Professional Documents

Culture Documents

Reservoir Rock Properties Analysis: Laboratory Work Book

Reservoir Rock Properties Analysis: Laboratory Work Book

Uploaded by

Echo ArdyoneOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reservoir Rock Properties Analysis: Laboratory Work Book

Reservoir Rock Properties Analysis: Laboratory Work Book

Uploaded by

Echo ArdyoneCopyright:

Available Formats

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 1

Sharif University of Technology

Reservoir Rock Properties

Analysis

2010

Laboratory Work Book

No. 26504

Mohsen Masihi

Department of Chemical and Petroleum Engineering

Sharif University of Technology, Tehran, Iran

masihi@sharif.edu

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 2

Table of contents

Course overview ................................................................................................................................ 3

Introduction ....................................................................................................................................... 5

1-Core and plug preparation .............................................................................................................. 6

1-1 Introduction .............................................................................................................................. 6

1-2 Core Slabbing........................................................................................................................... 6

1-3 Plugging using plug drill Press machine ................................................................................... 9

1-4 Trimming Core Plugs ............................................................................................................. 12

1-5 Core gamma logger ................................................................................................................ 15

2-Cleaning and saturation determination .......................................................................................... 24

2-1 Dean Stark ............................................................................................................................. 27

2-2 Retort Oven ............................................................................................................................ 29

2-3 Core Saturator ........................................................................................................................ 32

3-Porosity ........................................................................................................................................ 42

3-1 Hg porometer ......................................................................................................................... 47

3-2 KeyPhi instrument .................................................................................................................. 50

4-Resistivity .................................................................................................................................... 54

4-1 Electrical properties system atmospheric (EPS-A) .................................................................. 55

4-2 Electrical properties system 700 (EPS-700) ............................................................................ 59

5-Surface and interfacial tension ...................................................................................................... 60

5-1 IFT 700 instrument ................................................................................................................. 66

6-Capillary pressure ......................................................................................................................... 77

6-1 CAPRI instrument .................................................................................................................. 78

7-Permeability ................................................................................................................................. 86

7-1 KeyPhi instrument .................................................................................................................. 89

7-2 Benchtop Relative Permeameter (BRP 350) ........................................................................... 89

8- Rock Mechanical Properties ........................................................................................................ 97

8-1 Acoustic Velocity System (AVS 700) ..................................................................................... 97

References and further reading ...................................................................................................... 105

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 3

Course overview

This course provides an introduction to reservoir rock properties determination by core analysis. Part of

this course introduces the laboratory equipments as well as the procedures used for the core analysis.

Moreover, the theoretical aspects of the parameters used in the core analysis are briefly described.

Hence, the aim of this is to get familiar with of the main rock properties parameters, the way they can

be measured and the sources of errors in the results obtained from the laboratory measurements. At the

end of the course, you will learn what the main properties of rocks are and also you will learn how to

measure them and how to analyze the range of the uncertainty in the results.

These prepared course notes follow closely the sequence of material that will be presented. However,

these are further suggested materials:

1-J. S. Archie and Wall C. G., Petroleum engineering principles and practice. Graham & Trotman,

London, 1986.

2-J. W. Amyx, Bass D. M. and Whiting R. L., Petroleum reservoir engineering (physical properties).

McGraw Hill, Inc., 1988.

3- X. D. Jing, Rock properties course, Imperial College London, 2003

4- M. Masihi, Reservoir Rock Properties course, Sharif University of Technology, 2007.

5-T. Ahmed, Reservoir engineering handbook, Gulf professional publishing, 2001

6- M Ala, Jing, X. D. and Worthington P., Petrophysics course, Imperial College London, 2003

7- M Araujo Fresky, Rock properties, Imperial College London, 2004

Syllabus

1. Core and plug preparation: Introduction to the machines for the various steps of core preparation

including core slabbing, core pluging and trimming. Also sand/shale analysis and depth

matching through the use of core gamma logger will be introduced.

2. Cleaning and saturation determination. The available instruments for core cleaning as well as

saturation determination will be introduced. This includes extraction/distillation method for

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 4

core cleaning (Dean Stark), drying and heating for saturation determination (Retort Oven) and

core saturator for saturation of core before other experiments.

3. Porosity. An introduction to core porosity and various methods of its measurements. Describing Hg

porometer and KeyPhi instruments for porosity measurements.

4. Resistivity. Introduction to the EPS-A instrument for the rock conductivity measurements at surface

pressure and to the EPS-700 at overburden pressure.

5. Surface and interfacial tension. An introduction to various methods of IFT measurements.

Description of IFT700 instrument for measuring IFT.

6. Capillary pressure. Introduction to capillary measurement methods under drainage and imbibition

processes. Description of CAPRI instrument for measuring capillary pressures.

7. Permeability. An introduction to rock permeability. Description of KeyPhi instruments for absolute

permeability measurements and BRP-350 for gas/liquid absolute and relative permeabilities.

8. Rock mechanical Properties. An introduction on how to measure the rock properties like Youngs

modulus and Poissons ratio using AVS-700 instrument by application of the sonic waves.

Course structure

The course will consist of approximately 12 sessions (each one 3 hours) of laboratory works including

lectures. The course will be assessed by a final term examination and by laboratory reports.

The notes in some places cover more material than can reasonably be covered during the course and in

other places have deliberate gaps for more discussions. Please fell free to ask questions during the

course.

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 5

Introduction

Knowledge of the physical properties of the rock and interaction between hydrocarbon system and the

formation rock is crucial in understanding and evaluating the performance of a given reservoir. These

data are usually obtained from two main sources: core analysis and well logging. In this course book

we describe the analysis of cores. A core which is a solid cylinder of rock about 3 inches in diameter

and would usually be about 30 feet long is taken by replacing the drill bit by a core bit which is

capable of grinding out and retrieving the heavy cylinder rock. Once the cores are retrieved it is crucial

to properly handle (avoid damaging) and preserve them by avoiding exposure to air. When the core

arrives in the laboratory plugs are usually drilled 20-30 cm apart throughout the reservoir interval. Then

the plugs are analyzed with respect to porosity, permeability, saturation, grain density and lithology.

This analysis, which is performed at high sampling frequency and low cost, is called routine core

analysis. The results from routine core analysis are used in interpretation and evaluation of the

reservoir. Examples are prediction of gas, oil and water production, definition of fluid contacts and

volume in place, definition of completion intervals. There are other important measurements with the

aim of obtaining the detailed information about the multiphase flow behavior. This analysis, which is

performed at low sampling frequency due to high cost and more time due to gathering the data, is

called special core analysis. Special core analysis gives information about the rock wettability, the

distribution of oil, gas, and water in the reservoir (capillary pressure data), residual oil saturation and

multiphase flow characteristics (such as capillary pressure and relative permeability). Measurements of

electrical and acoustic properties, which are mainly used in the interpretation of well logs, are

occasionally included in special core analysis.

