Professional Documents

Culture Documents

Ijet12 04 04 047

Uploaded by

Mumtaz AliOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ijet12 04 04 047

Uploaded by

Mumtaz AliCopyright:

Available Formats

Mr. Gurunath V Shinde et al.

/ International Journal of Engineering and Technology (IJET)

Ergonomic analysis of an assembly workstation to identify time consuming and fatigue causing factors using application of motion study

Mr. Gurunath V Shinde #1, Prof.V.S.Jadhav *2

PG student, Department of Mechanical Engineering, Government College of Engineering, Karad, (Maharashtra-India), Pin-415124 1 gurunathshinde@yahoo.com * Professor, Department of Mechanical Engineering, Government College of Engineering, Karad, (Maharashtra-India),Pin-415124 2 vsjadhavs@rediffmail.com Abstract Ergonomics plays an important role in workers productivity. Workstation layout and work design are two major factors of ergonomics of workers efficiency. Now, manufacturers found that instead of investing lots of money on man, machine, material, method (4m),improving ergonomics of workplaces is cost saving. Ergonomics found great need when market demand is high and manufacturers need more output within short period. This study was conducted on assembly workstation of welding shop. Ergonomic study of this assembly workstation was done by using motion study. Observations were made by studying each element of motion film recorded by video recorder. Results from this study reveal that there is need to modify workstation layout according to ergonomic principles. Keywords: Ergonomics, Motion film, Fatigue factors, Productivity, Workplace Layout I. INTRODUCTION For productivity improvement in manufacturing industries, efficiency of worker plays an important role .Productivity of worker greatly depends upon ergonomic design of workstation. Efficient ergonomics in workstation design shows better interaction between man-machine systems. Lot of research has been done on analysing and improving ergonomics of workstation, facility layout and tool design. Study regarding operator performance and comfort in repetitive assembly task has been done (Shikdar et al, 2009).Workstation may function with less efficiency, if anthropometry data mismatches with workstation design ( Deros et al, 2009). Methodology has been proposed to analyse and classify assembly workplace layout configuration in relation to both technological and environmental parameters ( Battini et al, 2011). Effect of workstation design, assembly design, jig design and working postures on assembly line shows jig design have most significant effect on assembly line ( Saptari et al, 2011).Study of discomfort experienced by operators during process has been studied and analysis of working postures has been done in WinOWAS software to find out awkward postures (Ismail et al, 2009). Analysis of work stress during process among Indian workers has been carried in manufacturing industries of India ( Kumar et al, 2011).Ergonomic study on manual component insertion line in printed circuit board assembly has been done using method of questionnaire, direct interview and archived data ( Yeow et al and Sen et al,2006). This study is conducted on a metal part assembly workstation which has high cycle time. Objective of this study includes performance evaluation of workers during assembly process. In primary phase study regarding workstation layout, process design and product specification has been carried out. Further motion study is done for ergonomic study by capturing motion film of assembly process using high definition video recorder. Motion film is analysed for each motion element of workers body postures and movement of other body members. Results of motion study revealed various fatigue causing and time consuming factors related to worker and workstation layout. II. METHODOLOGY This study was conducted on assembly workstation in a welding shop. Four different metal parts from press shop are assembled by manual welding process. Assembly process consists of metal parts of different size and weights; they are kept in different bins around workplace. Two operators are working on this workstation. Their anthropometric measurements are carried out by direct interview with both operators. The main focus of this study is to find out complex task of assembly which leads to more time consumption and fatigue causing.

#

ISSN : 0975-4024

Vol 4 No 4 Aug-Sep 2012

220

Mr. Gurunath V Shinde et al. / International Journal of Engineering and Technology (IJET)

