Professional Documents

Culture Documents

Work Method Statement

Uploaded by

djvhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Work Method Statement

Uploaded by

djvhCopyright:

Available Formats

Annex A

Method Statement For Site Work

A1

INTRODUCTION

A Method Statement for Gas Turbine Units Site Work issued by CLP Power for OCGT units is given below. A1.1 SCOPE OF SALE The scope of sale encompasses two gas turbine generating units as typically shown by Figure A1.1. Inside the turbine/generator enclosures, as shown by Figure A1.2 the scope of sale will include all auxiliary equipment, instrument, panels, support structure, stairway and cladding.

A2

METHOD STATEMENT FOR THE WORK

A2.1

GENERAL

The Purchaser will be responsible for the removal and disposal of all equipment, components, materials and waste within the boundary of the works. The Goods will be available for dismantling and removal from 0800 hours on the date as stipulated in the Notice of Access to be granted by CLP Power. The Purchaser will dismantle and remove the Goods in accordance with the Dismantling Program and all Goods shall be wholly dismantled and removed from the Site no later than 12 months from the issue of a Letter of Acceptance by the Owner. A2.2 DE-MOTHBALLING The gas turbines have been deactivated since 1997 and the Purchaser will be responsible to remove all the blanks and covers that have been used for their preservation. A2.3 ISOLATION The Purchaser shall cut off as required and blank off at all terminal points of various systems as advised by CLP Power. For the equipment or system that complete isolation or shut down for interface is not possible, the Purchaser shall supply and install temporary piping, circuits, etc., for diversion of circuit by-pass, etc., to allow for the interface work. Upon completion of the inspection or interface, the Purchaser shall remove all temporary connection / installation and reinstate the existing equipment to the original configuration and status.

ENVIRONMENTAL RESOURCES MANAGEMENT

A1

CLP POWER

The Purchaser, when interfacing with the existing equipment or in the course of the inspection or dismantling, should take care that no damage of existing equipment will occur due to the work. A2.4 CABLE WORK For the underground pipe-work and cables removal, the Purchaser shall remove the trench covers and reinstate as advised by the CLP Power. All cables should be considered as LIVE unless the identification has been carried out by the Owner. The Purchaser shall be responsible to carry out trench excavation for removal of buried cables if required and also carry out trench backfilling and reinstatement of ground surface as advised by and to the satisfaction of the Owners Responsible Officer. The Purchaser shall be responsible for the removal of all signal and power cables within the gas turbine compound including the underground cables, if any. As to the remote end of the cable that is away from the compound, the Purchaser shall be responsible for disconnecting the termination at both ends. The termination of the cable ends shall be covered and protected by PVC tape in a proper manner and the free ends of the cable shall be placed to the satisfaction of the Owner. A2.5 DISPOSAL OF OIL AND CONTAMINANT The Purchaser shall be responsible to drain off all oil including but not limited to the fuel oil, lubrication oil, jacking oil and insulation oil before cutting of the pipes, tanks, oil filled cables and dismantling of the component or equipment of the gas turbine. The Purchaser shall be responsible for the disposal of waste oil and the associated contaminant in accordance with the local regulations and CLPs SHE and General Site Work Requirements as presented in Annex B. A2.6 DEMOLITION OF THE CHIMNEY AND SUPERSTRUCTURE

A.

The 4600mm diameter steel stack for turbine engine shall be removed from top down as per the procedure set out below and shown in Figure A1.3 a. Disconnect all service connections including power supply cable, earthing taps oscillation damper assembly and water supply pipe. Clear up the cone plate at the lower part of the stack giving way for space where temporary steel platform and stairway structure stands. Prepare of loading bay for trucks and clear operation area for mobile crane and working area for steel sorting. Erect steel platform and stairway as shown in Figure A1.3 A2

CLP POWER

b.

c.

d.

ENVIRONMENTAL RESOURCES MANAGEMENT

e. f.

Deliver flame cutting equipment to working place. Steel bottles and other hand tools shall be fixed or tied to the working platform in order to prevent from falling. Make through holes for shackles and hooks on each segment of steel plates. Cut steel segments to a weight less than the maximum safety load of mobile crane leaving 3 no. small uncut pieces (100mm wide) for connecting the stack. Hold the cut out segment by the mobile crane. Cut out the 100mm wide connecting prices. Lower by crane the cut segment to ground level. Repeat process as g. to k. until the whole steel stack is removed.

g.

h.

i. j. k. l.