The outline of this handout is organized as follows: We first describe the main pre-processing steps that

are considered on the core samples to be prepared before experiments. In chapter two we describe the

core cleaning methods, which are required before core analysis tests, as well as the saturation

determination methods. In the next chapter, the porosity measurement techniques are described and the

instruments available in the laboratory for the determination of the core porosity are described. In

subsequent chapters we then describe the techniques to measure and the available machines to

determine respectively the core sample resistivity, interfacial tension, capillary pressure and

permeability.

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 6

1-Core and plug preparation

1-1 Introduction

When a piece of rock or a core is wanted to be used for analysis as a sample in the laboratory, several

steps, as per-processing steps, should be considered on the sample to be prepared for experiments. The

main per-processing steps are as follow:

(i) slabbing; the cores need to be slabbed with the aim of making the rock structure visible. This can

simply be done by sawning down the middle of the core and cuting it at desired length.

(ii) plugging: one can drill the plugs at every one foot of the core.

(iii) trimming: both end of the plugs and core samples can be trimmed in order to produce high quality

thin sliced samples without disturbing the structure of the sample.

Moreover, core scanner and core gamma logger may be used for depth matching as well as describing

the core lithology and texture. The detail description of these per-processing steps and the equipments

to do these are described in this section.

1-2 Core Slabbing

Core slabbing is the first step in the preparation of samples for core laboratory experiments. The radial

core slabbing saw is a machine for cutting rocks into the smaller parts. This is basically for cutting a

big size outcrop rock into the smaller parts and/or cutting the longer cores to the shorter ones. Radial

core slabbing saw is designed for diamond cutting discs only, which is connected to the motor with a

shaft and two pulleys and the use of the cooling waters improves the slice quality and cutting speed and

reduces the heat which is produced by sawing process. Figure below shows the core slabbing machine

(Fig. 1).

However, students should considered the following safty notices:

1-This machine must only be operated by qualified personnel specially those who has had the

operation training and the safety regulations.

2-Protect yourself from any splash produced by wearing a suitable overall.

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 7

Figure 1: Core slabbing machine

Machine Description:

The machine has a motor which supplies the rotational motion for sawing. The main machine parts are:

Radial saw

Electro motor

Shaft, pulleys and rim

Adjustable tilting table

Cooling system, including pumps, water supply, flexible pipes

The rotational motion transmitted by two pulleys from electro motor. At either side, there are three

different stepped pulley couples. The speed of motion can be adapted by positioning the compound

diamond rim on the suitable stepped pulley couple on the electro motor and saw system. The dimension

of rock sample should be smaller than the max height of saw from table to be cut electively. Bigger

rocks should be broken to a proper part with other methods. One draw back of this machine is its noise.

The machine noise level is around 70 dBa. During the cutting process, the noise level depends on the

material to be cut, the type of disc used, the rotation speed and the cooling.

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 8

Experiment operation

The procedure for cutting a given sample is as follows:

If the rock is big then it should first be cut by another method

Put the sample on the table

Check the tension on the pulleys

Adjust the direction of water line on both saw and sample

Check water tanks and fill them if they are empty

Start the water pump and check the direction of water and check the flow

Start the saw by pressing the start bottom

Cut the sample by screwing up and down of the saw and pushing the sample table of machine

Press the stop button

Unclamp the core sample

However, in working with the machine consider the following safety issues: (i) prevent touching of saw

with the machine sample table, because of damaging of saw, (ii) protect yourself from any splash and

water drops by wearing overall and safety glasses.

You should consider the appropriate rotational speed. The motor shaft rotates at 1,440 rpm. When the

belt is on the central pulley either on motor side and disc side, the disc rotates at 1,440 rpm. When the

belt is on the small pulley on motor side and on the large pulley on the disc side, the disc rotated at

2,160 rpm and finally when the belt is on the large pulley on motor side and on the small pulley on the

disc side, the disc rotated at 960 rpm. The schematic diagram of pulleys at both motor side and disc

sides are illustrated in Fig. 2.

Motor 1 440 rpm Spindle disc holder

Figure 2: Pulleys

Cutting linear speed in meters/seconds versus disc diameter and speed are shown in Table 1.

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 9

Table 1: Cutting speed and disc diameters of core slabbing machine

Disc diameter

Disc rpm 300 350 400 450 500

960 15 17.5 20 22.5 25

1440 22.5 26.5 30 34 37.5

2160 34 39.5 45 51 56.5

For cooling of the saw and sample during the operation, water is used. Water is pumped from water

tank and poured directly to the sawing position on the sample. Then, the used water goes to the water

tank. Water tank is composed of to different tank. The recycled water first enters to the first tank, and

after precipitating of cuttings into this tank, the fresh water overflow to the main water tank.

Maintenance

Keep the machine clean.

Do not let water and waste in the tray.

Check carefully the v-belt and its strain.

1-3 Plugging using plug drill Press machine

The core cutting machine is designed to cut specimens from cores of between 4 to 6 inches, or from

blocks of a similar size. The produced plugs are in two different size of 1 and 1.5 inches. This machine

can be installed on any table (Fig. 3). By screwing down of a hollow plug drill, plugs are cut from the

samples.

However, students should considered the following saftey notices:

-The core cutting machine should only be used by qualified operators who have been suitably trained in

how to produce the quality of cut required under the prescribed safety conditions.

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 10

Figure 3: Core plugging machine

Machine Description:

The machine can accommodate cores measuring from to 3. A swivel joint with a tap allows

internal irrigation of the core drill and a hose fitted with a tap allows external irrigation of the core drill.

The speed can be adjusted by repositioning the belt (1800 rpm 2500 rpm 3500 rpm) like core

slabbing machine.

The machine comprises of:

clamping stand

column

Spindle-Motor unit

adjustable tilting table

protective housing

clamping unit

recycling tank

Table of machine has a rotating capability up to 45. This capability causes that user can make plugs

from any part of slab even deviated sides.

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 11

Experiment operation

Check the tension on the pulleys

Check the direction of the spindle

Fill the recycling tank

Screw down the core drill and lock it in place

Mount a core sample and lock it firmly in the clamping unit

Adjust the lower stop on the core drill. 1-2 mm before the end of slab is sufficient for

prevention of plugging the sample in plug driller. Touching of the driller with table causes

severe damage to the driller.

Close the core drill protective housing

Press the Start button

Open the irrigation taps

Check the flows

Cut the core sample

Press the Stop button

Unclamp the core sample

Speed of rotation can be adjusted by changing pulleys. The procedure for this operation is as:

open the pulley cover

loosen the 2 locking screws and pulley tension lever

pinch together the two sides of the spindle belt

change the position of the belt

tighten the belts with the lever and lock the two screws in place

close the cover

If the tension of pulleys is not sufficient then the belt should be changed. The procedure for changing

the belt is as follow:

make sure that the machine is disconnected

open the pulley cover

loosen the two clamping screws and the belt tensioning lever

pinch together the two sides of the spindle belt

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 12

change the belts

tighten the belts with the lever and lock the two screws

close the cover

Maintenance

keep the unit and the protective housings clean

remove debris and core particles

remove sludge

clean all moving parts

change the cooling fluid as soon as it is dirty

make sure that the machine is disconnected

remove the pump and the waste pipe from the recycling tank

empty the tanks

clean the tanks and the separators

fill the tank with cooling fluid

refit the pump and the waste pipe to the recycling tank

1-4 Trimming Core Plugs

After preparing plugs in core drill machine, all of them should be cut into desired size. This can be

done by trimming machine. Trimming machine is a bench model designed to produce fast, high quality

thin sliced samples from all materials without disturbing the structure of the sample (Fig. 4).