Hence ergonomic study is carried out using application of motion study by video recorder. Handy cam is used to record whole process in .MPEGV video format which is easy to use and transfer from device to computer. A. Workstation Design and Workplace Layout: Fig.no.1 (a) and (b) shows present workplace layout and design in side and top view respectively. Workstation consists of two operators working on LH side and RH side. The task consists of assembly of metal parts using manual welding process. The process consists of repetitive tasks which seem to be because of poor ergonomics. The assembly process includes picking and loading of parts from bins to workstation, handling welding gun for spotting, unloading and part transfer to next station. Operators are Indian male and average age of the workers is 25, average weight of workers is 72 kgs., Average height is 175 cms. Workplace consists of four bins for storage of four different metal parts. Dimension of bins are as shown in fig.1. (a) and (b).Though heights of all bins are 80 cms. Workstation layout dimensions are 275x200x90 cms. From these figures it is concluded that workplace layout is improper and needs to modify it. During assembly process various motions like rotation, more walk, bending, lifting etc. have been observed and these tasks highly repetitive if shift working hours are considered. Operators are not able to maintain standard body postures and movement because of poor workplace layout. Hence lead to fatigue like shoulder stress, back pain, neck pain etc. which reduces working efficiency.Fig.1. (b) Shows distance (in meters) covered by workers from original position to bins and control button.

Fig.1.a). Side view of workplace layout and design

Fig.1.b). Top view of workplace layout and design

ISSN : 0975-4024

Vol 4 No 4 Aug-Sep 2012

221

Mr. Gurunath V Shinde et al. / International Journal of Engineering and Technology (IJET)

B. Flowchart of assembly process : Following flowchart shows assembly process of metal parts on workstation,

Fig.2.Process flow of assembly operation TABLE 1 Frequency of activities during assembly process

Table no.1 shows frequency of various activities involved in assembly process by LH worker and RH worker. Workloads have seen to be equally distributed amongst both workers. Assembly process does not contain delay operations as shown by above table. C. Product Design: Fig.3.a. shows design of input metal parts, though thickness of all parts is constant i.e.0.3 cm while fig.3.b. shows final assembled single product. Following table shows specifications of input parts and final product. Part 2 and part 4 are heavier than other parts. Hence more effort is required while handling these parts. The total weight of final product is 15.214 kgs which needs more efforts while transferring finished product to next station. For example, this paragraph begins with a level-3 heading.

TABLE 2 Specifications of input parts and final product

ISSN : 0975-4024

Vol 4 No 4 Aug-Sep 2012

222

Mr. Gurunath V Shinde et al. / International Journal of Engineering and Technology (IJET)

Fig.3.a) Design of input parts

Fig.3. b) Design of final product

D. Motion Study: Critical analysis of workstation is done by using motion study. Every task performed by man or machine involves body members and their respective movements. The efficiency of these movements can be accurately determined by distance moved, control actions, co-ordination of different body members with each other and working conditions. The purpose of such motion study is to identify and understand motion bottlenecks related to human effort and system. In order to achieve required objective there is need to go into details of body and hand movements and thus best possible and most economical pattern of movements can be developed to perform efficient work or activity. This type of study involves making motion film of an operation to analyse frame by frame and result of each frame element like bending; lifting, twisting etc is noted. Following procedure is used for motion study analysis in this work, Recording of motion film is done by using high definition handy-cam in the .MPEG file format. Motion films in .MPEG format are analysed by using Windows Movie Maker, the inbuilt video editing software from Microsoft in windows operating system at 0.125X running speed. At this low speed it is easy to examine and analyse body motions while working at the workstations. Fig.no.4. shows motion study of workstation done in windows movie maker .The left hand side shows running film at speed of 0.125X and the right side shows film breakdown in small elements for each body motion. These elements are nothing but frames which shows particular activity done by worker e.g. frame 1 shows loading of part 1 i.e. left end of frame is the start of picking part and right end is the end of frame means loading part to station. These activities belong to therbligs grasp (G) and transport loaded (TL).

ISSN : 0975-4024

Vol 4 No 4 Aug-Sep 2012

223

Mr. Gurunath V Shinde et al. / International Journal of Engineering and Technology (IJET)

Fig.no.4.Motion film of assembly process in windows movie maker.

III.RESULTS A. Cycle time: Table no. 3. Shows result of each assembly task in seconds observed from motion study .From table total task time is calculated for assembly of product and it is found to be 132 seconds. Tasks are considered for both LH and RH worker and time required to each task by each worker is measured.

