Professional Documents

Culture Documents

Aliaje Aluminiu En-Aw

Uploaded by

Marius OlteanuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aliaje Aluminiu En-Aw

Uploaded by

Marius OlteanuCopyright:

Available Formats

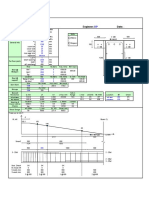

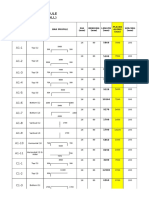

ALLOY

GENERAL INFORMATION

MECHANICAL PROPERTIES Min ultimate tensile strength (Mpa) Wall thickness A50 % min. Rp 0.2 min (Mpa)

E X T R U S I O N C AP A B I L I T Y Solid profiles Max profile diameter 90 mm 180 mm 180 mm 180 mm 180 mm 180 mm 180 mm 180 mm 90 mm 90 mm 90 mm

EU-code (EN 755)

Characteristic properties

Applications

Condition

EN AW-2024 (AlCu4Mg1)

High strength alloy, high fatigue strength

High strength fabricated or machined items in aircraft industries, general engineering, machinery, military equipment Heat exchangers, air condition evaporators, motor vehicle radiators

2024-O (H111) 2024-T3 , T3510 en T3511 2024-T8 , T8510 en T8511

All max. 250 max. 150 <15 395 290 15<e<50 420 290 <50 455 380

10 6 4

Yes

EN AW-3003 (AlMg1Cu)

Good mechanical properties, chemical resistant, good formability

3003-F

All

95

35

20

Yes

6005A-T4 Solid 6005A-T6 Solid EN AW-6005A (AlSiMg(A)) Good cold formability especially in temper T4, in T6 not recommended. Electrical and mechanical precision industries, structural engineering 6005A-T6 Solid 6005A-T4 Hollow 6005A-T6 Hollow 6060-T4 Very good weldability. Good cold Linear Motion, Heat sink sections, formability especially in temper T4. Electronic modules, Flexible Medium strength heat treatable alloy with assembly systems, special a strength slightly lower than 6005A. machinery elements, pneumatic Medium fatigue strength. Commonly used cilinders. Radiator and other heat alloy for very complex cross sections. exchanger applications. 6060-T5 6060-T6 6060-T64 6060-T66 6063-T4 Linear Motion, Heat sink sections, Electronic modules, Flexible assembly systems, special Good cold formability especially in temper T4, in T6 not recommended. machinery elements, pneumatic cilinders. Radiator and other heat exchanger applications. 6063-T5 6063-T6 6063-T64 6063-T66 6063A-T4 6063A-T5 6063A-T6

25 5 5<e10 10<e25 10 5 5<e15 25 5 5<e25 3 3<e25 15 3 3<e25 25 3 3<e25 10 10<e25 15 10 10<e25 25 <10 10<e25 10 10<e25 25 5

180 270 260 250 180 255 250 120 160 140 190 170 180 215 195 130 175 160 215 195 180 245 225 150 200 190 230 220 180 260 260 Max 160 205 270 290 310 Max 160 205 290 310 350

90 225 215 200 90 215 200 60 120 100 150 140 120 160 150 65 130 110 170 160 120 200 180 90 160 150 190 180 110 240 240 Max 110 110 230 250 260 Max 110 110 250 260 290

13 6 6 6 13 6 6 14 6 6 6 6 10 6 6 12 6 5 6 6 10 6 6 10 5 4 5 4 13 7 8 12 12 6 6 8 12 12 6 8 8

Yes

EN AW-6060 (AlMgSi)

Yes

EN AW-6063 (AlMg0.7Si)

Yes

EN AW-6063A (AlMg0.7Si)

Linear Motion, Heat sink sections, Electronic modules, Flexible assembly systems, special Good cold formability especially in temper T4, in T6 not recommended. machinery elements, pneumatic cilinders. Radiator and other heat exchanger applications.

