Professional Documents

Culture Documents

G Codes Milling: Click To See

Uploaded by

Karthik SrinivasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

G Codes Milling: Click To See

Uploaded by

Karthik SrinivasCopyright:

Available Formats

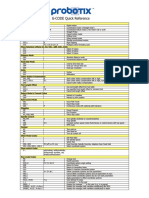

G AND M CODES

Click To See: How to Use Online Documents SURFCAM Online Documents

G AND M CODES

G Codes Milling

The following is a list of commonly used G Codes for CNC machines and their functionality.

CODE DESCRIPTION

G00 G01 G02 G03 G04 G07 G09 G10 G17 G18 G19 G20 G21 G22 G23 G27 G28 G29 G30 G31 G33 G40 G41 G42 G43 G44 G45 G46 G47 G48 G49 G50 G51 G52 G54 G55

Rapid Linear Positioning Linear Feed Interpolation CW Circular Interpolation CCW Circular Interpolation Dwell Imaginary Axis Designation Exact Stop Offset Value Setting XY Plane Selection ZX Plane Selection YZ plane Selection Input In Inches Input In Millimeters Stored Stroke Limit On Stored Stroke Limit Off Reference Point Return Check Return To Reference Point Return From Reference Point Return To 2nd, 3rd and 4th Ref. Point Skip Cutting Thread Cutting Cutter Compensation Cancel Cutter Compensation Left Cutter Compensation Right Tool Length Compensation + Direction Tool Length Compensation - Direction Tool Offset Increase Tool Offset Double Tool Offset Double Increase Tool Offset Double Decrease Tool Length Compensation Cancel Scaling Off Scaling On Local Coordinate System Setting Work Coordinate System 1 Selection Work Coordinate System 2 Selection

G and M Codes Copyright 2000 by Surfware, Inc. All Rights Reserved

G and M Codes CODE DESCRIPTION

G56 G57 G58 G59 G60 G61 G64 G65 G66 G67 G68 G69 G73 G74 G76 G80 G81 G82 G83 G84 G85 G86 G87 G88 G89 G90 G91 G92 G94 G95 G96 G97 G98 G99

Work Coordinate System 3 Selection Work Coordinate System 4 Selection Work Coordinate System 5 Selection Work Coordinate System 6 Selection Single Direction Positioning Exact Stop Mode Cutting Mode Custom Macro Simple Call Custom Macro Modal Call Custom Macro Modal Call Cancel Coordinate System Rotation On Coordinate System Rotation Off Peck Drilling Cycle Counter Tapping Cycle Fine Boring Canned Cycle Cancel Drilling Cycle, Spot Boring Drilling Cycle, Counter Boring Peck Drilling Cycle Tapping Cycle Boring Cycle Boring Cycle Back Boring Cycle Boring Cycle Boring Cycle Absolute Programming Incremental Programming Programming Of Absolute Zero Feed Per Minute Feed Per Revolution Constant Surface Speed Control Constant Surface Speed Control Cancel Return To Initial Point In Canned Cycles Return To R Point In Canned Cycles

M Codes Milling - Fanuc

CODE DESCRIPTION

M00 M01 M02 M03 M04

Program Stop Optional Stop End of Program Spindle On CW Spindle On CCW

Copyright 2000 by Surfware, Inc. All Rights Reserved

G and M Codes CODE DESCRIPTION

M05 M06 M07 M08 M09 M19 M20 M21 M22 M23 M24 M25 M26 M27 M28 M30 M98 M99

Spindle Stop Tool Change Mist Coolant On Flood Coolant On Coolant Off Spindle Orientation On Spindle Orientation Off Tool Magazine Right Tool Magazine Left Tool Magazine Up Tool Magazine Down Tool Clamp Tool Unclamp Clutch Neutral On Clutch Neutral Off End Program, Stop and Rewind Call Sub Program End Sub Program

G Codes Turning

STD SP. SP.C DESCRIPTION

G00 G01 G02 G03 G04 G07 G09 G10 G20 G21 G22 G23 G27 G28 G29 G30 G31 G32 G34 G36 G37

G00 G01 G02 G03 G04 G07 G09 G10 G20 G21 G22 G23 G27 G28 G29 G30 G31 G33 G34 G36 G37

G00 G01 G02 G03 G04 G07 G09 G10 G70 G71 G22 G23 G27 G28 G29 G30 G31 G33 G34 G36 G37

Rapid Linear Positioning Linear Feed Interpolation CW Circular Interpolation CCW Circular Interpolation Dwell Hypothetical Axis Interpolation, Sine Curve Exact Stop Offset Value Setting Input In Inches Input In Millimeters Stored Stroke Limit On Stored Stroke Limit Off Reference Point Return Check Return To Reference Point Return From Reference Point Return To 2nd, 3rd, and 4th Reference Point Skip Cutting Thread Cutting Variable Lead Thread Cutting Automatic Tool Comp. X Automatic Tool Comp. Z

