Professional Documents

Culture Documents

API 650 Tank Design Calculation

API 650 Tank Design Calculation

Uploaded by

josevega6Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

API 650 Tank Design Calculation

API 650 Tank Design Calculation

Uploaded by

josevega6Copyright:

Available Formats

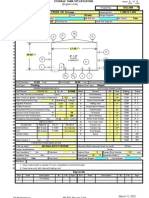

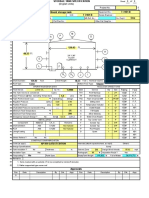

STORAGE TANK SPECIFICATION

(English Units)

Sheet

CRUDE OIL Storage

1 Service :

2 Location :

Kirwin

Unit :

3 Manufacturer :

Model :

PID115-EPF-01-112A1

4 P&ID No.

1 of 1

Project No.

1952.000

Equipment No. :

T-400 & T-405

Rev. No.

Design Engineer :

Mfr Ref. No. :

Plot Plan No. :

Two

No. Req'd :

Other Ref. Dwg No. :

5

6

7

8

10

11

12

50.00 Ft

13

14

32.00 Ft

15

16

48" X 48"

FLUSH

CLEANOUT

17

19

18

20

21

N1

22

N2

23

50.00

Cone

24 Shell Diameter :

25 Roof Type :

26

Feet

32.00 Feet

Shell Height :

CRUDE OIL

NOZZLES/CONNECTIONS

0.7900

Sp. Gr. :

28 This Tank Service is considered:

Cyclic

5.5

29 Vapor Pressure @ Max. Operating Temperature

30 Flash Point (Closed Cup) :

psia

Mark

Service

Qty

Size

Roof Manway

24"

Shell Manway

24"

Operating

Design

Flush Cleanout MW

48"x48"

31 Negative Pressure

oz/in.2

0.00

0.50

Stilling Vent

6"

32 Positive Pressure

psig

1.00

2.00

Temperature Indicator

1"

Outlet Nozzle

8"

Fill Nozzle

10"

Mixer Manway

30"

4"

----

33 (Hydro)test Pressure expressed in Psig

34 Minimum Fluid Temperature

35 Maximum Fluid Temperature

36 Emergency Vacuum Design ?

37

Yes

-25

200

Set @

0.0.3

oz/in.2

METALLURGY

38

Component

40 Roof

Water Draw Nozzle

Top Center Vent

8"

Sample Tap

3/4"

Material

CA, in.

Remarks

N1

57370

0.1250

Normalized

N2

Sample Tap

3/4"

516 Grade 55

0.1250

Normalized

Roof Nozzle

4"

Spare

2"

39 Shell & Bottom

Barrels

Sloped

OPERATING/DESIGN DATA

27 Fluid Stored :

11,191

Nominal Volume :

Bottom Floor Type:

41 Lining/Coating

42

43 Stress Relieve ?

44

Yes

for:

Rating

150#

125#

125#

125#

150#

150#

150#

150#

150#

150#

150#

150#

150#

150#

150#

150#

Face

F. F.

R. F.

R. F.

F. F.

L. J.

API

L. J.

F. F.

R. F.

API

R. F.

F. F.

L. J.

API

API

API

CONSTRUCTION/FABRICATION

API 650 LATEST EDITION

45 Code (as appl.):

Internals (attach separate sheet, as req'd):

46 Design Specifications:

47 Tank Insulation ?

No

48 Insulation Type:

49 Fireproofing ?

Thickness :

in.

Hot

Yes

Others:

Sump

Radiograph

Paint Spec.

Seismic Zone

85

EmptyTank Weight

Design Wind Velocity

% Inspection Req'd ?

lb

100

mph

Yes

Full of Water

lb

50 Remarks

51

1. Items marked with an asterisk (*) to be completed by Vendor/Fabricator.

52

2. Fixed cone roof with internal floating roof.

Approvals

Rev

0

Date

Description

For Inquiry

By

Chk.

Appr.

Rev

Date

Description

By

Chk.

Appr.