Yes

6061-T4 EN AW-6061 (AlMg1SiCu) Good cold formability in the temper T4, in Transportation, boiler making, T6 not recommended, not suitable for aerospace applications, helicopter very complex cross sections rotor blades

Yes

6061-T6 5<e25 6082-O (H111) Solid 6082-T4 Solid 6082-T5 Solid 6082-T6 Solid 6082-O (H111) Hollow 6082-T4 Hollow 6082-T6Hollow All 25 5 5 5<e25 All 25 <5 5<e15 40

EN AW-6082 (AlSi1MgMn)

Alloy with a strength somewhat higher than 6061. Medium high fatigue strength. Not suitable for complex sections. Good Flanges, hydraulic systems, cold formability in T4 temper after a nuclear technology, general high stabilizing heat treatment. Very good strength constructions corrosion resistance. Very good weldability. Good machinability.

Yes

EN AW -7020 (AlZn4.5Mg1)

Good welding, high fatigue strength

Dynamic constructions, Military applications

7020-T6

Yes

EN AW -7022 (AlZn5Mg3Cu)

Simular to AW 7075

Hydraulics, machine constructions

7022-T6 , T6510 en T6511

30

490

420

Yes

Yes, Technical discussion required Yes, Technical discussion required

EN AW -7075 (AlZn5.5MgCu)

Very high fatigue strength. Joining preferably by rivets, adhesives or screws

Aircraft and military highly stressed structural components

7075-T6 , T6510 en T6511 7075-T73 , T73510 en T73511

25 25<e60 25

530 540 485

460 470 420

4 5 Yes

For these ranges of wall thickness, the mechanical values and achievable tolerances are in conflict. Detailed technical discussion is needed to balance these two parameters. Rev. 5 / 26-7-2006 Rev. 4 / 20-6-2006 Rev. 3 / 9-5-2006 Rev. 2 / 8-11-2005 Rev. 1 / 25-8-2005

Hollow profiles No Yes Yes Yes Yes Yes Yes Yes Yes

You might also like

- 1 Ghansavangi DrawingDocument7 pages1 Ghansavangi Drawingunity.cempNo ratings yet

- Straight Shell D-1.0 & 0.7 M-LDocument1 pageStraight Shell D-1.0 & 0.7 M-LDeep SherawatNo ratings yet

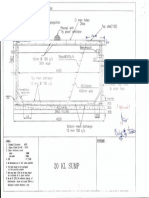

- 20 KL Sump: NW: - Providing Water Supply SchemeDocument1 page20 KL Sump: NW: - Providing Water Supply SchemeRaghavendra Kanigiri100% (1)

- Prima Catalouge 6 Pgs-MinDocument6 pagesPrima Catalouge 6 Pgs-MinVarun KapoorNo ratings yet

- 11018M Low Hydrogen RodsDocument1 page11018M Low Hydrogen Rodsjhax90No ratings yet

- Street Light Pole-Layout1 A3Document1 pageStreet Light Pole-Layout1 A3surveyargtNo ratings yet

- Stal S700 - Porownanie - 10-Hillong-Milan-VeljkovicDocument30 pagesStal S700 - Porownanie - 10-Hillong-Milan-VeljkovicAdam WoźniakNo ratings yet

- Max-E1 MotorDocument6 pagesMax-E1 MotorDavidGomezNo ratings yet

- Catalogue GUNUNG GARUDADocument40 pagesCatalogue GUNUNG GARUDAhendrobama50% (2)

- 64-2103 Tweco Mini Mig 160 AmpDocument1 page64-2103 Tweco Mini Mig 160 AmpcarlosNo ratings yet

- Spray Master: 250 Amp MIG GunDocument1 pageSpray Master: 250 Amp MIG GunLeonardo Martínez LópezNo ratings yet

- High Current Fuses: Mega and MEGA Clear Top Fuse Rated 32VDocument2 pagesHigh Current Fuses: Mega and MEGA Clear Top Fuse Rated 32VAliNo ratings yet

