Professional Documents

Culture Documents

Piping Plan & Numbering of Auxiliary Equipment: Drawings of Piping & Seal Chamber Drawings of Piping & Seal Chamber

Uploaded by

Oscar SalazarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Piping Plan & Numbering of Auxiliary Equipment: Drawings of Piping & Seal Chamber Drawings of Piping & Seal Chamber

Uploaded by

Oscar SalazarCopyright:

Available Formats

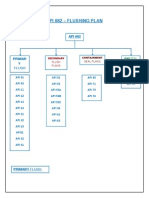

Piping Plan & Numbering of Auxiliary Equipment

In order to make best use of mechanical seals, appropriate auxiliary equipment and piping are required. The sketches shown on the right exemplify different piping arrangements. Numbering is based on the api standard. (API 610-8th, API 682-1st)

PS Cooler Stop Valve Cyclone Separator Pressure Switch PI Y Strainer Check Valve Pressure Gauge Reservoir TI Flow Control Valve Thermometer Flow Indicator Orifice

API plan

Drawings of piping & Seal chamber

Integral (internal) recirculation from pump discharge to seal.

API plan

Drawings of piping & Seal chamber

Recirculation from the pump discharge through a flow control orifice and a cooler, then into the seal chamber.

V Q/D

01

21

F Q/D

Dead-ended seal chamber with no circulation of flushed fluid.

Recirculation from the pump discharge through a strainer, a flow control orifice, and a cooler and into the seal chamber.

02

V CI/CO Q/D

22

F Q/D

Recirculation from pump discharge through a flow control orifice to the seal.

Recirculation from the pumping ring in the seal chamber through a cooler and back to the seal chamber.

11

F Q/D

23

F0

FI Q/D

Recirculation from pump discharge through a strainer and flow control orifice to the seal.

Recirculation from pump discharge through a cyclone separator delivering the clean fluid to the seal chamber.

12

31

F Q/D

V F Q/D

Recirculation from pump discharge through a strainer and flow control orifice to the seal.

Flush is injected into the seal chamber from an external source.

13

F Q/D

32

V F Q/D

Recirculation from pump discharge through a flow control orifice to the seal and back to the pump suction.

Recirculation from pump discharge through a cyclone separator delivering the clean fluid a cooler and then to the seal chamber.

14

FO FI Q/D

41

V F Q/D

Cooler Stop Valve Cyclone Separator PS Pressure Switch PI

Y Strainer Check Valve Pressure Gauge Reservoir TI

Flow Control Valve Thermometer Flow Indicator Orifice

API plan

Drawings of piping & Seal chamber

External reservoir providing a dead-ended blanket of fluid to the quench connection of the gland.

API 610 8th API CODE

1st Letter 2nd Letter 3rd Letter 4th Letter 5th Letter

51

Q/D

B: Balance U: Unbalance

Code E F G H I

Packing for stationary ring Viton Viton Teflon Nitrile Kalrez equivalent Grafoil As specified Boltex

Packing for rotating ring Teflon Viton Teflon Nitrile Kalrez equivalent Grafoil As specified Grafoil

External reservoir providing buffer fluid for outer seal of an unpressurized dual seal arrangement. Circulation is maintained by an internal pumping ring. The reservoir is usually continuously vented to a vapor recovery system.

S: Single T: Unpressurized Dual Type D: Pressurized Dual Type

F BI BO

52

R <End Plate Type> P: Without Bushing T: With Bushing A: With Auxiliary Seal X Z

Pressurized external barrier fluid reservoir supplying clean fluid to the seal chamber. Circulation is by an internal pumping ring. Reservoir presuere is greater than the process pressure being sealed.

53

F BI BO

Code L M

Ring1 Carbon Carbon Carbon Nickel bound tungsten carbide Silicon carbide As specified

Ring2 Cobalt bound tungsten carbide Nickel bound tungsten carbide Silicon carbide Silicon carbide Silicon carbide As specified

Pressurized external barrier fluid reservoir or system supplying clean fluid to the seal chamber. Circulation is by an external pump or pressure system. Reservoir pressure is greater than the process pressure being sealed.