Art Montemayor

March 12, 2002

Rev: 0

API 650 Storage Tank

API 650 Design Calculations

Shell Design :

D = Normal tank diameter , in feet

50.00

H = depth of tank , in feet

32.00

FROM ( BOTTOM COURSE) PLATE TO (TOP COURSE) PLATE

td = 2.6(D)(H -1)(G)/Sd=

0.174 in. Wall Thickness

Miniumum shell thickness, in inches, td = td / tt = 2.6(D)(H-1)/(St)

td =

0.224 in. (Includes Corrosion Allowance)

G = design Specific gravity of liquid

1

Sd = allowable Stress for Design condition 23,200

E = joint efficiency

0.85%

St = allowable stress 516-60 Hydro Test

24,900

CA = Corrosion Allowance

0.0625

For First Course (Bottom) 516-60 Plate

0.236

td = 2.6(D)(H -1)(G)/Sd =

0.189

td =td / tt = 2.6(D)(H-1)/(St) =

td = Miniumum shell thickness, in inches =

0.230

D = Normal tank diameter , in feet =

H = depth of tank , in feet =

G = design Specific gravity of liquid =

Sd = allowable Stress for Design condition

E = joint efficiency

St = allowable stress516-60 Hydro Test

50.00

32.00

1

21,300

0.85%

CA = Corrosion Allowance

24,000

0.0625

For Second Course 516-60 Plate

0.5000

td = 2.6(D)(H -1)(G)/Sd=

0.165

td =td / tt = 2.6(D)(H-1)/(St)

td = Miniumum shell thickness, in inches

D = Normal tank diameter , in feet

H = depth of tank , in feet

G = design Specific gravity of liquid

Sd = allowable Stress for Design condition

E = joint efficiency

St = allowable stress 516-60 Hydro Test

0.209

50.00

28

1

21,300

0.85%

CA = Corrosion Allowance

24,000

0.0625

For Third Course 516-60 Plate

0.3750

Page 2 of 8

FileName: 53038582.xls

WorkSheet: Steel Design

Art Montemayor

March 12, 2002

Rev: 0

API 650 Storage Tank

API 650 Design Calculations

Shell Design :

td = 2.6(D)(H -1)(G)/Sd=

0.196

td =td / tt = 2.6(D)(H-1)/(St) =

td = Miniumum shell thickness =

0.2365 inches

D = Normal tank diameter , in feet

H = depth of tank , in feet

G = design Specific gravity of liquid

Sd = allowable Stress for Design condition

E = joint efficiency

St = allowable stress 516-60 Hydro Test

CA = Corrosion Allowance

94.5

18

1

21,300

0.85%

For Fourth Course 516-60 Plate

0.2500

24,000

0.0625

td = 2.6(D)(H -1)(G)/Sd=

0.081

td =td / tt = 2.6(D)(H-1)/(St)

td = Miniumum shell thickness, in inches

0.1342

D = Normal tank diameter , in feet

H = depth of tank , in feet

G = design Specific gravity of liquid

Sd = allowable Stress for Design condition

E = joint efficiency

St = allowable stress 516-60 Hydro Test

CA = Corrosion Allowance

94.5

8

1

21,300

0.85%

For Fifth Course 516-60 Plate

0.2500

Annular Bottom Plate Thickness

D = Diameter in Feet

H = Height in Feet

V = Volume in Cubic Feet

24,000

0.0625

0.3750

50.00

32.00

Tank Shell surface =

D*H =

5,027 Ft2 of Shell surface area

Tank Roof surface =

D2/4 =

1,963 Ft2 of Roof Area (estimated)

Tank Floor surface =

D2/4 =

1,963 Ft2 of Bottom Floor area

Page 3 of 8

FileName: 53038582.xls

WorkSheet: Steel Design

Art Montemayor

March 12, 2002

Rev: 0

API 650 Storage Tank

FOUNDATION DESIGN:

Per API 650 (Appendix E)

Tank is unanchored, use equations pertaining to unanchored tanks,

for seismic loading.