- Cable Fibra Óptica Trimerx: Ducto Armado LSZH GyztzwDocument1 pageCable Fibra Óptica Trimerx: Ducto Armado LSZH GyztzwDavid E. I. GallardoNo ratings yet

- Welding Rod SelectionDocument1 pageWelding Rod Selectionbikas_sahaNo ratings yet

- Electrode SelectionDocument1 pageElectrode SelectionVijayabaraniNo ratings yet

- Electrode SelectionDocument1 pageElectrode SelectionRachel ThompsonNo ratings yet

- GS Plasto 4F-2021Document1 pageGS Plasto 4F-2021Mojtaba HashimNo ratings yet

- RF1000-R2, AISI316, FRAME AISI304 Main DWG, Rf1000: General Tolerances Scale ProductDocument1 pageRF1000-R2, AISI316, FRAME AISI304 Main DWG, Rf1000: General Tolerances Scale ProducthazemNo ratings yet

- 375 V EuromapDocument10 pages375 V Euromapdeadskinmask666No ratings yet

- Fibra Optica-Ducto Armado LSZH GYXTWDocument1 pageFibra Optica-Ducto Armado LSZH GYXTWJuan Espinosa RomeroNo ratings yet

- Zener Barrier: 2002 IS CatalogDocument1 pageZener Barrier: 2002 IS CatalogabcNo ratings yet

- EN 96 GigaLine A-DQ (ZN) B2Y OM4 Stranded 5000N BK LKD8AA70K110000Document2 pagesEN 96 GigaLine A-DQ (ZN) B2Y OM4 Stranded 5000N BK LKD8AA70K110000sehaad.ijmyouNo ratings yet

- Littelfuse MEGA DatasheetDocument2 pagesLittelfuse MEGA DatasheetVIKASNo ratings yet

- Properties of Common Spring MaterialsDocument2 pagesProperties of Common Spring MaterialsArnaldo Morbid CruzNo ratings yet

- Jis G 3539 SWCH 10aDocument1 pageJis G 3539 SWCH 10asujiyopptsrNo ratings yet

- Worshop RecommendationsDocument25 pagesWorshop RecommendationsEnoc Andrade100% (1)

- 234 Series,: 5×20 MM Medium-Acting 234 SeriesDocument3 pages234 Series,: 5×20 MM Medium-Acting 234 SeriesalexanderNo ratings yet

- Selection of Materials For WeldingDocument1 pageSelection of Materials For WeldingmohammedetaNo ratings yet

- MECHANICAL PROPERTIES of TitaniumDocument6 pagesMECHANICAL PROPERTIES of TitaniumAmr FawzyNo ratings yet

- Arosta309H EngDocument1 pageArosta309H Engrusf123No ratings yet

- 156 O Legato Interlock Foot Block 1600 X 800 X 800Document1 page156 O Legato Interlock Foot Block 1600 X 800 X 800BogdanBNo ratings yet

- Selection of Materials For WeldingDocument1 pageSelection of Materials For WeldingIshwarNo ratings yet

- Manual Book Mesin Series 2500.PDF-1Document18 pagesManual Book Mesin Series 2500.PDF-1Sulaim Al KautsarNo ratings yet

- PM Motor: Reference CharacteristicsDocument1 pagePM Motor: Reference CharacteristicsJaime Adolfo Mejia LeónNo ratings yet

- C-1/2Mo 1/2Cr-1/2Mo 1Cr-1/2Mo 1 1/4Cr-1/2Mo 2 1/4Cr-1Mo 5Cr-1/2Mo 7Cr-1/2Mo 9Cr-1Mo 9Cr-1Mo-1/4V-0.4Ni 11Cr 12Cr 13Cr 17CrDocument1 pageC-1/2Mo 1/2Cr-1/2Mo 1Cr-1/2Mo 1 1/4Cr-1/2Mo 2 1/4Cr-1Mo 5Cr-1/2Mo 7Cr-1/2Mo 9Cr-1Mo 9Cr-1Mo-1/4V-0.4Ni 11Cr 12Cr 13Cr 17CrmohamedNo ratings yet

