Professional Documents

Culture Documents

Gear Force & Stress4

Uploaded by

Gthulasi78Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gear Force & Stress4

Uploaded by

Gthulasi78Copyright:

Available Formats

AGMA Surface Strength Equation

Sfc is the allowable contact stress, psi CL is the surface-life factor CT is the temperature factor (same as KT) CR is the reliability factor (same as KR) CH is the hardness ratio factor Hardness ratio factor, CH CH should only be used for the gear design, for pinion design set CH equal to 1.0.

Ken Youssefi

Mechanical Engineering Dept.

20

AGMA Surface Strength Equation

Pitting resistance stress cycle factor ZN

Ken Youssefi

Mechanical Engineering Dept.

21

AGMA Surface Strength Equation

AGMA allowable surface fatigue strength

Ken Youssefi

Mechanical Engineering Dept.

22

AGMA Spur Gear Design Equations

Surface strength design equation, Stress = strength

Design steps

Calculate the transmitted load Select material, start with grade 1 with low hardness. Select standard full depth gears with pressure angle of 20o or 25o. Choose a face width, dP F dP Decide on: load type (uniform, non-uniform), mounting accuracy, # of cycles to failure, gear quality and reliability. Solve the design equation for the diameter. Or, select diameter and solve for material.

Ken Youssefi Mechanical Engineering Dept.

Outcome is Diameter and material

23

AGMA Spur Gear Design Equations

Bending strength design equation

Design steps

Assume a value for J (geometry factor), .35 to .45 Solve the design equation to obtain the diametral pitch, Pd Calculate the number of teeth for pinion and gear, determine the actual J and check against the assumed one, iterate if needed. The number of teeth on the pinion should be over 18 to avoid interference. For power transmission, 2 < Pd (diametral pitch) < 16 Iterate until optimum design is achieved.

Outcome is Diametral pitch, P

24

Ken Youssefi

Mechanical Engineering Dept.

You might also like

- C ClampDocument26 pagesC Clamparulmurugu100% (4)

- ch09 3Document155 pagesch09 3abdallah ghannamNo ratings yet

- Chapter 9 Spur Gear DesignDocument31 pagesChapter 9 Spur Gear DesignRamesh Martha100% (1)

- Gear Force & StressDocument30 pagesGear Force & StressRanjeethkumar JalalNo ratings yet

- Pitting Resistance Rating in AGMA, ISO and BSDocument8 pagesPitting Resistance Rating in AGMA, ISO and BSVarundeep Merugu NethaNo ratings yet

- Gear Force & Stress 7Document4 pagesGear Force & Stress 7gthulasi787126No ratings yet

- Machine Elements 3-Spur Gears 3Document26 pagesMachine Elements 3-Spur Gears 3Prayogi FajarNo ratings yet

- Gear AnalysisDocument33 pagesGear AnalysisRob Morien100% (1)

- NU Hammer TestDocument12 pagesNU Hammer Testraju_420034520No ratings yet

- Spur GearsDocument13 pagesSpur GearsRoshan ShanmughanNo ratings yet

- Solanki (2015) - Weight Optimization in Crane HookDocument5 pagesSolanki (2015) - Weight Optimization in Crane HookGogyNo ratings yet

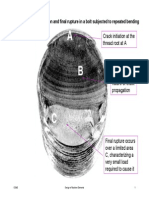

- Fatigue Failure Is Characterized by Three StagesDocument48 pagesFatigue Failure Is Characterized by Three Stagesankit_agechaniaNo ratings yet

- Design Spur Gear Study Material LectDocument6 pagesDesign Spur Gear Study Material Lectprashant mishraNo ratings yet

- ME364-04 Spur Helical GearsDocument51 pagesME364-04 Spur Helical Gearsqaps lrkNo ratings yet

- Design Optimization of Spur Gear Using SA and RCGADocument8 pagesDesign Optimization of Spur Gear Using SA and RCGAs d pavan kumarNo ratings yet