DATA GIVEN:

Seismic Zone;

Zone Coefficient

Importance Factor

Diameter of Tank

Height of Liquid Content (Design)

Shell Height

Design Specific Gravity

Z=

I =

D=

H=

Hs =

G=

tb =

Thickness of Bottom PL Under Shell

Yeild Strength of Bottom PL

Weight of Shell

Weight of Roof + Live Load = 107.4 + 210.4

Weight of Product

PI()/4(94.5)2 (44.5)(.79)(62.4)

Fby =

Ws =

Wy =

Wt =

3

0.3

1.0

94.5

44.5

48

0.79

0.3750

36,000 PSI

221 Kips

317.8 Kips

15,386 Kips

CALCULATIONS:

Seismic Coefficients:

Xs =

C1 =

D/H =

19.69 Ft

0.60

2.12

0.54

W1 =

8,231

0.45

W2 =

6,924

X1 /H =

0.38

X1 =

16.7

X2 /H =

0.59

X2 =

26.3

Per Fig. E-2

W1 / Wt =

W2 / Wt =

Per Fig. E-3

Per Fig. E-4

K = 0.6

Lateral Force Coefficients:

E-3.3

T =K (D 0.5 ) =.6 *(94.5 0.5) =

If Greater Than 4.5 seconds

5.83 Seconds

3.375 (s/T2) = 3.375*1.5/5.832 =

Page 4 of 8

0.149 Seconds

FileName: 53038582.xls

WorkSheet: Foundation Design - 1

Art Montemayor

March 12, 2002

Rev: 0

API 650 Storage Tank

FOUNDATION DESIGN:

Seismic Loads:

M = (Z)(I) { (C1)(Ws)(Xs)+(C1)(Wr)(Ht)+(C1)(W)(X)+(C2)(W2)(X2)}

(0.3)*(1.0)[ 0.6(221)(19.685)+ 0.6(317.8)(48.0)+ 0.6(8232)(16.7)+ 0.149(6924)(26.3)]

0.3

2610

9155

82485

27133

36415 Ft-Kips

V = (Z)(I) {(C1)(Ws)+(C1)(Wr)(Ht)+(C1)(W)(X)+(C2)(W2)(X2)}

(0.3)*(1.0)[ 0.6(221)+ 0.6(317.8)+ 0.6(8232)+ 0.149(6924)]

0.3

132.6

190.68

4939.2

1031.68

1888 kips

Reistance to Overturning:( E.4.1) API 650

WL = 7.9tb Fby G H

(G18)*(G16)*(G14)/(G13)2 )

1265580

7.9

Constant =

3,333

# / ft

3,333

# / ft

4153

# / ft

4153

# / ft

1125

Not to exceed 1.25*GHD

USE

Shell Compression: Per E-5

M=

36415 ft-kips

Wt + WL = 583.8 / (PI()*94.5) + 4.153

M / D2 (Wt + WL)

(G76)/(G13)2(6.12)

36415

6 Kips

54653

b = 1.815+1.273*36415/94.5^2

0.666 > 0.785

b =

Max. Longitudinal Compressive Force

7.0

7.0

UnAnchored Longitudinal Compressive Stress

7000 / 6

Allowable Longitudinal Compressive Stress

GHD2/t2

1.255 * 106 = Fa=106 (t) / D =

Anchorage Not Required

Page 5 of 8

1167

5.29 Kips

FileName: 53038582.xls

WorkSheet: Foundation Design - 1

Art Montemayor

March 12, 2002

Rev: 0

API 650 Storage Tank

FOUNDATION DESIGN:

Max. Overturning Moment Due To Seismic Loads.

Compression or Tension Due To Moment:

Seismic Base Shear:

36,415 Kips

5.19 kpf

0.27 kips

RINGWALL DESIGN:

Use Following Weight Values for Materials

Wt. of Steel

Wt. Of Compacted Soil

Wt. Of Concrete Wall

Wt. Of Product in Tank

490lb/ft3

110 lb/ft3

150 lb/ft3

50 lb/ft3

Horizontal Pressure on Ring Wall:

F=Kah(*p*H+1/2 soh)+270

0.3*6.0[(50*44.5+0.5*110*6.0)]+270

4,869 kips

Hoop Tension:

1/2FD= 1/2(4869)(94.5)

230 kips

As= 231/24.0

10 in.

