Professional Documents

Culture Documents

Lcie Bureau Veritas Atex Poster PDF

Lcie Bureau Veritas Atex Poster PDF

Uploaded by

George IstrateOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lcie Bureau Veritas Atex Poster PDF

Lcie Bureau Veritas Atex Poster PDF

Uploaded by

George IstrateCopyright:

Available Formats

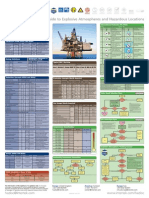

ATEX

Europe

GUIDE TO EXPLOSIVE ATMOSPHERES

Logo Ex : Use of equipment in potentially explosive atmospheres II : Equipment group : for surface industries 2 : Equipment category : for use in zone 1 G : Gas

International

SERIES: 2000 S.O. NO: 1W942408 Year of manufacture: 2008

MODEL: New

Ex : Equipment complies to types of protection standardized by Cenelec (European Standards) de : Types of protection used : d = flameproof enclosure e = increased safety IIC : Gas subdivision : most critical category, including hydrogen, acetylene and carbon disulphide T6 : Temperatures class : maximum 85C for an ambient temperature of 40C

II 2 G

Ex de IIC T6

LCIE 08 ATEX 6000X / IECEx LCI 08.0000X Company XYZ 3 Rue de l Avenir France 0081

identification number of Notified Body

PROTECTION CONCEPTS

GAS

USE PROTECTION ZONE 0 ia ma ib d e mb o pxb pyb ZONE 1 q b c d p k ic pzc nA ZONE 2 nL nR nC mc fr STANDARDS EN/IEC 6007911 EN/IEC 6007918 EN/IEC 6007911 EN/IEC 600791 EN/IEC 600797 EN/IEC 6007918 EN/IEC 600796 EN/IEC 600792 EN/IEC 600792 EN/IEC 600795 EN 134636* EN 134635* EN 134633* EN 134637* EN 134638* EN/IEC 6007911 EN/IEC 600792 EN/IEC 6007915 EN/IEC 6007915 EN/IEC 6007915 EN/IEC 6007915 EN/IEC 6007918 EN 134632* PRINCIPLE Intrinsic safety Encapsulation Intrinsic safety Flameproof Increased safety Encapsulation Oil filled Pressurised Pressurised Powder filled Control of ignition source Constructional safety Pressurisation Liquid immersion Intrinsic safety Pressurised Nonsparking Energy limited Restricted breathing Enclosed break Encapsulation Flow restriction ZONE 22 Flameproof ZONE 21 USE PROTECTION ZONE 20 ia ta ma ibD mb tb p d c b p k fr tc mc ic

EQUIPMENT

DUST

GAS GROUPS

PRINCIPLE Intrinsic safety Enclosure Encapsulation Intrinsic safety Encapsulation Enclosure Pressurised Flameproof Constructional safety Controf of ignition source Pressurisation Liquid immersion Flow restriction Enclosure Encapsulation Intrinsic safety

T T6 T5 T4 T3 T2 T1

DUST GROUPS

IIIA IIIB IIIC Combustible flying Non conductive dust Conductive dust

ATEX

1G 2G 3G 1D 2D 3D M1 M2

IECEx

Ga Gb Gc Da Db Dc Ma Mb

ZONE

0 1 2 20 21 22 MINING GAS DUST

STANDARDS EN/IEC 6007911 EN/IEC 612411 EN/IEC 6007918 EN/IEC 6007911 EN/IEC 6007918 EN/IEC 612411 EN/IEC 612412 EN 134633* EN 134635* EN 134636* EN 134637* EN 134638* EN 134632* EN/IEC 612411 EN/IEC 6007918 EN/IEC 6007911

I IIA IIB IIC

Methane* Propane* Ethylene* Hydrogen*

( * Representative gas )

TEMPERATURE CLASS

MAXI. SURFACE TEMPERATURE 85C 100C 135C 200C 300C 450C

* Concerning non electrical products

CERTIFICATION PROCEDURES

EUROPEAN ATEX CERTIFICATION PROCEDURES (Directive 94/9/EC)

ZONE 0 OR 20

ELECTRICAL AND NON ELECTRICAL EQUIPMENT (category 1)

APPROPRIATE PROCEDURE ACCORDING TO PRODUCTION MODE

INSTALLATION EQUIPMENT ZONE 0 OR 20 Electrical and non electrical equipment (category 1)

BATCH UNIT MASS

PROCEDURE FOR IECEx CERTIFICATION

ZONE 1 OR 21

ELECTRICAL EQUIPMENT (category 2) NON ELECTRICAL EQUIPMENT (category 2)