However, students should considered the following saftey notices:

Touching any resinous cutting wheel can be dangerous.

The machine is fitted with safety devices which prevent the wheel from turning when the hood

is open

This machine must only be used by a qualified person who has received the proper training

required to achieve the quality of cut and the high standard of safety envisaged by the

manufacturer.

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 13

Figure 4: Trimming core plug machine

Machine Description:

The basic model can work either in manual feed or with an optional hydraulic automatic feed which is

driven by the domestic water supply (Minimum pressure 1.5 bars). In the automatic mode, user can

determine the speed of rotation of saws. The machine consists of two radial saw that can work together

and cut both end of pugs simultaneously. Each cuts needs nearly 0.2 litter cooling water. This machine

is designed to work with all types of cutting wheel (resinous - diamond - boron carbide) and various

accessories and adaptations enable samples or core sections to be cut lengthways. These include cradles

or devices for holding the samples configurations using two wheels which allow parallel-sided sections

of continuous length to be cut in a single operation. The machine is fitted with a safety cut-out switch

which can be reset, or rewound should there be no power, as well as a gradual starting device. When

the cover is open this safety switch open the electric current and the machine dont work. The use of

passivated water is strongly recommended to avoid corrosion.

Experiment operation

The machine can work in both manual and automatic mode. By setting two lever taps on the body of

machine, three situations are achieved. The lever taps allow the wheel (saw) to advance or return.

quick back mode: in this mode the saws go back quickly and positioned at the start point. This

mode can be achieved by setting both taps down.

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 14

stop manual: in this mode user should handle the position of saws for trimming the plug

manually and can be achieved by setting top tap to up and bottom tap to dawn

automatic feed: in this situation samples are trimmed automatically by the machine. The

rotational speed of the saws can be adjusted by the Movement regulator beside the lever taps.

Manual mode

Steps for operating in manual mode are as follows:

Press the start bottom

Set the taps to " Quick back " position, at the end of the race, the lever is independent of jack,

Set the taps to the "Manual stop" position.

Adjust the direction of water line on saw and sample

Check water tanks and fill them if they are empty

Start the water pump and check the direction of water and check the flow

Close the protective housing of machine

By moving the saws to front start trimming of the sample

Press the Start button

Press the Stop button

Unclamp the core sample

Automatic feed (optional)

Steps for operating in automatic feed mode are as follows:

Press the start bottom

Set the taps to the " Automatic feed " position

Adjust the direction of water line on saw and sample

Check water tanks and fill them if they are empty

Start the water pump and check the direction of water and check the flow

Close the protective housing of machine

Gradually open the movement regulator until the required feed rate is obtained.

At the end of the cut, turn the taps to the "Rapid return position.

Press the Stop button

Unclamp the core sample

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 15

Maintenance

Apart from keeping the machine properly clean, no specific maintenance is required. Make sure that

any sediment or waste matter is removed from the tank before starting. Change the fluid according to

the frequency of use and its deterioration over time (shelf life).

1-5 Core gamma logger

The main purpose for using gamma logger is to correlate the depth of each section of core

with the depth of a log in the formation i.e. depth matching. Gamma rays in rocks arise

primarily from the radioactive decay of elements belonging to the "KUT" radioactive

families for Uranium 238, Thorium 232, and potassium isotope K-40. The Gamma logger

measures both total naturally occurring gamma radiation in core samples in API units, and

the spectral response in weight concentrations of thorium, uranium and potassium.

Machine Description:

The core samples are carried over the detector by a motor driven belt conveyor. The conveyor is 15 cm

wide and 3 meters long (belt length is 6 meters). The belt is marked in increments of 0.25 meters to aid

in placement of the core along the belt (Fig. 5). Speed and motion of the conveyor belt are controlled

with a stepper motor drive from the SmartLog software. Belt speed is set in the software as 3 cm/min,

but can be adjusted in Factory Setup.

Figure 5: Natural Gamma Logger

Measurement of the Spectral Log requires much more radiation data to determine the constituents and

hence a slow speed is necessary. Belt travel is synchronized with the gamma-ray data by the software.

The default time period for each scan is 500 seconds during which time the core travels 25 cm at belt

speed of 3cm/min. Thus, one data point is obtained for every 25 cm depth of the core.

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 16

The gamma radiation is detected by a 3x3" Sodium Iodide crystal and photomultiplier located below

the belt in the center of the conveyor. The detector is protected from ambient radiation with low

activity virgin lead shielding.

Calibration

The process of calibration is as follows:

Belt speed:

1. From the main APPLILAB screen, set the speed to the minimum value of 0.150 ft/min and

validate with OK.

2. Have a stop watch ready. Start the belt and the stop watch. Once the belt has moved by a

minimum of 1 foot, write down the exact belt displacement and the time elapsed. Repeat these

steps for various speeds e.g. for 0.450 ft/min to the maximum speed of 0.750 ft/min.

3. In the file: C:\AppliLab\Project\NGL200 \GammaLogger.xls, open the tab Calibration.

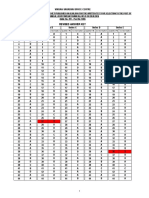

4. Report the set point, distance and time in related columns (Fig 6). The effective "measure"

speed is calculated in the last column. The graph, the gain and the offset are automatically

updated. Note: if the coefficient R

2

is less than 0.9990, repeat the measurement. Save and close

the Excel file.

Figure 6: Illustration of belt speed calibration

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 17

Probe:

In Fig. 7, gain refers to the probe amplifier gain. The amplifier gain can be adjusted in either automatic

or manual mode. Gain calibration must be refreshed from time to time to fit the probe response drift

with aging.

After a gain calibration, you must calibrate the "zero" (background). Natural radioactivity

(background) is usually of low level, especially apparent background accessible to the probe set in the

lead shield. However, this apparent background is not negligible compared to the natural radioactivity

in core sample. Natural radioactivity (background) depends on various factors such as local geology,

climate (rain, temperature) etc...

Automatic gain calibration:

Stop the belt if it was moving. Remove any sample and standard U, Th and K from the belt.

Install the "hot Thorium" standard provided with the equipment on the belt, directly over the

detector in the lead tunnel.

Double click on the trend area to pop up this window (calibration window). Click on the button

to start the gain automatic determination. The duration is about 3 hours. The calibration time

countdown is displayed in the right top corner.

At the end of the acquisition, the gain is automatically adjusted to fit the standard.