TABLE 3 Elemental break up of assembly process

Cycle time calculation: End time: 10:02:12 AM Start time: 10:00:00 AM Cycle time: 00:02:12=132 seconds

ISSN : 0975-4024

Vol 4 No 4 Aug-Sep 2012

224

Mr. Gurunath V Shinde et al. / International Journal of Engineering and Technology (IJET)

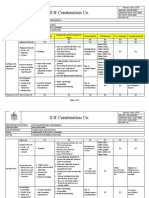

B. Ergonomic Analysis: When operators are interviewed for getting information regarding awkward postures and complex task, various illnesses are informed by these workers including neck pain, back pain, shoulder pain etc. lead to reduced efficiency of workers and in severe cases long duration pains. Motion study revels reasons of these illnesses. Analysis of these factors is done by motion film and root causes of these things are found out. Table no.4. Shows ergonomic analysis of workstation obtained from motion study.

TABLE 4 Bottleneck factors analysed by motion study

ISSN : 0975-4024

Vol 4 No 4 Aug-Sep 2012

225

Mr. Gurunath V Shinde et al. / International Journal of Engineering and Technology (IJET)

Fig.no.5. Recommended distance for arms (in cms) (Sanders and McCormick, 1993)

IV.CONCLUSIONS This work was conducted on an assembly station in welding shop. The shop was facing problem of less efficiency of workers due to poor ergonomics and in some severe cases hazardous health issues are found. Here attempt has been made to identify fatigue causing factors which leads to reduced efficiency of workers hence less productivity of workstations. To study and analyse factors causing less efficiency, motion study technique is used. The other source of data is interview with workers, managers, archived documents etc. Ergonomically improved workplace layout helps in reduced stress on workers, elimination of repetitive tasks, cycle time reduction and hence increased productivity. Fig.no.5 shows recommended working area for human left and right hand, the dimensions are shown in centimetres (Sanders and McCormick, 1993). Normal area can be easily reachable by swiping forearm while maximum area refers to be reached by spreading arm from shoulder. Following conclusions are made from this study: 1. Natural motions of workers are constrained by poor workstation design and layout. Material handling, tool handling, control system operation have seen significant effect on worker efficiency. 2. Workers are seen to be unaware of ergonomic principles as body postures and movements are seen to be not following standard work procedure. 3. Frequent body postures like bending ,twisting, eye movements, lifting have seen in single product assembly though company works for 8 hrs , hence health issues are observed like back pain, shoulder pain , wrist pain , neck pain etc. lead to less efficiency of workers. 4. Tool design and part design have significant effect on worker efficiency as tool is seen to be heavy to handle, geometry of tool are not supportive towards smooth operation. 5. Workers are seen to be having discomfort while handling parts as sharp edges and large size of metal parts may lead to fear of injury. Also tool and parts are not supportive for gripping. Following recommendation are suggested in order to overcome above problems: 1. Workers must be trained to aware and follow standard work procedure including standard body postures, motion sequences. Training should be given in order to follow standard procedure for tool and material handling. 2. Modify the workstation layout and design so as to suitable for good body postures and good tool-work piece contact. 3. Use of low cost mechanical automation assistance can reduce complex tasks and hence reduces fatigue. 4. Some work must be assigned for foot usage like foot pedal so to avoid muscular stress and cramp to muscles. 5. Increase comfort situation by implementing healthy environment like air supply system, good lightning system etc. ACKNOWLEDGMENT Our study is greatly acknowledged from managers and workers of a company. We are especially thankful to Principal, Dr.Prof.R.Y.Patil and Dr.Prof.C.Y.Simikeri. REFERENCES

[1] Deros B.M., Khamis N.K.(2011) An ergonomics study on assembly line workstation design. American Journal of Applied Sciences 8 (11):1195-1201. [2] Battini D., Faccio M., (2011), New methodological framework to improve productivity and ergonomics in assembly system design, International Journal of industrial ergonomics 41(30-32).

