Professional Documents

Culture Documents

Epdm 70-Compound 55914 - Technical Data Sheet

Uploaded by

Kek Siang MingOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Epdm 70-Compound 55914 - Technical Data Sheet

Uploaded by

Kek Siang MingCopyright:

Available Formats

SEALING ELEMENTs

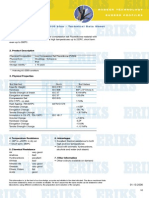

E P D M 7 0 - c o m p o u n d 5 5 9 1 4 - Te c h n i c a l D a t a S h e e t 1. Introduction EPDM 70-compound 55914 is an EPDM Terpolymer sulphur cured. It is the industrial standard EPDM O-Ring compound.

2. Product Description

Chemical Composition : Physical form : Colour : Odour : Storage stability * : Ethylene / Propylene / Diene Terpolymer O-Rings / Mouldings Black None 7 years

* : Following ISO 2230 conditions

3. Physical Properties Test Method Norm Hardness ISO 48 Method M Tensile Strength at break ISO 37 Elongation at break ISO 37 Specific Weight ISO 2781 Compression Set ISO 815 25% compression - 22h/100C on slab on O-Ring (3,53 mm) Heat Ageing 70h/100C ISO 188 Hardness Change Volume Change Acetone immersion 46h/23C ISO 1817 after drying 22h/100C Hardness Change Volume Change Weight Change Test Values 70 5 IRHD min 10 MPa min 250% 1,13

max 16% max 26% max +14 max -10%

max +6 max -6% max -5%

4. Temperature Resistance -50 to +130C TR10 (low temp. resistance): -40C 5. Chemical Resistance Air : excellent Alcohol : excellent Alkali : excellent Fats : unsatisfactory Hydrocarbons : unsatisfactory Ethers : excellent Esters : unsatisfactory Acids : fair Oils : unsatisfactory Water : excellent Steam : good

6. Advantages Very good compression-set Stock item for ca 3000 dimensions

7. Other Information See also our compound 55914PC for better steam and temperature resistance.

This information is, to the best of our knowledge, accurate and reliable to the date indicated. The above mentioned data have been obtained by tests we consider as reliable. We dont assure that the same results can be obtained in other laboratories, using different conditions by the preparation and evaluation of the samples.

12.01.2010

42

You might also like

- ERIKS - FVMQ Silicone 80 614010 BlueDocument1 pageERIKS - FVMQ Silicone 80 614010 BlueHerpadianaNo ratings yet

- Eriks - Epdm 70-Compound 559301Document1 pageEriks - Epdm 70-Compound 559301HerpadianaNo ratings yet

- ERIKS - Neoprene 60-Compound 329301 WhiteDocument1 pageERIKS - Neoprene 60-Compound 329301 WhiteHerpadianaNo ratings yet

- ERIKS - NBR 70-Compound 366301Document1 pageERIKS - NBR 70-Compound 366301HerpadianaNo ratings yet

- ERIKS - Genuine Viton GF 75-Compound 514141Document1 pageERIKS - Genuine Viton GF 75-Compound 514141HerpadianaNo ratings yet

- ERIKS - Genuine Viton-Compound 514206Document1 pageERIKS - Genuine Viton-Compound 514206HerpadianaNo ratings yet

- ERIKS - Datasheet - FKM 70-Compound 514308Document1 pageERIKS - Datasheet - FKM 70-Compound 514308DarkedgeNo ratings yet

- Eriks Epdm 70 Compound 55985Document2 pagesEriks Epdm 70 Compound 55985chethanNo ratings yet

- Eriks - Datasheet - Aflas 75-Compound 223002 PDFDocument1 pageEriks - Datasheet - Aflas 75-Compound 223002 PDFVictor Flores ResendizNo ratings yet

- ERIKS - Datasheet - FKM 75-Compound 514010 WhiteDocument1 pageERIKS - Datasheet - FKM 75-Compound 514010 WhiteDarkedgeNo ratings yet

- ERIKS - Datasheet - Genuine Viton 70-Compound 514674 BlueDocument1 pageERIKS - Datasheet - Genuine Viton 70-Compound 514674 BlueDarkedgeNo ratings yet

- ERIKS - Datasheet - FKM 75-Compound 514206 Copolymer For Vulc-O-RingDocument1 pageERIKS - Datasheet - FKM 75-Compound 514206 Copolymer For Vulc-O-RingDarkedgeNo ratings yet

- Kalrez 0090 Data SheetDocument2 pagesKalrez 0090 Data SheetGambeatNo ratings yet

- Tejipar - Darabos VajDocument2 pagesTejipar - Darabos VajChâu Chúm ChímNo ratings yet

- Chemical Resistance GuideDocument36 pagesChemical Resistance GuideHeiner PalaciosNo ratings yet

- Jeffamine ED-600 Polyetheramine: Technical BulletinDocument2 pagesJeffamine ED-600 Polyetheramine: Technical BulletinAnonymous oSf3D0No ratings yet