The removal of the gas turbine should follow the demolition of the superstructure. The gas turbine will be dismantled into a number of major blocks, e.g., generator, turbine and prime mover to facilitate the reassembly of the unit. These major blocks will be removed by mobile crane and transferred by truck to the heavy loading berth for packing into containers and temporary storage. The gas turbine components will be transported by barge to the nearby container terminal for export. B. The chimney supporting steel structure and the superstructure shall be removed as per the procedure below: Steel structure removal sequence: a. Top plate. b. Top beam. c. Bracing / tie bars. d. Middle beam. e. Corner posts. f. Holding down bolts.

g. Base plate. All bolts & nuts shall be maintained tight when steel members removal is carried out. During the cutting of the steel member appropriate hanging equipment shall be deployed for the prevention of free falling of the cut member.

ENVIRONMENTAL RESOURCES MANAGEMENT

A3

CLP POWER

A2.7

SITE CLEARANCE AND DE-CONTAMINATION The Purchaser shall regularly clear away and remove from the Site all waste, scrap or deleterious material accruing from his operations. The Purchaser shall be responsible for clearance of the oil inside the lubrication and jacking oil system, coupled with the fuel oil within the boundary of the works. The Purchaser shall be responsible for the site clearance, de-contamination, disposal of the waste oil and all the contaminant in accordance with the legislative regulations and SHE and General site Work requirements presented in Annex B.

A2.8 A2.8.1

RESTORATION OF SITE Bund Wall of Unit Transformer, Generator Transformer and the Plinth of the Ancillary Equipment Beyond the Gas Turbine House (see Figure A1.4) a. The bund wall of unit transformer, generator transformer and the plinth of the ancillary equipment such as the gas/oil cooler will be removed by a hydraulic breaker. The hydraulic breaker will be covered by a blanket for the suppression of noise and dust. In addition, spray will be applied to the area to mitigate the blowing of dust. The bottom of the bund wall will be removed to a depth about 100 mm below ground level. The waste will be removed by a grab lorry as soon as the quantity is sufficient. A plastic cover will be put on the top of the lorry and spray will be applied to the waste for dust suppression. The area will be backfilled and restored to ground level with cement.

b.

c.

ENVIRONMENTAL RESOURCES MANAGEMENT

A4

CLP POWER

You might also like

- RF Return Line FilterDocument8 pagesRF Return Line Filterboobalan_shriNo ratings yet

- Blasting and Painting ProcedureDocument6 pagesBlasting and Painting Procedureanon_994898767No ratings yet

- WPS Sa 517Document2 pagesWPS Sa 517DHANANNJAI SINGH -No ratings yet

- Method Statement for Miscellaneous Metal WorksDocument6 pagesMethod Statement for Miscellaneous Metal WorksYuvaraj PonrajNo ratings yet

- Technical Proposal Descaling Removal Pulai - A (2013 ASD)Document22 pagesTechnical Proposal Descaling Removal Pulai - A (2013 ASD)hash117No ratings yet

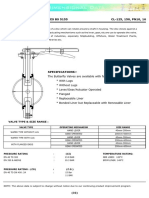

- Butterfly ValveDocument4 pagesButterfly ValveghjtyuNo ratings yet

- Elbow Trimming ProcedureDocument5 pagesElbow Trimming ProcedureMechanical Static WRKNo ratings yet

- BW Filmfill EngDocument4 pagesBW Filmfill EngkylegazeNo ratings yet

- Insulation RequirementsDocument6 pagesInsulation RequirementsNisarNo ratings yet

- Pig Launcher Fabrication and Installation Activity PlanDocument1 pagePig Launcher Fabrication and Installation Activity PlanbeqsNo ratings yet

- Technical Brochure Gre Site Activities: 44 Years ExperienceDocument30 pagesTechnical Brochure Gre Site Activities: 44 Years ExperienceSebastian RajeshNo ratings yet

- 131 - 1.9.1.2-85T - 316 Stainless SteelDocument4 pages131 - 1.9.1.2-85T - 316 Stainless SteelFtg WwfdfNo ratings yet

- Interseal 670HDocument2 pagesInterseal 670Hmadmax_mfpNo ratings yet

- C1729 Is A New ASTM Standard For Aluminum JacketingDocument2 pagesC1729 Is A New ASTM Standard For Aluminum JacketingTushar Arekar100% (2)

- Fluor: Gulf Asia Contracting Company LLCDocument3 pagesFluor: Gulf Asia Contracting Company LLCRajesh JoeNo ratings yet

- Pulley Manufacturing ProceduresDocument4 pagesPulley Manufacturing ProceduresVijayakumar SamyNo ratings yet

- E25NAFLON Expansion BellowsDocument22 pagesE25NAFLON Expansion BellowsRezza Octova GochirNo ratings yet

- Electrically Dissipating Mortar for Tiling and Brick LiningsDocument2 pagesElectrically Dissipating Mortar for Tiling and Brick Liningsshankarkl100% (1)

- Weld Built-Up ProcedureDocument1 pageWeld Built-Up ProcedureMohd Shafuaaz KassimNo ratings yet

