesBrochure Lightblade Ledeng_waleed2008No ratings yet

- Ipcamera TutorialDocument5 pagesIpcamera Tutorialeng_waleed2008No ratings yet