Figure 7: Illustration of window of gain calibration

Zero calibration:

During zero calibration, the apparent background is scanned during a set time (Standard duration is

set to 10,000s to suit 99% of cases).Then this "zero" spectrum is automatically memorized. During

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 18

next core scan campaign; this "zero" will be automatically subtracted from all the spectrum

measurements. Note that zero calibration must be refreshed from time to time. Calibration of zero

must follow a gain calibration. The zero (spectral) needs to be experimentally recorded (no manual

edition is possible).

To calibrate the zero:

Double click on the trend area to display calibration window.

Stop the belt if the belt was moving. Remove any sample and standard from the belt.

Click on the button to start the zero (spectral) determination. The time countdown is displayed

in the right top corner.

Automatic calibration for U, Th and K channels:

The calibration for U, Th and K can be operated in either automatic or manual mode. Channels

calibration must be refreshed from time to time to fit the probe response drift with aging. In order

to calibrate U, Th and K in sequence:

Double click on the trend area to pop up calibration window.

Check and adjust the Reference values as per the certificates.

Stop the belt if the belt was moving. Remove any sample and standard from the belt.

Install the standard U over the detector in the lead tunnel, and then click on the button

accordingly to start a spectrum scan.

The running process title and the time countdown are displayed in the top right corner of the

trend window.

After completion of the spectrum acquisition, the countdown is reset and the probe amplifier is

automatically adjusted to match the region of interest of the standard.

Repeat theses steps in sequence similarly for Th and then K standards.

Experiment operation

After completing the calibrations (belt, gain, zero and U, Th and K channels), you can start the

measurement of your core samples. Lay the cores in order of depth with the shallow end nearest to the

lead tunnel. Align the first

core with the groove each side of the belt. Avoid installing the cores far from

the longitudinal axis (Fig 8). The operation can be done manually or automatically.

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 19

Figure 8: Illustration of core laying on the conveyor

Manual operation:

Manual operation is possible for specific uses disconnected from spectral logging. In case

you run the spectrum acquisition manually, the duration is free and the conveyor can be

stopped. This function can be used for checking the level of cores before selecting the

conveyor speed for instance.

The conveyor manual operation is basically used during of speed calibration. If you run the

conveyor at the same time as manual spectral acquisition, you cannot link the position with

the depth. Therefore, a spectral gamma logging should be conducted in automatic mode.

Figure 9: Illustration of input value dialogue box

-To run the conveyor from the interface application, you can access to the belt speed set point

(bottom left) and to the ON / OFF switch (bottom right). Click in the window to pop up input

value dialogue box (Fig. 9).

-Type a value in the range from 0.15 to 0.75 ft/min and validate with OK.

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 20

-Click on button labeled Click to start the belt to start the conveyor. When facing the electrical

cabinet, the belt moves from left to right. To stop the conveyor, click on button labeled Click to

stop the belt.

-You can start the spectral acquisition by clicking on GO. The spectral radioactivity (counts in Y axis,

energy in X axis) is refreshed continuously. Equivalent values of Uranium, Thorium and K

(potassium) and total activity are directly displayed at the bottom of the window, according to

calibration data. The Y axis is auto ranged and the scale is displayed in the top left corner.

-Click in the spectrum trend window (Fig 10): a vertical line is drawn at the mouse position. The

energy level (X value) is displayed and the total counts (Y value) is refreshed continuously.

-You can stop the spectral acquisition by clicking on the button Stop. The spectral trend remains

displayed as the relevant concentration of U, Th, K and the total activity.

Note: When you click on clear, the curve, the relevant concentration of U, Th, K and the total

activity are cleared out from the memory.

Figure 10: Illustration of the spectrum trend window

Automatic operation:

-To start the spectral acquisition, click on the button Start Measure. After a few seconds, you are

requested to name the file that will be used for your report. Here we select "MyReport". If this

name does not exist yet, this file will be created as a copy of the master GammaLogger.xls. The

file is opened. If a file with this name has already existed, it will be open. You are prompted to

check the parameters and to press start. It is time to edit the core identification and check the

belt speed as follow (Fig 11).

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 21

Figure 11: Illustration of the spectral gamma ray report file

-You can edit the yellow cells only (column B). For instance, you cannot edit the belt speed directly.

The belt speed is calculated from the Sample Increment and the Sample Duration that you can

edit. In this example the current depth is 1,004 ft, and the initial depth is 1,000. This illustrates

how to go on with a file used earlier. In this case, the previous data from 1,000 to 1,003 will be

kept and the core scan starts from 1,004. Therefore, the Active Line (calculated by Excel) is 17;

in front of the Sample Depth 1,004. Note: In case you set the current depth to 1,002 ft, and the

core scan starts from 1,004. The data from 1,000 to 1,002 (excluded) will be kept, and the data

from 1,002 (inclusive) will be overwritten with new data. Moreover, changing the sample

increment or duration, will change the belt speed and the sample depth (automatic

recalculation).

-In our example the Sample Increment is 1 foot. We can skip 1, 2, 3 feet or any multiple of the

Sample Increment. To skip a missing core section, just enter "1" in the suitable cell(s) in the

column B in regard of the relative depth. In our XLS illustration, we skip the samples l,006

and 1,007. Finally we scan the sample beginning at depth 1,005, then we go on with the

sample beginning at 1,008 depth.

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 22

-Once the previous steps are completed, click on start to run the experiment.

-Confirm the sample depth read at current depth in the XLS file. If you want to change, click on NO.

-On the experiment is completed, the XLS file is automatically saved and closed. Open the

MyReportxls (in our example, the report file was named by the operator "MyReport"). The path

is: C:\AppliLab\Project\NGL200\Excel Files\MyReport.xls.

-Open the tab GammaLog. We can see the values of equivalent U, Th, K and total gAPI interpreted

from the calibration versus the sample depth (Fig 12).

Figure 12 : Illustration of the values of equivalent U, Th, K and total gAPI interpreted from the

calibration versus the sample depth in the report

-Open the tab Graph. We can see the values of equivalent U, Th, K and total gAPI interpreted from the

calibration versus the sample depth (Fig 13).

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 23

Figure 13: Illustration of the variation of equivalent U, Th, K and total gAPI interpreted from the

calibration versus the sample depth

Maintenance

Check that nothing can obstruct the belt motion.

Check that drums and rollers are aligned to drive the belt in straight line.

A lateral drift of 2 - 3 cm is not a problem if the belt comes back to the initial position.

Avoid to load the cores far from the longitudinal axis

Check the belt and chain tension once a month.

Check that the motor fan is still efficient to cool the motor once a year.