- Maintain Submersible Pumps Oil Check DiagnosisDocument36 pagesMaintain Submersible Pumps Oil Check DiagnosiskaritocorredorpeaNo ratings yet

- MS For Fabrication of Above-Ground Storage TankDocument8 pagesMS For Fabrication of Above-Ground Storage Tankdadz mingiNo ratings yet

- AST Nozzle Repair Req.Document10 pagesAST Nozzle Repair Req.Irvansyah RazadinNo ratings yet

- Wartsila India Ltd Boiler Hydro Test ProcedureDocument2 pagesWartsila India Ltd Boiler Hydro Test ProcedureKarthi KeyanNo ratings yet

- 1-Manual Horizontal Stand CTS670 ST7H PDFDocument121 pages1-Manual Horizontal Stand CTS670 ST7H PDFManikandaprabhu ManickamNo ratings yet

- Renderoc TGDocument2 pagesRenderoc TGMansoor Ali50% (2)

- EM-SRC-0005-Marking Packaging Preservation and Shipping Requirements PDFDocument37 pagesEM-SRC-0005-Marking Packaging Preservation and Shipping Requirements PDFdang2172014No ratings yet

- Boiler & AuxiliariesDocument13 pagesBoiler & Auxiliariesprats123456No ratings yet

- 800D SeriesDocument3 pages800D Seriesvkeie0206No ratings yet

- Method Statement For Insulation WorksDocument16 pagesMethod Statement For Insulation WorksAhmed Farman AlqaysiNo ratings yet

- 8474l-000-Jsd-2310-001-2-Protective CoatingDocument31 pages8474l-000-Jsd-2310-001-2-Protective Coatinglebienthuy100% (1)

- Lowering Pipe SafelyDocument5 pagesLowering Pipe SafelyLarry Ubu100% (1)

- Data SheetDocument12 pagesData SheetAJAY1381No ratings yet

- Blasting Painting ProcedureDocument4 pagesBlasting Painting ProcedureRyanNo ratings yet

- Lesson Pipe Line Components: Sub-ObjectiveDocument24 pagesLesson Pipe Line Components: Sub-Objectivemister pogiNo ratings yet

- BTE Dome Brochure Jun 10Document2 pagesBTE Dome Brochure Jun 10م.ذكى فضل ذكىNo ratings yet

- MESC SPE 74-018 - 2010 - Nickel Alloy Pipe To Astm b167Document7 pagesMESC SPE 74-018 - 2010 - Nickel Alloy Pipe To Astm b167sathi11189No ratings yet

- Orbinox VG08 Knife Gate ValveDocument8 pagesOrbinox VG08 Knife Gate ValveYorkistNo ratings yet

- Vessel Final BoxDocument14 pagesVessel Final Boxmanoj thakkarNo ratings yet

- Structural Steel ErectionDocument7 pagesStructural Steel Erectionzaki fadlNo ratings yet

- Quality Assurance ManualDocument6 pagesQuality Assurance ManualEdgarDavidDiazCamposNo ratings yet

- Section 9-Inspection-Philosophy PDFDocument20 pagesSection 9-Inspection-Philosophy PDFWinsonLimHuiWahNo ratings yet

- A6pm-Iip-40-K042-00006 Rev0-CDocument35 pagesA6pm-Iip-40-K042-00006 Rev0-CRajesh JoeNo ratings yet

- GRP Tank Technical Data SheetsDocument39 pagesGRP Tank Technical Data Sheetsdavid JohnNo ratings yet

- Sikadur®-52 LP: Product Data SheetDocument3 pagesSikadur®-52 LP: Product Data SheetMuamer Jasna ĐulovićNo ratings yet

- Feasibility Report CNG Filling StationDocument46 pagesFeasibility Report CNG Filling StationFisha FishaNo ratings yet

- Tankguard 412 Jotun PaintDocument6 pagesTankguard 412 Jotun PaintGurdeep Sungh AroraNo ratings yet

- D. Specs For Field & Shop PaintingDocument10 pagesD. Specs For Field & Shop PaintingrajeshNo ratings yet

- Technical Specification for Oil-Injected Screw Air CompressorDocument13 pagesTechnical Specification for Oil-Injected Screw Air Compressorashish kumar pandeyNo ratings yet

- Chapter 1 Oil Seal IntroductionDocument0 pagesChapter 1 Oil Seal IntroductionZMCONTROLNo ratings yet

- User'S Manual: MANUAL NO - GL240-UM-153Document150 pagesUser'S Manual: MANUAL NO - GL240-UM-153Ta100% (1)

- FRP Installation GuideDocument8 pagesFRP Installation GuideDouglas HillNo ratings yet

- Nitrogen Generator Functional TestDocument10 pagesNitrogen Generator Functional TestBudi UtomoNo ratings yet