USE - 6 # 9 Bars Ea. Face

USE - # 4 Bars at 12" on Center

Minimum RingWall Thickness:

T = 2W / *p*h - 2h ( c - so)

W = 1100

(2)(1100)/50(44.5)-2(6.0)(150-110)

12"

1.26

Use 16" Thick Concrete Wall

Top of Ground Elevation

16"

48"

12"

Page 6 of 8

FileName: 53038582.xls

WorkSheet: Foundation Design - 2

Art Montemayor

March 12, 2002

Rev: 0

API 650 Storage Tank

Concrete Tensile Stress:

fct = c(Es)(As)+T / Ac + n (As)

.0003(29*106)(10)+231000/(16*72)+(9*10)

318000

1242

.15(3000)

256 psi

450 psi

OK

Soil Bearing:

Try 3'- 6" Footing

Weight. of Wall = 1.33*5.0*.150

Weight of Footing = 3.5*1.0*.150

Weight of Fill = 2.17*4.0*.110

1.0 kips

0.525 kips

0.95 kips

2.48 kips

Case 1

Load from Shell + Roof + Live Load =

Weight of Wall +Footing + Fill =

Bearing Pressure =

3.58/3.50

1.1 kips

2.48 kips

1.0 kips

Case 2

Dead + Live Load + Earthquake Load =

P = 3.58 + 5.19 =

H=

Moment at Base of Footing =

.270(6.0)

Bearing Pressure Under Footing =

8.77/3.5*1

2.51+.79

Allowable Pressure = 3.0*1.33

8.77 kips

0.270 kips

1.62 kips

2.51 kips

3.30 kips

3.99

OK

USE -4 # 9 Bars in Footing

USE - # 4 Bars at 12" Horizontal

Page 7 of 8

FileName: 53038582.xls

WorkSheet: Foundation Design - 2

Art Montemayor

March 12, 2002

Rev: 0

API 650 Storage Tank

DETAILED FOUNDATION DESIGN:

47" - 3"

Center Line of Tank

Slope 1" per ft.

12"

10"

10" Pad of Sand

Well-Compacted Gravel

95% Compacted

50 / 100 % Passing # 4 Sieve

6 # 9 Bars Each Face Eq. Spaced

4'0"

# 4 Bars 12" O/C Each Face

95 % Compacted Subgrade or fill Material

1'-4" Wall

12"

(4) # 9 Bars Eq. Spaced

3' - 6"

NOTES:

1. Oiled sand to be mixture of sand and liquid asphalt (mc70):

2. Use 10 gallons of asphalt per cubic yard of sand:

3. Top of concrete to be smooth and level with 1/8" +/- in any 30 feet of circumferential length:

4. Maximum Deiation to be less than 1/4" overall:

Page 8 of 8

FileName: 53038582.xls

WorkSheet: Foundation Design - 3

You might also like

- API 650 Tank Design CalculationDocument8 pagesAPI 650 Tank Design Calculationmail_younes659283% (30)

- Tank DesignDocument8 pagesTank DesignAhmed El Hawari100% (1)

- Tank Shell Design - LATESTDocument12 pagesTank Shell Design - LATESThgagNo ratings yet

- 1 Design Calculation For Tank Bund Wall T-1700 (Offspec Crude Oil Tank) Bund WallDocument2 pages1 Design Calculation For Tank Bund Wall T-1700 (Offspec Crude Oil Tank) Bund WallShahrin MamatNo ratings yet

- Ldo Storage Tank Calculation 170Document12 pagesLdo Storage Tank Calculation 170Alvin SmithNo ratings yet

- API 650 Tank Design 5Document31 pagesAPI 650 Tank Design 5gon972001No ratings yet

- Sulfuric Acid Tank - APIDocument4 pagesSulfuric Acid Tank - APISakthi VelNo ratings yet

- API 650 Tank Design CalculationDocument8 pagesAPI 650 Tank Design Calculationlecongdinh100% (1)

- TangkiDocument8 pagesTangkiCarey Rich67% (3)

- Din 2576 Manufacture Din2576 Flange and Flanges Plate of Din 2576 Pn10, PN 10Document3 pagesDin 2576 Manufacture Din2576 Flange and Flanges Plate of Din 2576 Pn10, PN 10Mohammed EljammalNo ratings yet

- Conveyor Design-DraftDocument42 pagesConveyor Design-Draftmkchy1295% (22)

- API650SH" Sheet A Saved As 97-09-165 Page set-up"API650SH" A1/K44 A45/K86 A87/K130 A131/K146Document11 pagesAPI650SH" Sheet A Saved As 97-09-165 Page set-up"API650SH" A1/K44 A45/K86 A87/K130 A131/K146nassmechNo ratings yet