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 24

2-Cleaning and saturation determination

After preparing the core plugs samples, the core samples must be cleaned of residual fluids and

thoroughly dried. The cleaning process may also be apart of fluid saturation determination. Let us

first define the fluid saturation as the ratio of the fluid volume in a given core sample to the

pore volume of the sample. Mathematically this is:

1

g

w o

w o g

p p p

w o g

V

V V

S S S

V V V

S S S

+ +

where

w

V ,

o

V ,

g

V and

p

V are water, oil, gas and pore volumes respectively and , ,

w o g

S S S are water, oil

and gas saturations. Note that fluid saturation may be reported either as a fraction of total porosity or as

a fraction of the effective porosity. Since fluid in pore spaces that are not interconnected can not be

produced from a well, the saturations are more meaningful if expressed on the basis of the effective

porosity. The weight of water collected from the sample is calculated from the volume of water by:

w w w

W V

Where

w

is water density in g/cm3. The weight of oil removed from the core may be computed as,

o l w

W W W

Where

l

W is the weight of liquids leaving the core sample in gr. Oil volume may then be calculated as

/

o o

W . Pore volume

p

V is determined by a porosity measurement, and oil and water saturation may be

calculated by the above equation. Gas saturation can be determined using the summation equation.

There are several methods to clean and evaluate the fluid saturation within a core plug sample. Here we

briefly review some of them:

1-Direct Injection of Solvent

The solvent is injected into the sample in a continuous process. The sample is held in a rubber sleeve

thus forcing the flow to be uniaxial.

2-Centrifuge Flushing

A centrifuge which has been fitted with a special head sprays warm solvent onto the sample. The

centrifugal force then moves the solvent through the sample. The used solvent can be collected and

recycled

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 25

3-Gas Driven Solvent Extraction

The sample is placed in a pressurized vessel of solvent containing dissolved gas. The solvent fills the

pores of sample. When the pressure is decreased, the gas comes out of solution; expands, and drives

fluids out of the rock pore space. This process can be repeated as many times as necessary

4-Soxhlet Extraction

A Soxhlet extraction apparatus is the most common method for cleaning sample, and is routinely used

by most laboratories. As shown in Fig. 14a, toluene is brought into a slow boil in a Pyrex flask, its

vapors move upwards and the core becomes engulfed in the toluene vapors (at approximately 110 C).

Eventually the amount of water within the core sample in the thimble will be vaporized. The toluene

and water vapors enter the inner chamber of the condenser; the cold water circulating around the inner

chamber condenses both vapors to immiscible liquids. Recondensed toluene together with liquid water

falls from the base of the condenser onto the core sample in the thimble; the toluene soaks the core

sample and dissolves any oil with which it conic into contact. When the liquid level within the Soxhlet

tube reaches the top of the siphon tube arrangement, the liquids within the Soxhlet tube are

automatically emptied by a siphon effect and flow into the boiling flask. The toluene is then ready to

start another cycle. A complete extraction may take several days to several weeks in the case of low

API gravity crude or presence of heavy residual hydrocarbon deposit within the core. Low permeability

rock may also require a long extraction time

Figure 14: Schematic diagram of (a) Soxhlet and (b) Dean- Stark apparatus

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 26

5-Dean-Stark Distillation-Extraction

The Dean-Stark distillation provides a direct determination of water content. The oil and water area

extracted by dripping a solvent, usually toluene or a mixture of acetone and chloroform, over the plug

samples. In this method, the water and solvent are vaporized, recondensed in a cooled tube in the top of

the apparatus and the water is collected in a calibrated chamber (Fig. 14b). The solvent overflows and

drips back over the samples. The oil removed from the samples remains in solution in the solvent. Oil

content is calculated by the difference between the weight of water recovered and the total weight loss

after extraction and drying.

6-Vacuum Distillation

The oil and water content of cores may be determined by this method. As shown in Fig. 15, a sample is

placed within a leak-proof vacuum system and heated to a maximum temperature of 230

o

C. Liquids

within the sample are vaporized and passed through a condensing column that is cooled by liquid

nitrogen.

Figure 15: Vacuum distillation Apparatus

7-Retort Oven

The retort oven is used to determine the porosity and total saturation of water (S

w

) and residual

saturation of oil (S

ro

) in core samples, either fresh or preserved ones.

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 27

Comparison of these methods:

The direct-injection method is effective, but it is slow. The method of flushing by using centrifuge is

limited to plug-sized samples. The samples also must have sufficient mechanical strength to withstand

the stress imposed by centrifuging. However, the procedure is fast. The gas driven-extraction method is

slow. The disadvantage here is that it is not suitable for poorly consolidated samples or chalky

limestones. The distillation in a Soxhlet apparatus is slow, but is gentle on the samples. The procedure

is simple and very accurate water content determination can be made. Vacuum distillation is often used

for full diameter cores because the process is relatively rapid. Vacuum distillation is also frequently

used for poorly consolidated cores since the process does not damage the sample. The oil and water

values are measured directly and dependently of each other.

In each of these methods, the number of cycles or amount of solvent which must be used depends on

the nature of the hydrocarbons being; removed and the solvent used. Often, more than one solvent must

be used to clean a sample. The solvents selected must not react with the minerals in the core. The

commonly used solvents are: acetone/benzene, benzes/methol alcohol, carbon/tetrachloride,

chloroform, methylene dichloride, mexane, naphtha, tetra chloroethylene, toluene, trichloro ethylene

and xylene. Toluene and benzene are most frequently used to remove oil and methanol and water is

used to remove salt from interstitial or filtrate water. The cleaning procedures used are specifically

important in special core analysis tests, as the cleaning itself may change wettabilities. The core sample

is dried for the purpose of removing connate water from the pores, or to remove solvents used in

cleaning the cores. When hydratable minerals are present, the drying procedure is critical since

interstitial water must be removed without mineral alteration. Drying is commonly performed in a

regular oven or a vacuum oven at temperatures between 50C to 105

o

C. If problems with clay are

expected, drying the samples at 60C and 40 % relative humidity will not damage the samples.

2-1 Dean Stark

The distillation extraction (Dean stark) method for determination of the fluid saturation depends upon

the distillation of the water fraction, and the solvent extraction of the oil fraction from the sample. The

sample is weighed and the water fraction is vaporized by boiling solvent. The water is condensed and

collected in a calibrated receiver. Vaporized solvent also condenses, soaks the sample, and extracts the

oil. The sample is oven dried and weighed. The oil content is determined by gravimetric difference.

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 28

Machine Description

This consists of a distillation / extraction glassware unit and a heating mantle with thermostatic

controller. The glassware for one sample is composed of boiling flask with extractor, a sample support

screen, volumetrically graduated water receiving tube of 5 or 10 ml, condenser and desiccant drying

tube. A soft tubing is also used to connect the condenser to the water cooling unit. All these devices are

mounted on a frame rack (Fig.16).

Figure 16: Dean Stark apparatus model (left) DS_1.5x6 and (right) DS_4x3

Experiment operation:

The objective of the experiment is to determine the oil, water and gas saturation of a core sample. The

procedure is as foolow:

1. Weigh a clean, dry cellulose thimble. Use tongs to handle the thimble.

2. Place the cylindrical core plug inside the thimble, then quickly weigh the thimble and sample.

3. Fill the extraction flask two-thirds full with toluene. Place the thimble with sample into the long

neck flask.