Copyright 2000 by Surfware, Inc. All Rights Reserved

G and M Codes STD SP. SP.C DESCRIPTION

G40 G41 G42 G50 G65 G66 G67 G68 G69 G70 G71 G72 G73 G74 G75 G76 G90 G92 G94 G96 G97 G98 G99

G40 G41 G42 G92 G65 G66 G67 G68 G69 G70 G71 G72 G73 G74 G75 G76 G77 G78 G79 G96 G97 G94 G95 G90 G91

G40 G41 G42 G92 G65 G66 G67 G68 G69 G72 G73 G74 G75 G76 G77 G78 G20 G21 G24 G96 G97 G94 G95 G90 G91

Tool Nose Rad. Comp. Cancel Tool Nose Radius Comp. Left Tool Nose Radius Comp. Right Programming Of Absolute Zero User Macro Simple Call User Macro Modal Call User Macro Modal Call Cancel Mirror Image For Double Turrets On Mirror Image For Double Turrets Off Finishing Cycle Stock Removal, Turning Stock Removal, Facing Repeat Pattern Peck Drilling, Z Axis Grooving, X Axis Thread Cutting Cycle Cutting Cycle A Thread Cutting Cycle Cutting Cycle B Constant Surface Speed Control Constant Surface Speed Cancel Feed Per Minute Feed Per Revolution Absolute Programming Incremental Programming

Copyright 2000 by Surfware, Inc. All Rights Reserved

You might also like

- A32vii Class Manual Rev 02242009 2Document158 pagesA32vii Class Manual Rev 02242009 2Nova Tek100% (2)

- G & M CodesDocument2 pagesG & M Codespsathishthevan100% (1)

- Manuale - SINUMERIK 802DDocument32 pagesManuale - SINUMERIK 802DCARMELONo ratings yet

- Fanuc G-Code List - Helman CNCDocument2 pagesFanuc G-Code List - Helman CNCkais kaskar100% (3)

- Program ExampleDocument48 pagesProgram ExamplecmganklNo ratings yet

- PATENT DUCTUS ARTERIOSUS Concept MapDocument2 pagesPATENT DUCTUS ARTERIOSUS Concept MapErika CadawanNo ratings yet

- Machine Tool Pocket Guide 190215 PDFDocument50 pagesMachine Tool Pocket Guide 190215 PDFHarish ChandrashekarNo ratings yet

- CNC CodeDocument2 pagesCNC Codeswapnil0% (1)

- 808D GM Codes QuickDocument5 pages808D GM Codes QuickrianrureNo ratings yet

- Master List of CNC G and M CodesDocument2 pagesMaster List of CNC G and M CodesChong Yee HowNo ratings yet

- Mori Seiki GM CodeDocument10 pagesMori Seiki GM CodevusvusNo ratings yet

- Fanuc G CodeDocument3 pagesFanuc G CodeRevolusiSoekarno100% (1)

- G-Codes and M-Functions - MillingDocument1 pageG-Codes and M-Functions - MillingJuan Carlos Cárdenas TufiñoNo ratings yet

- Fanuc 0m-ADocument3 pagesFanuc 0m-ASanchai ProgaeewNo ratings yet

- Doosan G76Document17 pagesDoosan G76Pham LongNo ratings yet

- G Code FanukDocument5 pagesG Code FanukCucoș Marius MarianNo ratings yet

- Live Tool Drill TapDocument25 pagesLive Tool Drill TapRA Javier100% (1)

- CNC Turn-Mill G and M CodesDocument51 pagesCNC Turn-Mill G and M CodespptmnltNo ratings yet

- Fanuc Lathe ProgramDocument93 pagesFanuc Lathe Programnguyenanhso100% (1)

- Haas G72 Type I Rough and G70 Finish Facing Program ExampleDocument3 pagesHaas G72 Type I Rough and G70 Finish Facing Program ExampleCnc Page100% (1)

- CNC Programing ConceptDocument11 pagesCNC Programing ConceptGatot PrasetyoNo ratings yet

- TNC 426 Help CodeDocument39 pagesTNC 426 Help CodeMilos LazovicNo ratings yet

- CNC English Code Controller SystemDocument17 pagesCNC English Code Controller Systemmarciano1980No ratings yet

- FANUC F0i-D Spec E-13 SpecificationsDocument14 pagesFANUC F0i-D Spec E-13 Specificationsmt7038No ratings yet