- Bitoner Resin C5 BT-1200H TDSDocument2 pagesBitoner Resin C5 BT-1200H TDSdamiendamNo ratings yet

- Biotemp: Biodegradable Dielectric Insulating FluidDocument4 pagesBiotemp: Biodegradable Dielectric Insulating FluidSamuel PakianathanNo ratings yet

- Cosmolubric HF-130: Description Features/ BenefitsDocument1 pageCosmolubric HF-130: Description Features/ BenefitsLuHa1No ratings yet

- Explosive DecompressionDocument11 pagesExplosive DecompressionAndrey EkkertNo ratings yet

- Eriks - VMQ Silicone Profile St-ztt-70-001Document1 pageEriks - VMQ Silicone Profile St-ztt-70-001HerpadianaNo ratings yet

- Gazguard 026: Units Typical Value Initial PropertyDocument2 pagesGazguard 026: Units Typical Value Initial PropertyTeguh SetionoNo ratings yet

- Viton DS - Downloaded - 90 ShoreDocument1 pageViton DS - Downloaded - 90 ShoreazadeazNo ratings yet

- Main Characteristics Value Unit Test Method: Percentage of Renewable Carbon (Calculation) 28-32Document1 pageMain Characteristics Value Unit Test Method: Percentage of Renewable Carbon (Calculation) 28-32gauravbtechpolymerNo ratings yet

- Duoline Best Practices Intervention & Chemical CompatabilityDocument5 pagesDuoline Best Practices Intervention & Chemical CompatabilityWISSAMSOULIMANNo ratings yet

- 4 - Prevost - Oil Analysis PDFDocument42 pages4 - Prevost - Oil Analysis PDFbcqbaoNo ratings yet

- Impreglon 410M DataSheetDocument2 pagesImpreglon 410M DataSheetMehrad LahutiNo ratings yet

- Fabric Technical Specifications: AppendixDocument4 pagesFabric Technical Specifications: AppendixAani MazharNo ratings yet

- Loctite Ea 9309.3naDocument5 pagesLoctite Ea 9309.3naechobravo1No ratings yet

- Specifications and Tests of Glazed Ceramic TileDocument3 pagesSpecifications and Tests of Glazed Ceramic Tilelucky259No ratings yet

- Garlock Stress Saver LiteratureDocument4 pagesGarlock Stress Saver Literature윤종주No ratings yet

- Dupont™ Zytel 70G13Hs1L Nc010: Nylon ResinDocument6 pagesDupont™ Zytel 70G13Hs1L Nc010: Nylon ResinZaimari FerminNo ratings yet

- Torlon Processing and PostprocessingDocument26 pagesTorlon Processing and Postprocessingfrox123No ratings yet

- 4105 DatasheetDocument2 pages4105 DatasheetAsad NaeemNo ratings yet

- 0133-138 Tehnicki Karakteristiki Za UpatstvoDocument6 pages0133-138 Tehnicki Karakteristiki Za UpatstvoZoran DanilovNo ratings yet

- Accredited Laboratory Scope of Testing for Saudi Aramco Total Refining and Petrochemical Company LabDocument6 pagesAccredited Laboratory Scope of Testing for Saudi Aramco Total Refining and Petrochemical Company LabSarbast KhoshnawNo ratings yet

- ERIKS Fluor Elastomer 90 - Compound 514530 - Technical DatasheetDocument1 pageERIKS Fluor Elastomer 90 - Compound 514530 - Technical DatasheetDarkedgeNo ratings yet

- Van Hy917 H TDDocument8 pagesVan Hy917 H TDAditi RojatkarNo ratings yet

- Polyester Resin For Closed Mold Processing and PultrusionDocument2 pagesPolyester Resin For Closed Mold Processing and PultrusionmutazsalihNo ratings yet

- NBR 70-Compound 36626 - Technical Data SheetDocument1 pageNBR 70-Compound 36626 - Technical Data SheetGuillaume JaNo ratings yet

- Seta Verification Materials: STVM MTVMDocument2 pagesSeta Verification Materials: STVM MTVMdchyNo ratings yet

- Eriks - Datasheet - NBR 70-Compound 366005Document1 pageEriks - Datasheet - NBR 70-Compound 366005Guillaume JaNo ratings yet

- Gasket Corrosion Guide Page 1Document1 pageGasket Corrosion Guide Page 1KiranNo ratings yet

- Gasket Corrosion Resistance Guide Page-1Document1 pageGasket Corrosion Resistance Guide Page-1KiranNo ratings yet

- How To Optimize OIT Tests?: Thermal AnalysisDocument4 pagesHow To Optimize OIT Tests?: Thermal AnalysisSunil Devdutt ThakoreNo ratings yet

- VBC Former Wd-858D: Water Soluble Drawing FluidDocument1 pageVBC Former Wd-858D: Water Soluble Drawing FluidSinh LeNo ratings yet