ZONE 2 OR 22

ELECTRICAL AND NON ELECTRICAL EQUIPMENT (category 3)

ZONE 1 OR 21 Non electrical equipment (category 2)

BATCH UNIT MASS

ZONE 2 OR 22 Electrical and non electrical equipment (category 3)

BATCH UNIT MASS

Electrical equipment (category 2)

BATCH UNIT MASS

PRODUCTION EC type examination ( annex III ) Production quality assurance ( annex IV ) Product verification ( annex V ) Conformity to type ( annex VI ) Product quality assurance ( annex VII ) Internal control of production ( annex VIII ) Unit verification ( annex IX ) N.B. = ATEX notified body

OR

EC type examination ( annex III ) Unit verification ( annex IX )

OR

EC type examination ( annex III ) Unit verification ( annex IX )

OR

Unit verification ( annex IX ) Internal control of production ( annex VIII )

OR

Unit verification ( annex IX ) Internal control of production ( annex VIII )

REVIEW OF REQUIREMENTS AND TESTING RESULT BY THE TEST CARRIED OUT CERTIFICATION BODY ( EXCB) BY THE TESTING LABORATORY ( EXTL )

N.B. N.B. N.B. N.B.

N.B. N.B.

Issuance of validated report ( EXTR ) by the EXCB

N.B. N.B.

Quality assessment report ( QAR ) by EXCB

OR

Production quality assurance ( annex IV ) Product verification ( annex IV )

OR

Conformity to type ( annex VI ) Product quality assurance ( annex VII )

Acknowledgement receipt of dossier

(2) (2) (2)

N.B. N.B. (1) N.B.

(2) (2) (2)

N.B. (1) (2) = technical dossier sent to N.B.

Issuance of IECEx certificate of conformity by EXCB

= Through notified body ( N.B.)

(1) = certificate of conformity on vonlonteer request

COMPARISON ZONES / DIVISIONS

Explosible atmosphere NEC500 / CSA IEC6007910 Continuously present Often present Accidentally present Division 2 Zone 2 or 22 Division 1 Zone 0 or 20 Zone 1 or 21

INGRESS PROTECTION OF ENCLOSURES ACCORDING TO EN/IEC 60529

PROTECTION AGAINST SOLID BODIES

IP

0

50mm

CORRELATION BETWEEN IP AND NEMA250

NEMA 1 NEMA 2 NEMA 3 NEMA 3R NEMA 3S NEMA 4 and 4X NEMA 5 NEMA 6 and 6P NEMA 12 and 12K NEMA13 IP10 IP11 IP54 IP14 IP54 IP56 IP52 IP67 IP52 IP54

PROTECTION AGAINST LIQUIDS

IP

0 1

15

TESTS

No protection Protected against solid bodies larger than 50mm ( e.g. accidental contact with hand ) Protected against solid bodies larger than 12,5mm ( e.g. finger of the hand ) Protected against solid bodies larger than 2,5mm ( tools, wires ) Protected against solid bodies larger than 1mm ( fine tools, small wires ) Protected against dust ( no harmfull deposit )

TESTS

No protection Protected against verticallyfalling drops of water ( condensation ) Protected against drops of water falling at up to 15 from the vertical Protected against drops of water falling at up to 60 from the vertical Protected against projections of water from all directions Protected against jets of water from all directions Completly protected against jets of water of similar force to heavy sea

15 cm mini

1

12,5mm

COMPARISON IEC/Cenelec AND NEC

USA / CANADA REPRESENTATIVE SUBSTANCES IEC / EUROPE

Class Division Group Zone Group

60

GAS VAPOR

12

A B C D

Acetylene Hydrogen Cyclopropane, Ethyl ether, Ethylene Acetone, Benzene, Butane, Propane, Hexane, Paint solvant, Natural gas

012

II C II C II B II A III C III B III A

2,5mm

1mm

IP ratings do not indicate any degree of corrosion resistance

DUST

II

1 12

E F G

Magnesium, Aluminium, 2021 Conductive dust with R 105 Ohms/cm Coal 202122 Flour, Non conductive dust with R 105 Ohms/cm 202122

ACCESS TO NATIONAL CERTIFICATIONS

Country China Korea Brazil Russia Documentation Chinese explosion proof certificate Korean national certificate INMETRO certificate GOST certificate + RTN LCIE local partner PCECCQST NEPSI / SIPAI KGS BV Brazil NANIO CCVE

FIBER Cotton, Linen, Wood, Hemp 12 III FLYING* * div.1 = when handled, manufactured or used

div.2 = when stored, handled but not in manufacturing process

Completly protected against dust

Protected against the effects of immersion Protected against the effects of prolonged immersion under specified conditions