4. Tighten the ground joint fittings. Start circulating cold water in the condenser.

5. Turn on the heater and adjust the rate of boiling so that the reflux from the condenser is a few

drops of solvent per second. The water circulation rate should be adjusted so that excessive

cooling does not prevent the condenser solvent from reaching the core sample.

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 29

6. Continue the extraction until the solvent is clear.

7. Read the volume of collected water in the graduated tube. Turn off the heater and cooling water

and place the sample into the oven (from 105C to 120C), until the sample weight does not

change. The dried sample should be stored in a desiccater.

8. Obtain the weight of the thimble and the dry core.

9. Calculate the loss in weight W

l

, of the core sample due to the removal of oil and water.

10. Measure the density of a separate sample of the oil.

11. Calculate the oil, water and gas saturations after the pore volume V

p

of the sample is

determined.

Table 2: Data sheet for Dean Stark experiment

W

org

gr

W

dry

gr

w

gr/cc

o

gr/cc

V

w

cc

W

o

gr

V

o

cc

V

p

cc

S

o

S

w

S

g

W

org

= Weight of original saturated sample

W

dry

= Weight of desaturated and dry sample

2-2 Retort Oven

The retort oven is used to determine the porosity and total saturation of water (S

w

) as well as the

residual saturation of oil (S

ro

) in the fresh or preserved core samples (Fig. 17). Note that the saturations

which are determined in a laboratory are generally different from the field saturations. These

differences come from:

Invasion of drilling mud, or of mud filtrate

Expansion of gas due to pressure drop during upraise of core to surface

To some errors of manipulations, as core sample washing with water or drying without cares

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 30

Figure 17: A retort oven device

Machine Description

The retort oven is composed of following items:

Insulated oven with heat control with a maximum operating temperature of 700 C.

12 traps and stainless steel screens

stainless steel tank for condensed water

The procedure of the test is as follow:

Install water supply to each end of bath which has a baffle in centre, ie each end independent of

other end.

Set required temperature using UP and DOWN arrows buttons only.

Heat the chamber (cover closed) to 540-650 C (10001200 F). When retort cups are placed in

the heated enclosure, the temperature will fall down about 400 C, and then will go up again.

The fresh sample is roughly crushed, weight = 125 grams, and placed in the retort cup.

Volume of the crushed sample = VT with VT = Weight / Natural density

Note : measurement must be realized on an another piece of core whatever is its form, about 30

cm

3

, weighed with its fluids, water, oil, gas and with total volume will have been determined

with a volumetric pump.

Place all the retort cups (12 max) in the retort, even there is no sample to analyze in each of

them and close the retort which is under voltage. The receiving graduated 20 cc tubes clean are

in place.

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 31

Read the volume of water INI.W collected after T minutes. This time T corresponds

exclusively to the water contained into the pores of the sample and not to the water contained

into the clays. It is determined in pointing out according to the time (or to the temperature) the

volume of water collected into the receiving tubes. It is the value of the time which corresponds

with the middle of the plateau, or of the inflection point (in case of clayey samples).

Read the volume of water FINAL W collected when temperature reaches 650 C.

Read the volume of oil OBS.O collected when the temperature reaches 650 C. This quantity

of oil collected is by default because oil is lost by cracking during heating, from which a

calibration is needed.

Calibration

In sands samples contained in retort cups, one places growing known quantities of oil from Occ to

10cc. Using normally the retort oven, one notes the OBS.O volumes. Then plot working curves of

correction: see correction table (for example a retort oven and crude oil 45 API)

Table 3: calibration table

Reading observed,

OBS.O cc

Reading corrected,

CORR.O cc

0

traces

0.05

0.1

0.2

1.0

0

0.1

0.15

0.25

0.35

1.40

For reading higher then 1.0 cc, add 0.4 to determine the corrected volume. Correction of the volume of

oil collected. Use the precedent table. It is determined CORR.O.

Calculation

Amount of oil in the sample:

.

100

CORRO

Ob

VT

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 32

Amount of water in the sample:

.

100

INIT W

Wb

VT

Amount of gas contained in the sample Gb is determined by volumetric mercury pump.

Porosity :

Ob Wb Gb + +

Total saturation of water :

100

TW

Wb

S

Residual saturation of oil :

100

RO

Ob

S

2-3 Core Saturator

Prior to perform any core flood experiment, we need a saturated rock sample. Automatic saturator is

a device used to prepare samples for such experiments. The automatic saturator is used to inject water

or brine into the sample.

Machine Description

This machine can either work on automatic mode and semi-automatic mode. Although standard

parameters fulfil most of applications, the operator can easily change the duration steps of the

automated mode. Furthermore, it is possible to shift to semi-auto or manual mode for any specific

process. In the semi automated mode the operator controls the Electro-Valves, as in the manual mode

where the operator work with the manual valves. In semi-auto and manual mode the steps duration and

valve sequence is custom. For very low permeability samples, you can increase the "additional sample

evacuation" step to evacuate the samples longer than the saturant (and avoid vaporization and salt

concentration change or precipitation). This system is composed of the following items as shown in

Fig. 18 and its main feature is summarized in Table 4.

A console with injection pump, valves and PLC (Programmable Logical Controller)

2 jars (one saturant TANK, one vacuum TRAP)

A pressure vessel

A vacuum pump

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 33

Figure 18: Main components of the automatic saturator

Table 4: Main features of automatic saturator

psi 2000 Maximum saturating pressure

mm 58 Cell diameter

mm 300 Cell height

VAC, 50 Hz 220 Power supply

To achieve a good quality saturation on a low permeability sample, thoroughly evacuation (sample and

test brine) is followed by saturation at pressure controlled via a turn-key unattended program.

Experiment operation:

To do the experiment, some pre-steps to prepare the system are necessary before using either

automatic, semi-auto or manual modes. These are four main steps to prepare the system:

i)Setting the target pressure. For setting the target pressure you can use the knob on the pressure gauge.

You can change the set point by rotating the knob to move the red tip needle to the requested value.

(Fig. 19)

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 34

Figure 19: Setting the target pressure

ii)Setting the pump. The pump panel is located at the right low corner of the console (Fig. 20left).

Screw the knob to reduce the flow rate. The setting must be at least higher than 30% of the range (Fig.

20right). Before starting an automatic process, switch On the pump. If you plan to run a semi-

automatic mode or manual mode, you will switch on the pump on request.

Figure 20: Illustration of: (left) setting the pump and (right) pump flow rate

iii)Sample loading. Discharge the pressure in the unit by setting the manual valves MV3 to by-pass and

MV2 to vent. Disconnect the tubing from the lid. Then open the cell by unscrewing the lid. After you

are checking the sample identification, install the sample with the tray into saturator cell. Eeventually

complete the volume with some plain plugs in order to reduce the volume of brine to inject (Fig. 21).

Figure 21: Illustration of sample loading

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 35

Check the lid seal. Screw the lid to the pressure vessel. Connect back the tubing. Install the tray with

samples into the saturator cell. Check the lid seal. Figure 22 shows a home-made hook to lift the tray.