- MEHLER Technical Datasheet Conveyor Belt FabricsDocument1 pageMEHLER Technical Datasheet Conveyor Belt FabricsQC OWIT BalamuruganNo ratings yet

- Material With Electrode SelectionDocument3 pagesMaterial With Electrode SelectionpmkarNo ratings yet

- Sensata Gigavac Mx16 Series Open Contactors Datash-3077712Document4 pagesSensata Gigavac Mx16 Series Open Contactors Datash-3077712Dragan M.No ratings yet

- Welding Rod Selection PDFDocument1 pageWelding Rod Selection PDFBalasubramanian RasuNo ratings yet

- Toolox 44 DatenblattDocument4 pagesToolox 44 DatenblattJosevi Jiménez MerinoNo ratings yet

- Safety and Service News PDFDocument29 pagesSafety and Service News PDFRafik MessaNo ratings yet

- Concrete A2Document1 pageConcrete A2Darshan ShahNo ratings yet

- General Description: % Ir Min (S) Max (S)Document1 pageGeneral Description: % Ir Min (S) Max (S)muhammetNo ratings yet

- Max-Rnpp-Smaw001 - C17Document5 pagesMax-Rnpp-Smaw001 - C17Md. Sahabul IslamNo ratings yet

- Tig - Mig Welding ConsumablesDocument2 pagesTig - Mig Welding ConsumablesandyhaggerNo ratings yet

- 2013 04 Fujitsu Primergy RoadmapDocument52 pages2013 04 Fujitsu Primergy RoadmapAnonymous YLI2wFNo ratings yet

- Diodos Zener 1N746-1N759 1N957A-1N986A 1N4370-1N4372 (Motorola)Document6 pagesDiodos Zener 1N746-1N759 1N957A-1N986A 1N4370-1N4372 (Motorola)Grover Condori JimenezNo ratings yet

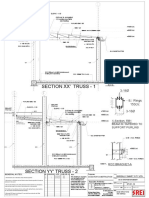

- Drawing of Truss Shed 2Document2 pagesDrawing of Truss Shed 2Rohit SinghNo ratings yet

- 64-2103 Tweco Tuff N Lite MigDocument2 pages64-2103 Tweco Tuff N Lite MigcarlosNo ratings yet

- How To Select ElectrodeDocument2 pagesHow To Select Electrodesbmmla100% (1)

- 600 Shape DIA LengthDocument1 page600 Shape DIA LengthImranuddin SyedNo ratings yet

- Concrete Beam DesignDocument4 pagesConcrete Beam DesignpetersiglosNo ratings yet

- Dextra Tunnel Soft EyeDocument44 pagesDextra Tunnel Soft EyeShahin ShajahanNo ratings yet

- F C-Mo: C: AWS SFA 5.28 W P ER70S-A1 H, F, Vu, Oh CDocument1 pageF C-Mo: C: AWS SFA 5.28 W P ER70S-A1 H, F, Vu, Oh CAshok RajNo ratings yet

- Ce 5Document1 pageCe 5Cyril AleaNo ratings yet

- 10KL Sump DrawingDocument1 page10KL Sump DrawingAbdul Mateen MahammadNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- BCM Lift SlabDocument1 pageBCM Lift SlabSanchita JhaNo ratings yet

- SANY - SCC 800C - 80 TDocument17 pagesSANY - SCC 800C - 80 TAnonymous VqTus7QAwNo ratings yet

- Thermal Properties of Nanomaterials and Nanocomposites: T. Savage and A. M. RaoDocument2 pagesThermal Properties of Nanomaterials and Nanocomposites: T. Savage and A. M. RaoPradeep Kumar ReddyNo ratings yet

- Construction Quality Assurance Workplan PDFDocument84 pagesConstruction Quality Assurance Workplan PDFFadi AlabdullahNo ratings yet