YOUR CONTACTS :

Emmanuel Carr emmanuel.carre@lcie.fr +33 1 40 95 61 09 JeanMichel Simon jeanmichel.simon@lcie.fr +33 1 40 95 63 11

LCIE Bureau Veritas 33 av du Gnral Leclerc 92260 FontenayauxRoses France www.lcie.fr www.lcie.com

PARTNERSHIP :

CSA ( Canada ) UL ( United States ) FM ( United States ) KTL ( Korea ) UCIEE ( Brazil ) US Cost Guard ( United States ) TIIS ( Japan ) CQST (China) NEPSI SIPAI (China) PCEC (China) KGS (Korea) BV Argentina BV Brazil

1m

LCIE SERVICES :

IECEx certification ATEX certification Assesment of the manufacturers quality system Storage of technical files Technical assistance Training Testing

You might also like

- Hazardous Area Table IEC & NEC (NEMA) Cooper Crouse Hinds PDFDocument1 pageHazardous Area Table IEC & NEC (NEMA) Cooper Crouse Hinds PDFAgustinus Made Theo Dwijaya100% (4)

- International Standard: Cryogenic Vessels - Valves For Cryogenic ServiceDocument6 pagesInternational Standard: Cryogenic Vessels - Valves For Cryogenic ServiceRamazan YaşarNo ratings yet

- KSBB-BS Breather Valve Data SheetDocument2 pagesKSBB-BS Breather Valve Data Sheetfathonix0% (1)

- Wetted Area CalculationDocument1 pageWetted Area CalculationSusheel WankhedeNo ratings yet

- Sop GSSDocument3 pagesSop GSSArun MurugaiyanNo ratings yet

- iUPS101: XXXX Ii 2 G Ex D (E) Iib T6 GBDocument1 pageiUPS101: XXXX Ii 2 G Ex D (E) Iib T6 GBAdemola Olajide TejumolaNo ratings yet

- Boiler Protection FsssDocument2 pagesBoiler Protection FsssAnish181No ratings yet

- NEMA 250 Type 4 Enclosures PDFDocument4 pagesNEMA 250 Type 4 Enclosures PDFMike SantiagoNo ratings yet

- BS 470 Entry PVDocument8 pagesBS 470 Entry PVbonnicoNo ratings yet

- Understanding Ped For Asme VesselsDocument33 pagesUnderstanding Ped For Asme VesselsRamakrishnan SrinivasanNo ratings yet

- Section 1 Explosive Atmospheres 07-2017 Rev 3Document17 pagesSection 1 Explosive Atmospheres 07-2017 Rev 3kingmltNo ratings yet

- Recommendation Handling of Norit GL 50Document9 pagesRecommendation Handling of Norit GL 50Mátyás DalnokiNo ratings yet

- A Review of Steel and Its Interaction With Hydrogen Diana M. Ayala Valderrama, Yinela A. Young MosqueraDocument22 pagesA Review of Steel and Its Interaction With Hydrogen Diana M. Ayala Valderrama, Yinela A. Young MosquerayinelaNo ratings yet

- 275 Reflux 819 Fo mt103 e PDFDocument93 pages275 Reflux 819 Fo mt103 e PDFsilver lauNo ratings yet

- Iso 21969 2009 en PDFDocument8 pagesIso 21969 2009 en PDFAnonymous P7J7V4No ratings yet

- Side Mounted HandwheelDocument20 pagesSide Mounted HandwheelaaaNo ratings yet

- Insulation Kits Data SheetDocument2 pagesInsulation Kits Data SheetCalvin WongNo ratings yet

- Regulator VNN-505 - DN50Document25 pagesRegulator VNN-505 - DN50aminNo ratings yet

- TBV Cryogenic Ball Valves CAMERONDocument20 pagesTBV Cryogenic Ball Valves CAMERONboudissaNo ratings yet

- Marking Non Electrical Equipment Ex PDFDocument1 pageMarking Non Electrical Equipment Ex PDFMMNo ratings yet

- Butterfly Torque Selection GuideDocument3 pagesButterfly Torque Selection Guidedragon2065No ratings yet

- IR HL Heatless DryerDocument1 pageIR HL Heatless DryerYing Kei ChanNo ratings yet

- STAHL Poster Safety RealityDocument1 pageSTAHL Poster Safety Realityedwardesjr100% (1)

- Redundant Solenoid ValveDocument2 pagesRedundant Solenoid ValveAmanda PorterNo ratings yet