N O

54

BI

BO

P X

Tapped Connections for the Purchaser's Use.

61

Q/D

External source providing a quench.

[Reference] Quenching flow rate (set us standard)

Quenching fluid Flow rate 12R /min 0.5kg/Hr 0.3kg/Hr

62

Q/D F

Water Steam N2Gas

You might also like

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- Seal Flushing PlansDocument11 pagesSeal Flushing PlansSakthikumar ChandrasekaranNo ratings yet

- Flushing PlanDocument4 pagesFlushing PlanRamesan12345789No ratings yet

- Yazd-System Description For Clean Drain System PDFDocument7 pagesYazd-System Description For Clean Drain System PDFace-winnieNo ratings yet

- Understanding Process Equipment for Operators and EngineersFrom EverandUnderstanding Process Equipment for Operators and EngineersRating: 4.5 out of 5 stars4.5/5 (3)

- Plumbing ExamDocument218 pagesPlumbing ExamJhobs BesmonteNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Provide Expansion Loop in Vertical DropDocument12 pagesProvide Expansion Loop in Vertical DropVikash TiwariNo ratings yet

- Multi Heat Plumbing Schematic PDFDocument2 pagesMulti Heat Plumbing Schematic PDFParameswararao BillaNo ratings yet

- Im316 Flow MeasurementDocument67 pagesIm316 Flow MeasurementSelvarajNo ratings yet

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Especificacion TACO AC (F) - CBXDocument5 pagesEspecificacion TACO AC (F) - CBXpca97No ratings yet

- Foam SystemsDocument18 pagesFoam SystemsGigieseNo ratings yet

- Plans PDFDocument62 pagesPlans PDFHamed HamedNo ratings yet

- Mechanical Seal Plan - Pocket Guide (John Crane)Document62 pagesMechanical Seal Plan - Pocket Guide (John Crane)Tarun Chandra100% (5)

- Control Valve Calculation SpreadsheetDocument1 pageControl Valve Calculation Spreadsheetpetrolhead1No ratings yet

- How To Size A Liquid Control Valve - Blackmonk EngineeringDocument9 pagesHow To Size A Liquid Control Valve - Blackmonk EngineeringKyriakos MichalakiNo ratings yet

- Lab Report: Instrumentation and ControlDocument7 pagesLab Report: Instrumentation and ControlmjunaidNo ratings yet

- Controlled Circulation PumpDocument5 pagesControlled Circulation PumpLakshminarayanNo ratings yet

- API 682 Short Guide Most Common Plans and Operational InformationDocument40 pagesAPI 682 Short Guide Most Common Plans and Operational InformationFarhan TalibNo ratings yet

- Addis Ababa Science and Technology University: College of Electrical and Mechanical EngineeringDocument10 pagesAddis Ababa Science and Technology University: College of Electrical and Mechanical EngineeringEskiasNo ratings yet

- Control Valves in Process PlantDocument8 pagesControl Valves in Process Plantmukramah.yusufNo ratings yet

- HD 191 Bladder TankDocument5 pagesHD 191 Bladder TankPiyush JainNo ratings yet

- Pipe Friction LossDocument6 pagesPipe Friction LossHoongNo ratings yet

- Piping Plans Pocket Guide HorizontalDocument49 pagesPiping Plans Pocket Guide Horizontalmuho1No ratings yet

- Method Statement For Replacing Ball ValveDocument3 pagesMethod Statement For Replacing Ball Valveamg007100% (3)

- IVPL Control Valve Sizing ManualDocument20 pagesIVPL Control Valve Sizing ManualGanesh YadavNo ratings yet

- Control Valve PresentationDocument61 pagesControl Valve PresentationDhanny Miharja100% (1)