Figure 22: Illustration of hooking to lift the tray

iv)Jars preparation. Poor the saturant (brine) into the tank jar (2 ports model). Let enough free space for

bubbling during degassing. Empty the water trapped in the jar (1 port) connected to the vacuum pump.

Close the two jars. (Fig. 23)

Figure 23: Illustration of jar preparation step

1-Automatic mode

Switch the selector in horizontal position to Automatic option. The green bulb is lightening.

Press on the button START, the green bulb "IN PROGRESS" is lightening.

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 36

There are six steps (sample and saturant evacuation, sample additional saturation, saturant to atm

pressure, by-pass opens, pump priming, saturation under pressure) that are processed automatically.

Once the cycle is completed, the green bulb "COMPLETE" is lightening.

You can abort the cycle at any time by pressing on the STOP button. Check the pressure and the

pumps status.

Figure 24 shows the switch time table with default time span. The global duration is about 3 1/2 hour.

The long durations are respectively T6 (saturation under pressure), T2 (additional saturation), T1

(sample and saturant evacuation) and for 2, 1 and 1 hours. Others durations are similar to a

commutation time. Note that any of these durations can be modified. The sample and saturant

evacuation step start simultaneously with T2 but as soon as T2 is elapsed, the saturant is isolated while

the sample goes on to be evacuated until T1 is elapsed. This allows evacuating the saturant for a shorter

time T2 than the sample evacuated during T1 and to prevent from potential saturant evaporation (in

case of brine etc). Make sure that no manual valve is set open during semi-auto process.

Stop

E

n

d

o

f

S

t

e

p

#

1

E

n

d

o

f

S

t

e

p

#

2

E

n

d

o

f

S

t

e

p

#

3

E

n

d

o

f

S

t

e

p

#

4

E

n

d

o

f

S

t

e

p

#

5

E

n

d

o

f

S

t

e

p

#

6

Start

S

a

m

p

l

e

a

n

d

S

a

t

u

r

a

n

t

e

v

a

c

u

a

t

i

o

n

Completed In progress

S

a

m

p

l

e

a

d

d

i

t

i

o

n

a

l

e

v

a

c

u

a

t

i

o

n

S

a

t

u

r

a

n

t

t

o

a

t

m

.

p

r

e

s

s

.

B

y

-

p

a

s

s

o

p

e

n

P

u

m

p

P

r

i

m

i

n

g

S

a

t

u

r

a

t

i

o

n

@

p

r

e

s

s

u

r

e

ON

EV4 EV4

ON

EV5 EV5

ON

EV6 EV6

ON

EV7 EV7

ON

EV8 EV8

Pump run Pump

T5 : 1' T4 : 2' T3 : 1' T6 : 120 '

after

about

3 1/2 h

T2 : 60 '

T1 : 90 '

Figure 24: The time duration of six steps used in the automatic mode

Step1: Samples and brine evacuation with T2 = 60 min (note that T1 starts simultaneously)

The valves EV4 and EV5 are open to the vacuum pump during T2 (not T1)

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 37

Check that the vacuum pump is running and bubbles appear immediately in the saturant jar (as for

boiling water). If no bubble comes after the first minute elapsed, stop the process and fix the leak.

Check that no saturant (brine) is going out from the trap jar to the vacuum pump.

Step 2: Relieving vacuum in the brine jar with T1 = 90 min, ends 30 min after T2

The valve EV5 is closed to isolate saturant brine jar from the vacuum pump. T2 (1 minute default

value) is devoted to these operations (see Fig. 25 for the steps 1 & 2)

Vacuum

Vent

8

5

6

7

4

By-Pass

Pump

(stopped)

Vacuum

Vent

8

5(open)

6

7(closed)

4

By-Pass

Step#1 Sample & Saturant evacuation T2=60 min

Step#2 Sample additional evacuation T1-T2=30 min

T1=90min starts at same time as T2

Figure 25: Illustration of the schematic connections used in the steps 1 and 2

Step 3: Saturant to atmosphere pressure with T3 = 1 min

The valve EV8 is open: the vacuum is relieved in the desaturant jar. The brine pressure builds up to

atmospheric but stay degassed.

You can stop the vacuum pump.

step 4: By-pass opens with T4 = 2 min

The by-pass EV6 is open, thus the saturant invades the sample vessel under push-pull action of

atmospheric pressure at valve EV8 and vacuum at valve EV4 (see Fig. 26 for the steps 3 & 4)

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 38

Vacuum

Vent

8

5

6

7

4

By-Pass

Vacuum

Vent

8

5

6

7

4

By-Pass

Step# 3 Saturant to atm. pressure T3 = 1 min Step#4 By-pass open T4 = 2 min

Figure 26: Illustration of the schematic connections used in the steps 3 and 4

Step5: Pump priming with T5 = 1 min

Ev7 is open to feed the pump with the saturant

The pump starts and is primed.

Vacuum

Vent

8

5

6

7

4

By-Pass

Pump run

Vacuum

Vent

8

5

6

7

4

By-Pass

Step#6 Saturation @ pressure T6 = 120 min Step#5 Pump priming T5 = 1 min

Figure 27: Illustration of the schematic connections used in the steps 5 and 6

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 39

Step6: Pressuring the sample vessel with T6 = 120 min.

Ev6 is closed. The saturant path is through the pump only.

The injection pump hold on (stops temporarily) as the pressure set point ("target") is reached.

If the pressure decreases before T6 is elapsed, the pump restarts to build-up the pressure up back to the

target value. This ensures the saturation of low permeability samples (see Fig. 27 for the steps 5 & 6)

2-semi automatic mode

Semi auto mode is a custom process where operator uses the appropriate switches, as in manual mode.

For this switch the selector to Manual. To operate the electro-valves: press once the button of a valve,

the green bulb switches lightening as the valves open. Press once again to close the valve. (Fig. 28)

Figure 28: button of valves panel from which the operating mode can be changed

Note that you run a single mode at once (e.g. semi-auto, automatic or manual). Also when an automatic

mode is running, just press the STOP button before starting a manual mode.

3-Manual mode

Manual mode is a custom process where operator adjusts the EV valves manually. Make sure that no

electro-valve is set open during manual process. Switch the selector to Manual. You can open as many

valves as you want at the same time and run any step of yours as long as required. Figure 29 shows the

various status of tank.

The valves and pump sequence to reproduce the automatic process in the manual mode is as follow:

Check that the vacuum pump is running and bubbles appear immediately in the saturant jar (as if

the water was boiling). If no bubble comes within the first minute, stop the process and fix the leak.

Check that no desaturant (brine) is going out from the trap jar to the vacuum pump.