- Face-To-Face Valve Dimensions - EN-558-1: DN Basic Seriess 1 2 3 4 5 6 7 8 9 10 11 12Document3 pagesFace-To-Face Valve Dimensions - EN-558-1: DN Basic Seriess 1 2 3 4 5 6 7 8 9 10 11 12Jorge FerrerNo ratings yet

- Type: Cocon 13: Operators-ManualDocument33 pagesType: Cocon 13: Operators-ManualAbraham Tellez FloresNo ratings yet

- I/p ConverterDocument6 pagesI/p ConverterAMIT KUMARNo ratings yet

- Fisher Cryogenic ValveDocument12 pagesFisher Cryogenic ValvePratik PatelNo ratings yet

- QR 1008 Fire Pump JockeyDocument1 pageQR 1008 Fire Pump JockeyLéandre Ettekri NdriNo ratings yet

- EIGA StandardsDocument4 pagesEIGA StandardsGnaniar IlangoNo ratings yet

- Fire Walls Fire Risk Hazards of Electrical Equipment BS EN 61936 1 2010Document7 pagesFire Walls Fire Risk Hazards of Electrical Equipment BS EN 61936 1 2010Rajesh JoshiNo ratings yet

- Buckling Pin Pressure Relief Technology PDFDocument12 pagesBuckling Pin Pressure Relief Technology PDFfkboulosNo ratings yet

- A Guide To European (Eec) Certification For Hzardus AreasDocument5 pagesA Guide To European (Eec) Certification For Hzardus AreasDeepak DinkarNo ratings yet

- Petrom OMV Corporatenorm L 3001 Rom Eng Rev.1 2007-04-10Document80 pagesPetrom OMV Corporatenorm L 3001 Rom Eng Rev.1 2007-04-10luciandu100% (1)

- PROTEGO Correct Application of Flame Arresters March 2021Document76 pagesPROTEGO Correct Application of Flame Arresters March 2021Pablo HerreroNo ratings yet

- Degrees of Protection Provided by Enclosures ThisDocument2 pagesDegrees of Protection Provided by Enclosures ThisPemaWangchukNo ratings yet

- Spotleak 1007 PDFDocument7 pagesSpotleak 1007 PDFrandhyalejandroNo ratings yet

- Derivation of Pressure Loss To Leak Rate Formula From The Ideal Gas LawDocument3 pagesDerivation of Pressure Loss To Leak Rate Formula From The Ideal Gas Lawsatheez3251No ratings yet

- Hazardous Area SH CourseDocument22 pagesHazardous Area SH CourseafnakshNo ratings yet

- API Specification 6D 24th Edition Errata 10 20210803Document1 pageAPI Specification 6D 24th Edition Errata 10 20210803ANANDNo ratings yet

- Pressure - Vacuum Relief Valve - Part 1Document10 pagesPressure - Vacuum Relief Valve - Part 1winarnobNo ratings yet

- Protego PDFDocument18 pagesProtego PDFNemezis1987No ratings yet

- Chimney & Venting Sizing HandbookDocument50 pagesChimney & Venting Sizing HandbookCallGRNo ratings yet

- Din en Iso 13849 2 2013Document90 pagesDin en Iso 13849 2 2013Bryce TurnerNo ratings yet

- Unidirectional ProverDocument2 pagesUnidirectional ProverGanjar Al Kaspandi100% (1)

- Samson: Evaluating The Calculation Accu-Racy Provided by The Relevant Noise Prediction Standards For Control ValvesDocument12 pagesSamson: Evaluating The Calculation Accu-Racy Provided by The Relevant Noise Prediction Standards For Control ValvesGopinath GunasekaranNo ratings yet

- Spec For Rim Seal Fire Protection SystemDocument5 pagesSpec For Rim Seal Fire Protection Systemshashi ranjanNo ratings yet

- Pressure Relief Valve Data Sheet-Rev01Document1 pagePressure Relief Valve Data Sheet-Rev01thawdarNo ratings yet

- HT BucefaDocument2 pagesHT Bucefarafa100% (1)

- Hazardous Area Chart - BartecDocument1 pageHazardous Area Chart - BartecPutraSumatera100% (1)

- En 12874Document45 pagesEn 12874chintu_nimmagadda100% (1)

- Scanner 2000 Hardware ManualDocument154 pagesScanner 2000 Hardware ManualErik TapiasNo ratings yet

- PSV BasicsDocument24 pagesPSV BasicsBobby VonnNo ratings yet

- ExtronicsWallchart 160708Document1 pageExtronicsWallchart 160708Shyam VarunNo ratings yet

- Intertek Poster A1 (HazLoc - Guide) - 0Document1 pageIntertek Poster A1 (HazLoc - Guide) - 0Antonio FilipeNo ratings yet