- Department of Mechatronics and Control Engineering University of Engineering and Technology, LahoreDocument34 pagesDepartment of Mechatronics and Control Engineering University of Engineering and Technology, LahoreEman FatimaNo ratings yet

- Mechanical Seal Piping PlansDocument56 pagesMechanical Seal Piping Plansaltieri1100% (2)

- 4TH Class Part B Review QuestionsDocument14 pages4TH Class Part B Review QuestionsCalvin Jude GoveiaNo ratings yet

- Engineering Technical Bulletins: Selecting Valves and Piping CoilsDocument4 pagesEngineering Technical Bulletins: Selecting Valves and Piping Coilsforevertay2000No ratings yet

- Cilindros GriffcoDocument1 pageCilindros GriffcoRobert ClavijoNo ratings yet

- BOPs and Their ControlDocument59 pagesBOPs and Their ControlYoun Seok Choi100% (1)

- BOPs and Their ControlDocument59 pagesBOPs and Their Controlelflaco79No ratings yet

- Control Valve2Document20 pagesControl Valve2Roshny PFNo ratings yet

- Specification 2012 Part 1 Water Supply Tube Wellsand Sewerage 10 May 2012Document250 pagesSpecification 2012 Part 1 Water Supply Tube Wellsand Sewerage 10 May 2012Ramachandra SahuNo ratings yet

- Pump Seal PlansDocument56 pagesPump Seal PlansKwang Je LeeNo ratings yet

- Utilities: Plumbing Answer KeyDocument10 pagesUtilities: Plumbing Answer KeyLouie Xannel Medina100% (2)

- Flow Coefficient DefinitionDocument62 pagesFlow Coefficient DefinitionPraful PatilNo ratings yet

- REPORTpp 1Document16 pagesREPORTpp 1gajulavamshikrishna02No ratings yet

- LOGICOSDocument82 pagesLOGICOSManoloEskobarNo ratings yet

- PARCOL HB ControlValve Sizing 2013Document24 pagesPARCOL HB ControlValve Sizing 2013gion_ro401100% (1)

- API Plans - FlowserveDocument66 pagesAPI Plans - FlowserveJosé Alberto Herrera100% (2)

- 02 110 Foam Bladder TankDocument6 pages02 110 Foam Bladder Tankarachman297988No ratings yet

- Hydraulic CircuitsDocument61 pagesHydraulic Circuitshamidou100% (2)

- S001-13 Installation SchemeDocument4 pagesS001-13 Installation SchemeJoe JohnsonNo ratings yet

- Hydraulic CalculationB1Document8 pagesHydraulic CalculationB1Abhay BhoirNo ratings yet

- Selection Control ValvesDocument7 pagesSelection Control ValvesVeera Mani100% (1)

- FM Lab ManualDocument9 pagesFM Lab ManualAbhimanyu Singh BhatiNo ratings yet

- Dosing Pots: SpecificationDocument3 pagesDosing Pots: SpecificationMohamed AdelNo ratings yet

- CPE562 Chemical Process Control: Homework #1 Process & Instrumentation DiagramDocument7 pagesCPE562 Chemical Process Control: Homework #1 Process & Instrumentation DiagramSaber Minato AzrulNo ratings yet

- API Mechanical Seal Piping Plan Booklet LORES 4C MAR2016Document90 pagesAPI Mechanical Seal Piping Plan Booklet LORES 4C MAR2016Kamlesh Kamlesh Etwaro100% (1)

- Lab ReportDocument23 pagesLab ReportAmy Farhana100% (1)

- Process Presentation Shell and Tube Heat Exchanger GalfarDocument84 pagesProcess Presentation Shell and Tube Heat Exchanger GalfarKishore SakhileNo ratings yet

- Ms NF992Document2 pagesMs NF992Oscar SalazarNo ratings yet

- EKK ProductsDocument3 pagesEKK ProductsOscar SalazarNo ratings yet

- EAGLE Mechanical Seals: Stationary Mounted, High Temperature, Edge Welded Metal Bellows SealDocument2 pagesEAGLE Mechanical Seals: Stationary Mounted, High Temperature, Edge Welded Metal Bellows SealOscar SalazarNo ratings yet