ISSN : 0975-4024

Vol 4 No 4 Aug-Sep 2012

226

Mr. Gurunath V Shinde et al. / International Journal of Engineering and Technology (IJET)

[3] Saptari A., Lai W.S. (2011), Jig design, assembly line design and work station design and their effect to productivity. Jordan Journal of Mechanical and Industrial Engineering Vol.5, No. 1(9-16). [4] Kumar K.S. (2011), Analysis and modeling of work stress in manufacturing industries in Kerala, India, International Journal of Modern Engineering Research.Vol.1, No.2, (552-558). [5] Ismail A.R., Yeo M. L.,(2009) , Assessment of Postural Loading among the Assembly Operators: A Case Study at Malaysian Automotive Industry. European Journal of Scientific Research Vol.30 No.2, (224-235). [6] Santos J, Sarriegi J.M.( 2007). Using ergonomic software in non-repetitive manufacturing processes: A case study. International Journal of Industrial Ergonomics 37: 267-275. [7] Shikdar A., Al-Hadhrami M.,( 2007 ). Smart workstation design: an ergonomics and methods engineering approach. International Journal of Industrial and Systems Engineering. 2(4), 363-374. [8] Yeow P.H.P., Sen R.N., (2006), Productivity and quality improvements, revenue increment, and rejection cost reduction in the manual component insertion lines through the application of ergonomics International Journal of Industrial Ergonomics 36:367377. [9] Mavrikios D.,(2006),An approach to human motion analysis and modeling, International Journal of Industrial Ergonomics, Vol.36 No.11, (979-989). [10] Shikdar A.A., Hadhrami M.A., (2005) Operator Performance and Satisfaction in an Ergonomically Designed Assembly Workstation, The Journal of Engineering Research, vol.2 number-1(69-76). [11] Ulin S.S., Keyserling W.M.,(2004), Case Studies of Ergonomic Interventions in Automotive Parts Distribution Operations, Journal of Occupational Rehabilitation,Vol.14,No.4.

ISSN : 0975-4024

Vol 4 No 4 Aug-Sep 2012

227

You might also like

- Ijetae 0415 85Document4 pagesIjetae 0415 85ifyNo ratings yet

- Design and Fabrication of Special Purpose Tool Fixture For CNC TurretsDocument5 pagesDesign and Fabrication of Special Purpose Tool Fixture For CNC TurretsHarits PamitranNo ratings yet

- Design and Development of Progressive Tool For Mold Tag: Articles You May Be Interested inDocument11 pagesDesign and Development of Progressive Tool For Mold Tag: Articles You May Be Interested inmazen banatNo ratings yet

- Development of The Compound Die Forming Technology United Between Semi-Progressive and Transfer DieDocument9 pagesDevelopment of The Compound Die Forming Technology United Between Semi-Progressive and Transfer DieranggaganjarNo ratings yet

- Ergonomics Assessment of Workstation Design in Automotive IndustryDocument7 pagesErgonomics Assessment of Workstation Design in Automotive IndustryGabriel AboroenceiNo ratings yet

- Design and Fabrication of Portable Drilling and Boring MachineDocument4 pagesDesign and Fabrication of Portable Drilling and Boring MachineVIVA-TECH IJRINo ratings yet

- Design and Development of Fixture For Eccentric ShaftDocument6 pagesDesign and Development of Fixture For Eccentric ShafttuongnvNo ratings yet

- Desain Otomatis KonveyorDocument8 pagesDesain Otomatis KonveyoragungNo ratings yet

- Turning Fixtures 5 PDFDocument12 pagesTurning Fixtures 5 PDFgsudhanta1604100% (2)

- Lean Manufacturin and Six SegmaDocument9 pagesLean Manufacturin and Six Segmashahid_ali21No ratings yet

- Analysis and Simulation PDFDocument4 pagesAnalysis and Simulation PDFPaulo VictorNo ratings yet

- Group Number 11 Paper PubhishDocument4 pagesGroup Number 11 Paper PubhishVaibhav ChopadeNo ratings yet

- Fmea of Sheet Metal ComponentsDocument10 pagesFmea of Sheet Metal Componentsvkms100% (2)

- Industrial Engineering - Lab Manual - 06052016 - 054139AM PDFDocument58 pagesIndustrial Engineering - Lab Manual - 06052016 - 054139AM PDFSaya100% (1)

- Design, Analysis and Performance Evaluation of A Mechanical GyratorDocument7 pagesDesign, Analysis and Performance Evaluation of A Mechanical GyratorijrdtNo ratings yet

- Fundamentals of Machine Design 3252Document509 pagesFundamentals of Machine Design 3252greenwind007100% (1)

- Jig Design Assembly Line Design and Work Station DDocument9 pagesJig Design Assembly Line Design and Work Station DabcdNo ratings yet