- Tankguard 412: Technical Data SheetDocument6 pagesTankguard 412: Technical Data SheetMuneer ahmedNo ratings yet

- Gaskets and Types of Gaskets Materials 140125122923 Phpapp01Document9 pagesGaskets and Types of Gaskets Materials 140125122923 Phpapp01Siswati OctaviaNo ratings yet

- Method Statement For Site Work: Annex ADocument9 pagesMethod Statement For Site Work: Annex ASara KhushbashNo ratings yet

- Method Statement Site WorkDocument6 pagesMethod Statement Site WorkMuthukumarNo ratings yet

- Va Nca 23 13 23Document6 pagesVa Nca 23 13 23Ali AlomyNo ratings yet

- Iso 5199Document21 pagesIso 5199pankajNo ratings yet

- Works Method Statement 2Document4 pagesWorks Method Statement 2tanbqtb03No ratings yet

- VOL II - Technical-Co Boiler Dismantling PDFDocument538 pagesVOL II - Technical-Co Boiler Dismantling PDFNassimNusNo ratings yet

- Lamprell plc ProspectusDocument165 pagesLamprell plc ProspectusdjvhNo ratings yet

- B - 8.8 - ZSS006 STD Spec For Piping Flushing Testing InspectionDocument9 pagesB - 8.8 - ZSS006 STD Spec For Piping Flushing Testing Inspectionnaseema1No ratings yet

- Three Phase Separators - Times DefinitionDocument5 pagesThree Phase Separators - Times DefinitionMohsin MohammedNo ratings yet

- Caddzoom: CADD Centre's Annual Meet at ChennaiDocument2 pagesCaddzoom: CADD Centre's Annual Meet at ChennaidjvhNo ratings yet

- B - 7.21 - ITP For Control ValveDocument2 pagesB - 7.21 - ITP For Control ValvedjvhNo ratings yet

- Lamprell Presentation 2013Document26 pagesLamprell Presentation 2013djvhNo ratings yet

- S-Mart Gasket TypesDocument8 pagesS-Mart Gasket TypesdjvhNo ratings yet

- Lamprell plc Annual Report & Accounts 2012Document104 pagesLamprell plc Annual Report & Accounts 2012djvhNo ratings yet

- Equipment Erection PDFDocument13 pagesEquipment Erection PDFkasturisunilkumar86% (7)

- 760 JacketPipingDetailsDocument25 pages760 JacketPipingDetailskaolinminerNo ratings yet

- Registered Vendors List as of June 2013Document124 pagesRegistered Vendors List as of June 2013djvhNo ratings yet

- Brochure Producedwater Sorbwater For WEBDocument12 pagesBrochure Producedwater Sorbwater For WEBManvendra SinghNo ratings yet

- Ring Joint Catalog 1Document20 pagesRing Joint Catalog 1guttykNo ratings yet

- Procedures To Install, Stress-Relieve The Welds, and Maintain A Mogas RSVP Ball ValveDocument2 pagesProcedures To Install, Stress-Relieve The Welds, and Maintain A Mogas RSVP Ball ValvedjvhNo ratings yet

- Ring Gaskets For 125 LBDocument4 pagesRing Gaskets For 125 LBdjvhNo ratings yet

- AKTTAP Macalady Principles of Project ManagementDocument52 pagesAKTTAP Macalady Principles of Project ManagementdjvhNo ratings yet

- If emDocument15 pagesIf emapi-3700440No ratings yet

- Suggested Vendor ListDocument22 pagesSuggested Vendor ListintequabNo ratings yet

- Piping PDFDocument46 pagesPiping PDFGORO43100% (1)

- Piping PDFDocument46 pagesPiping PDFGORO43100% (1)

- Cata - Flange ANSI - pdf1299758077 PDFDocument48 pagesCata - Flange ANSI - pdf1299758077 PDFNikhil PanchalNo ratings yet

- The Cat ChroniclesDocument28 pagesThe Cat ChronicleskancherlashankarNo ratings yet

- The Welding of Aluminium - Mig & Tig Fusion - Pocket Guide PDFDocument36 pagesThe Welding of Aluminium - Mig & Tig Fusion - Pocket Guide PDFrogersampaiocostaNo ratings yet

- Tubes and PipesDocument40 pagesTubes and PipesAran ChandranNo ratings yet

- Arun Sharma ArticlesDocument40 pagesArun Sharma Articlesnaveen1830% (1)

- Brayton Cycle: The Ideal Cycle For Gas-Turbine Engines in Relation To Power PlantsDocument15 pagesBrayton Cycle: The Ideal Cycle For Gas-Turbine Engines in Relation To Power PlantsmechturboNo ratings yet

- wg11 ShipbuildDocument65 pageswg11 Shipbuildshravan.bhumkarNo ratings yet

- g5 FinalDocument111 pagesg5 FinalajayikayodeNo ratings yet