- API 650 Tank Design 1Document5 pagesAPI 650 Tank Design 1Nguyễn Thành Trung100% (1)

- Ldo Storage Tank CalculationDocument7 pagesLdo Storage Tank CalculationchetanmaleNo ratings yet

- Molasses Tank 18092020Document31 pagesMolasses Tank 18092020Keshav GopaulNo ratings yet

- API 650 Storage Tank TCA PreparationDocument86 pagesAPI 650 Storage Tank TCA PreparationBimal DeyNo ratings yet

- Tender No: RCC/NR/UPSO-II/ENG/PT-07/19-20 Public Tender:-: Page 76 of 200Document7 pagesTender No: RCC/NR/UPSO-II/ENG/PT-07/19-20 Public Tender:-: Page 76 of 200Shilpa SinghNo ratings yet

- 114-F - OASE Solution Storage Tank - R0 PDFDocument33 pages114-F - OASE Solution Storage Tank - R0 PDFManish542No ratings yet

- Tank Calc - Api650Document90 pagesTank Calc - Api650kamleshyadavmoney100% (4)

- Fresh HDO Storage TankDocument42 pagesFresh HDO Storage TankHgagselim SelimNo ratings yet

- Engineering Group: Kuwait Oil Company (K.S.C.)Document14 pagesEngineering Group: Kuwait Oil Company (K.S.C.)Aravindan Ganesh KumarNo ratings yet

- Tank Data Sheet.Document4 pagesTank Data Sheet.Ranjan Kumar100% (1)

- Bunded Steel Fuel Tanks - SmallDocument1 pageBunded Steel Fuel Tanks - SmallNAHASALI11No ratings yet

- Design and Study of Floating Roofs For Oil Storage TanksDocument12 pagesDesign and Study of Floating Roofs For Oil Storage TanksDavid RodriguesNo ratings yet

- Sample Calculation For Ammonia Tank - API 620 11th EdDocument43 pagesSample Calculation For Ammonia Tank - API 620 11th EdAde FaruroziNo ratings yet

- New Storage Tanks Design GuidelinesDocument6 pagesNew Storage Tanks Design GuidelineschrisevabNo ratings yet

- Api-650-Tank DesignDocument29 pagesApi-650-Tank DesignJoeNo ratings yet

- Calculate The Wall Thickness of Methanol Storage TankDocument4 pagesCalculate The Wall Thickness of Methanol Storage TankhaidirNo ratings yet

- Tank Stability 10.0: Shell Dimension, NewDocument4 pagesTank Stability 10.0: Shell Dimension, NewjonedNo ratings yet

- BS-VI Projects For Panipat Refineriy of IOCL: Column/ Tower Carbon Stee L, CladDocument301 pagesBS-VI Projects For Panipat Refineriy of IOCL: Column/ Tower Carbon Stee L, CladPradip ShindeNo ratings yet

- Tank Project ScheduleDocument1 pageTank Project SchedulecliffrajjoelNo ratings yet

- Boiler Specification 2Document3 pagesBoiler Specification 2AbdulBasitNo ratings yet

- Floating Roof Design (Liquid Hight)Document4 pagesFloating Roof Design (Liquid Hight)Hamid MansouriNo ratings yet

- Inigneers India Lltvilteid: ElevationDocument7 pagesInigneers India Lltvilteid: ElevationSandip SurNo ratings yet

- Tank GADocument1 pageTank GASubramanian100% (1)

- Data Sheet For T-8101.RevCDocument5 pagesData Sheet For T-8101.RevCSuresh SjNo ratings yet

- Cons Tank enDocument27 pagesCons Tank enSujesh Beherain Vasudeva100% (1)

- API 650 Datasheet 1Document16 pagesAPI 650 Datasheet 1alwacsNo ratings yet

- Premium TankDocument26 pagesPremium TankAnonymous p0iwBo50% (2)

- Design Calculation For Dirty Brackish Water Tank (129-0T2540)Document9 pagesDesign Calculation For Dirty Brackish Water Tank (129-0T2540)Dhakshina KNo ratings yet

- PTS Storge Tanks DesignDocument1 pagePTS Storge Tanks DesignFaiz AbdullahNo ratings yet

- API 650 Water Storage TankDocument6 pagesAPI 650 Water Storage TankJoeNo ratings yet