- G CodeDocument9 pagesG CodeArga Rio MugafiNo ratings yet

- Doosan-Fanuc High Speed ModeDocument2 pagesDoosan-Fanuc High Speed Modemarkoskitp100% (1)

- CNC LectureDocument16 pagesCNC LectureJyoti Patole JadhavNo ratings yet

- M Ang G Code Mesin CNC Mori SeikiDocument13 pagesM Ang G Code Mesin CNC Mori SeikiWirdiIanNo ratings yet

- Kia SKT210SYDocument94 pagesKia SKT210SYrastaeggNo ratings yet

- MTB Tech BlogDocument41 pagesMTB Tech Blog이종훈No ratings yet

- Module 4Document59 pagesModule 4Musadiq Ahmed100% (1)

- A Letter Engraving Custom MacroDocument15 pagesA Letter Engraving Custom Macrofirepower117No ratings yet

- Programming Fanuc OtDocument13 pagesProgramming Fanuc OtsaminziNo ratings yet

- Puma Work Ejector Tip ReplacementDocument3 pagesPuma Work Ejector Tip ReplacementpaulNo ratings yet

- 3 CNC ProgrammingDocument59 pages3 CNC ProgrammingbusterrrNo ratings yet

- G Codes PDFDocument1 pageG Codes PDFKrocodileNo ratings yet

- CNC02 - DAY9-11 - Basic Turning ProgrammingDocument26 pagesCNC02 - DAY9-11 - Basic Turning Programmingmohammadarif afgan100% (1)

- Advanced CNC Programming & Code PDFDocument38 pagesAdvanced CNC Programming & Code PDFAswath SridharNo ratings yet

- Module 2 Part 1Document147 pagesModule 2 Part 1FRANCIS THOMASNo ratings yet

- Fanuc Ot Turning Offline PogrDocument138 pagesFanuc Ot Turning Offline PogrR GanesanNo ratings yet

- NC ProgrammingDocument23 pagesNC ProgrammingAkash Byju100% (1)

- CNC ProgrammingDocument20 pagesCNC ProgrammingMansingh YadavNo ratings yet

- 3 CNC Programming R2Document51 pages3 CNC Programming R2KANAV BHARDWAJNo ratings yet

- CNC LecturaDocument157 pagesCNC LecturaPablo PillajoNo ratings yet

- Polar Coordinate Interpolation Function G12.1: Layout of The X-C Coordinate System PlaneDocument10 pagesPolar Coordinate Interpolation Function G12.1: Layout of The X-C Coordinate System PlaneElias Mora BecerraNo ratings yet

- Text (Basic)Document52 pagesText (Basic)MaisaGamePlays Wolff100% (1)

- ALL CNC Printouts PROGRAMS PRINTOUTDocument26 pagesALL CNC Printouts PROGRAMS PRINTOUTGajananNo ratings yet

- Heidenhain TNC 620 User ManualDocument48 pagesHeidenhain TNC 620 User ManualBombacı MülayimNo ratings yet

- CNC Stands For Computer Numerical Control, And: G-Code. CNC Was Developed inDocument4 pagesCNC Stands For Computer Numerical Control, And: G-Code. CNC Was Developed inKhateeb Ul Islam QadriNo ratings yet

- Doosan Puma 2600y PDFDocument24 pagesDoosan Puma 2600y PDFAngel LeydanNo ratings yet

- UNIT 7 - CNC - Lecture 3 - ProgrammingDocument33 pagesUNIT 7 - CNC - Lecture 3 - ProgrammingRakshithNo ratings yet

- Fanuc G68 Rotate Co-Ordinate System For Milling Program ExampleDocument3 pagesFanuc G68 Rotate Co-Ordinate System For Milling Program ExampleHarshal DhawasNo ratings yet

- G Codes CommandsDocument45 pagesG Codes CommandsordamNo ratings yet

- Makino 3Document90 pagesMakino 3maneesh100% (1)

- Doosan MX Series M-Code ListDocument8 pagesDoosan MX Series M-Code Listenamicul50No ratings yet

- FANUC G Code of LatheDocument2 pagesFANUC G Code of Latheteam1 M y B100% (1)

- M - Code DefinitionsDocument4 pagesM - Code DefinitionsAlex AdmasNo ratings yet

- CNC Proğramlamada G Ve M KodlariDocument2 pagesCNC Proğramlamada G Ve M KodlariYUNUSNo ratings yet

- M&G CodesDocument11 pagesM&G CodesÇağdaş Akalınlı100% (1)

- CNC G M KodlarıDocument2 pagesCNC G M KodlarıMürsel cncNo ratings yet

- G Codes GSK983MDocument2 pagesG Codes GSK983MYuazaNo ratings yet

- 000 A Ee 0230028 513 R0Document13 pages000 A Ee 0230028 513 R0onur gunesNo ratings yet