- Expert System For Rolling Load Prediction in 20 Hi Sendzimir MillDocument5 pagesExpert System For Rolling Load Prediction in 20 Hi Sendzimir MillIAEME PublicationNo ratings yet

- Modeling and Analysis of Base Plate For Brake Spider Fixture by Fem Using Ansys SDocument5 pagesModeling and Analysis of Base Plate For Brake Spider Fixture by Fem Using Ansys SIAEME PublicationNo ratings yet

- An Ergonomics Study On Assembly Line Workstation DesignDocument7 pagesAn Ergonomics Study On Assembly Line Workstation DesignWeld TechNo ratings yet

- Ergonomic Analysis of Construction Jobs in India: A Biomechanical Modelling ApproachDocument7 pagesErgonomic Analysis of Construction Jobs in India: A Biomechanical Modelling ApproachBERLIAN ANNISA NUR RAHMASARINo ratings yet

- Lean Thi Nki NG: Single Minute Exchange of Dies: Literature ReviewDocument11 pagesLean Thi Nki NG: Single Minute Exchange of Dies: Literature ReviewBhanuj VermaNo ratings yet

- Performance Measurement 3Document10 pagesPerformance Measurement 3IAEME PublicationNo ratings yet

- International Journal of Engineering Research and DevelopmentDocument8 pagesInternational Journal of Engineering Research and DevelopmentIJERDNo ratings yet

- Ergo Study 2.studyDocument8 pagesErgo Study 2.studyRonillo PormonNo ratings yet

- Modeling and Analysis of Support Pin For Brake Spider Fixture by Fem Using Ansys SoftwareDocument6 pagesModeling and Analysis of Support Pin For Brake Spider Fixture by Fem Using Ansys SoftwareRupali PatilNo ratings yet

- Productivity AnalysisDocument15 pagesProductivity AnalysisNithinNo ratings yet

- Design of Machine ElementsDocument508 pagesDesign of Machine ElementsPrashanth Kumar93% (15)

- Module 1 Lesson 1Document11 pagesModule 1 Lesson 19703422499No ratings yet

- Fabrication of U-Type, V-Type, L-Type Angle Bending MachineDocument74 pagesFabrication of U-Type, V-Type, L-Type Angle Bending MachineCrispNo ratings yet

- Optimizing Surface RoughnessDocument7 pagesOptimizing Surface Roughnesskarpaga raj aNo ratings yet

- Ergonomics in Machine ShopDocument8 pagesErgonomics in Machine ShopAliyana ShresthaNo ratings yet

- Analysis of Flywheel: Akshay P. Punde, G.K.GattaniDocument3 pagesAnalysis of Flywheel: Akshay P. Punde, G.K.GattaniKelsey RyanNo ratings yet

- Process Information Model For Sheet Metal OperationsDocument10 pagesProcess Information Model For Sheet Metal OperationsgcldesignNo ratings yet

- Computer-Aided Design: Matthieu Rauch, Jean-Yves Hascoet, Jean-Christophe Hamann, Yannick PlenelDocument9 pagesComputer-Aided Design: Matthieu Rauch, Jean-Yves Hascoet, Jean-Christophe Hamann, Yannick Plenelshaukat khanNo ratings yet

- Investigation of The Effect of Built Orientation On Mechanical Properties and Total Cost of FDM PartsDocument6 pagesInvestigation of The Effect of Built Orientation On Mechanical Properties and Total Cost of FDM PartsAnilNo ratings yet

- SMED Implementation in A Press Shop: T.G.Arul, A.Manimaran, P.RanjithDocument6 pagesSMED Implementation in A Press Shop: T.G.Arul, A.Manimaran, P.RanjithRohan SharmaNo ratings yet

- Recent Trends in Computer Adied Fixture Design Review On ApproachesDocument4 pagesRecent Trends in Computer Adied Fixture Design Review On ApproachesesatjournalsNo ratings yet

- New Ie Lab Manual 2015Document46 pagesNew Ie Lab Manual 2015Free ka maal la reNo ratings yet

- Design-Out Maintenance On Frequent Failure of Motor Ball Bearings-2-3 PDFDocument10 pagesDesign-Out Maintenance On Frequent Failure of Motor Ball Bearings-2-3 PDFIAEME PublicationNo ratings yet