- Acid StorageDocument1 pageAcid StorageChelsea SkinnerNo ratings yet

- API 650-Water SS Tank-060914Document84 pagesAPI 650-Water SS Tank-060914A.K.M Shafiq MondolNo ratings yet

- B ABK 5000 1 API 650 Calculation ReportDocument50 pagesB ABK 5000 1 API 650 Calculation ReportZackNo ratings yet

- Oisd STD 118Document26 pagesOisd STD 118Tarun SahuNo ratings yet

- Agitator SizingDocument4 pagesAgitator SizingArbee AquinoNo ratings yet

- 7-12-0007 Rev6 (Pipe Leg Support)Document1 page7-12-0007 Rev6 (Pipe Leg Support)sumit kumar100% (1)

- ITP F TK-4101 & TK-4201 A/B: Persian Gulf Star Gas Condensate Refinery-Kal Station Booster PumpDocument20 pagesITP F TK-4101 & TK-4201 A/B: Persian Gulf Star Gas Condensate Refinery-Kal Station Booster PumpHamid MansouriNo ratings yet

- Condensate StorageTank - R0 - 24march 2022Document44 pagesCondensate StorageTank - R0 - 24march 2022kpsahuNo ratings yet

- JMS For Erection of Stiffener Angle With Existing Curb Channel With Erection of Deflector Plate Arrangement For Tank006Document9 pagesJMS For Erection of Stiffener Angle With Existing Curb Channel With Erection of Deflector Plate Arrangement For Tank006AshutoshNo ratings yet

- ORM.) Engineers: India Limited Ladder Rungs For Manhole / DemisterDocument1 pageORM.) Engineers: India Limited Ladder Rungs For Manhole / DemistersahilNo ratings yet

- AIR BLOWERS Calculation of Air Pipe SizeDocument30 pagesAIR BLOWERS Calculation of Air Pipe SizeEngFaisal Alrai100% (1)

- Guides For Storage Tanks Nozzles OrientationDocument6 pagesGuides For Storage Tanks Nozzles OrientationAmir Razmi100% (1)

- Data Sheet For Absorber Reflux Drum (GTPT-V-250-003)Document4 pagesData Sheet For Absorber Reflux Drum (GTPT-V-250-003)Mohamed hamza souissiNo ratings yet

- API 650 Tank Design CalculationsDocument8 pagesAPI 650 Tank Design Calculationsツ ツNo ratings yet

- API 650 Tank Design CalculationsDocument8 pagesAPI 650 Tank Design CalculationsVinoth Rajendra50% (4)

- API 650 Tank Design CalculationDocument9 pagesAPI 650 Tank Design CalculationSunday PaulNo ratings yet

- API 650 Tank Design CalculationDocument8 pagesAPI 650 Tank Design CalculationNorazlan Shah Mahadi100% (1)

- API 650 Tank Design CalculationDocument8 pagesAPI 650 Tank Design CalculationHoracio RodriguezNo ratings yet

- API 650 Tank Design 1Document5 pagesAPI 650 Tank Design 1Fabian Nuñez Diaz100% (1)

- API 650 Tank Design 1Document5 pagesAPI 650 Tank Design 1Jose Ortiz100% (1)

- Seconardy TreatmentDocument43 pagesSeconardy TreatmentMohammed EljammalNo ratings yet

- Fourier Series TutorialDocument80 pagesFourier Series TutorialJose VillegasNo ratings yet

- Asme PVP2011 57108 Final PDFDocument12 pagesAsme PVP2011 57108 Final PDFMohammed EljammalNo ratings yet

- Using The Failure Assessment Diagram Method With Fatigue Crack Growth To Determine Leak-before-RuptureDocument15 pagesUsing The Failure Assessment Diagram Method With Fatigue Crack Growth To Determine Leak-before-RuptureMohammed EljammalNo ratings yet

- Strengths: ConveyorsDocument2 pagesStrengths: ConveyorsMohammed EljammalNo ratings yet

- Din 3015Document17 pagesDin 3015Mohammed Eljammal100% (1)

- WHP-East Piatu-Roark Calc & Stiffener-Rev0Document18 pagesWHP-East Piatu-Roark Calc & Stiffener-Rev0namasral100% (4)