- IGCSE Edexcel CircuitsDocument87 pagesIGCSE Edexcel CircuitsКіра Струлєва ОлексіївнаNo ratings yet

- Eve Berlin PDFDocument2 pagesEve Berlin PDFJeffNo ratings yet

- Chemistry 2019Document17 pagesChemistry 2019Amr Khaled Amar Mohamed salh عمرو خالد عمار محمود صالحNo ratings yet

- Double Corbel PDFDocument5 pagesDouble Corbel PDFSushil Dhungana100% (1)

- Esab Cab 460S: A Standard Column and Boom For Flexible Weld MechanizationDocument2 pagesEsab Cab 460S: A Standard Column and Boom For Flexible Weld MechanizationEnaam AtaallahNo ratings yet

- Waves in Continuous Media PDFDocument149 pagesWaves in Continuous Media PDFvicher2020No ratings yet

- Petronor Marine TerminalDocument6 pagesPetronor Marine TerminalSaurav NaskarNo ratings yet

- KaranthDocument9 pagesKaranthRakesh KhannaNo ratings yet

- New Estimate CPM (Recovered)Document28 pagesNew Estimate CPM (Recovered)Art AV B LimNo ratings yet

- Recent Trend of Finfet Devices and Its Challenges: A ReviewDocument5 pagesRecent Trend of Finfet Devices and Its Challenges: A ReviewRayaan Ahmed ShariffNo ratings yet

- Lymph Node Removal (Lymphadenectomy) - Health Information - Bupa UKDocument10 pagesLymph Node Removal (Lymphadenectomy) - Health Information - Bupa UKFanti Aldesia HafildNo ratings yet

- Mudra Mala - Mudras Meaning 2019Document15 pagesMudra Mala - Mudras Meaning 2019ulises plantillasNo ratings yet

- Lab - 2 EEng 3112 Single Phase Transformer TestsDocument5 pagesLab - 2 EEng 3112 Single Phase Transformer TestsNatenael NigusNo ratings yet

- Stryker X7000 Endoscopy Light Source - Service ManualDocument31 pagesStryker X7000 Endoscopy Light Source - Service Manualpatrick1009100% (2)

- RF Power LDMOS Transistors: MRFE6VP61K25HR6 MRFE6VP61K25HR5 MRFE6VP61K25HSR5 MRFE6VP61K25GSR5Document23 pagesRF Power LDMOS Transistors: MRFE6VP61K25HR6 MRFE6VP61K25HR5 MRFE6VP61K25HSR5 MRFE6VP61K25GSR5Claudinei FigueiraNo ratings yet

- Mark Scheme Transport QuestionsDocument3 pagesMark Scheme Transport QuestionsJohn OsborneNo ratings yet

- Trans-Boundary Fisheries Resources Management (Compatibility Mode)Document16 pagesTrans-Boundary Fisheries Resources Management (Compatibility Mode)KruNont MatchPointNo ratings yet

- First Battle of PanipatDocument3 pagesFirst Battle of Panipatparand2003100% (1)

- Text1-Introduction To Cost Accounting-Student ResourceDocument22 pagesText1-Introduction To Cost Accounting-Student Resourcekinai williamNo ratings yet

- Sahaj - MedicalDocument5 pagesSahaj - Medical'Living DollNo ratings yet

- Libro 3º BásicoDocument98 pagesLibro 3º BásicoCheveux du Feu83% (6)

- KBS Series Piezo BuzzersDocument1 pageKBS Series Piezo BuzzersBenjamín Varela UmbralNo ratings yet

- Hazard and RiskDocument25 pagesHazard and RiskJennica Mae ClemenoNo ratings yet

- Surface Chemistry APSPDocument15 pagesSurface Chemistry APSPAshutosh ChawdharyNo ratings yet

- 50 Phrasal Verbs (Printing Version)Document3 pages50 Phrasal Verbs (Printing Version)Nagore MonteroNo ratings yet

- 10.2.2.3 Packet Tracer - Troubleshooting Single-Area OSPFv2 Instructions - ILMDocument2 pages10.2.2.3 Packet Tracer - Troubleshooting Single-Area OSPFv2 Instructions - ILMSergio TejedorNo ratings yet

- Bearing Capacity - 2Document36 pagesBearing Capacity - 2EICQ/00154/2020 SAMUEL MWANGI RUKWARONo ratings yet

- Technical Guide - Installing Coverings and Profiles PDFDocument40 pagesTechnical Guide - Installing Coverings and Profiles PDFSamNo ratings yet