- Gear Agma IIDocument49 pagesGear Agma IInathNo ratings yet

- ME364-04 Spur Helical GearsDocument67 pagesME364-04 Spur Helical GearsPuBg PrONo ratings yet

- MEM201 L6-Tolerance RCDocument82 pagesMEM201 L6-Tolerance RCNizar Pratama PutraNo ratings yet

- Optimum Design of A Subsonic Axial - Ow Compressor Stage: Applied EnergyDocument9 pagesOptimum Design of A Subsonic Axial - Ow Compressor Stage: Applied EnergyOnnuri WonNo ratings yet

- Rigid Pavement Design1Document21 pagesRigid Pavement Design1s100% (1)

- Chapter 2. Limits, Tolerance and Fits - RevisedDocument44 pagesChapter 2. Limits, Tolerance and Fits - RevisedNguyễn Sĩ CườngNo ratings yet

- MEM201 L6-Tolerance RCDocument31 pagesMEM201 L6-Tolerance RCKaliya PerumalNo ratings yet

- Chapter 7 - MachiningDocument96 pagesChapter 7 - MachiningTejkumarigurungNo ratings yet

- Spur GearDocument107 pagesSpur GearMuhammadUmairShafiqNo ratings yet

- Factores Esfuerzo EngranesDocument19 pagesFactores Esfuerzo EngranesRodrigo ValdezNo ratings yet

- Formula Book For Structural Analysis-TC50312EDocument43 pagesFormula Book For Structural Analysis-TC50312EAbhiraj PatilNo ratings yet

- Tension Part-2 and CompressionDocument42 pagesTension Part-2 and Compressionsyed muneeb haiderNo ratings yet

- DTS Presentation 2 BearingsDocument14 pagesDTS Presentation 2 BearingsYashraj RathiNo ratings yet

- Symbol RMDocument7 pagesSymbol RMSiti MaimunahNo ratings yet

- Spur and Helical Gear DesignDocument45 pagesSpur and Helical Gear Designkibromgidey12No ratings yet

- Experiment No 10 - Exercises in Preparation of Detailed Production DrawingsDocument29 pagesExperiment No 10 - Exercises in Preparation of Detailed Production DrawingsS S PatilNo ratings yet

- GD&TDocument31 pagesGD&TgopojiNo ratings yet

- Common Terms Used:: Bevel, Worm and Cross Helical GearsDocument15 pagesCommon Terms Used:: Bevel, Worm and Cross Helical GearsSurulivelrajantNo ratings yet

- Virtual Joist Girder PPDocument77 pagesVirtual Joist Girder PPgeorgelennon68No ratings yet

- Major Design Project Brief 2017Document6 pagesMajor Design Project Brief 2017Dilshan JayasuriyaNo ratings yet

- AleatorioDocument19 pagesAleatorioLucas Araujo de AlmeidaNo ratings yet

- Chapter 4 Steel (23-24)Document52 pagesChapter 4 Steel (23-24)nyankyalps5No ratings yet

- Chapter 4 SteelDocument52 pagesChapter 4 SteelHtet Myat AungNo ratings yet

- Design Philosophy, Tension Member Design L2V1Document37 pagesDesign Philosophy, Tension Member Design L2V1November RainNo ratings yet

- AVP Catalog 3Document121 pagesAVP Catalog 3Antonio CaballeroNo ratings yet

- Fatigue FailureDocument47 pagesFatigue FailureOmar KhanNo ratings yet

- Virtual Joist Girder PP 091912Document77 pagesVirtual Joist Girder PP 091912Fasteel ConstruccionesNo ratings yet

- SMEA1601Document91 pagesSMEA1601Aashrith VNo ratings yet

- Design Optimization of Friction Clutch: K Tripathi, Member DR M D Agrawal, FellowDocument5 pagesDesign Optimization of Friction Clutch: K Tripathi, Member DR M D Agrawal, FellowmeameyaNo ratings yet