- Ms LB500Document2 pagesMs LB500Oscar SalazarNo ratings yet

- EAGLE Mechanical Seals: Rotating Outside Mount SealDocument2 pagesEAGLE Mechanical Seals: Rotating Outside Mount SealOscar SalazarNo ratings yet

- Ms MA240Document2 pagesMs MA240Oscar Salazar100% (1)

- Ms LA200Document2 pagesMs LA200Oscar SalazarNo ratings yet

- Engineering Guide For Bearing SelectionDocument7 pagesEngineering Guide For Bearing Selectionpetar2001No ratings yet

- SKF Roller Bearing CatalogueDocument452 pagesSKF Roller Bearing CatalogueDarpanrshah67% (3)

- EAGLE Mechanical Seals: Bi-Directional, Single Coil Spring SealDocument2 pagesEAGLE Mechanical Seals: Bi-Directional, Single Coil Spring SealOscar SalazarNo ratings yet

- EKK ProductsDocument3 pagesEKK ProductsOscar SalazarNo ratings yet

- API 682 Qualification Mechanical Seal: Type A Seal Type B Seal Type C SealDocument1 pageAPI 682 Qualification Mechanical Seal: Type A Seal Type B Seal Type C SealOscar SalazarNo ratings yet

- Ms BA600Document2 pagesMs BA600Oscar SalazarNo ratings yet

- Ms EK777Document2 pagesMs EK777Oscar SalazarNo ratings yet

- Lubrication SelectionDocument11 pagesLubrication Selectionjr110livecomNo ratings yet

- Wastewater BrochureDocument8 pagesWastewater BrochureOscar SalazarNo ratings yet

- Why Buy This Bearing For Another 90 Years 4813 EDocument0 pagesWhy Buy This Bearing For Another 90 Years 4813 EOscar SalazarNo ratings yet

- Extra ToughDocument2 pagesExtra ToughOscar SalazarNo ratings yet

- Water Pump BearingsDocument11 pagesWater Pump BearingsOscar SalazarNo ratings yet

- 32 SHQ ASG 282 Industrial Solutions Selector Guide 200904 85Document43 pages32 SHQ ASG 282 Industrial Solutions Selector Guide 200904 85Oscar SalazarNo ratings yet

- CorrosionDocument16 pagesCorrosionOscar SalazarNo ratings yet

- Bullet Point: Nippon Pillow Block Co., LTDDocument2 pagesBullet Point: Nippon Pillow Block Co., LTDOscar SalazarNo ratings yet

- SKF Shaft SealDocument379 pagesSKF Shaft Sealsatish_trivediNo ratings yet

- Nema Abcde Torque Curves PDFDocument2 pagesNema Abcde Torque Curves PDFvtadlimbekarNo ratings yet

- SKF 361202 RDocument1 pageSKF 361202 ROscar SalazarNo ratings yet

- 266433Document3 pages266433Oscar SalazarNo ratings yet

- 260661Document90 pages260661Oscar SalazarNo ratings yet

- Products Guide: Europe Middle East Africa AmericasDocument59 pagesProducts Guide: Europe Middle East Africa AmericasOscar SalazarNo ratings yet

- Rolamentos EquivalenciasDocument102 pagesRolamentos EquivalenciasniceajpaNo ratings yet

- Design and Development of Centrifugal Pump ImpellerDocument7 pagesDesign and Development of Centrifugal Pump ImpellerSindhurNo ratings yet

- CE8394 Fluid Mechanics and Machinary PDFDocument80 pagesCE8394 Fluid Mechanics and Machinary PDF18M129 Manjeeth SNo ratings yet

- Filter Oil Comressor BaruDocument1 pageFilter Oil Comressor BaruSyahrul SaputraNo ratings yet