- Tool Path Planning For Manufacturing of Asymmetric Parts by Incremental Sheet Metal Forming by Means of Robotic ManipulatorDocument11 pagesTool Path Planning For Manufacturing of Asymmetric Parts by Incremental Sheet Metal Forming by Means of Robotic Manipulatormohamad ma'rufNo ratings yet

- Value Stream MappingDocument9 pagesValue Stream MappingIAEME PublicationNo ratings yet

- Mohammed2020 Article ErgonomicAnalysisOfAWorkingPosDocument8 pagesMohammed2020 Article ErgonomicAnalysisOfAWorkingPostemesgen DemssieNo ratings yet

- Senny 2021 IOP Conf. Ser. Earth Environ. Sci. 794 012098Document12 pagesSenny 2021 IOP Conf. Ser. Earth Environ. Sci. 794 012098MusaNo ratings yet

- Biw Basic Document - Iit ProjectDocument6 pagesBiw Basic Document - Iit ProjectArshadNo ratings yet

- Automatic Revetting Machine 2020Document8 pagesAutomatic Revetting Machine 2020Anil DubeNo ratings yet

- Design PhilosophyDocument9 pagesDesign PhilosophyLakim ArsenalNo ratings yet

- 1 s2.0 S235197891730536X Main PDFDocument10 pages1 s2.0 S235197891730536X Main PDFAlexandre SilvaNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Finite Element Analysis for Design Engineers, Second EditionFrom EverandFinite Element Analysis for Design Engineers, Second EditionNo ratings yet

- Engineering Applications: A Project Resource BookFrom EverandEngineering Applications: A Project Resource BookRating: 2.5 out of 5 stars2.5/5 (1)

- Up and Running with Autodesk Inventor Simulation 2011: A Step-by-Step Guide to Engineering Design SolutionsFrom EverandUp and Running with Autodesk Inventor Simulation 2011: A Step-by-Step Guide to Engineering Design SolutionsNo ratings yet

- Creating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowFrom EverandCreating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowRating: 4 out of 5 stars4/5 (1)

- Training Facility Norms and Standard Equipment Lists: Volume 1---Precision Engineering or MachiningFrom EverandTraining Facility Norms and Standard Equipment Lists: Volume 1---Precision Engineering or MachiningNo ratings yet

- Instructions For Candidates: Dawood University of Engineering and TechnologyDocument2 pagesInstructions For Candidates: Dawood University of Engineering and TechnologyMumtaz AliNo ratings yet

- Tux Paint PDFDocument1 pageTux Paint PDFMumtaz AliNo ratings yet

- Noise in The Workplace: What You Should KnowDocument20 pagesNoise in The Workplace: What You Should KnowMumtaz AliNo ratings yet

- IndustryDocument3 pagesIndustryMumtaz AliNo ratings yet

- Akheion Phare DisDocument4 pagesAkheion Phare DisMumtaz AliNo ratings yet

- Critical Analysis of Work Place in Assembly LineDocument2 pagesCritical Analysis of Work Place in Assembly LineMumtaz AliNo ratings yet

- MUMTAZ Practical Genral CADDocument61 pagesMUMTAZ Practical Genral CADMumtaz AliNo ratings yet

- User Factor (Human), Computer and InteractionDocument154 pagesUser Factor (Human), Computer and InteractionSandra Suriya A/l JayasuriNo ratings yet

- Perception of The Technical Drafting Students Towards Their Drafting ChairsDocument28 pagesPerception of The Technical Drafting Students Towards Their Drafting ChairsJamesNo ratings yet

- POGO Product Design Specification BriefDocument8 pagesPOGO Product Design Specification BriefJonny Eggins100% (1)

- Vehicle ErgonomicsDocument35 pagesVehicle ErgonomicsRamit100% (1)

- Delmia Workplace Ergonomics SolutionDocument2 pagesDelmia Workplace Ergonomics Solutionaymen ben aichaNo ratings yet

- Indigenous Therapies - Sleep and WorkDocument13 pagesIndigenous Therapies - Sleep and WorkRaabiyaNo ratings yet

- HF in Maintenance MOOCDocument32 pagesHF in Maintenance MOOCMuhammad Nuril FahmiNo ratings yet