- Veradel Pellets PDFDocument7 pagesVeradel Pellets PDFkirandevi1981100% (1)

- WL Coolants Kencool PDSDocument1 pageWL Coolants Kencool PDSAung Myat ThuNo ratings yet

- ChemGuide 8677 PDocument32 pagesChemGuide 8677 PPiok Piere TenengNo ratings yet

- Bitoner Resin C5 BT-2104 TDSDocument2 pagesBitoner Resin C5 BT-2104 TDSdamiendamNo ratings yet

- MfiDocument10 pagesMfiareliabijahNo ratings yet

- Tridac Iso-6: Product DescriptionDocument2 pagesTridac Iso-6: Product DescriptionDr. Ahmed Abdel-HakimNo ratings yet

- Hysol EA9395 Data SheetDocument4 pagesHysol EA9395 Data SheetenjeeNo ratings yet

- 105 Ta D411-350Document3 pages105 Ta D411-350isaacalvareztejanoNo ratings yet

- Technical Data: Three Bond 1104 Liquid GasketDocument4 pagesTechnical Data: Three Bond 1104 Liquid GasketMochammad irhamNo ratings yet

- Gas Sweetening and Processing Field ManualFrom EverandGas Sweetening and Processing Field ManualRating: 4 out of 5 stars4/5 (7)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Welder Practice Questions: Welder Practice Questions Similar to Red Seal or AWS Welder ExamFrom EverandWelder Practice Questions: Welder Practice Questions Similar to Red Seal or AWS Welder ExamNo ratings yet

- Defect MinimizationDocument8 pagesDefect MinimizationKek Siang MingNo ratings yet

- Wire Pull Test Standards PDFDocument1 pageWire Pull Test Standards PDFChung LeNo ratings yet

- m705 grn360 Kv20series20flyDocument2 pagesm705 grn360 Kv20series20flyKek Siang MingNo ratings yet

- Mesh Size EquivalentsDocument2 pagesMesh Size EquivalentsFrancisco Chavez ContrerasNo ratings yet

- I Answered As Follows:: The Accidental Admission or Escape of Liquid or Gas or Light Through A Hole or CrackDocument5 pagesI Answered As Follows:: The Accidental Admission or Escape of Liquid or Gas or Light Through A Hole or CrackKek Siang MingNo ratings yet

- Free Documents 12Document1 pageFree Documents 12Kek Siang MingNo ratings yet

- Alloys Tempers:: The Temper or Delivery StateDocument8 pagesAlloys Tempers:: The Temper or Delivery StateKek Siang MingNo ratings yet

- 3.1.5. PolyethyleneDocument4 pages3.1.5. PolyethyleneKek Siang MingNo ratings yet

- Free Documents 11Document1 pageFree Documents 11Kek Siang MingNo ratings yet

- ISO 9001-2015 Vs ISO 9001-2008 Matrix ENDocument11 pagesISO 9001-2015 Vs ISO 9001-2008 Matrix ENTomas Morales100% (1)

- Free Documents 13Document1 pageFree Documents 13Kek Siang MingNo ratings yet

- Free Download 1Document1 pageFree Download 1Kek Siang MingNo ratings yet

- Free Documents 10Document1 pageFree Documents 10Kek Siang MingNo ratings yet

- Mesh Size EquivalentsDocument2 pagesMesh Size EquivalentsFrancisco Chavez ContrerasNo ratings yet

- Free Documents 8Document1 pageFree Documents 8Kek Siang MingNo ratings yet

- Free Documents 8Document1 pageFree Documents 8Kek Siang MingNo ratings yet

- Free Documents 9Document1 pageFree Documents 9Kek Siang MingNo ratings yet

- Free Download 3Document1 pageFree Download 3Kek Siang MingNo ratings yet

- Free Documents 5Document1 pageFree Documents 5Kek Siang MingNo ratings yet

- Free Documents 6Document1 pageFree Documents 6Kek Siang MingNo ratings yet

- Customer CompliantDocument6 pagesCustomer Compliantsuraj100% (2)

- Free DocumentsDocument1 pageFree DocumentsKek Siang MingNo ratings yet

- Free Documents 4Document1 pageFree Documents 4Kek Siang MingNo ratings yet

- Free Documents 7Document1 pageFree Documents 7Kek Siang MingNo ratings yet

- Free DownloadDocument1 pageFree DownloadKek Siang MingNo ratings yet

- Taking Control of Supplier QualityDocument6 pagesTaking Control of Supplier QualityKristijan RušecNo ratings yet

- Particle SizeDocument30 pagesParticle SizeviantnurulitaNo ratings yet

- Particle SizeDocument30 pagesParticle SizeviantnurulitaNo ratings yet

- MP2009-Chapter 1 Introduction To PhysicsDocument18 pagesMP2009-Chapter 1 Introduction To Physicssainsmathspa5550100% (1)

- Customer CompliantDocument6 pagesCustomer Compliantsuraj100% (2)