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 40

Figure 29: Illustration of tank status by setting it to: the vent, the vacuum pump, be isolated

There are 7 steps with various the ellipse(s), point(s) and the valve(s) actions. You can set custom

duration for each step. The default duration is summarized in Table 5:

Table 5: A summery of the default durations for 7 steps

Step Duration

(min)

Process

1 30 Global evacuation,

2 60 Sample additional evacuation

3 1 Relieving vacuum in saturant tank

4 2 By-pass open

5 1 Pump priming

6 120 Sample saturation at pressure

7

Release vessel pressure

These are the description of various steps. Also Fig. 30 show the connections at each step.

step 1: set V2 to the vacuum (global evacuation).

step 2: set V2 to the close and set V1 to the vacuum (sample additional evacuation).

step 3: set V3 to the vent (relieving vacuum in saturant tank)

step 4: set V3 to the By-pass (by-pass open)

step 5: set V3 to the pump (pump priming)

step 6: stop the vacuum pump and set V1 to the close (pump brine into core vessel for 120 min)

step 7: Finally, cycle is completed.

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 41

Manual Step 2:

Sample Evacuation

Manual Step 1:

Global Evacuation

Vent

2 1

3

Vent

2 1

3

Vacuum

Closed

Closed

Stop

Vacuum

Vacuum

(Action )

Vent

2 1

3

Manual Step 3: Relieving

vacuum in the brine tank

Vent

2 1

3

Manual Step 4:

By-pass open

Vent

Vacuum Vacuum

By-pass

Pump

Manual Step 5:

Pump priming

Vacuum

Vent

2 1

3

Run

Vent

2 1

3

Manual Step 6:

Sample saturation @pressure

Vacuum

Vent

2 1

3

Manual Step 7:

Release the vessel pressure

By-pass

Stop

Vacuum

Figure 30: Illustration of the schematic connections used in the steps 1-7

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 42

3-Porosity

From the viewpoint of petroleum engineers one of the most important property of a reservoir rock is

porosity. Porosity is a measure of storage capacity of a reservoir. It is defined as the ratio of the pore

volume to bulk volume, and it may be expressed as either a percent or a fraction,

PoreVolume BulkVolume Grain Volume

BulkVolume BulkVolume

Two types of porosity are total or absolute porosity and effective porosity. Total porosity is the ratio

of all the pore spaces in a rock to the bulk volume of the rock while the effective porosity

e

is the ratio

of interconnected void spaces to the bulk volume. Thus, only the effective porosity contains fluids that

can be produced from wells. For granular materials such as sandstone, the effective porosity may

approach the total porosity, however, for shales and for highly cemented or vugular rocks such as some

limestones, large variations may exist between effective and total porosity.

Porosity may be classified according to its origin as either primary or secondary. Primary or original

porosity developed during deposition of the sediment. Secondary porosity is caused by some geologic

process subsequent to formation of the deposit. These changes in the original pore spaces may be

created by ground stresses, water movement, or various types of geological activities after the original

sediments were deposited. Fracturing or formation of solution cavities often will increase the original

porosity of the rock.

Figure 31: Cubic packing (a), rhombohedral (b), cubic packing with two grain sizes (c), and

typical sand with irregular grain shape (d).

Grain size distribution and sorting can influence the porosity. For a uniform rock grain size,

porosity is independent of the size of the grains. A maximum theoretical porosity of 48% is achieved

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 43

with cubic packing of spherical grains, as shown in Fig. 31a. Rhombohedral packing, which is more

representative of reservoir conditions, is shown in Fig. 31b; the porosity for this packing is 26%. If a

second, smaller size of spherical grains is introduced into cubic packing Fig. 33c, the porosity

decreases from 48 to 14%. Thus, porosity is dependent on the grain size distribution and the

arrangement of the grains, as well as the amount of cementing materials. Not all grains are spherical,

and grain shape also influences porosity. Typical reservoir sand is illustrated in Fig. 31d.

Moreover, the rock compaction can affect the porosity. This is the process of volume reduction due

to an externally applied pressure. For extreme compaction pressures, all materials show some

irreversible change in porosity. This is due to distortion and crushing of the grain or matrix elements of

the materials, and in some cases, recrystallization. The variation of porosity with change in pressure

can be represented by,

2 1

( )

2 1

f

C P P

e

Where

2

and

1

are porosities at pressure

2

P and

1

P respectively, and C

f

is formation

compressibilit y. Formation compressibilit y is defined as summation of both grain and pore

compressibilit y. For most petroleum reservoirs, grain compressibilit y is considered to be

negligible. Formation compressibilit y can be expressed as,

1

f

dV

C

V dP

where dP is change

in reservoir pressure. For porous rocks, the compressibility depends explicitly on porosity.

Porosity measurement on core plugs:

The porosity of reservoir rock may be determined by using core analysis, well logging technique or

well testing. The question of which source of porosity data is more reliable can not be answered

without reference to a specific interpretation problem. These techniques can all give correct porosity

values under favorable conditions. The porosity determined from core analysis has the advantage that

no assumption needs to be made as to mineral composition, borehole effects, etc. However, since the

volume of the core is less than the rock volume which is investigated by a logging device, porosity

values derived from logs are frequently more accurate in the case of heterogeneous reservoirs.

From the definition of porosity, it is evident that the porosity of a sample of porous material can be

determined by measuring any two of the three quantities: bulk volume, pore volume or grain volume

from core plugs (Fig. 32).

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 44

Figure 32: representation of the different volumes in a plug

i) Bulk volume:

Although the bulk volume may be computed from measurements of the dimensions of a uniformly

shaped sample, the usual procedure utilizes the observation of the volume of fluid displaced by the

sample. The fluid displaced by a sample can be observed either volumetrically or gravimetrically. In

either procedure it is necessary to prevent the fluid penetration into the pore space of the rock. This

can be accomplished by:

(1) coating the sample with paraffin or a similar substance,

(2) saturating the core with the fluid into which it is to be immersed, or

(3) using mercury.

Gravimetric determinations of bulk volume can be accomplished by observing the loss in the weight

of the sample when immersed in a fluid or by change in weight of a pycnometer with and without

the core sample.

ii) Pore volume:

All the methods measuring pore volume yield effective porosity. The methods are based on either the

extraction of a fluid from the rock or the introduction of a fluid into the pore spaces of the rock. One

of the commonly used methods is the helium technique, which employs Boyle's law. The helium gas

in the reference cell isothermally expands into a sample cell. After expansion, the resultant

equilibrium pressure is measured. The Helium porosimeter apparatus is shown schematically in

Error! Reference source not found.

Helium has the following advantages over other gases:

(I) Its small molecules rapidly penetrate into small pores.

(2) It is an inert gas and does not adsorb on rock surfaces (air may do),

(3) It can be an ideal gas (i.e., z = 1.0) for pressures and temperatures usually used in the test,

Reservoir Rock Properties Analysis, Mohsen Masihi

Department of Chemical & Petroleum Engineering, Sharif University of Technology, Tehran, IRAN 45

(4) It has a high diffusivity so affords a useful mean for determining porosity of low

permeability rocks.

Figure 33: Schematic diagram of helium porosimeter apparatus.

The schematic diagram of the helium porosimeter shown in Fig. 33 has a reference volume V