- 207-x Marking UkDocument4 pages207-x Marking UkgueridiNo ratings yet

- Equipment Certification Guide For Hazardous Areas: North America Atex and Iec Ex ComparisonDocument1 pageEquipment Certification Guide For Hazardous Areas: North America Atex and Iec Ex ComparisonBalan PalaniappanNo ratings yet

- Ingress SafetyDocument1 pageIngress Safetyjohn_tigerNo ratings yet

- ATEX-affisch MaluxDocument1 pageATEX-affisch MaluxHomer SilvaNo ratings yet

- Cryogenics Safety Manual: A Guide to Good PracticeFrom EverandCryogenics Safety Manual: A Guide to Good PracticeNo ratings yet

- Assignment On New Business IdeaDocument13 pagesAssignment On New Business IdeaShourav100% (2)

- Future LotDocument7 pagesFuture Lotkumar40No ratings yet

- HSC Chemistry Lesson Plan 22Document7 pagesHSC Chemistry Lesson Plan 22Ali HaidarNo ratings yet

- Hydroelectric Power PlantDocument7 pagesHydroelectric Power PlantKristine Ann ReclosadoNo ratings yet

- Valve Testing StandardsDocument6 pagesValve Testing Standardsjjirwin100% (2)

- Better Burner Specifications PDFDocument4 pagesBetter Burner Specifications PDFAbdul HayyeNo ratings yet

- 1 s2.0 S0009250917300313 Main PDFDocument14 pages1 s2.0 S0009250917300313 Main PDFdretorNo ratings yet

- Erp Practice Exam1-2014Document41 pagesErp Practice Exam1-2014Anas JivrajNo ratings yet

- Amcrps Gen Cat GB 2012-2Document52 pagesAmcrps Gen Cat GB 2012-2VardhanNo ratings yet

- Fire Investigation Report SampleDocument15 pagesFire Investigation Report SampleandrianwicakNo ratings yet

- Principles of Hall ProcessDocument8 pagesPrinciples of Hall ProcessVenky100% (1)

- VivaDocument13 pagesVivapapia_das876156No ratings yet

- Antares Engineering RSDocument56 pagesAntares Engineering RSMukesh Kumar GuptaNo ratings yet

- Marine Fuel OilsDocument7 pagesMarine Fuel Oilsjoy_dhNo ratings yet

- Iesc 104Document11 pagesIesc 104Ty GravesNo ratings yet

- HCL Acid & RubberDocument2 pagesHCL Acid & RubberEdgarDavidDiazCamposNo ratings yet

- Morgan CityDocument3 pagesMorgan CityRhiannon BallardNo ratings yet

- NOTE - Introduction Waste Fuel Technologies Biogas Bio CNG PDFDocument22 pagesNOTE - Introduction Waste Fuel Technologies Biogas Bio CNG PDFMarcus NguyễnNo ratings yet

- Question and AnswerDocument40 pagesQuestion and AnswerJeannepauline SanchezNo ratings yet

- Powering Canada's TerritoriesDocument64 pagesPowering Canada's TerritoriesNunatsiaqNews100% (1)

- Renewable Energy in India: Visvesvaraya Technological University Belagavi, KarnatakaDocument18 pagesRenewable Energy in India: Visvesvaraya Technological University Belagavi, KarnatakaGhost ModeNo ratings yet

- Physics AIL ProjectDocument13 pagesPhysics AIL ProjectINESH AGRAWALNo ratings yet

- Global Warming: Ayushman Mishra Grade 8, BDocument32 pagesGlobal Warming: Ayushman Mishra Grade 8, BzeeschoolNo ratings yet

- Secondary RecoveryDocument58 pagesSecondary RecoveryLemuel ViolanteNo ratings yet

- Hazard Classification 6-28-10Document7 pagesHazard Classification 6-28-10Alejandro Chumpitaz MarchanNo ratings yet

- IPL ListDocument41 pagesIPL Listkapare1209No ratings yet

- Chemistry Chemical Equation and ReactionDocument7 pagesChemistry Chemical Equation and Reactionsmriti khannaNo ratings yet

- Chapter 4 Periodic Table of ElementsDocument3 pagesChapter 4 Periodic Table of ElementsSpike Chingyen100% (1)

- E Report The Philippines On The Cusp of Growth - CleanedDocument18 pagesE Report The Philippines On The Cusp of Growth - CleanedAvegail ArmadoNo ratings yet

- UAS Science G8 Sem1 2018 - 2019Document2 pagesUAS Science G8 Sem1 2018 - 2019Defitra MardianaNo ratings yet