- Multi Variable Optimization of Surface Grinding Process Using Genetic AlgorithmDocument10 pagesMulti Variable Optimization of Surface Grinding Process Using Genetic AlgorithmTJPRC PublicationsNo ratings yet

- QC Beton KerasDocument3 pagesQC Beton KerasAdityo Budi UtomoNo ratings yet

- Introduction & Analysis of Members: Design of PSC ElementsDocument42 pagesIntroduction & Analysis of Members: Design of PSC ElementsNaveen Gowda k sNo ratings yet

- Geometry Design Model of A Precise Form-Milling Cutter Based On The Machining CharacteristicsDocument16 pagesGeometry Design Model of A Precise Form-Milling Cutter Based On The Machining Characteristicschoprarun100% (1)

- Spur Gear DesignDocument51 pagesSpur Gear Designmshebbal2212100% (1)

- Cps First ReviewDocument11 pagesCps First ReviewRavi MaggidiNo ratings yet

- Gear Reducers: Design Notes For Course Project On Gear Reducer DesignDocument60 pagesGear Reducers: Design Notes For Course Project On Gear Reducer DesignronkabtNo ratings yet

- CV761 06 Pavement-Design RigidDocument57 pagesCV761 06 Pavement-Design RigidAntony Paul OregeNo ratings yet

- Statement of The Problem: - Spur Gear DriveDocument40 pagesStatement of The Problem: - Spur Gear DriveEdmil Jhon AriquezNo ratings yet

- Weibull Tutorial 2Document6 pagesWeibull Tutorial 2Gthulasi78No ratings yet

- Weibull Tutorial 1Document5 pagesWeibull Tutorial 1Gthulasi78No ratings yet

- BLDC - 2 Of3Document5 pagesBLDC - 2 Of3Gthulasi78No ratings yet

- Synchronous PM Motors: Stator Field Needs To Be Close To Orthogonal (90°) To Rotor Field To GetDocument4 pagesSynchronous PM Motors: Stator Field Needs To Be Close To Orthogonal (90°) To Rotor Field To GetGthulasi78No ratings yet

- BLDC 2Document4 pagesBLDC 2Gthulasi78No ratings yet

- BLDC 2Document4 pagesBLDC 2Gthulasi78No ratings yet

- Sensorless BLDC Motor Control With BEMF Zero-Crossing DetectionDocument6 pagesSensorless BLDC Motor Control With BEMF Zero-Crossing DetectionGthulasi78No ratings yet

- Reliability Prediction 1Document6 pagesReliability Prediction 1Gthulasi78No ratings yet

- Brushless DC Motors Are A Type of Synchronous MotorDocument5 pagesBrushless DC Motors Are A Type of Synchronous MotorGthulasi78No ratings yet

- Engine Dynamic Properties - 7Document3 pagesEngine Dynamic Properties - 7Gthulasi78No ratings yet

- Engine Dynamic Properties - 1Document5 pagesEngine Dynamic Properties - 1Gthulasi78No ratings yet

- Hybrid Car TechnologyDocument5 pagesHybrid Car TechnologyGthulasi78No ratings yet

- Engine Dynamic Properties - 6Document5 pagesEngine Dynamic Properties - 6Gthulasi78No ratings yet

- Ref Dr. A. Tolga Bozdana Notes Over The NetDocument5 pagesRef Dr. A. Tolga Bozdana Notes Over The NetGthulasi78No ratings yet

- Basics of A Electric Motor: Dcmotor 1Document10 pagesBasics of A Electric Motor: Dcmotor 1Gthulasi78No ratings yet

- Voltage Source Inverter - 1Document7 pagesVoltage Source Inverter - 1Gthulasi78No ratings yet

- E-Coating Process FinalDocument3 pagesE-Coating Process FinalGthulasi78No ratings yet

- Engine Dynamic Properties-3Document5 pagesEngine Dynamic Properties-3Gthulasi78No ratings yet