- Dixit - 2006 - ERGONOMIC STUDIES ON AGRICULTURAL WORKERS PERFORMING SELECTED FARM OPERATIONS IN COTTON CROPS PDFDocument195 pagesDixit - 2006 - ERGONOMIC STUDIES ON AGRICULTURAL WORKERS PERFORMING SELECTED FARM OPERATIONS IN COTTON CROPS PDFDivya DivyachilaNo ratings yet

- APAC AIG Investigation Analysis Workshop ManualDocument230 pagesAPAC AIG Investigation Analysis Workshop ManualOfelia Umpire RuizNo ratings yet

- IE464 - T2 - Engineering Anthropometry and Workspace DesignDocument32 pagesIE464 - T2 - Engineering Anthropometry and Workspace DesignIbrahem Abdulrahman100% (2)

- Topic Outline: Unit 1: Introduction To Ergonomics and Facilities PlanningDocument56 pagesTopic Outline: Unit 1: Introduction To Ergonomics and Facilities PlanningZayn Artus100% (3)

- Human Factors & ErgonomicsDocument57 pagesHuman Factors & ErgonomicsPawan Kumar100% (3)

- Computer Monitor Height, Angle, and Distance - Ergonomics GuidelinesDocument17 pagesComputer Monitor Height, Angle, and Distance - Ergonomics Guidelineslee.tetleie1675No ratings yet

- Research On The Design of The Elderly Wardrobe Based On ErgonomicsDocument6 pagesResearch On The Design of The Elderly Wardrobe Based On ErgonomicsMelisa MathiasNo ratings yet

- 5 Everyday Workplace SafetyDocument11 pages5 Everyday Workplace SafetyBUTCH FAJARDONo ratings yet

- Better Safe Than Sorry: Methods For Risk Assessment of Psychosocial HazardsDocument18 pagesBetter Safe Than Sorry: Methods For Risk Assessment of Psychosocial HazardsBegoña MartinezNo ratings yet

- 10.1201 b14391 PreviewpdfDocument204 pages10.1201 b14391 PreviewpdfGabriela LisbethNo ratings yet

- Demasco 1994Document17 pagesDemasco 1994Juan Ignacio Ruiz DIazNo ratings yet

- Work Psychology: Psychological Processes in Work ContextDocument322 pagesWork Psychology: Psychological Processes in Work ContextShalini SinghalNo ratings yet

- Study of Vehicle Utilities and Load Unloading Facilities of City Public Transport Based On Ergonomics AssessmentDocument7 pagesStudy of Vehicle Utilities and Load Unloading Facilities of City Public Transport Based On Ergonomics Assessmentrahmat alfathbNo ratings yet

- Production and Operations ManagementDocument43 pagesProduction and Operations ManagementBoycie TarcaNo ratings yet

- Ishwar Adhikari CSM NoteDocument109 pagesIshwar Adhikari CSM NoteBinit BänstøłäNo ratings yet

- Occupational Health Nursing 2011Document26 pagesOccupational Health Nursing 2011sandesh ujagareNo ratings yet

- Abdel Malek 2004 International Journal of Industrial Ergonomics A Mathematical Method For Ergonomic Based Design Placement 34 5Document20 pagesAbdel Malek 2004 International Journal of Industrial Ergonomics A Mathematical Method For Ergonomic Based Design Placement 34 5Lukmanul ChakimNo ratings yet

- Management of Manualhandling in The Construction SectorDocument20 pagesManagement of Manualhandling in The Construction SectorJames McloughlinNo ratings yet

- JHA Conveyor Belt ChangingDocument9 pagesJHA Conveyor Belt ChangingMohammad Sharique PathanNo ratings yet

- Automotive Cockpit HMIDocument2 pagesAutomotive Cockpit HMIIQPC GmbHNo ratings yet

- Office Layout and Office EnvironmentDocument47 pagesOffice Layout and Office EnvironmentVenusNo ratings yet

- Ergonomics Case Study Cleaning StationsDocument3 pagesErgonomics Case Study Cleaning StationsMohamed OsamaNo ratings yet

- Design and Analysis Ergonomics Workstation in Stamping IndustryDocument10 pagesDesign and Analysis Ergonomics Workstation in Stamping Industryhemanth_aero78931No ratings yet