- Compressible FlowDocument50 pagesCompressible FlowBazil BoliaNo ratings yet

- Venturi MeterDocument5 pagesVenturi Meterashok pradhanNo ratings yet

- On GLOBE VALVEDocument22 pagesOn GLOBE VALVEAditya AcharyaNo ratings yet

- 7a. Steel Pipeline FittingDocument37 pages7a. Steel Pipeline Fittingamaliabdulkader100% (1)

- Howell Bunger Valve 05 HBGR Text New Cover PDFDocument4 pagesHowell Bunger Valve 05 HBGR Text New Cover PDFRoger Labra LlanoNo ratings yet

- Ansi B16.9-16.28-MSS SP-43Document3 pagesAnsi B16.9-16.28-MSS SP-43vangie3339515No ratings yet

- Fundamentals of Fluid Mechanics: Chapter 8: Flow in PipesDocument92 pagesFundamentals of Fluid Mechanics: Chapter 8: Flow in Pipesintern kncesbNo ratings yet

- Hydraulics ReviewerDocument3 pagesHydraulics ReviewerRalph CastilloNo ratings yet

- SVT - Casting Valve-Compressed PDFDocument32 pagesSVT - Casting Valve-Compressed PDFHoang Mai HoaNo ratings yet

- Ship Fuel Oil CalculationDocument84 pagesShip Fuel Oil Calculation123habib123fikri92% (12)

- Pressure Testing Requirements For Valves CBD-P-07 Rev.00Document9 pagesPressure Testing Requirements For Valves CBD-P-07 Rev.00SDP02100% (1)

- 2d - RS Rotary Air Blower PDFDocument6 pages2d - RS Rotary Air Blower PDFHoàn Đức VinhNo ratings yet

- Gradually Varied FlowDocument37 pagesGradually Varied Flowprashanthreddyh100% (2)

- Inspection of Relief DevicesDocument50 pagesInspection of Relief Deviceslpatarroyo55783% (6)

- Paraller Gate Valves CatalogueDocument37 pagesParaller Gate Valves CataloguesizmaruNo ratings yet

- Lecture Mod 3Document15 pagesLecture Mod 3amlan sahuNo ratings yet

- Re90010 06 - 2016 07Document1,284 pagesRe90010 06 - 2016 07Sergio Reyes100% (1)

- PIP IPS Irrigation FittingsDocument1 pagePIP IPS Irrigation FittingsByron RodasNo ratings yet

- Testing and Evaluation of The Vertical Fire Sprinkler System Located at The Sevice BuildingDocument17 pagesTesting and Evaluation of The Vertical Fire Sprinkler System Located at The Sevice BuildingMarc Danielle G Josue IINo ratings yet

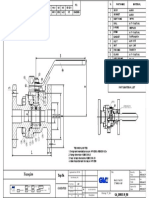

- Ball Valves - 2 Inch - Class 300 - A105N - RF ItaliaDocument1 pageBall Valves - 2 Inch - Class 300 - A105N - RF Italialion100_saadNo ratings yet

- Instructions: High Pressure Float Valve Régulateur Modulant de Niveau Haute Pression HFIDocument4 pagesInstructions: High Pressure Float Valve Régulateur Modulant de Niveau Haute Pression HFIcaovadio88No ratings yet

- HWG - Boq-1Document13 pagesHWG - Boq-1Prashant Singh ChauhanNo ratings yet

- Fluid Mechanics ManualDocument45 pagesFluid Mechanics ManualJm CayapasNo ratings yet

- Air CompressorDocument7 pagesAir CompressorYemaneDibetaNo ratings yet

- Piping Engineering Note Nitrogen Purge SystemDocument20 pagesPiping Engineering Note Nitrogen Purge SystemchrysanthiiiiiiNo ratings yet

- FMDUDocument5 pagesFMDUJoão Vitor Apolinário FerreiraNo ratings yet

- Valmatic - Sure Seal Foot ValvesDocument2 pagesValmatic - Sure Seal Foot ValvesKayrol AmryNo ratings yet