- Lubrication Cross Reference ChartDocument1 pageLubrication Cross Reference ChartmountaineerjdmNo ratings yet

- Fabrication of U-Type, V-Type, L-Type Angle Bending MachineDocument74 pagesFabrication of U-Type, V-Type, L-Type Angle Bending MachineCrispNo ratings yet

- In Memoriam: Heinz Isler - IASSDocument2 pagesIn Memoriam: Heinz Isler - IASSkatsiboxNo ratings yet

- Fbr-Arzatoare-Gaz-Gas p70 2 100 2 150 2 GBDocument1 pageFbr-Arzatoare-Gaz-Gas p70 2 100 2 150 2 GBAvacaritei Munteanu DanNo ratings yet

- NSCP Definition of TermsDocument25 pagesNSCP Definition of TermsArch Edwin DuazoNo ratings yet

- VICO 2023 Design ChairDocument23 pagesVICO 2023 Design ChairOki Rohadi PurwantoNo ratings yet

- CH 14 - Integrated Logistics Support (Rev 20 Apr 11)Document40 pagesCH 14 - Integrated Logistics Support (Rev 20 Apr 11)matchutNo ratings yet

- Load Testing, Inspection of Cranes, Lifting Gears and AppliancesDocument5 pagesLoad Testing, Inspection of Cranes, Lifting Gears and Applianceseddie2166100% (1)

- IccpDocument8 pagesIccpanbu19101977No ratings yet

- Pennar - Decking Profile-REPLYDocument3 pagesPennar - Decking Profile-REPLYkushaljp8989No ratings yet

- Abb MVDocument66 pagesAbb MVHansika RajapakshaNo ratings yet

- Embedded System: Shibu K VDocument40 pagesEmbedded System: Shibu K Vvishal_16278No ratings yet

- Ujjain GuideLineReport 2018201943101 ENGLISH GuidelineFullDocument824 pagesUjjain GuideLineReport 2018201943101 ENGLISH GuidelineFullaki4u67% (3)

- Ce 405 Doe CompleteDocument13 pagesCe 405 Doe CompleteJed Christian Dagatan MedranoNo ratings yet

- RF400FCUMDocument216 pagesRF400FCUMRoodoolfoRucoobaTovarNo ratings yet

- Elec TFC 45 Serial 171 CR106487 - GBDocument61 pagesElec TFC 45 Serial 171 CR106487 - GBmliugong100% (1)

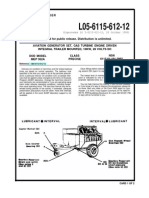

- Lo5-6115-612-12 Mep-362aDocument2 pagesLo5-6115-612-12 Mep-362aAdvocate50% (2)

- Shock AbsorberDocument28 pagesShock AbsorberwasundesagarNo ratings yet

- Installation Instructions: Analogue Instruments - Sealed and Ruggedised Meters 08X SeriesDocument2 pagesInstallation Instructions: Analogue Instruments - Sealed and Ruggedised Meters 08X SeriesMauricio GuanellaNo ratings yet

- SR EN 1993 1 6 - NA - 2011 enDocument9 pagesSR EN 1993 1 6 - NA - 2011 enACSNo ratings yet

- Inclinometer Digitilt Vertical Inclinometer Probe DatasheetDocument2 pagesInclinometer Digitilt Vertical Inclinometer Probe Datasheetapi-3706095No ratings yet

- Bar Bending Schedule Pit Area (Slab & Wall)Document51 pagesBar Bending Schedule Pit Area (Slab & Wall)jebrijaNo ratings yet

- YYC Rack CatalogDocument22 pagesYYC Rack Catalogyzmouse100% (1)

- Sika PDS - E - Sikagard - 715 WDocument2 pagesSika PDS - E - Sikagard - 715 Wlwin_oo2435No ratings yet

- 359 Graphite Sheet: Maximum TemperatureDocument1 page359 Graphite Sheet: Maximum TemperatureDaniel MendozaNo ratings yet